Patents

Literature

33results about How to "Improve first-class rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

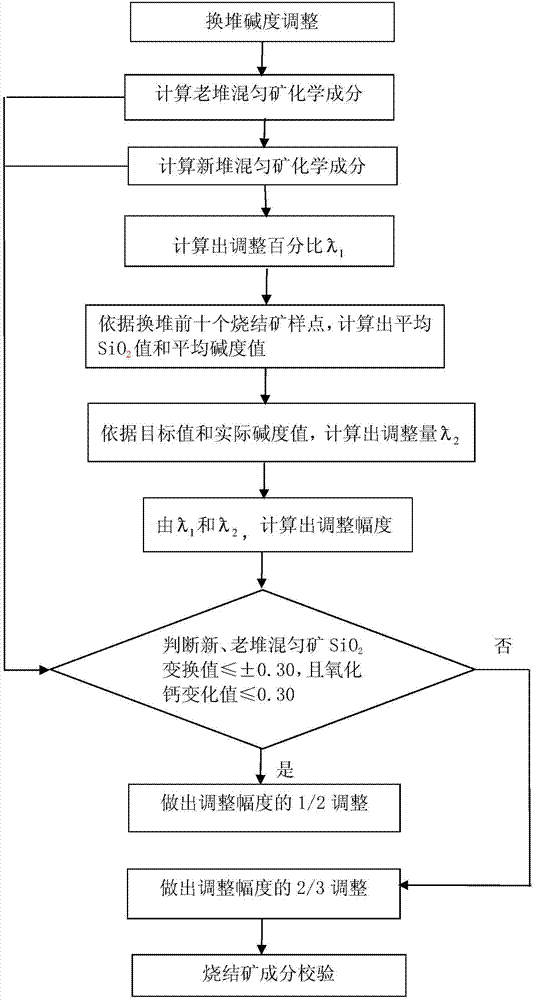

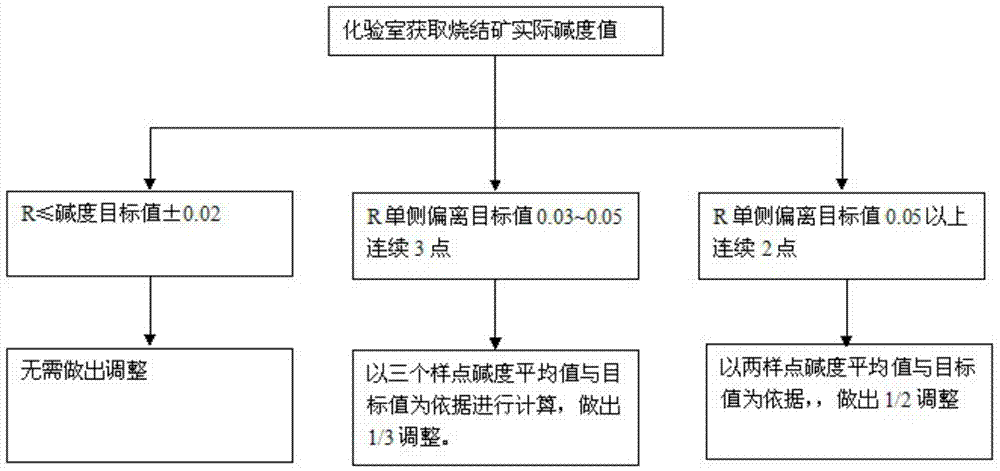

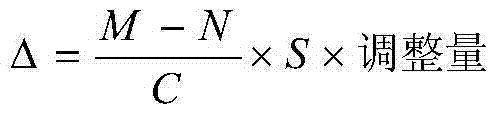

Method for regulating basicity of sintered ore

The invention relates to a method for regulating the basicity of sintered ore. The method comprises three steps of 1) daily alkalinity regulation, 2) replaced pile alkalinity regulation and 3) ingredient check, wherein in the daily alkalinity regulation process, the alkalinity is accurately regulated through simple and convenient calculation; the replaced pile alkalinity regulation further comprises the determination of the service time of the new stockpile, the first step of replaced pile alkalinity calculation and the second step of replaced pile alkalinity calculation; in the pile replacing process, information such as pile replacing time, ingredient change and regulation quantity is accurately mastered through simple and convenient calculation; the alkalinity is regulated step by step and layer by layer; finally, the regulation amplitude is the product of the theoretical regulation percentage and the regulation quantity. The method provided by the invention is capable of quickly regulating the basicity of the sintered ore, therefore, the regulation time is shortened, and the alkalinity percent of pass and the ratio of first-grade products of the sintered ore are increased; in the period of replacing the pile of the evenly mixed ore, the influence of the raw material ingredient change on the alkalinity of the sintered ore can be effectively reduced, and non-fluctuation pile replacement is realized; as a result, the quality of the sintered ore is stabilized and smooth operation of the blast furnace is guaranteed.

Owner:TIANJIN IRON & STEEL GRP

Culture material for black fungus cultivation

InactiveCN102351609ASave resourcesEasy to controlFertilizer mixturesInsect pestMonopotassium phosphate

The invention relates to a culture material for black fungus cultivation. Based on the total weight of the culture material, the culture material is made from the following ingredients of: by weight, 30-75% of a Jatropha curcas branch powder, 15-50% of weed tree sawdust or cotton seed hull or xylitol slag, 8-30% of wheat bran or rice bran, 0.05-1% of potassium dihydrogen phosphate, 0.2-5% of gesso and 0.2-5% of quicklime. The culture material for black fungus cultivation is used to produce artificial log cultivated black fungus and greatly control the growth of mixed bacterium and insect pest. The black fungus has excellent quality and good taste with high first degree quality rate, high biological efficiency and stable output. In addition, resources can be saved.

Owner:深圳市前海厚志科技有限公司

Goose-down fur processing technique

InactiveCN101314799AHigh strengthImprove first-class rateTanning treatmentPre-tanning chemical treatmentOrganic acidChemistry

The invention relates to a fur production method that is a goose-fur processing technology, which has the technical proposal as follows: an anticorrosion technology which combines a dry-salted method and a freezing method is adopted; based on the artificial defatting and the softening degreasing, organic solvent is degreased; the pickling process is executed by organic acid through multiple acid addition; the tanning is executed by a plurality of tanning agents; an amphoteric fatliquor is used for comprehensive fatliquoring; a reductive bleaching agent and a whitening agent are adopted and combined for rinsing and whitening. By adopting the goose-fur processing technology in the technical proposal, the produced products have high strength, are soft and fluey as well as pure white and flamboyant, are very suitable for the manufacture of high-grade fur clothes, and provide condition to the development of goose skin industry.

Owner:INNER MONGOLIA YUBIAO FOOD

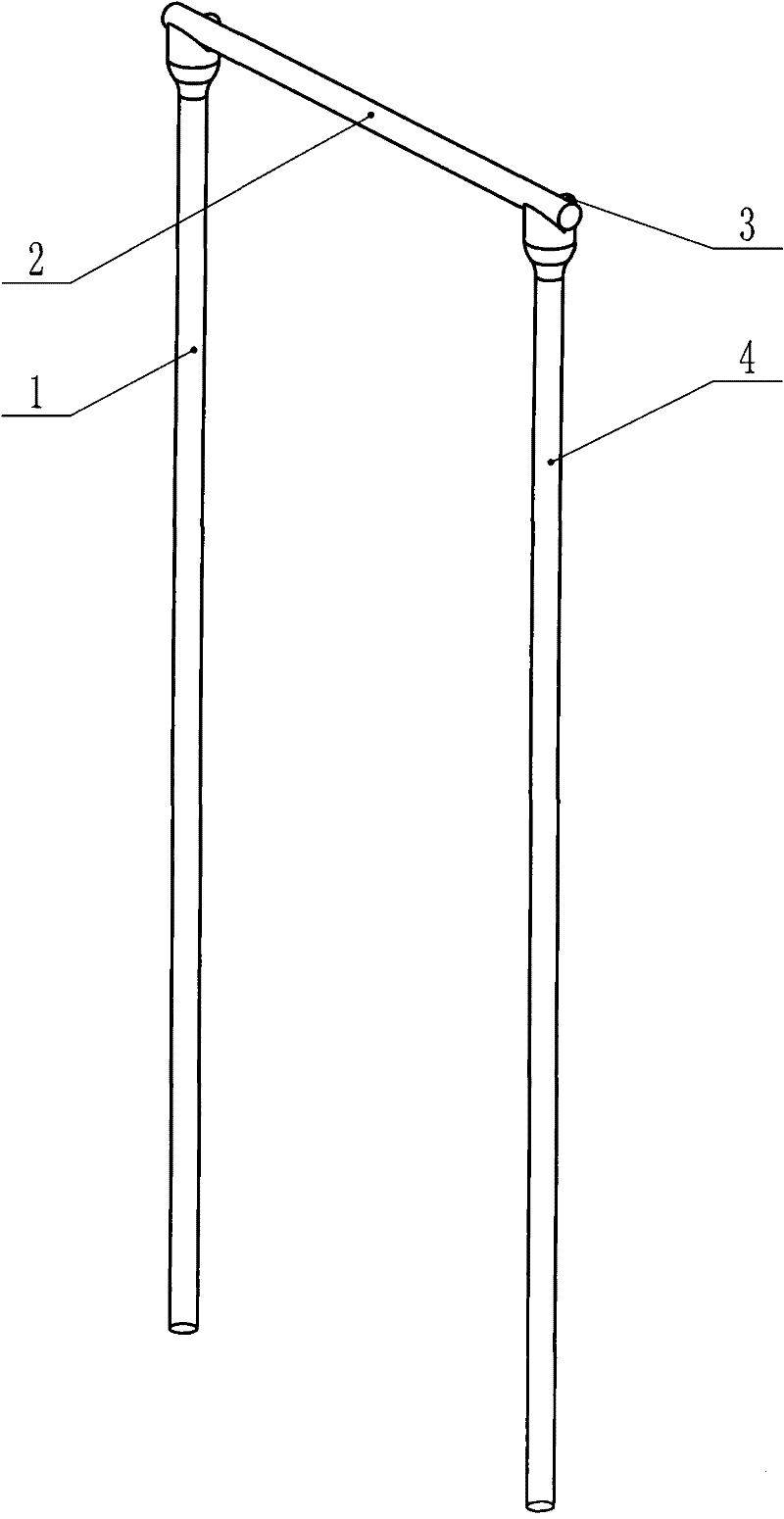

Manufacture technology of whole 'U'-shaped silicon core

ActiveCN101775643AUniform resistancePrevent lodgingBy pulling from meltManufacturing technologyEngineering

The invention discloses a manufacture technology of a whole 'U'-shaped silicon core, relating to the technical field of drawing silicon core. The technology specifically comprises the following steps of: making the silicon core into a whole 'U'-shaped seed crystal, and tightly clamping the 'U'-shaped seed crystal with an upper shaft lifting system; putting a raw material stick on a material tray seat on a lower shaft lifting system, leading the raw material stick to be near to a high-frequency heating coil, and operating the high-frequency heating coil to heat the end of the raw material stick; leading the whole 'U'-shaped seed crystal to descend, and leading the vertical section of the whole 'U'-shaped seed crystal to penetrate through the inner hole of the high-frequency heating coil to be inserted into a melting zone of the raw material stick; slowly lifting up the whole 'U'-shaped seed crystal, so that the two seed crystal heads of the whole 'U'-shaped seed crystal are respectively lead molten silicon at the head of the raw material stick to be crystallized at the end of the seed crystal, and the two heads of the 'U'-shaped seed crystal are continuously drawn to be the silicon core; and stopping a furnace after the silicon core is drawn to a stated length to withdraw the 'U'-shaped silicon core. The whole 'U'-shaped silicon core drawn by the technology effectively reduces the design of a reduction furnace, the complexity of manufacture, and the unit energy consumption for manufacturing polycrystalline silicon.

