High-strength functional form filtration apparatus made of magnesium and its making process

A filter device and manufacturing process technology, applied in the field of magnesium high-strength functional filter device and its manufacturing process, can solve the problem of not finding special steel mold casting and continuous casting purification technology and equipment, and achieve superior combined structure and mutual Reasonable configuration, the effect of improving mechanical and physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] The raw materials used in the following formula are magnesium carbonate, calcium carbonate and fused magnesia with a MgO content of 96% and sintered calcium oxide clinker. It is divided into three types according to the CaO content: 90%, 95%, and 99%, and ZrO 2 High-purity zirconia and TiO with a content of 99% 2 For high-purity titanium dioxide with a content of 98.5-99%, the added binder is a supersaturated solution of phosphate.

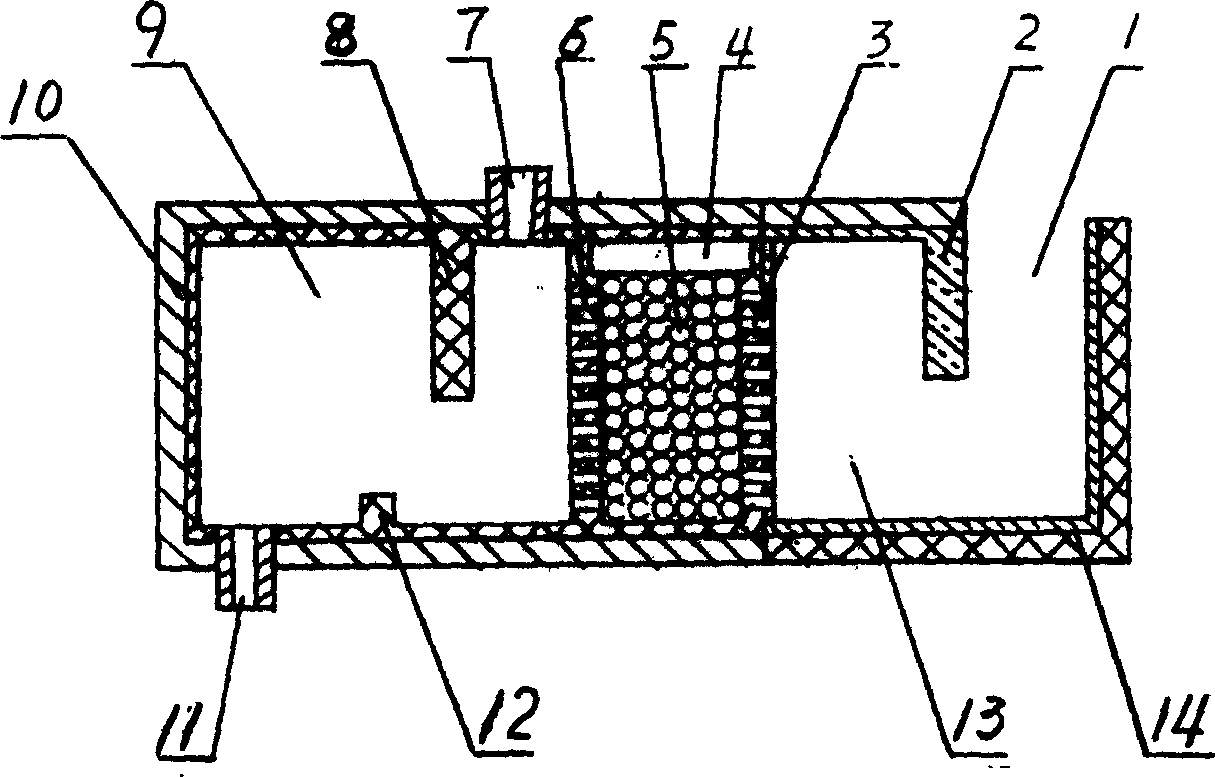

[0034] In the batching, the matrix raw material is fused magnesia, the reaction layer and the porous equal-diameter spherical filter medium are sintered calcium oxide clinker, and the method used each time is as follows:

