A vacuum valve remote control system and method

A remote control system and control system technology, which is applied in the field of vacuum valve remote control system, can solve problems such as leakage of cryostat sealing ring, poor vacuum degree, and failure of refrigeration system to return to normal working state, so as to achieve convenient structural installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

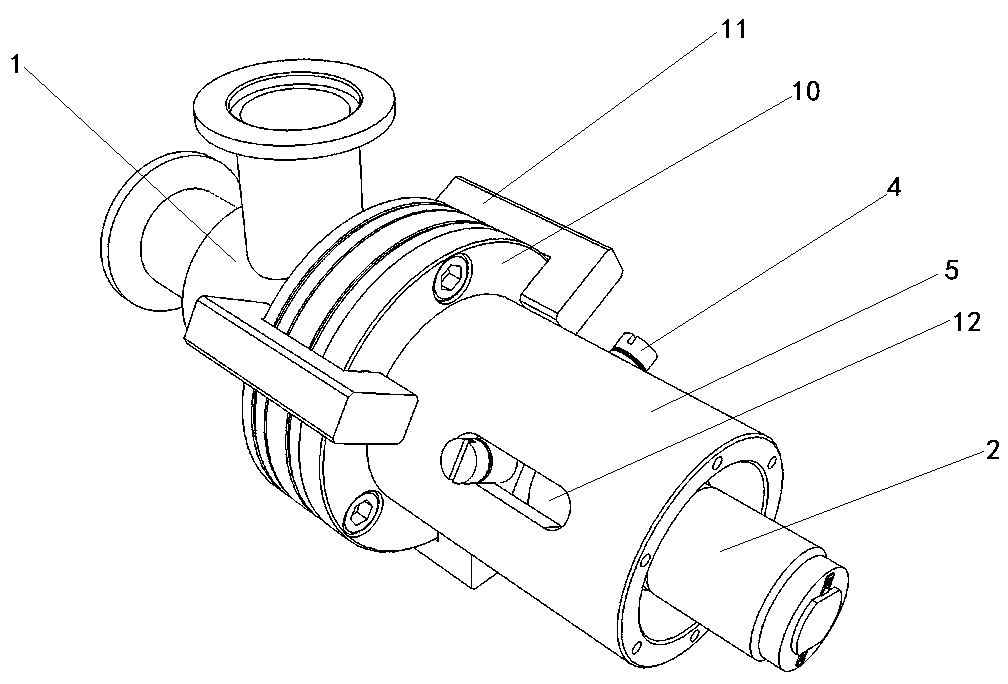

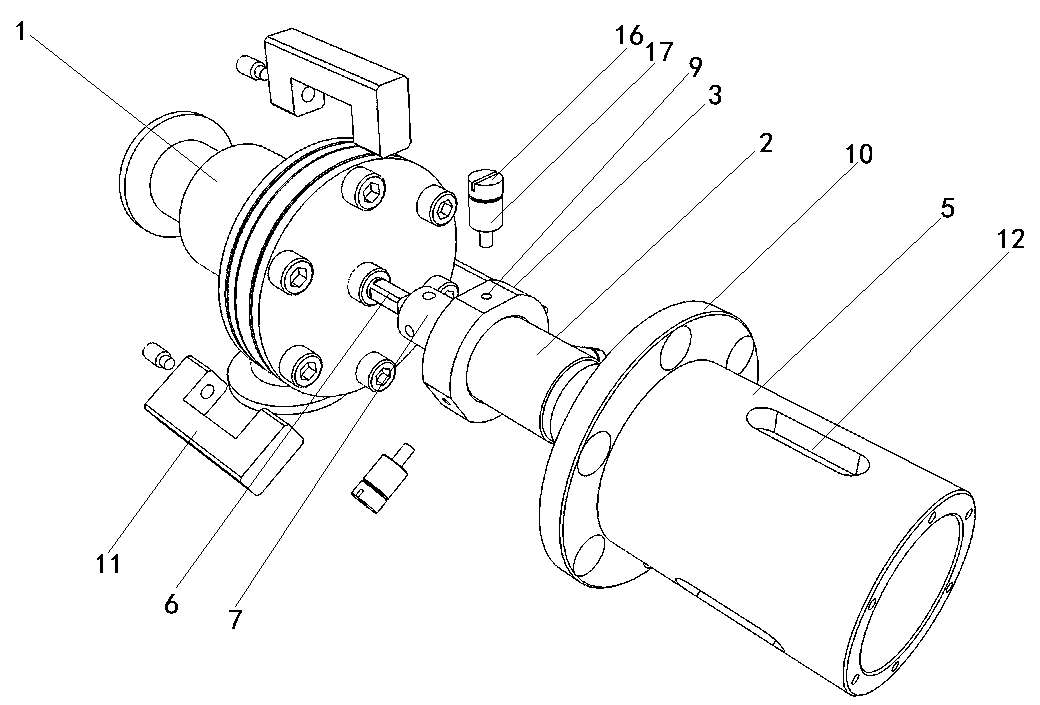

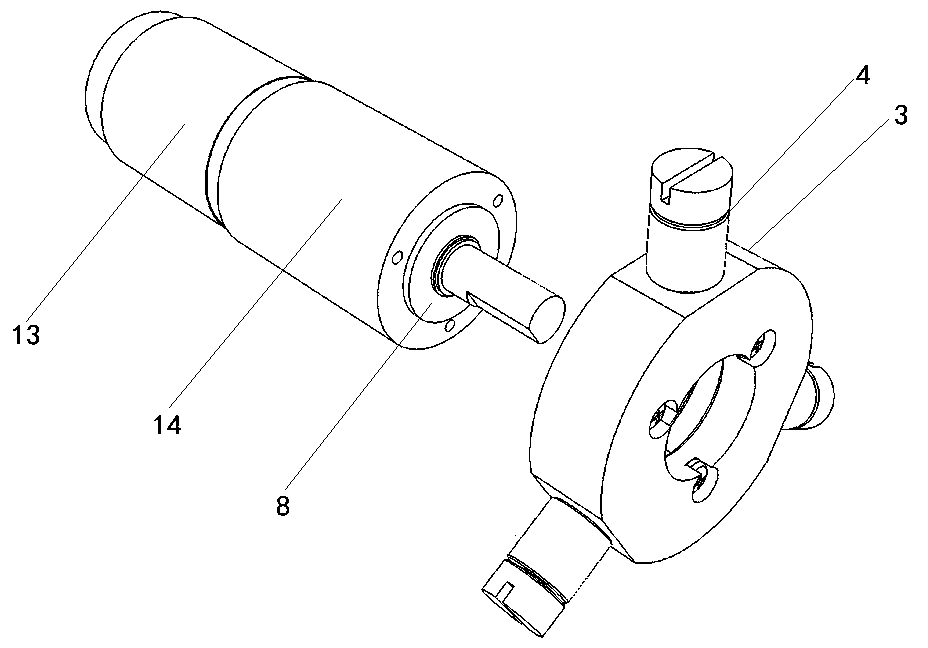

[0029] The present invention is described in further detail in conjunction with accompanying drawing now.

[0030] Vacuum valves are vacuum system components used in vacuum systems to change the direction of airflow, adjust the size of airflow, and cut off or connect pipelines. At present, there are many types of vacuum valves on the market. According to the driving mode, they can be divided into automatic valves, power-driven valves and manual valves. According to the working pressure, they can be divided into low vacuum valves, high vacuum valves and ultra-high vacuum valves. It is a non-metallic and metal sealing valve. Considering the working pressure, working temperature, valve size and ensuring low leakage rate, etc., this design selects the AVB-CU-KF25-M high vacuum valve produced by Taiwan Riyang Electronic Technology (HTC) Company. This series of vacuum valves has manual and electric driving modes, and the electric driving mode requires working gas assistance (an add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com