Owner:LUOYANG JINNUO MECHANICAL ENG

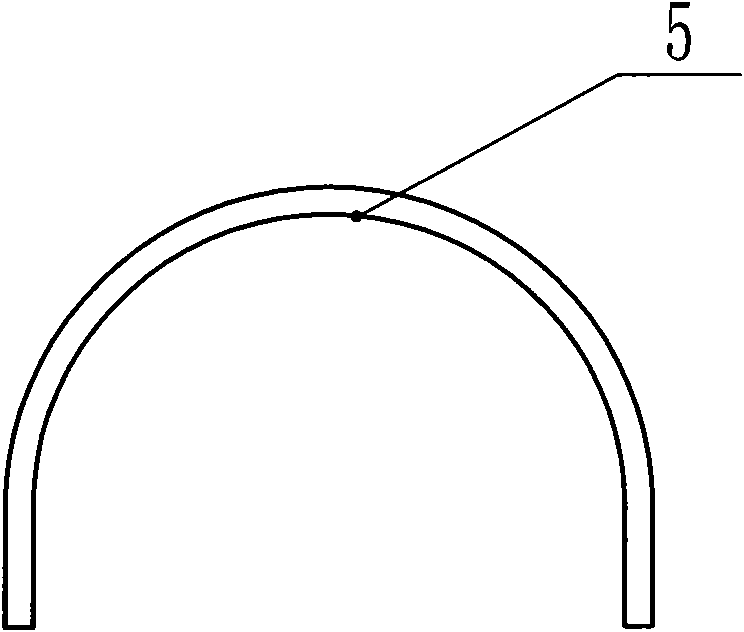

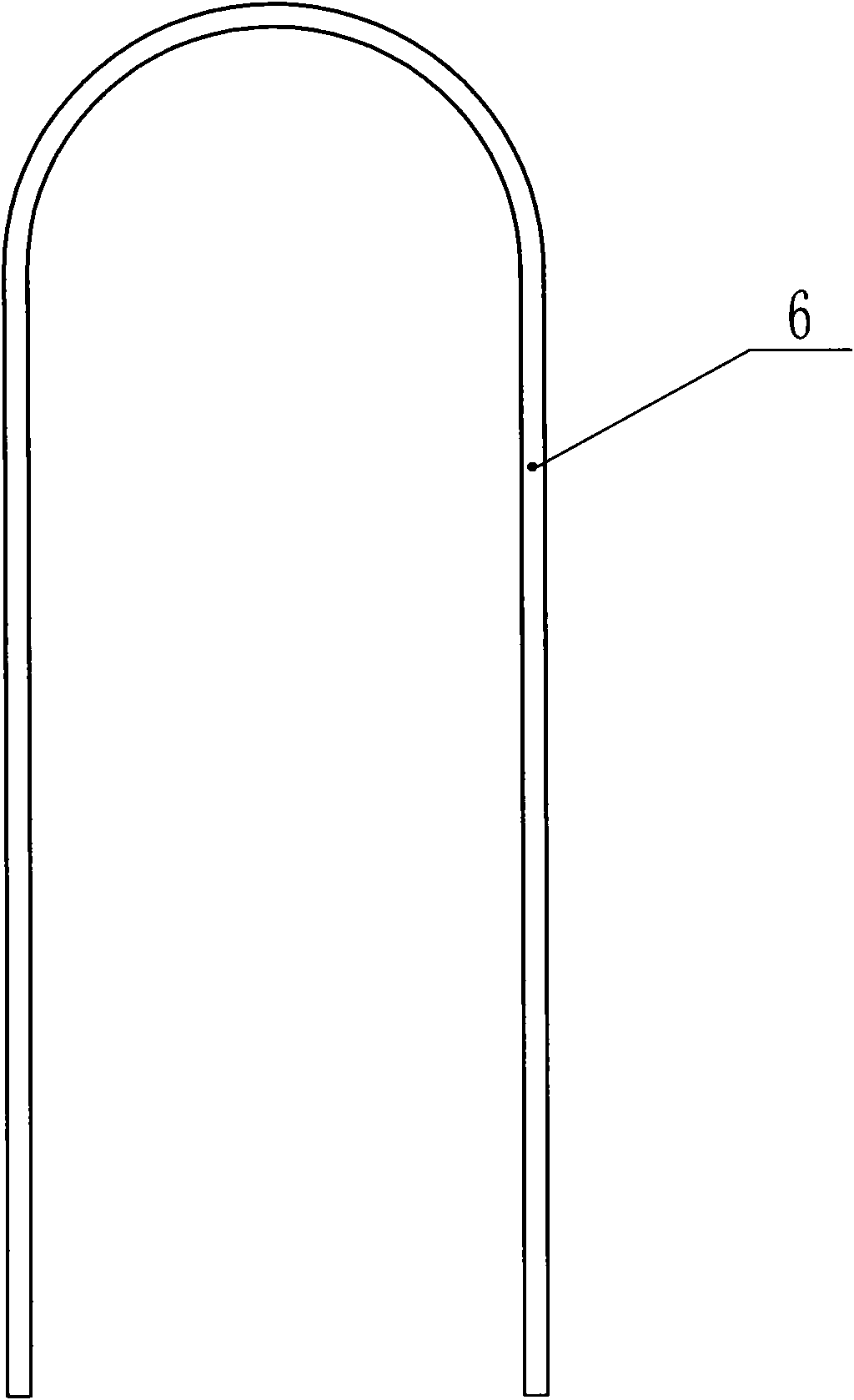

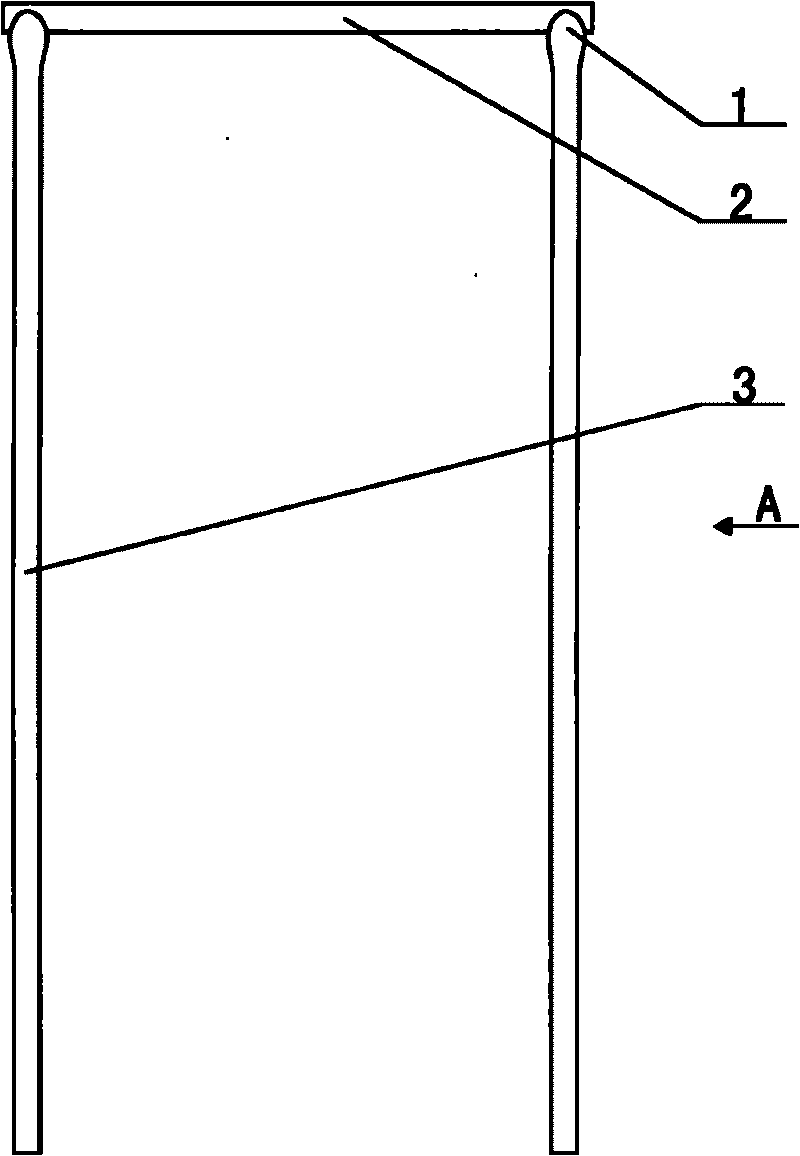

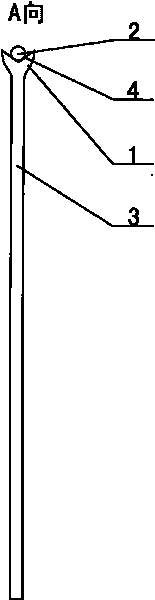

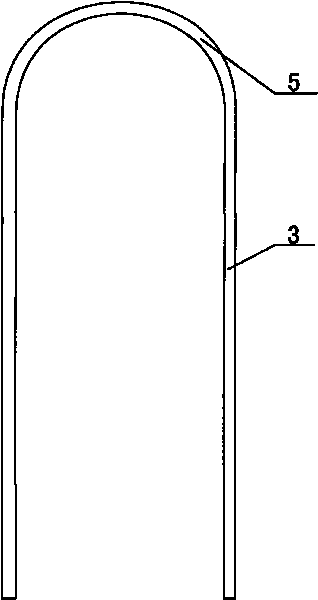

Whole 'U'-shaped silicon core structure

InactiveCN101723376AUniform resistancePrevent lodgingSilicon compoundsElectrical resistance and conductanceHigh voltage

The invention relates to a silicon core structure, in particular to a whole 'U'-shaped silicon core structure which comprises a silicon core body; the middle part of a silicon core is provided with a circular arc (5) or at least two circular arcs (5), and a straight connecting silicon core (6) is arranged between every two circular arcs (5) for connection; two vertical silicon cores (3) are respectively connected with one end of the two circular arcs (5) arranged at the outmost periphery, so as to form the whole 'U'-shaped silicon core structure. As no interface is arranged in the whole 'U'-shaped silicon core structure, the running resistance of the whole silicon core of an electrode is more uniform; and more particularly, the phenomenon of silicon core lodging caused in the production process can be effectively avoided. Furthermore, the silicon core structure reduces the complexity of design and manufacturing of a reduction furnace, thus not needing high-voltage breakdown and reducing the unit power consumption of polycrystalline silicon production.

Owner:LUOYANG JINNUO MECHANICAL ENG

Special fertilizer for red sage root and fertilization method of red sage root

InactiveCN101928172AIncrease productionHigh outputFertilising methodsFertilizer mixturesSalvia miltiorrhizaTrace element

The invention discloses a special fertilizer for red sage root and a fertilization method of red sage root. The total amount of the applied fertilizer is as follows: 204.55-218.07 kg / hm<2> for N, 248.26-263.09 kg / hm<2> for P2O5, 127.84-135.74 kg / hm<2> for K2O, 3.06-3.28 kg / hm<2> for MnSO4 and 3.06-3.27 kg / hm<2> for ZnSO4; the fertilizer is applied twice to be respectively used as the basal fertilizer and the additional fertilizer; the amount of the applied basal fertilizer is as follows: 30% of the total amount of N, 100% of the total amount of P2O5, 70% of the total amount of K2O and 50% of the total amount of MnSO4 and ZnSO4; and the amount of the applied additional fertilizer is as follows: 70% of the total amount of N, 30% of the total amount of K2O and 50% of the total amount of MnSO4 and ZnSO4. By the optimal combination of major elements and trace elements, the yield of the red sage root is increased by 20.5-25.6%, the output value is increased by 31.5-40.5%, and the first-grade product rate of the red sage root is increased by 17.1-19.3%.