Embodiment 1

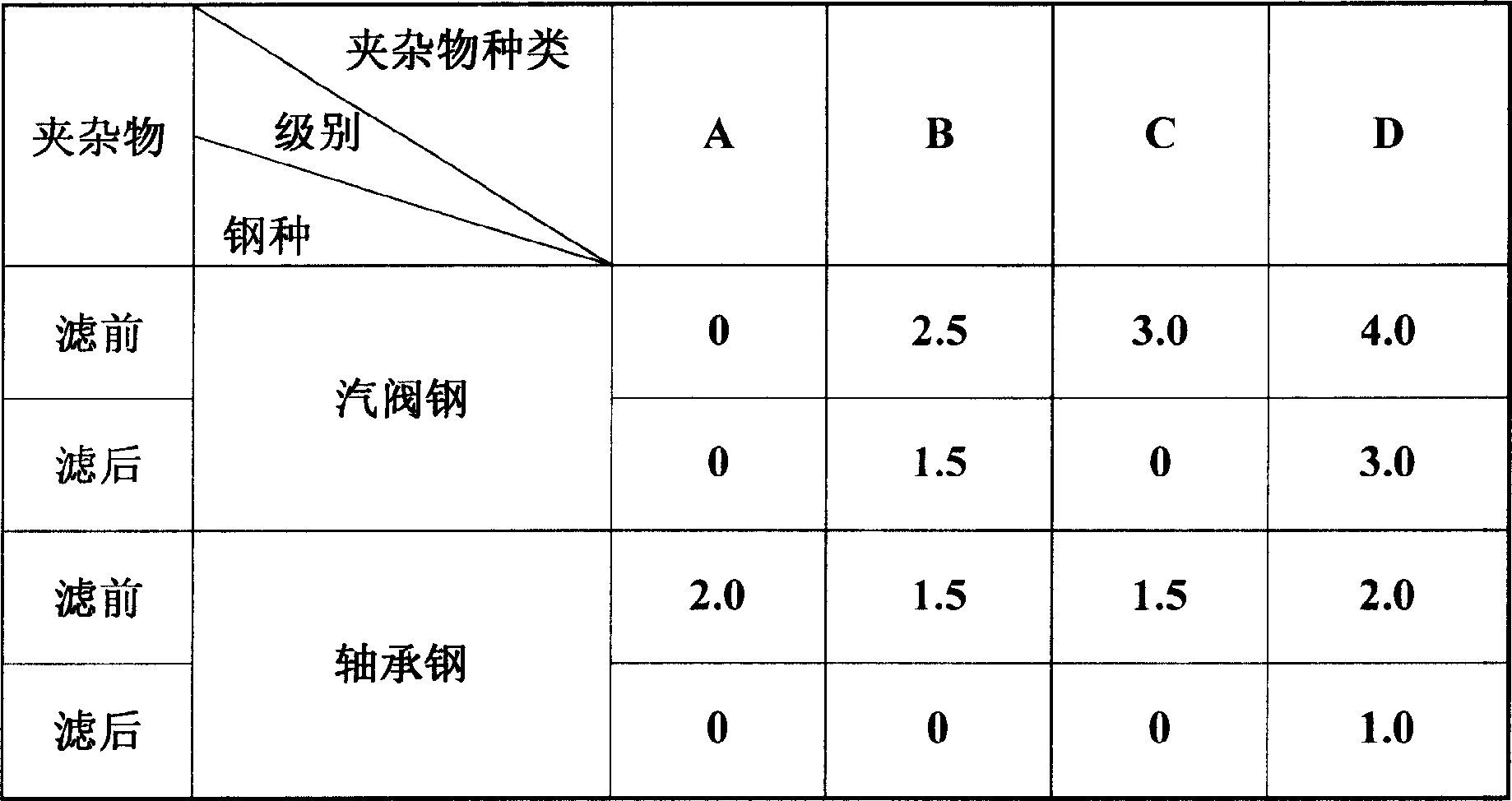

[0036] The right casing, the reaction layer of the composite perforated plate, the raw material formula adopted by the calcium oxide slag retaining plate and the spherical filter medium are 80 parts by weight of sintered calcium oxide clinker containing 90% CaO, 20 parts by weight of calcium carbonate and an appropriate amount of zirconium dioxide and The titanium dioxide and the phosphate supersaturated solution binder are added in 4 to 6 parts by weight and kneaded together to form a mixture, which is formed by pressing, dried and sintered. The difference is that the outer layer of the right box and the other side of the composite porous plate use 100 parts of fused magnesia containing MgO96%, add 4 to 5 parts by weight of phosphate supersaturated solution for mixing, and manufacture it according to the above-mentioned production method. The matrix of the box and the composite porous plate.

[0037] The raw materials used as the left box used in the Shengjing steel chamber a...

Embodiment 2

[0043] The manufacturing method of the filter device is the same as that of Embodiment 1. The difference is that the raw materials used in the right box body, the reaction layer of the composite porous plate, the calcium oxide slag retaining plate, and the spherical filter medium are: 80 parts by weight of sintered calcium oxide clinker with a CaO content of 95%, and 20 parts by weight of calcium carbonate. Add appropriate amount of zirconium dioxide, titanium dioxide, and phosphate supersaturated solution binder to 4 to 6 parts by weight, and knead together to form a mixture; and the outer layer of the right box and the other side of the composite porous plate use raw materials and production methods constant.

[0044] The raw materials and production methods used for the left box used as the steel chamber remain unchanged. According to the requirements of various mixture formulas and production processes, a high-strength functional filter device is made to filter and purify...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com