Method for greening side slopes with greening brick cages

A technology for slopes and brick cages, applied in the field of greening slopes using greening brick cages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The composition ratio of the mixed soil in this example is: 50 parts of planting soil, 30 parts of organic matter, 100 parts of fertilizer, 20 parts of water-retaining agent, 20 parts of soil corrosion inhibitor, 70 parts of soil improver, 5000 parts of binder, aggregate 40 parts of agent, 10 parts of stabilizer, 10 parts of pH reliever and 8000 parts of water.

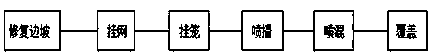

[0032] First, repair the rocky slope, trim the slope surface according to the slope ratio, slope height, and flatness, and clean the slope surface such as pumice, so that the treated slope surface is flat and the slope ratio is consistent. After the slope surface is repaired, use an electric drill to drill holes on the slope, fix the anchor rods on the stone holes, and then connect the barbed wire to the anchor rods to fix the barbed wire mesh on the side slope to complete the hanging net. After the net is hung, the barbed wire brick cage is connected with the anchor rod and the barbed wire so that it is also f...

Embodiment 2

[0035] The slope in this embodiment is a soil slope, and the greening operation steps are the same as those in Embodiment 1, the only difference is that the composition ratio of the mixed soil is: 100 parts of planting soil, 20 parts of organic matter, 50 parts of fertilizer, water retention 5 parts of agent, 10 parts of soil anticorrosion agent, 50 parts of soil conditioner, 3000 parts of binder, 30 parts of pellet agent, 10 parts of stabilizer, 20 parts of PH alleviating agent and 5000 parts of water. The grass species adopted is Bermudagrass seeds.

Embodiment 3

[0037] The slope in this embodiment is a rocky slope, and the greening operation steps are the same as in Embodiment 1, the only difference is that the composition ratio of the mixed soil is: 75 parts of planting soil, 25 parts of organic matter, 75 parts of fertilizer, water retention 12 parts of agent, 15 parts of soil anticorrosion agent, 75 parts of soil conditioner, 4500 parts of binder, 40 parts of pellet agent, 7 parts of stabilizer, 15 parts of PH alleviating agent and 6500 parts of water. The grass species adopted are Bahia grass, Bermudagrass, and Leucaena seeds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com