Owner:NORTHWEST A & F UNIV

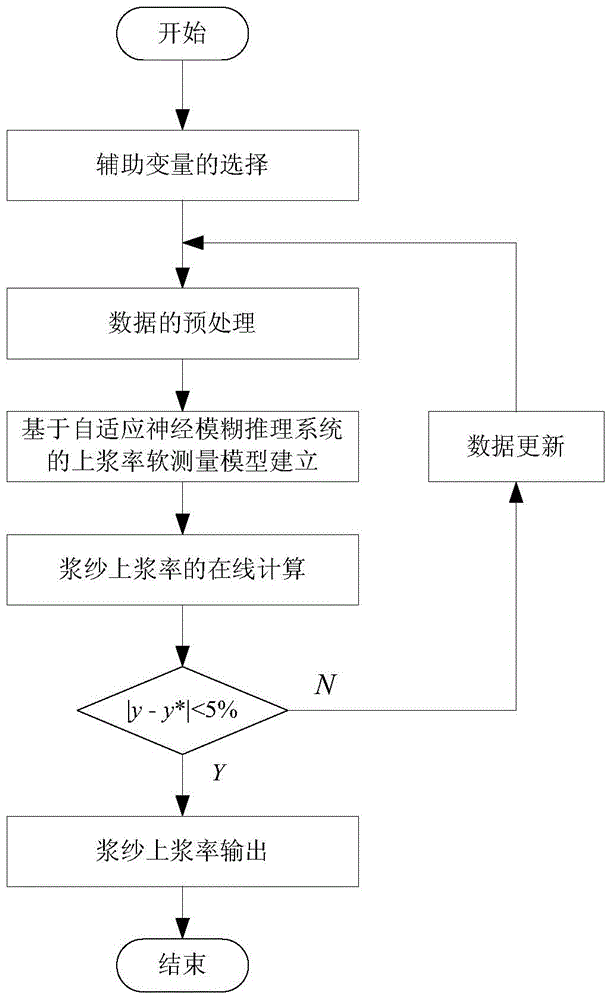

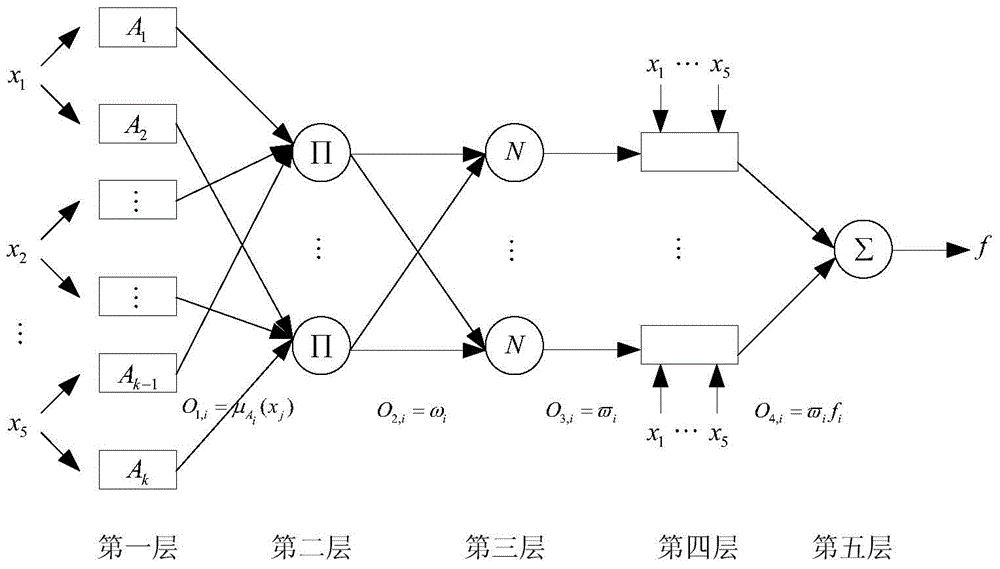

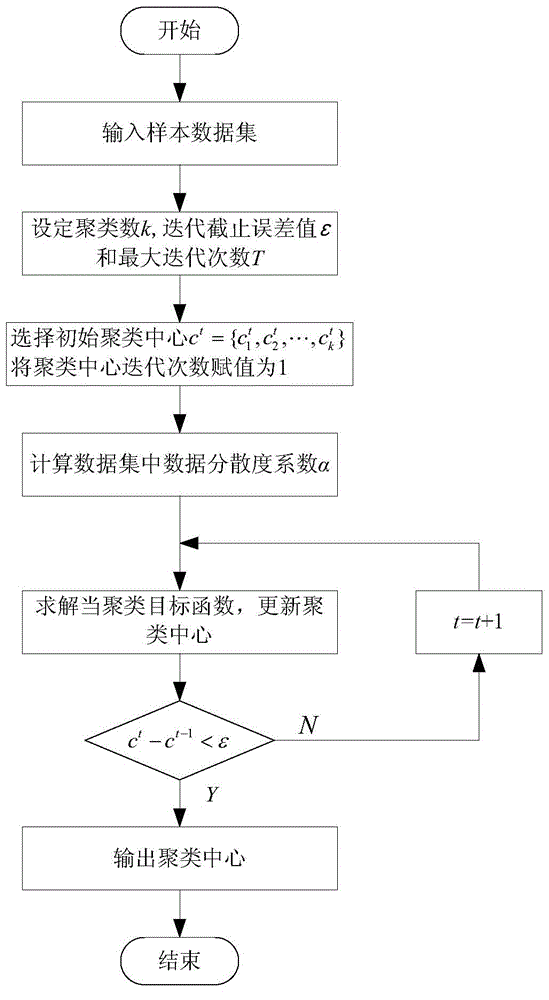

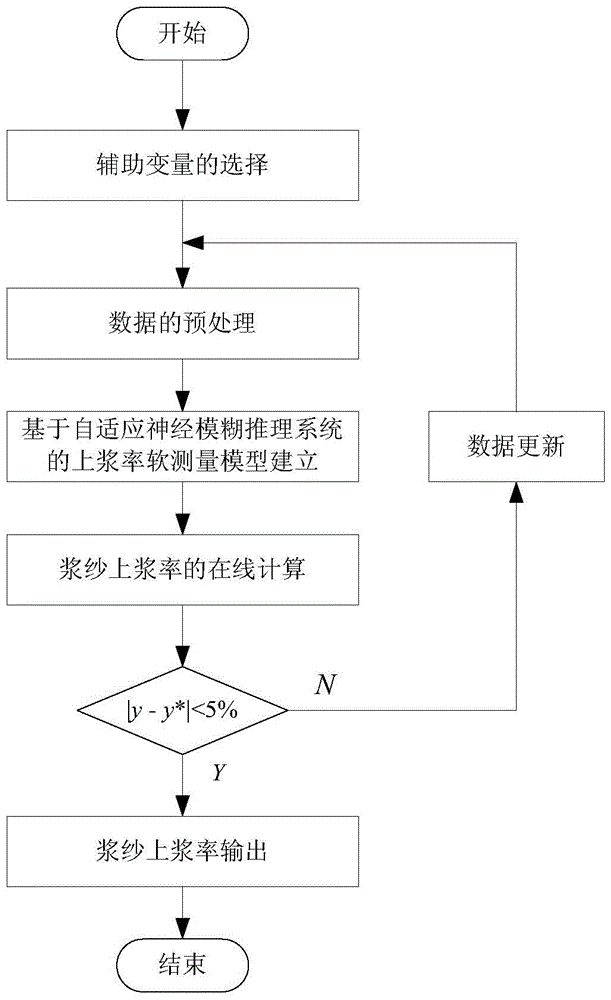

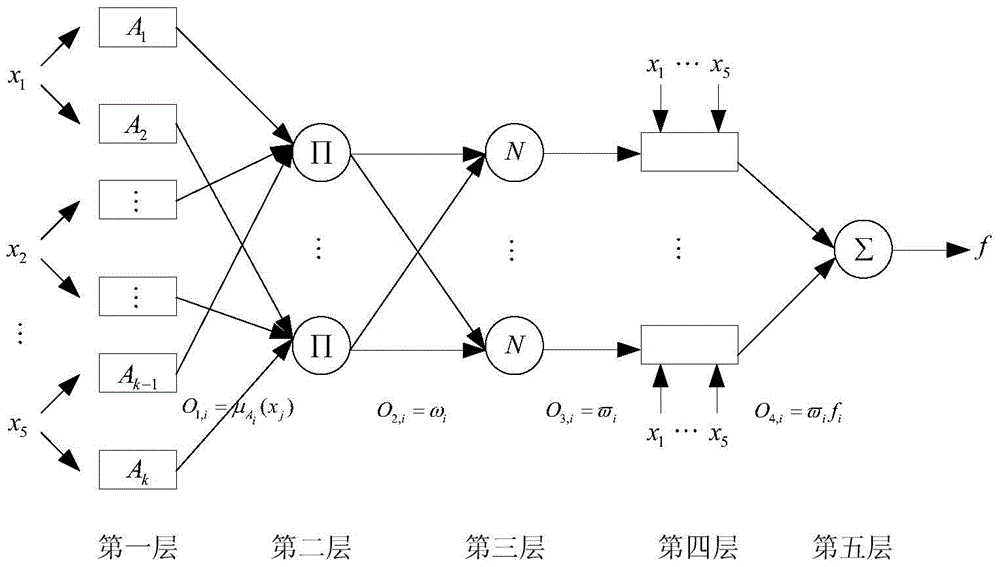

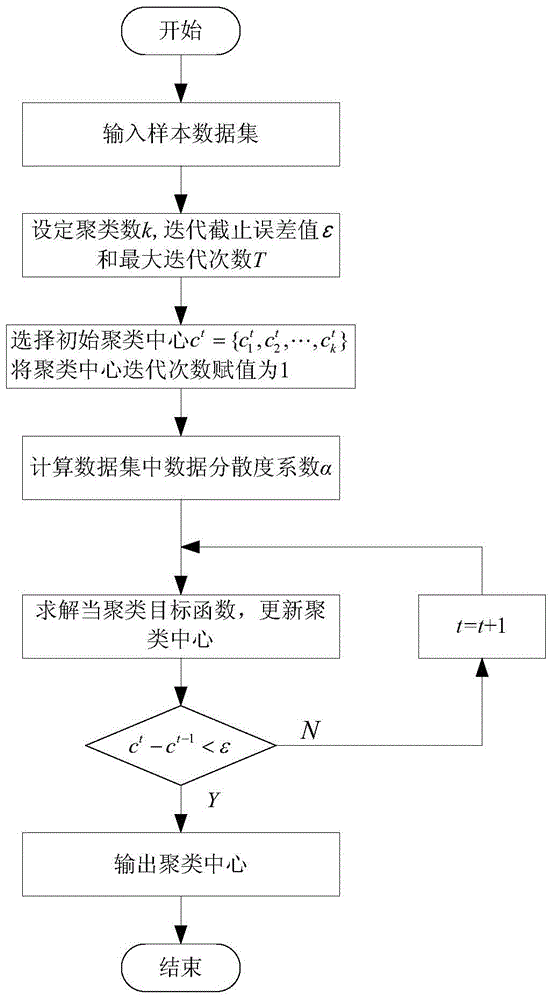

Intelligent soft measurement method of slashing sizing percentage

ActiveCN103559417ACalculation speedHigh precisionFuzzy logic based systemsSpecial data processing applicationsData setMaterial consumption

The invention relates to an intelligent soft measurement method of a slashing sizing percentage, and belongs to the technical field of automatic measurement. The method comprises steps as follows: according to composition analysis of a sizing mechanism and a slasher, auxiliary variables for soft measurement of the slashing sizing percentage are determined and comprise a slasher speed, pressure of a low-pressure sizing roller of the slasher, pressure of a high-pressure sizing roller of the slasher, concentration of size in a size box of the slasher and temperature of the size in the size box of the slasher; historical operating data of the slasher are collected, and a sample data set is established; a slashing sizing percentage soft measurement model is established, and a relation between the auxiliary variables and slashing sizing is obtained; and the slashing sizing percentage is calculated on line. According to the method, the slashing sizing percentage can be accurately calculated on line, the calculation speed and the accuracy are high, the online detection can be realized, and energy consumption and material consumption in the slashing production process can be reduced; the application range is wide, and online soft measurement of other quality indexes such as moisture regain, a elongation percentage and the like can be realized after a data source is appropriately modified; and the slashing production can conveniently share information with other links of cotton textile production, and references are provided for operations of other links.

Owner:SHENYANG POLYTECHNIC UNIV

Method for bionic wild cultivation of black fungi in walnut frost

InactiveCN106831143AReduce prolonged exposureSave resourcesBio-organic fraction processingAnimal corpse fertilisersFrostHyphomycetes

The invention discloses a method for bionic wild cultivation of black fungi in a walnut frost, and belongs to the technical field of edible mushroom cultivation. The method disclosed by the invention is simple and low in pollution rate in the cultivation process. The methodspecifically comprises the following steps: preparing a medium, bagging and sterilizing the medium, inoculating, performingmycelium culture, establishing a yard, transplanting into the frost, and performing fungus growthmanagement. By adopting the method, the insect and disease rates of black fungi and walnuts in the cultivation process can be reduced, the yield of the black fungi and the fungus polysaccharide content of the black fungi are both prior to those of field cultivation products, very good quality can be achieved, and relatively good commercialperformance can be achieved.

Owner:QINGYANG DUNBO TECH DEV CO LTD

Fertilizer special for platycodon grandiflorum and fertilizing method thereof

InactiveCN102924151AIncrease productionHigh outputFertilising methodsFertilizer mixturesAnimal scienceEnvironmental geology

The invention discloses a fertilizing method of a fertilizer special for platycodon grandiflorum. The fertilizing amount is that N is 425.9-434.5kg / hm<2>, P2O5 is 141.37-144.22kg / hm<2>, K2O is 80.55-82.17kg / hm<2>, MnSO4 is 6.42-7.1kg / hm<2>, and ZnSO4 is 4.38-4.84kg / hm<2>. Two fertilizing processes including base fertilizer fertilizing and topdressing are carried out, the base fertilizer fertilizing uses 20% of N using amount, 100% of P2O5 using amount, 30% K2O using amount, 50% of MnSO4 using amount and 50% of ZnSO4 using amount, and topdressing uses 80% of N using amount, 70% of K2O using amount, 50% of MnSO4 using amount and 50% of ZnSO4 using amount. Yield of the platycodon grandiflorum increases 22.6-26.3% through optimization of major elements and microelements, and the production value improves 32.7-42.9%.

Owner:INST OF AGRO FOOD SCI & TECH SHANDONG ACAD OF AGRI SCI

Rosin production and processing technology

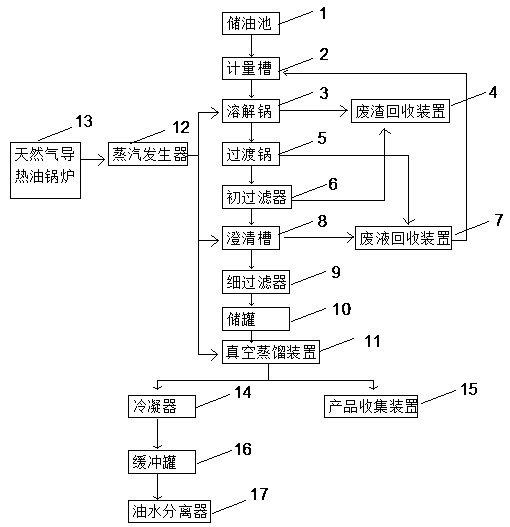

InactiveCN111171727AReduce volatilityIncrease profit by 1%Fatty substance recoveryNatural resin purificationProcess engineeringOil water

The invention discloses a rosin production and processing technology. Adopted equipment comprises a grease storage tank which is connected with a metering tank, the metering tankis connected with a dissolving pot, and the dissolving pot which is respectively connected with a waste residue recovery device and a transition pot; the transition pot is connected with a primary filter and a waste liquidrecovery device;the waste liquid recovery device is connected with the metering tank;the primary filter is connected with aclarification tank and thewaste residue recovery device respectively, the clarification tank is connected with afine filter, the fine filter is connected with astorage tank, and the storage tank is connected with a vacuum distillation pot; the dissolving pot, the clarificationtank and the vacuum distillation pot are all connected with asteam generator; the steam generator is connected with a natural gas heat-conducting oil boiler; the vacuum distillation pot is respectively connected with two discharge pipes, one discharge pipe is connected with a condenser, the other discharge pipe is connected with a product collecting device, the vacuum distillation pot is connected with a buffer tank, and the buffer tank is connected with an oil-water separator. The first-grade product rate of rosin production and processing is improved.

