Anti-scouring tapping hole sleeve brick

A taphole and anti-scouring technology, applied in the field of refractory materials, can solve the problems of frequent replacement of taphole sleeve bricks and low taphole life, achieve good anti-scouring and anti-oxidation performance, improve high-temperature strength, and shorten replacement The effect of frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

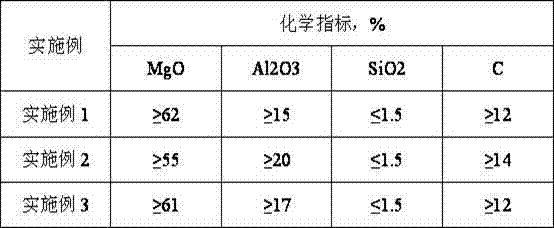

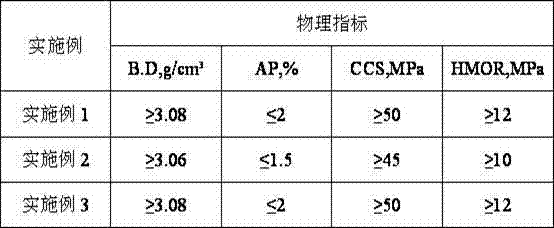

Embodiment 1

[0021] An anti-erosion taphole sleeve brick is made of the following raw materials according to the ratio:

[0022] Fused magnesia 62kg

[0023] Corundum 15kg

[0024] Magnesium aluminum spinel 5kg

[0025] Graphite 12kg

[0026] High temperature asphalt 2kg

[0027] Aluminum powder 2kg

[0028] Resin powder 2kg.

[0029] Liquid resin (as a binder) 3kg

Embodiment 2

[0031] An anti-erosion taphole sleeve brick is made of the following raw materials according to the ratio:

[0032] Fused magnesia 51kg

[0033] Corundum 20kg

[0034] Magnesium aluminum spinel 10kg

[0035] Graphite 14kg

[0036] High temperature asphalt 2kg

[0037] Aluminum powder 2kg

[0038] Resin powder 1kg

[0039] Liquid resin (as a binder) 2kg

Embodiment 3

[0041] An anti-erosion taphole sleeve brick is made of the following raw materials according to the ratio:

[0042] Fused magnesia 57kg

[0043] Corundum 15kg

[0044] Magnesium aluminum spinel 10kg

[0045] Graphite 12kg

[0046] High temperature asphalt 1kg

[0047] Metal aluminum powder 3kg

[0048] Resin powder 2kg

[0049] Liquid resin (as a binder) 1kg

[0050] The preparation process of the anti-erosion taphole sleeve brick described in the above-mentioned embodiments 1-3 is as follows: detection of chemical composition of raw materials-weighing and batching-mixing and stirring-machine pressing forming-drying-bonding.

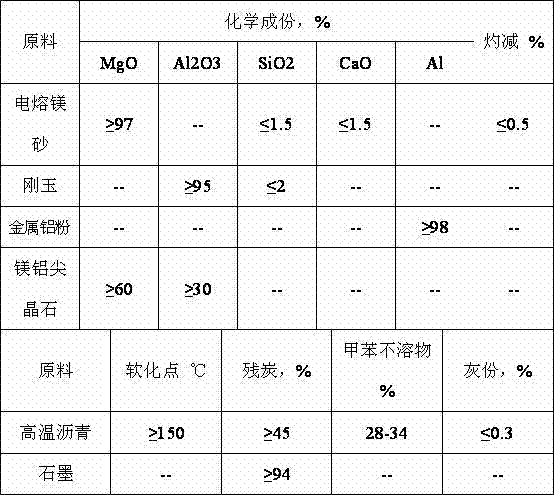

[0051] A. Material selection and preparation:

[0052] Fused magnesia: MgO content in fused magnesia ≥ 97.0%, particle size ≤ 5mm; fused magnesia follows the standard YB / T5266-2004, and fused magnesia with grades FM970, FM975, FM980, FM985, FM990 can be used ,. When in use, detect the chemical composition MgO, SiO2, CaO; the detection requiremen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com