General device of locomotive body assembly

A general-purpose device and car body technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of long manual clamping auxiliary time, troublesome production operations, low work efficiency, etc., and achieve shortened clamping The effect of assisting time, improving work efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

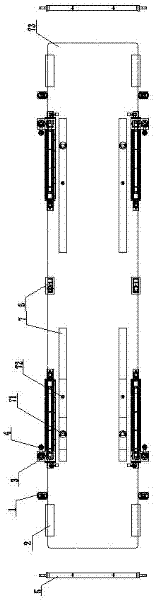

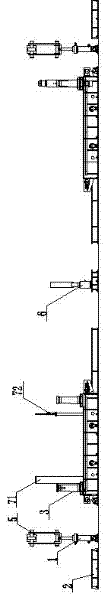

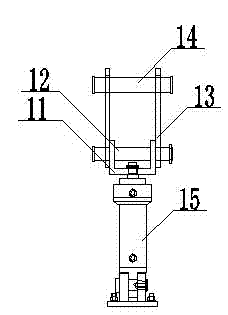

[0019] A general device for locomotive car body assembly, including an end tensioning device 1, an end measuring platform 2, a side beam support device 3, a pressing device 4, an end tensioning crossbeam 5, a middle support jacking device 6, Side bearing measurement platform 7, connecting seat 11, pin one 12, pull ring 13, pin two 14, oil cylinder 15, sprocket one 31, transmission chain 32, chain bracket 33, support seat 34, chain pin transition seat 35 , sprocket wheel two 36, cycloid hydraulic motor 41, screw mandrel 42, screw nut 43, briquetting block 44, rotary pressure head 45, mobile inner tube 46, fixed overcoat 47, outer lateral bearing standard rod 71 and measuring ruler 72.

[0020] Such as figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a side view of the present invention, the left side of the end tensioning device 1 is provided with an end measuring platform 2, the right side is provided with a side beam supporting device 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com