Owner:普洱市思茅区森盛林化有限责任公司

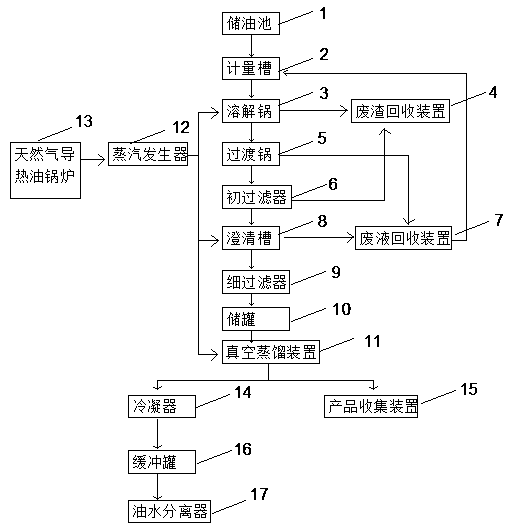

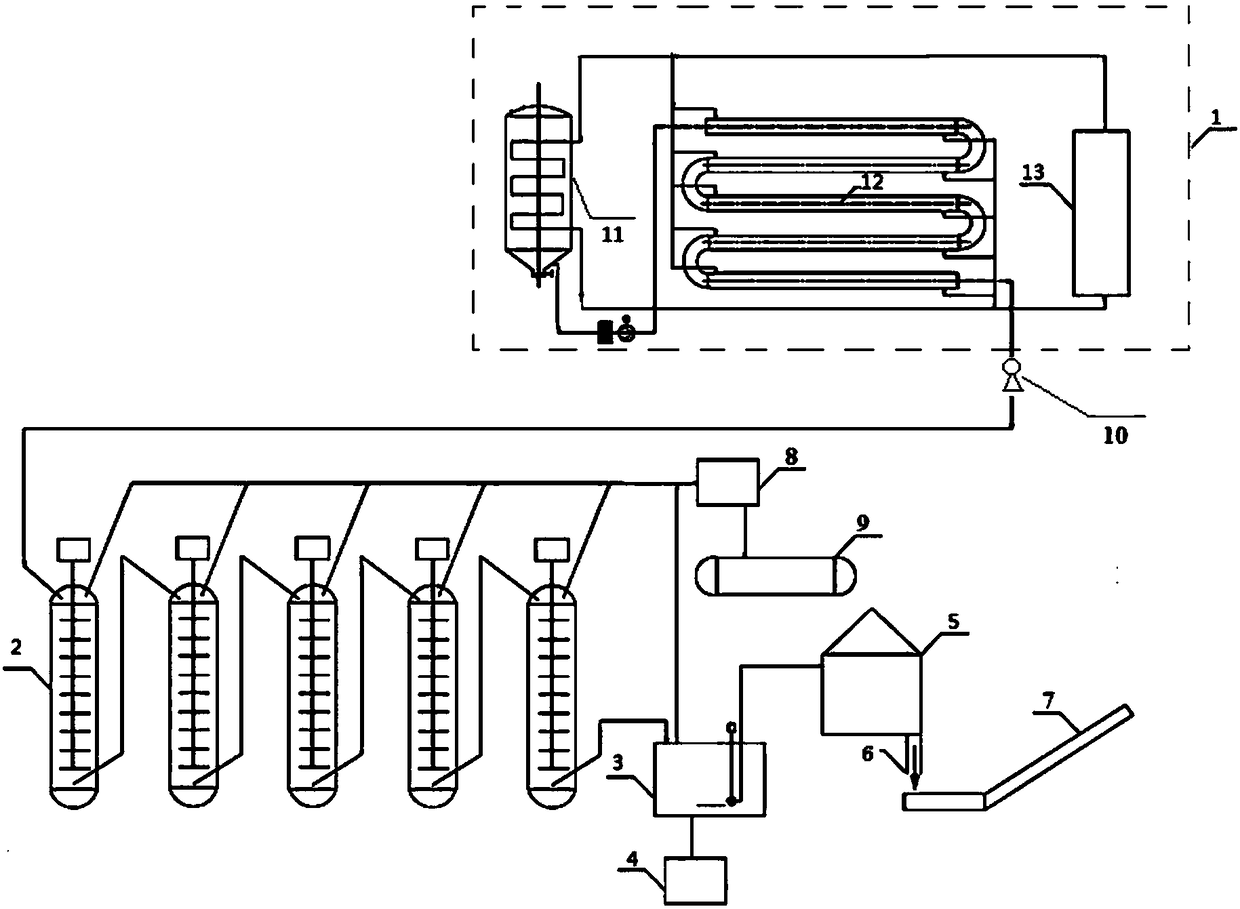

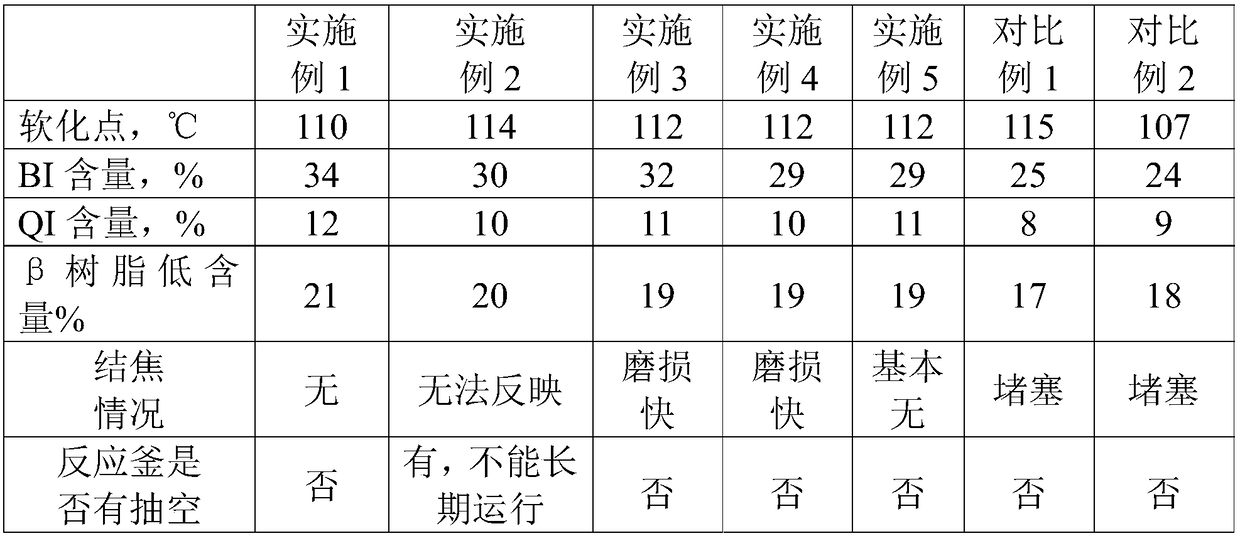

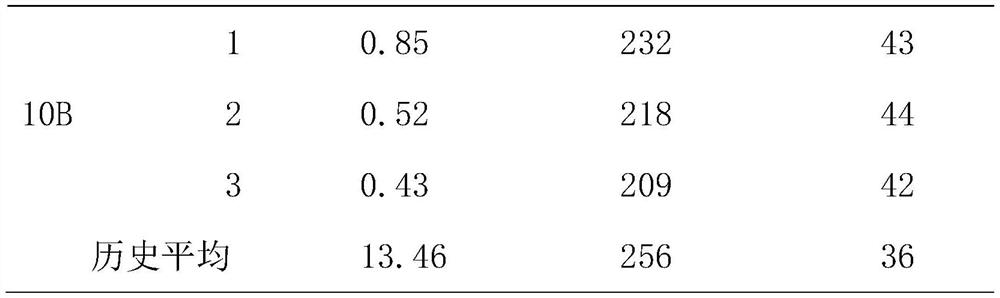

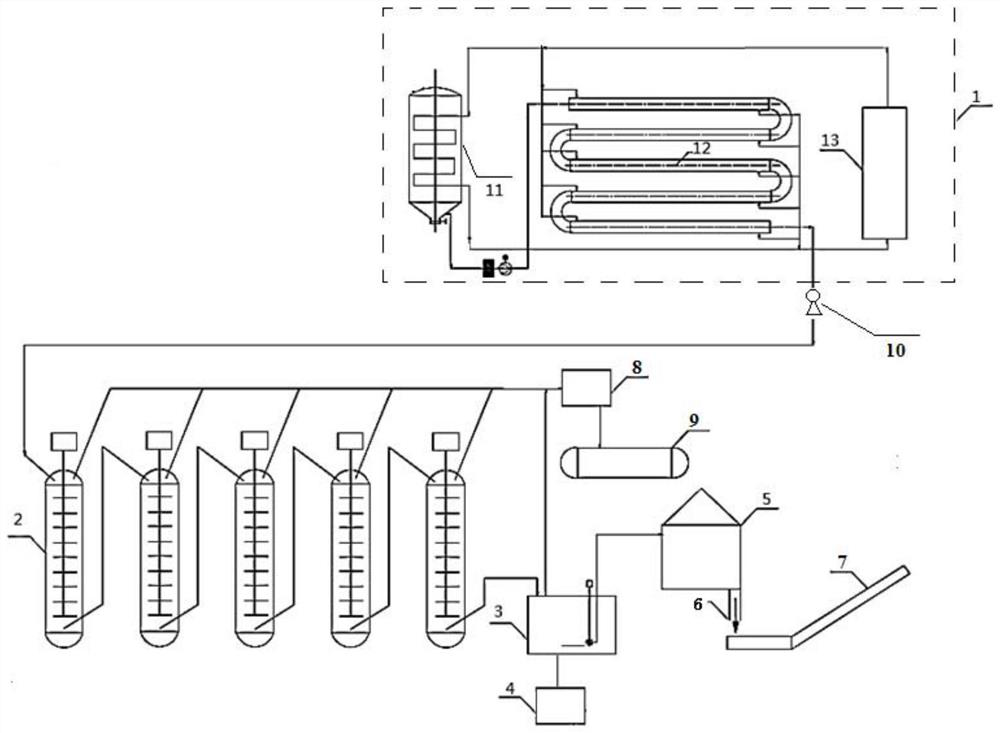

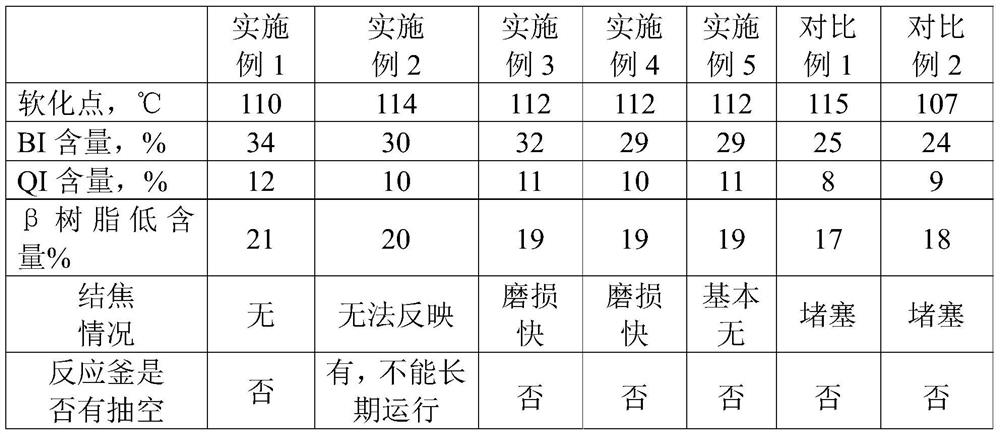

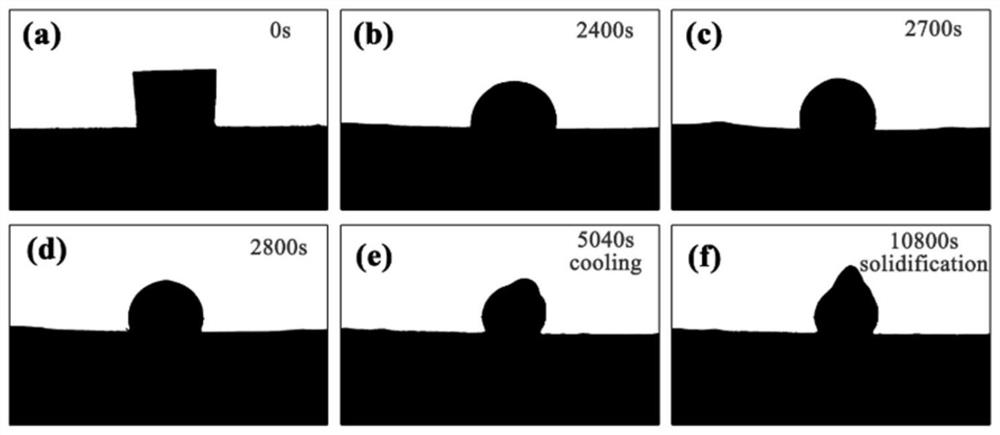

Modified asphalt as well as continuous production method and system thereof

ActiveCN108424780AHeating fastRaising the temperature can realize rapid asphalt polymerizationWorking-up pitch/asphalt/bitumen by chemical meansWorking-up pitch/asphalt/bitumen by thermal meansMolten saltProcess engineering

The invention relates to the field of modified asphalt production and discloses modified asphalt as well as a continuous production method and system thereof. The system comprises a continuous heatingand feeding system (1) and an asphalt polymerization reaction system (2) located at the downstream of the continuous heating and feeding system (1); a discharging hole of the continuous heating and feeding system is connected with a feeding hole of the asphalt polymerization reaction system; the continuous heating and feeding system comprises an asphalt liquid storage unit (11) and an asphalt liquid heating unit (72); the asphalt polymerization reaction system comprises 2-8 stages of reactors connected in series and at least one stage of standby reactor; the asphalt liquid heating unit comprises spaces for respectively filling asphalt and molten salt. The method comprises the steps: heating an asphalt liquid to a preset temperature to form molten asphalt, and adding the molten asphalt into the asphalt polymerization reaction system for a contact reaction; and heating the molten asphalt by using molten salt, wherein the polymerization reaction system comprises the 2-8 stages of reactors connected in series and the at least one stage of standby reactor. The obtained modified asphalt is uniform in softening point, good in stability, low in low-molecular component content and capableof realizing continuous production.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Culture compost used for cultivation of auricularia polytricha and preparation method thereof

InactiveCN104761365AMeeting nutritional needsPromote growthBio-organic fraction processingOrganic fertiliser preparationWood ashSugar

The invention provides culture compost used for cultivation of auricularia polytricha and a preparation method thereof. The culture compost used for cultivation of auricularia polytricha is prepared from the following components in parts by mass: 20-25 parts of corncob, 20-25 parts of cottonseed hull, 35-40 parts of mulberry twig wood chips, 2-5 parts of plant ash, 5-8 parts of bean flour, 1-3 parts of saw powder, 0.4-0.6 part of white granulated sugar, 1-3 parts of lime and 1-3 parts of gypsum. The invention also discloses a preparation method of the culture compost used for cultivation of auricularia polytricha. The culture compost used for cultivation of auricularia polytricha can meet requirements of auricularia polytricha on nutrients when growing, fertilizer does not need to be supplemented in a growth process, and the produced auricularia polytricha is large, grows rapidly and is good in taste, high in ratio of first-grade products and low in incidence.

