Method for recycling cobalt from waste and old lithium ion battery

A lithium-ion battery and lithium battery technology, applied in the direction of cobalt oxide/cobalt hydroxide, etc., can solve the problems of secondary pollution, increased treatment costs, and limit the scale of waste lithium battery treatment, and achieve the effect of simple and feasible preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

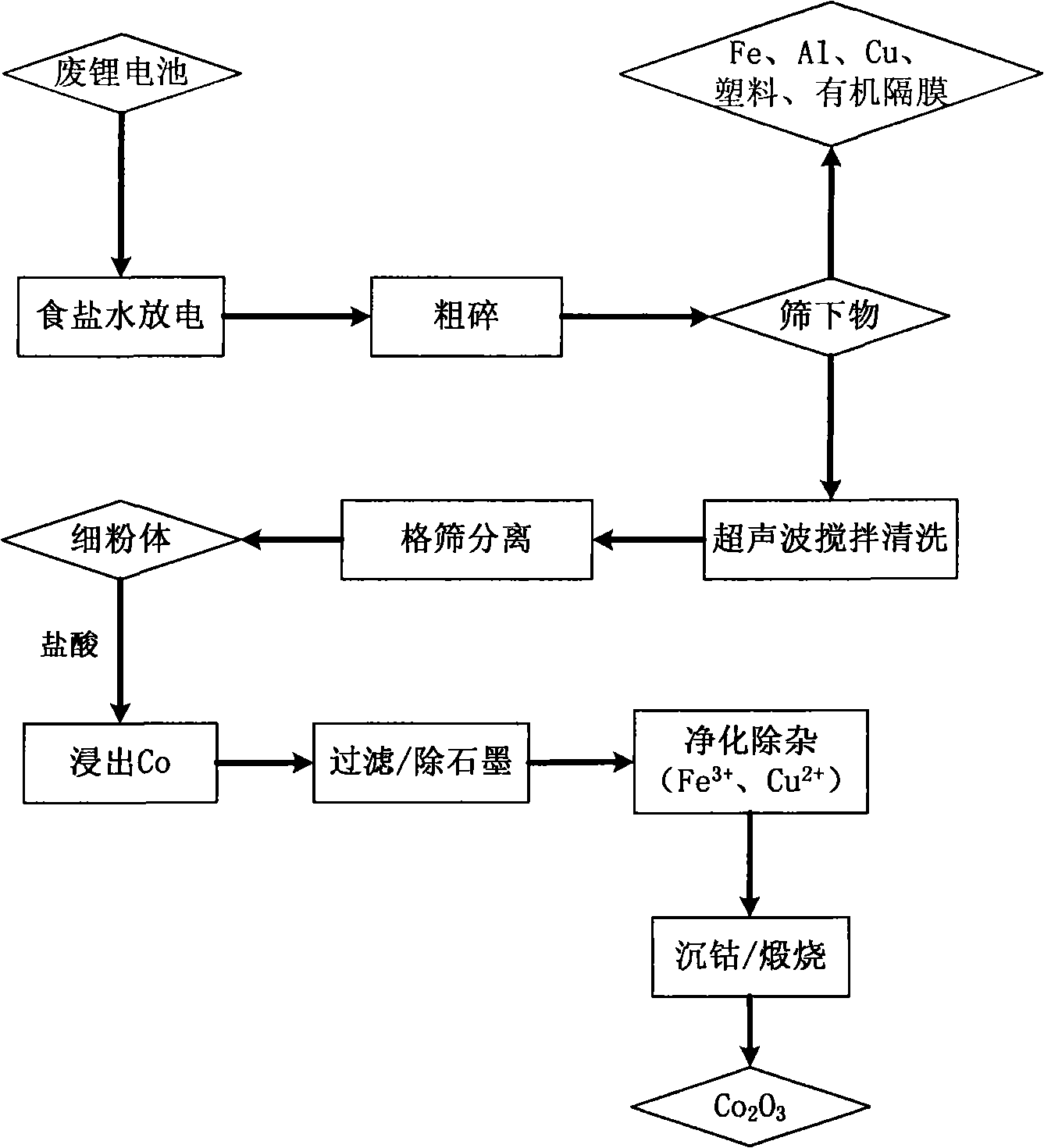

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is illustrated below in conjunction with embodiment.

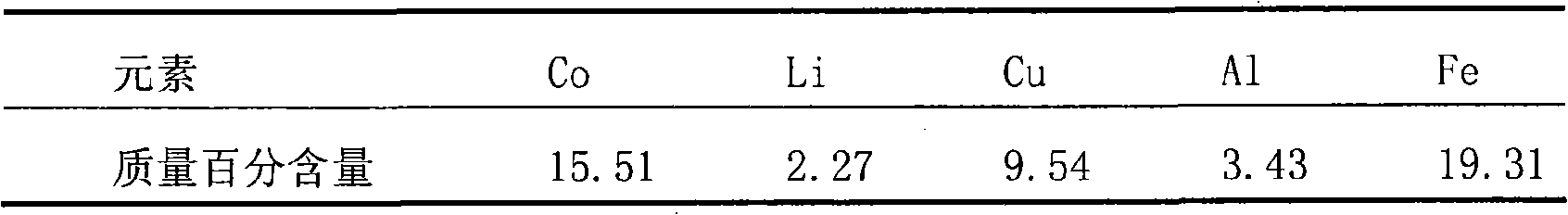

[0028] Take 5 waste lithium batteries, with a total weight of 230g, and the metal components are shown in Table 1. The non-metallic substance part includes carbon, plastic casing, organic diaphragm and electrolyte, etc.

[0029] Table 1 Lithium-ion battery metal component content (%)

[0030]

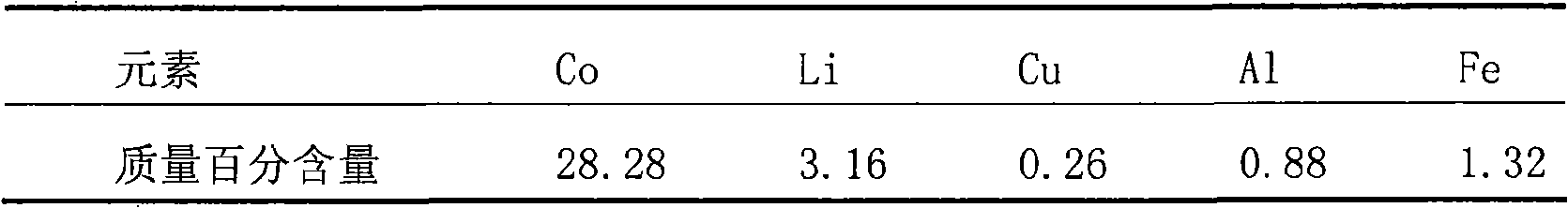

[0031] These batteries were soaked in salt water for 5 hours to release the residual electricity. On the one hand, the short circuit of the battery during the crushing process was avoided to cause an explosion, and on the other hand, the content of lithium intercalation in the CuC electrode was reduced. Air-dry the fully discharged battery, and then crush the waste lithium battery with a crusher equipped with a 12mm aperture screen to obtain 206.6g of undersize; pour the undersize into an ultrasonic cleaning tank for ultrasonic cleaning, at room temperature, fully Wash under stirring conditions for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com