Continuous multi-stage constant-temperature-difference cooling crystallizer

A technology of cooling crystallization and constant temperature difference, applied in the direction of solution crystallization, etc., can solve the problems of difficult control of heat transfer temperature difference, affect product quality, crystal purity can not meet the requirements, etc., to improve operating efficiency and quality stability, crystal particle distribution range The effect of reproducibility of stable, stable and reliable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with embodiment:

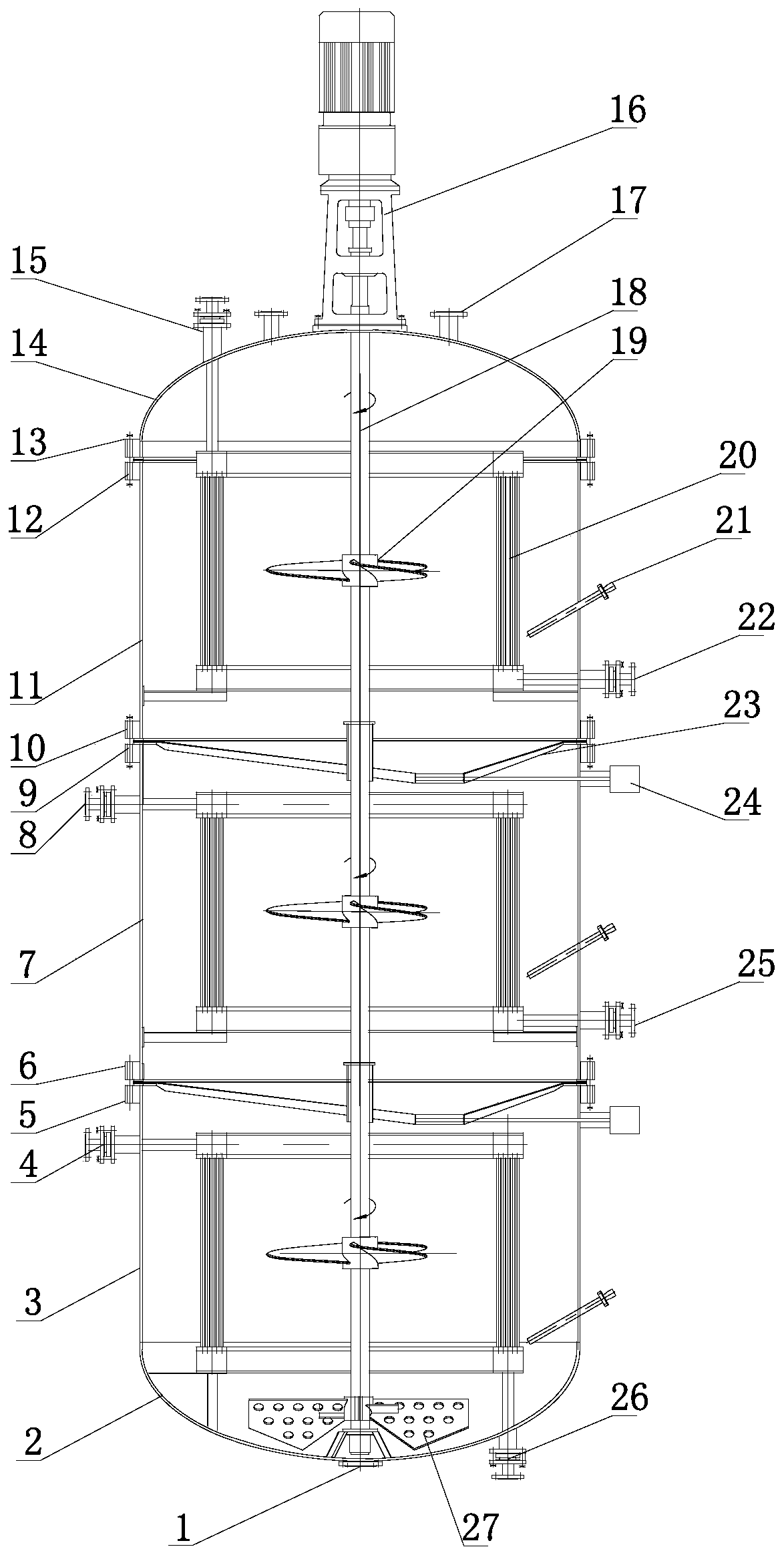

[0037] Such as Figure 1-12 As shown, the continuous multi-stage constant temperature difference cooling crystallizer of the present invention includes a crystallizer body, and the crystallizer body is composed of a lower head 2, a lower cylinder 3, a middle cylinder 7, an upper cylinder 11, and an upper head 14, the lower head 2 and the lower cylinder 3 are fixedly connected by welding, the lower cylinder 3 and the middle cylinder 7 are connected through the lower flange 5 and the middle flange 6, and the middle cylinder 7 and the upper cylinder 11 are connected through the middle The second flange 9 and the last flange 10 are connected, and the upper cylinder 11 and the upper head 14 are connected through the upper second flange 12 and the head flange 13 .

[0038] The top of the upper head 14 and the bottom of the lower head 2 are respectively provided with a feed port 17 and a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com