Owner:韦双梅

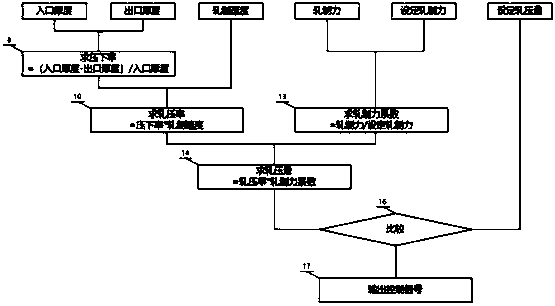

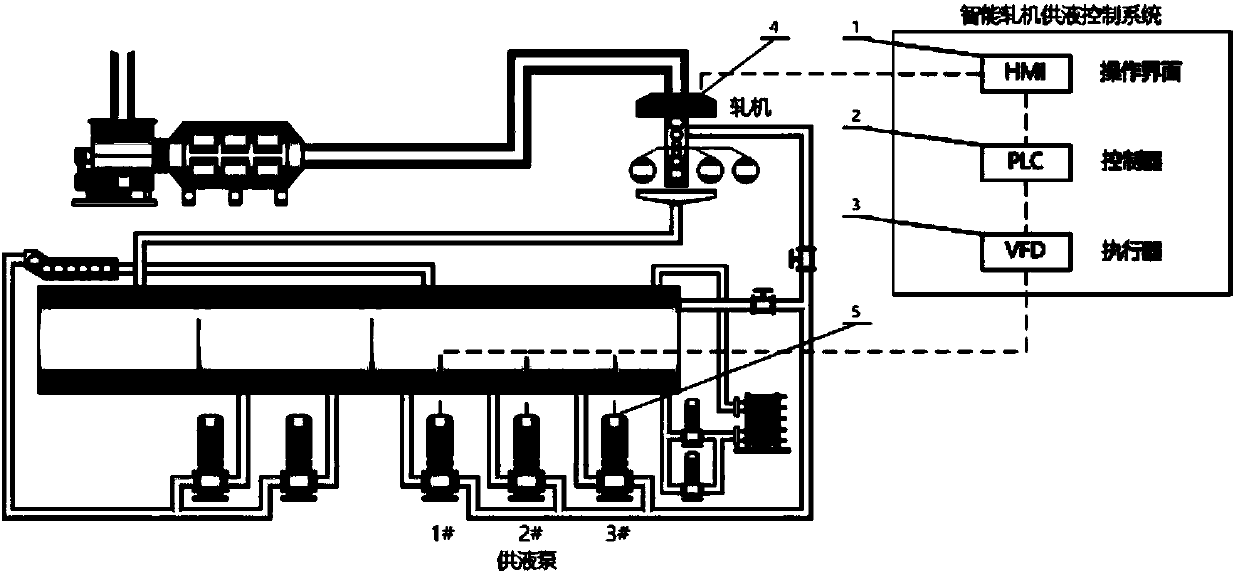

Intelligent rolling mill liquid supply control system

InactiveCN111036691AQuality improvementReduce energy consumption for liquid supplyTemperature control deviceControl signalSoftware system

The invention belongs to the technical field that: the invention relates to intelligent control, energy consumption reducing and plate shape improvement over a technical lubrication liquid supply system of a cold-rolled steel plate rolling mill. The invention solves the technical problems of poor plate shape, emulsion spots, low first-grade product rate and the like in a fixed liquid supply mode.The technical scheme is as follows: an adopted control system comprises a hardware system and a software system. The hardware system mainly comprises an operation interface, a controller and an actuator. The operation interface has the functions of data acquisition, parameter setting and operation monitoring; the controller has the functions of analyzing and calculating the acquired data and outputting a control signal; and the actuator has the functions of receiving the control signal and outputting a control command to control equipment. The software system mainly comprises an acquisition program and a control program. The acquisition program has the function of acquiring process data of a rolling mill. The control program has the function of performing calculation and judgment accordingto the process data and outputting a control signal. The invention is mainly used for the technical lubrication liquid supply system of the cold-rolled steel plate rolling mill.

Owner:何定武 +1

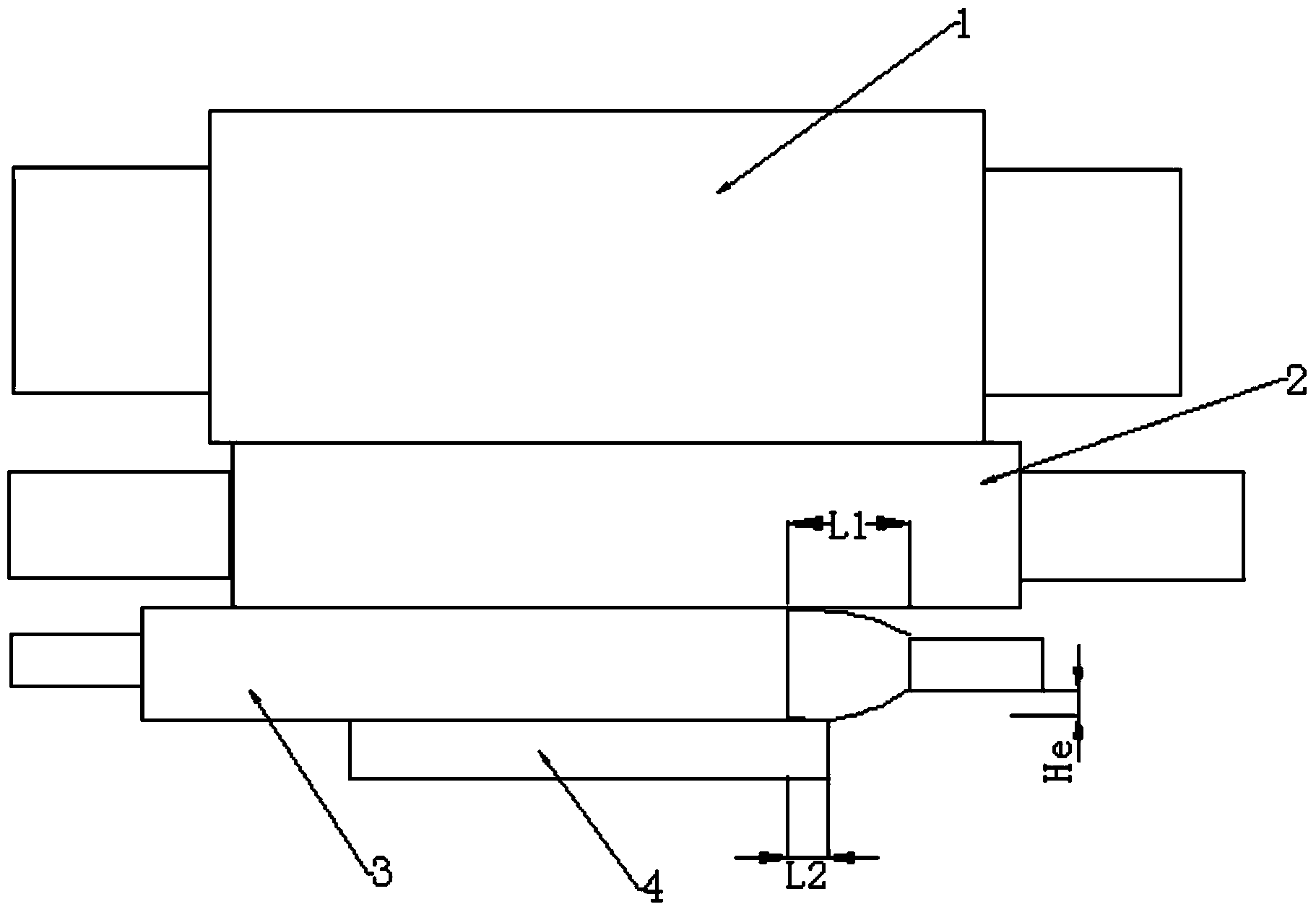

UCM six-roller mill

InactiveCN103394513AImprove first-class rateReduce trimmingRollsMetal rolling arrangementsEngineeringThinning

The invention relates to the technical field of cold rolling mills and provides a UCM six-roller mill. The UCM six-roller mill comprises fixed rollers, intermediate rollers and work rollers which are arranged in sequence from top to bottom, wherein a chamfer is arranged at an end part of each work roller; the conicity width of the chamber at the end part of the work roller is 20 mm to 50mm; the conicity height of the chamber is 20 microns to 80 microns. By adoption of the technical scheme, the UCM six-roller mill has the advantages and benefits as follows: the plate crown of non-oriented silicon steel produced by the normal six-roller mill can be controlled at 0.08 mm approximately, the ratio of first-grade products of cold-rolled silicon steel can be increased by 50%, the thickness of edge parts in edge part thinning areas is reduced to 15mm from 20 mm, edge cutting amount of finished products is reduced by 5 mm, and the material yield is increased by 1% approximately.

Owner:TIANJIN RONGTAI ADVANCED COMPOSITE MATERIAL

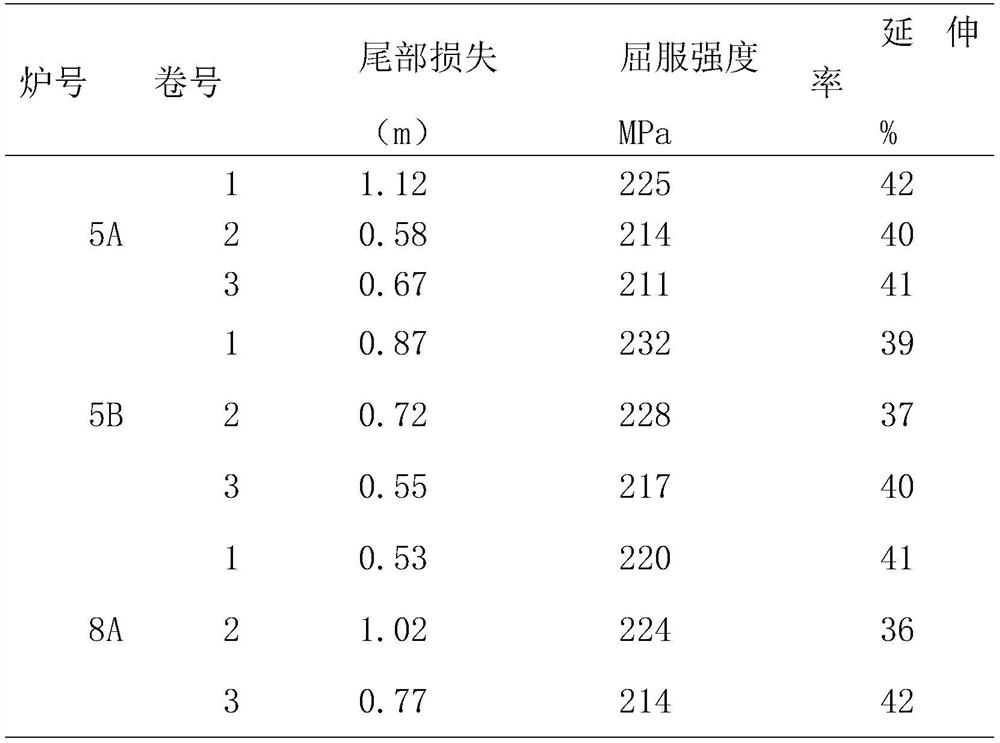

Cold-rolling annealing method of cold-rolled strip steel

InactiveCN112226597ASticky Tail Problem SolvedHigh elongationHeat treatment process controlElectrolysisStrip steel

The invention discloses a cold-rolling annealing method of cold-rolled strip steel. The method` comprises the following steps that S1, strip steel is selected, the strip steel Is machined until a thickness is 2.0 mm-3.5 mm, then the strip steel is placed on a conveying mechanism, the conveying mechanism is enabled to face an inlet of a preheating furnace, and the strip steel is fed into a preheating furnace for preheating and treatment; S2, the strip steel is heated, specifically, the preheated strip steel is conveyed into a heating furnace to be heated, and a temperature rising speed of a temperature is changed according to the requirement of heating of the strip steel; S3, strip steel heat preservation is conducted, specifically, the heated strip steel enters a balancing furnace to be subjected to heat preservation, and the heat preservation time is 12 h-15 h; and S4, the strip steel is cooled, the strip steel is taken out of the furnace after heat preservation to be subjected to hotline pickling, continuous pickling is performed by adopting a special pickling line, and meanwhile, electrolysis is performed. The tail sticking problem of the cold-rolled strip steel is thoroughly solved, and a first-grade product rate of a finished product is greatly increased. After tail sticking is solved and the mechanical property of the finished product is improved, the machining cost is controlled, and the application field of the product is greatly expanded.

Owner:SICHUAN HUIYUAN STEEL CONSTR SCI & TECH

Modified asphalt and its continuous production method and system

ActiveCN108424780BHeating fastRaising the temperature can realize rapid asphalt polymerizationWorking-up pitch/asphalt/bitumen by chemical meansWorking-up pitch/asphalt/bitumen by thermal meansMolten saltProcess engineering

The invention relates to the field of modified asphalt production, and discloses modified asphalt and its continuous production method and system. The system includes: a continuous heating feed system (1) and a downstream asphalt polymerization reaction system (2), and a continuous heating feed system The discharge port is connected with the feed port of the asphalt polymerization system; the continuous heating feed system includes an asphalt liquid storage unit (11) and an asphalt liquid heating unit (72), and the asphalt polymerization system includes 2-8 grades of reactors connected in series and at least Level 1 standby reactor; bituminous liquid heating unit includes space for filling bitumen and molten salt separately. The method includes: heating the asphalt liquid to a predetermined temperature to form an asphalt melt, and adding it to an asphalt polymerization reaction system for contact reaction; heating the molten asphalt through molten salt; the polymerization reaction system includes 2-8 reactors connected in series and at least 1 level spare reactor. The obtained modified asphalt has uniform softening point, good stability, low content of low-molecular components, and can be continuously produced.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

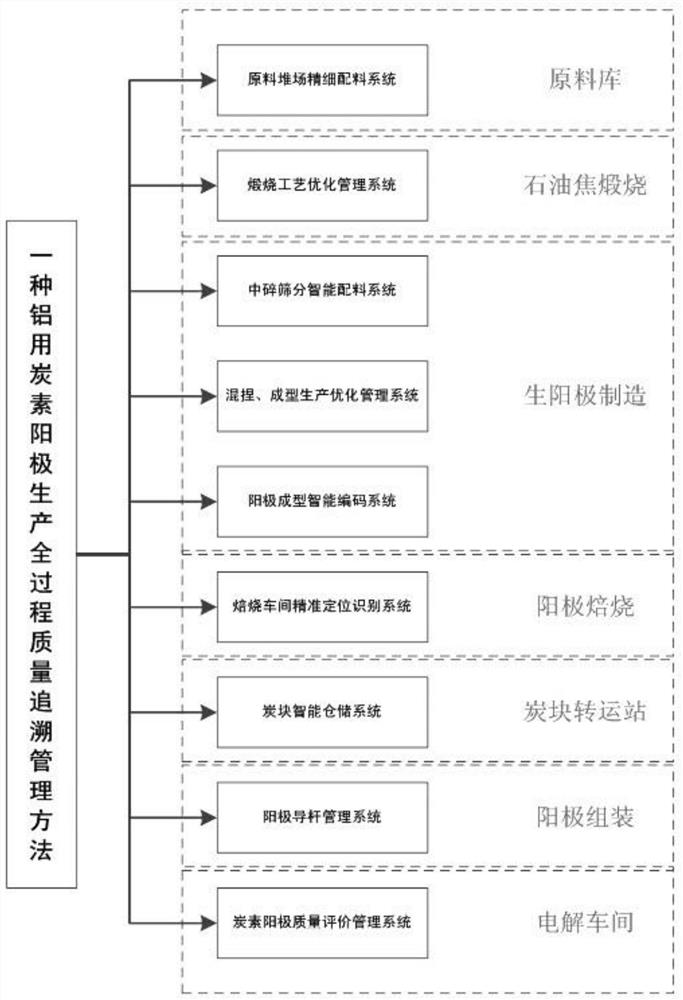

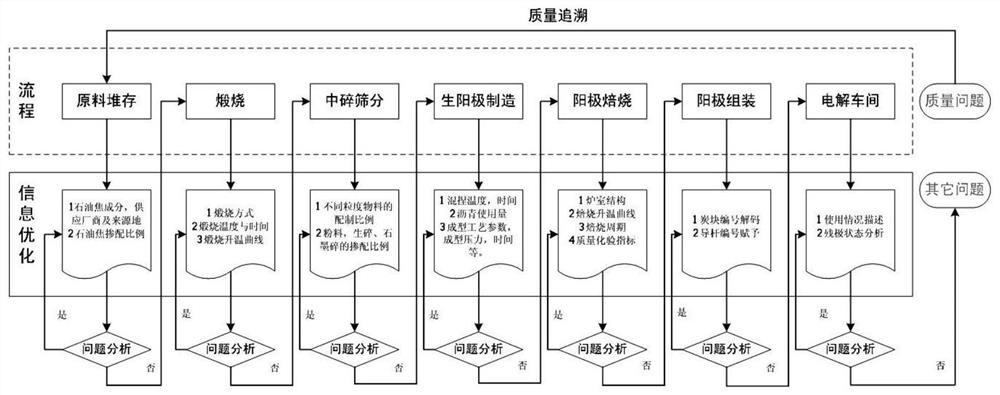

A quality traceability management method for the whole production process of carbon anode for aluminum

ActiveCN110738434BSolve the problem of single curing production process parametersRealize unattendedForecastingResourcesMachine visionProcess engineering

The invention discloses a quality traceability management method for the whole production process of carbon anodes for aluminum. By assigning physical identity attributes to carbon anodes, the matching and correlation of information including process parameters in the production and use of carbon anodes and time correspondence are realized; through the development of identity Endow physical attributes with machine vision recognition equipment to realize the tracking of physical attributes; through the means of developing system software, complete the storage, conversion and preprocessing of production process information data; finally, through data mining and machine learning, establish the quality of carbon anode production process system prediction model. Through the development of the above-mentioned related devices and system development, the present invention can optimize the technical parameters of the production process, realize the precise correspondence and association between the process data and the anode production batches, and find out the cause of the problem if there is an anode and quality problem, and solve the problem. Adjust in time to improve the quality of anode production, reduce the unqualified rate, and increase the rate of first-class products.

Owner:GUIYANG AL-MG DESIGN & RES INST

Culture material for black fungus cultivation

InactiveCN102351609BSave resourcesEasy to controlFungiFertilizer mixturesInsect pestMonopotassium phosphate

The invention relates to a culture material for black fungus cultivation. Based on the total weight of the culture material, the culture material is made from the following ingredients of: by weight, 30-75% of a Jatropha curcas branch powder, 15-50% of weed tree sawdust or cotton seed hull or xylitol slag, 8-30% of wheat bran or rice bran, 0.05-1% of potassium dihydrogen phosphate, 0.2-5% of gesso and 0.2-5% of quicklime. The culture material for black fungus cultivation is used to produce artificial log cultivated black fungus and greatly control the growth of mixed bacterium and insect pest. The black fungus has excellent quality and good taste with high first degree quality rate, high biological efficiency and stable output. In addition, resources can be saved.

Owner:深圳市前海厚志科技有限公司

A method for eliminating molybdenum dioxide dripping material

ActiveCN106186069BReduce labor intensityReduce wearMolybdenum oxides/hydroxidesHydrogenReduction treatment

A method for eliminating molybdenum dioxide dripping material disclosed by the invention is specifically implemented according to the following methods: 1) select molybdenum trioxide as the raw material for preparation; The screen should be fixed, and the edges of the screen should be tied tightly with thin iron wires. Finally, a thin aluminum-plastic plate should be wrapped on the outside of the screen, and the interface of the aluminum-plastic plate should be fixed with rivets; Measure, then make a thermal insulation cap with a thin aluminum-plastic plate according to the measured size, and attach a layer of thermal insulation material layer on the inner wall of the thermal insulation cap, and finally put the prepared thermal insulation cap on the head of the hydrogen return pipeline; 4) pair the flat The five temperature zones in the four-tube low-temperature reduction furnace are adjusted respectively; 5) The selected molybdenum trioxide is placed in the adjusted flat four-tube low-temperature reduction furnace for inverse hydrogen reduction treatment, and finally molybdenum dioxide is obtained. The molybdenum dioxide obtained by the method of the invention is relatively loose, and at the same time, the molybdenum dioxide oversize is reduced.

Owner:JINDUICHENG MOLYBDENUM CO LTD

Manufacture technology of whole U-shaped silicon core

ActiveCN101775643BUniform resistancePrevent lodgingBy pulling from meltManufacturing technologyEngineering

The invention discloses a manufacture technology of a whole 'U'-shaped silicon core, relating to the technical field of drawing silicon core. The technology specifically comprises the following steps of: making the silicon core into a whole 'U'-shaped seed crystal, and tightly clamping the 'U'-shaped seed crystal with an upper shaft lifting system; putting a raw material stick on a material tray seat on a lower shaft lifting system, leading the raw material stick to be near to a high-frequency heating coil, and operating the high-frequency heating coil to heat the end of the raw material stick; leading the whole 'U'-shaped seed crystal to descend, and leading the vertical section of the whole 'U'-shaped seed crystal to penetrate through the inner hole of the high-frequency heating coil tobe inserted into a melting zone of the raw material stick; slowly lifting up the whole 'U'-shaped seed crystal, so that the two seed crystal heads of the whole 'U'-shaped seed crystal are respectively lead molten silicon at the head of the raw material stick to be crystallized at the end of the seed crystal, and the two heads of the 'U'-shaped seed crystal are continuously drawn to be the siliconcore; and stopping a furnace after the silicon core is drawn to a stated length to withdraw the 'U'-shaped silicon core. The whole 'U'-shaped silicon core drawn by the technology effectively reduces the design of a reduction furnace, the complexity of manufacture, and the unit energy consumption for manufacturing polycrystalline silicon.

Owner:LUOYANG JINNUO MECHANICAL ENG

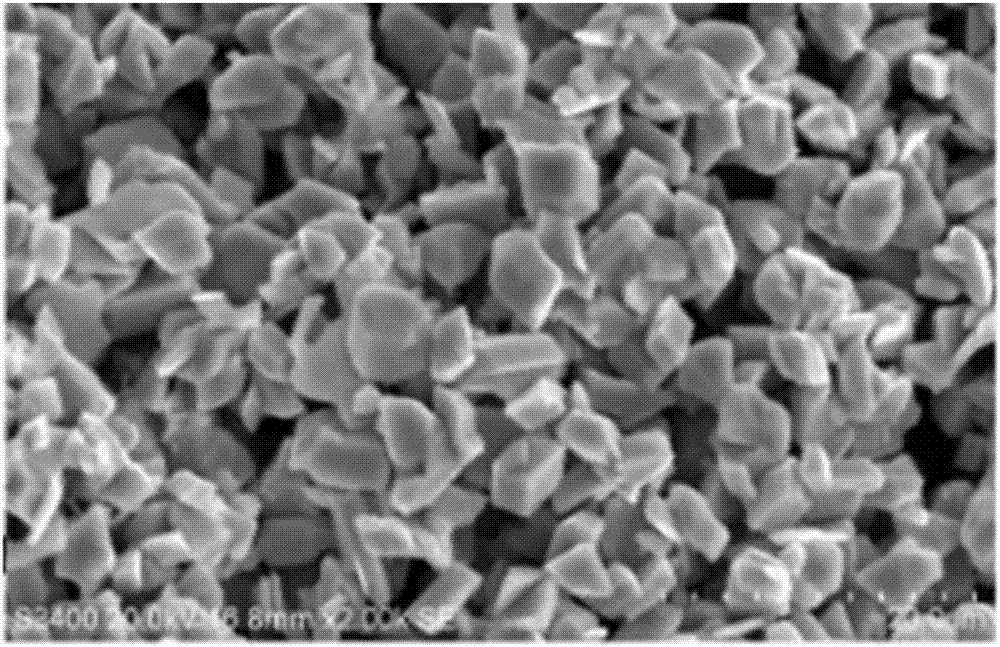

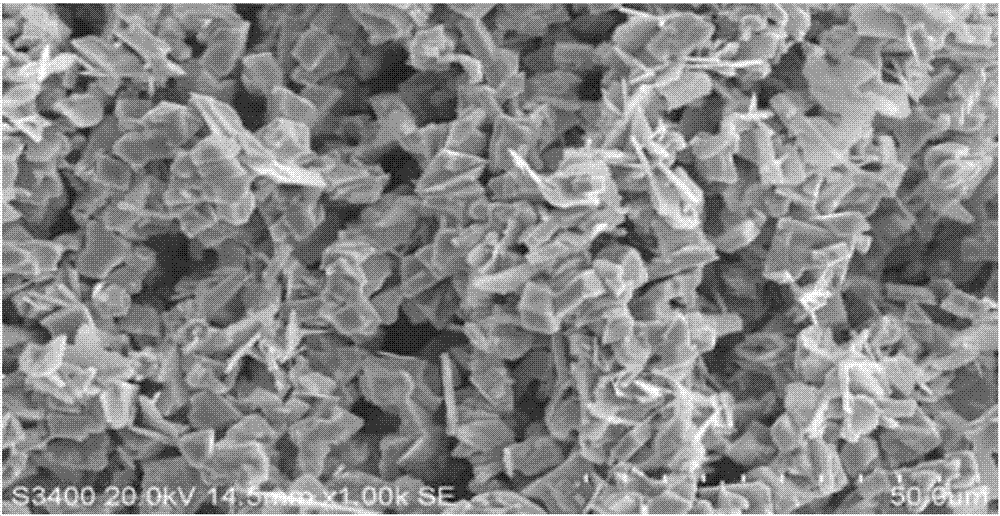

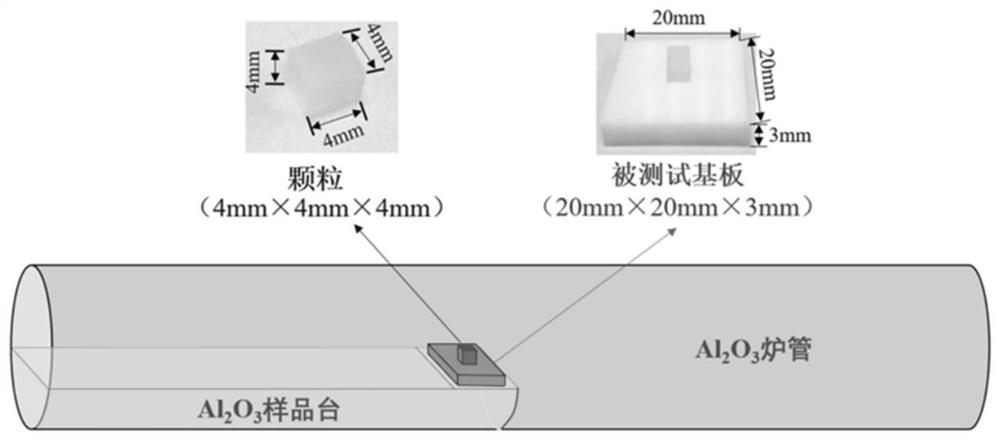

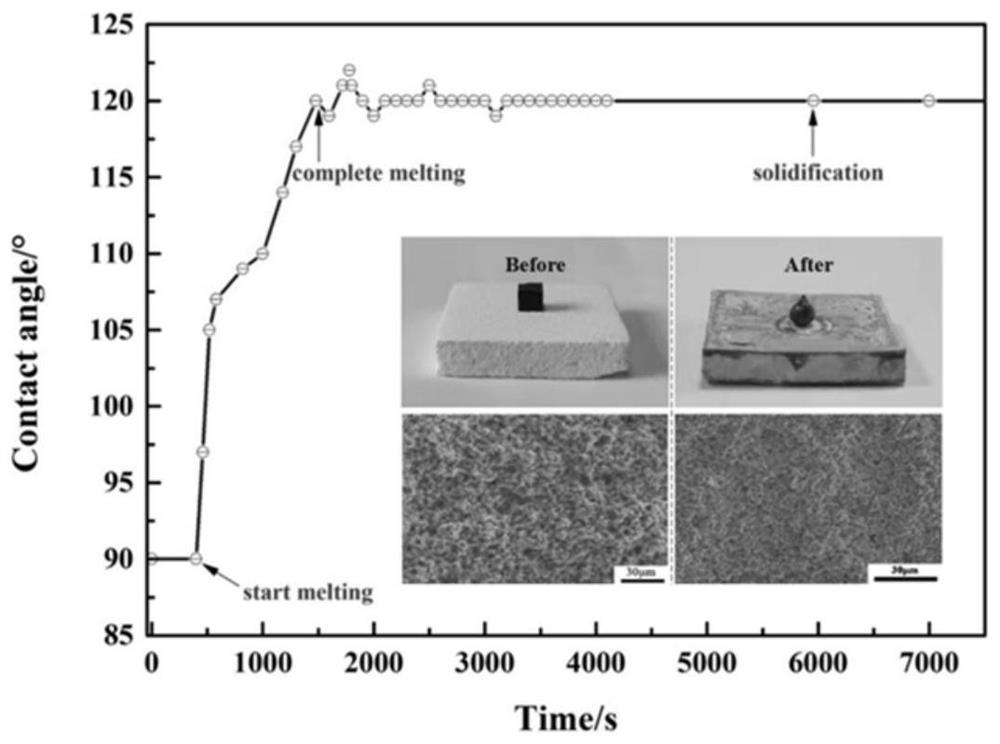

Preparation process of composite ceramic coating release agent

PendingCN114477781AImprove first-class rateAntioxidant is goodPolycrystalline material growthCoatingsCeramic coatingPolyvinyl alcohol

The invention discloses a composite ceramic coating release agent for silicon ingot demolding in the preparation process of solar grade polycrystalline silicon. The composite ceramic coating release agent is prepared from silicon oxynitride, beta silicon nitride, polyvinyl alcohol and water. The thermal and mechanical properties of Si2N2O are similar to those of a Si3N4 material, but the oxidation resistance, thermal shock resistance and chemical stability of Si2N2O are superior to those of the Si3N4 material. The Si melt shows super-hydrophobic property to the Si2N2O material, and the Si melt and the Si2N2O material do not have chemical reaction, so that the condition of quality reduction caused by adhesion and impurity diffusion of the Si cast ingot can be effectively reduced, and the purpose of improving the first-grade product rate of polycrystalline Si is achieved; the free energy of the beta-Si3N4 is lower than that of the alpha phase, the preparation difficulty is low, and the cost for preparing the same amount of Si3N4 powder and the alpha phase is 3-5 times that of the beta phase, so that the preparation cost can be effectively controlled by using the beta-Si3N4-based coating. In conclusion, the Si2N2O / beta-Si3N4 composite ceramic coating is a demolding coating which is superior to traditional Si3N4 in thermodynamic property and wettability and is low in cost.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

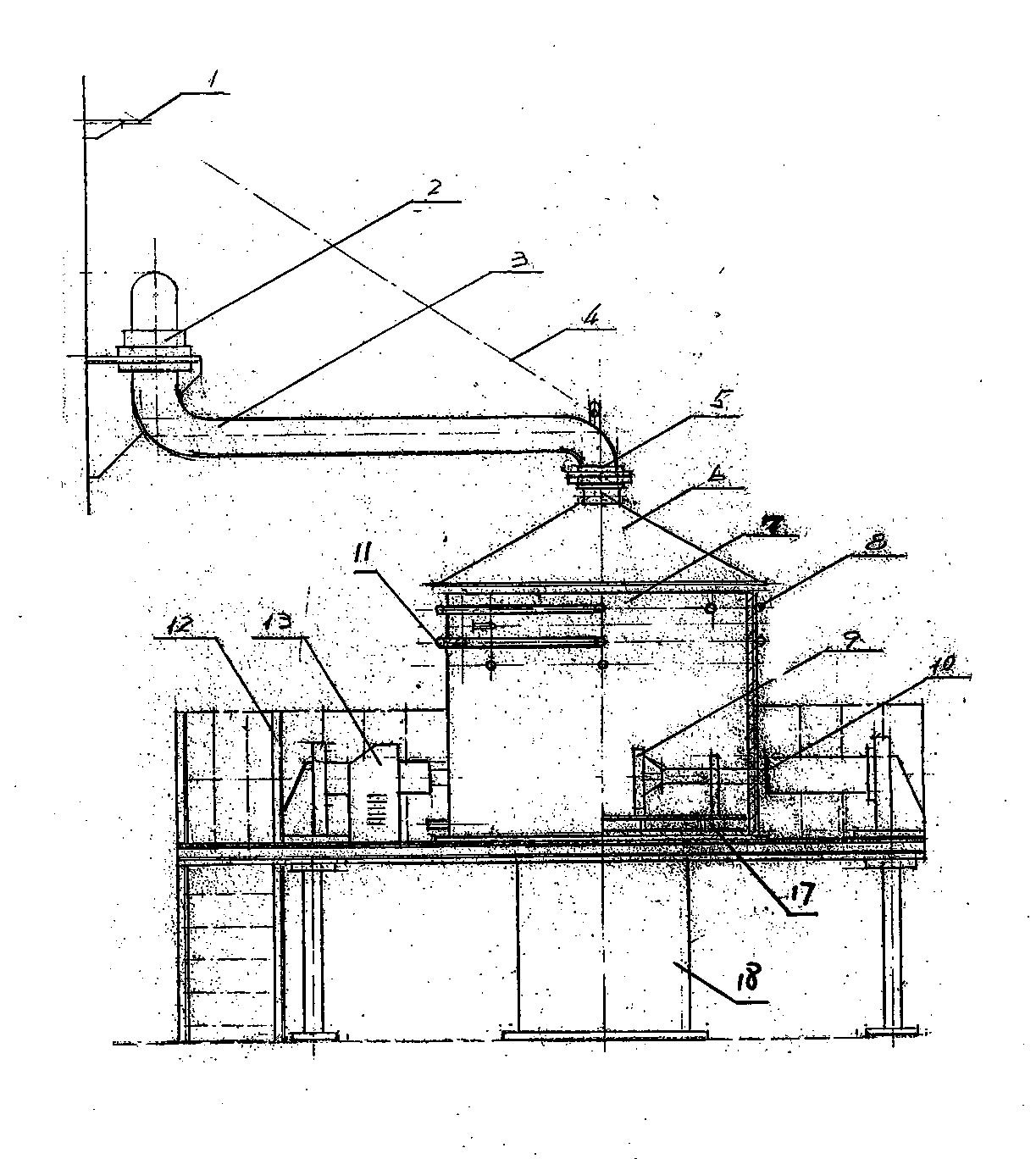

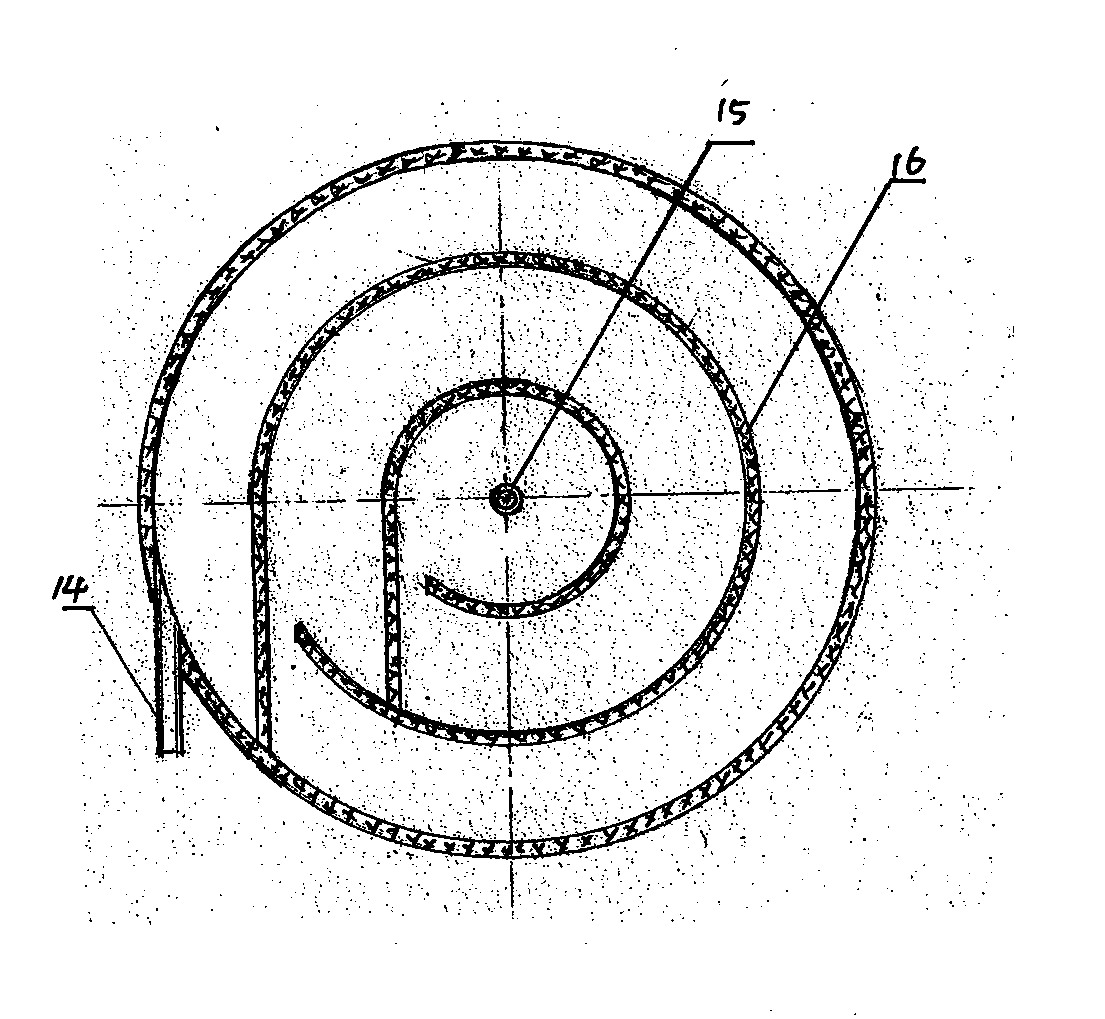

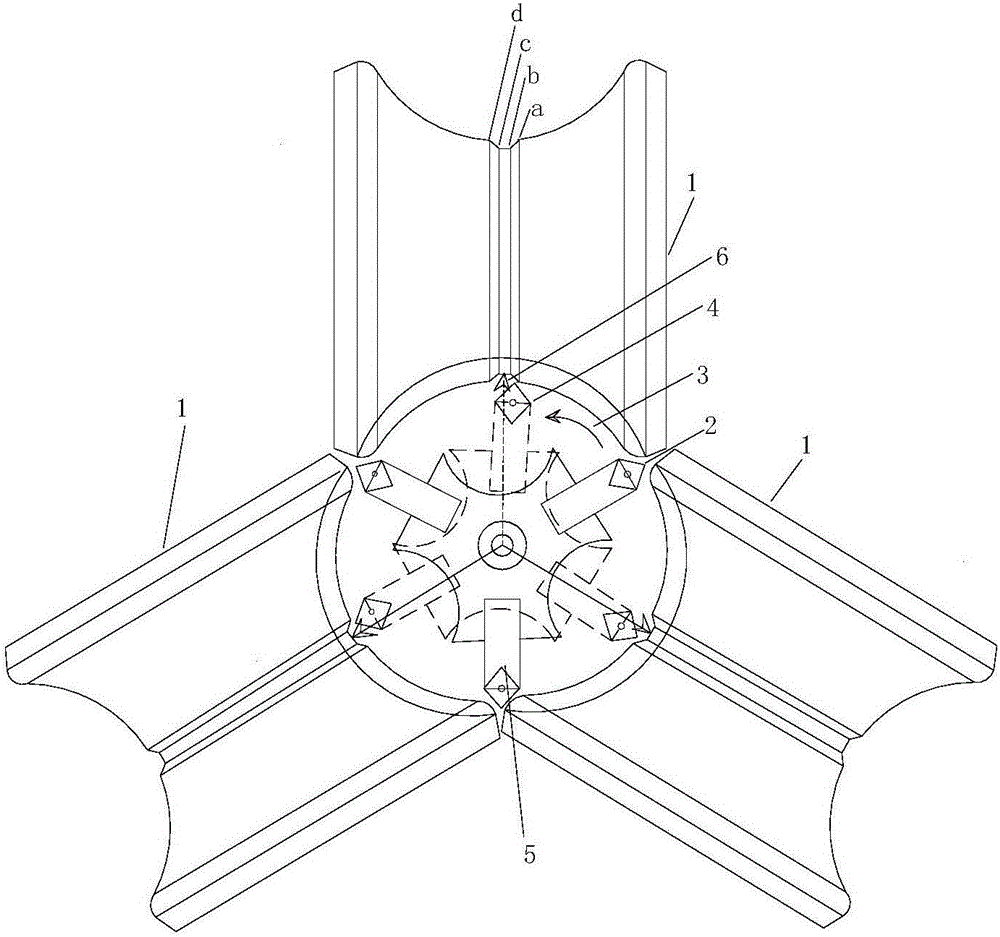

Quartz high temperature melting lump waterpower spurting breaking device

ActiveCN102527482BImprove first-class rateSave resourcesGrain treatmentsSputteringMechanical pressure

A quartz high temperature melting lump waterpower spurting breaking device comprises a corrosion resistant cylinder body arranged on a machine frame. A water cooling base plate is positioned at the bottom of the cylinder body, a gas collection cover is arranged at the top of the cylinder body, a pair of extrusion heads are positioned on the water cooling base plate, and a cylinder body wall self-cooling system and a high temperature melting lump inflowing water spurting system are arranged on the cylinder body. Quartz ore is arranged in a resistor furnace to be melted into a lump shape to be arranged on the water cooling base plate which is arranged in the cylinder body. Simultaneously, two groups of spurting water are started to perform cold explosion on quartz high temperature melting lump, and when high temperature quartz melting lump is in a shock cooling physical state, the ore generates concentrated cracks and is loosened, the extrusion heads further exert mechanical pressure on the quartz lump bodies, and finally, quartz is smashed into fine blocks of about 10mm. The quartz high temperature melting lump waterpower spurting breaking device achieves civilized construction and environments, improves quality and stability of products, remarkably improves rate of first products and provides conditions for large-scale industrial production.

Owner:江苏省晶瑞石英工业开发研究院有限公司

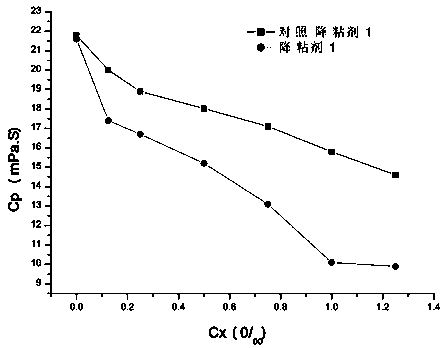

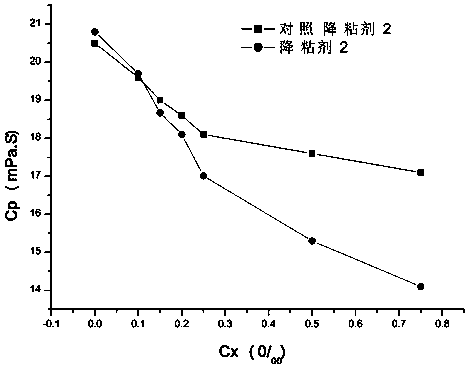

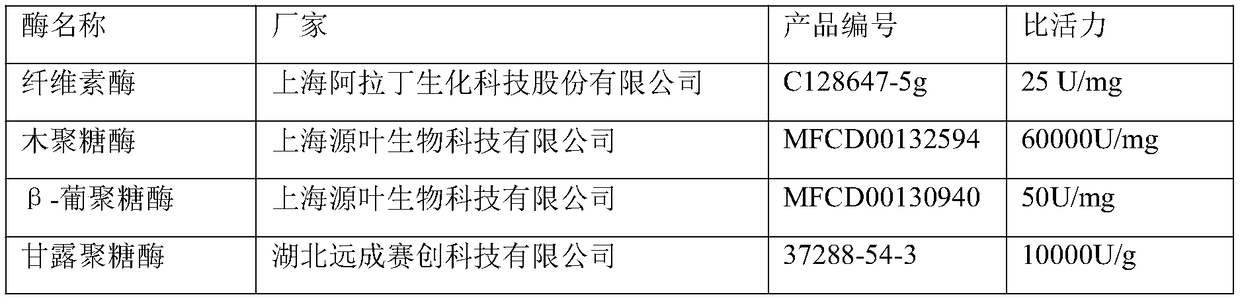

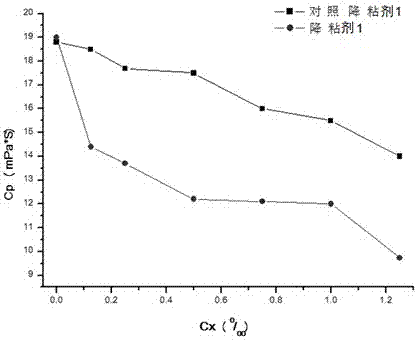

Mutant of pectin lyase from Aspergillus niger and viscosity reducer of corn syrup in alcohol fermentation production

ActiveCN105112396BEfficient viscosity reductionFast viscosity reductionFood processingAnimal feeding stuffEscherichia coliPectin lyase

The invention provides an aspergillus niger pectin lyase mutant and a viscosity reducer for syrup during corn ethanol fermentation production, and relates to the field of biotechnologies. Lysine at the 241st positions of amino acid sequences of aspergillus niger pectin lyase is replaced by methionine to obtain the mutant. The invention further provides an encoding gene of the mutant. A method for preparing the mutant includes fermenting Escherichia coli with the encoding gene of the mutant to obtain the mutant. The viscosity reducer for the syrup during corn ethanol fermentation production is a mixture of the mutant and one or two types of cellulase, xylanase, beta-glucanase, mannanase, glutamine transaminase and lipase. The aspergillus niger pectin lyase mutant, the viscosity reducer and the encoding gene have the advantages that the aspergillus niger pectin lyase mutant is excellent in enzyme stability and catalytic activity, and the method for preparing the aspergillus niger pectin lyase mutant is simple; the viscosity of the syrup can be quickly and efficiently reduced by the viscosity reducer during corn ethanol fermentation production under the condition of low energy consumption.

Owner:NANJING NORMAL UNIVERSITY

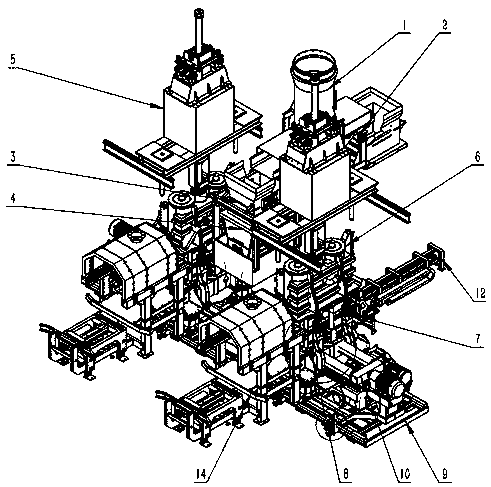

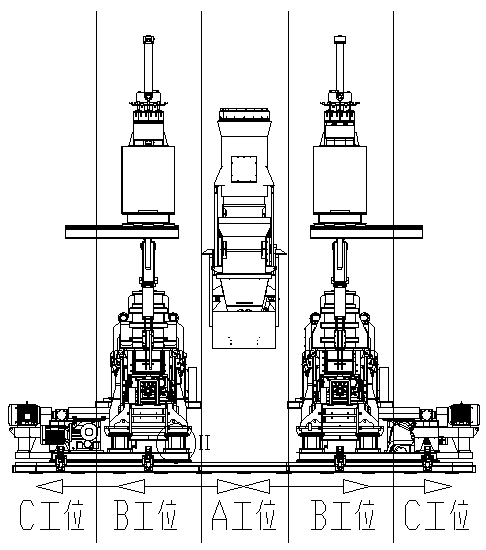

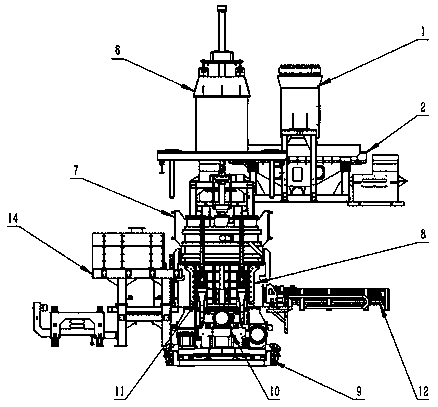

Anode carbon block vibration forming machine

The invention discloses an anode carbon block vibration forming machine, and belongs to the field of electrolytic aluminum. The problems that in the prior art, during production of different anode carbon blocks, mold replacement, dismounting and mounting are inconvenient, equipment maintenance is inconvenient, and the high-yield requirement is needed are solved. The anode carbon block vibration forming machine comprises a storage hopper, a feeder, a distributor, a static weighing hopper, a heavy hammer component, a mold, a vibration table conveying device, a vibration table drive device, a carbon block push-out device and a carbon block pull-out device, wherein the vibration table comprises a vibration table frame and vibration table mold guide rods; the two vibration table mold guide rodsare symmetrically arranged on the vibration table frame and arranged on the vibration table frame; the mold is arranged on the vibration table mold guide rods; two sets of second locking devices aresymmetrically arranged on the two sides of the vibration table frame; and two balance shafts opposite in rotation direction are arranged in a vibration table cavity. According to the device, the anodecarbon block production period is shortened, the production efficiency is improved, and the production cost is saved.

Owner:LANZHOU ZHICHENG MACHINERY EQUIP CO LTD +1

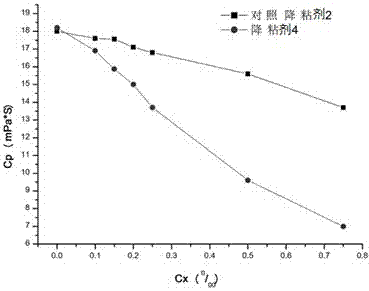

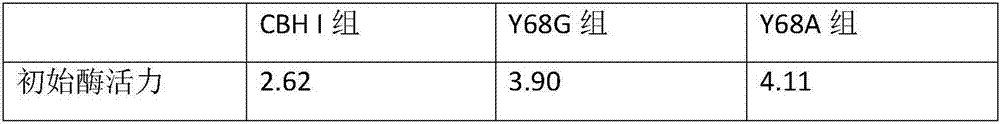

Mutant of cellulosic exoglucanase cbh I and viscosity reducer of syrup in corn fuel ethanol fermentation production

InactiveCN105018446BImprove stabilityHigh catalytic activityHydrolasesTransferasesCellulosePectinase

The invention provides a mutant of cellulose exocellobiohydrolase CBH I and viscosity reducer of syrup in corn fuel ethanol fermentation production and relates to the field of biotechnology. The mutant of the cellulose exocellobiohydrolase CBH I is obtained by replacing the 68th tyrosine of the amino acid sequence of the cellulose exocellobiohydrolase CBH I with glycine or alanine. The viscosity reducer is a mixture of the mutant of the cellulose exocellobiohydrolase CBH I and one or more than two of pectinase, xylanase, beta-glucanase, mannase, glutamine transaminase and lipase. The mutant of the cellulose exocellobiohydrolase CBH I is great in enzyme stability and catalytic activity, and the preparation method is simple and efficient. By adopting the viscosity reducer, viscosity reduction can be conducted on the syrup in the corn fuel ethanol fermentation production rapidly and efficiently under the condition of low energy consumption.

Owner:NANJING TIANKAI BIOTECH

An intelligent soft measurement method for sizing rate of sizing

ActiveCN103559417BCalculation speedHigh precisionFuzzy logic based systemsSpecial data processing applicationsDecreased energyData acquisition

An intelligent soft measurement method for sizing sizing ratio belongs to the technical field of automatic measurement. According to the analysis of the sizing mechanism and the composition of the sizing machine, the auxiliary variables for the soft measurement of the sizing rate of the sizing machine are determined to be: the speed of the sizing machine, the pressure of the low-pressure sizing roller of the sizing machine, the pressure of the high-pressure sizing roller of the sizing machine, and the pressure in the sizing tank of the sizing machine. Size concentration and size temperature in the sizing tank of the sizing machine; collect the historical operation data of the sizing machine to establish a sample data set; establish a soft sensor model for the sizing rate of the sizing, and obtain the relationship between the auxiliary variable and the sizing; the sizing rate of the sizing Calculate online. The method of the invention can accurately calculate the sizing rate of sizing on-line, has fast calculation speed and high precision, can realize on-line detection, and reduces energy and material consumption in the sizing production process; it has a wide range of applications, and can be used for other quality after proper modification of the data source. Indicators such as moisture regain, elongation, etc. can be measured online; it can easily share information with other links in cotton textile production, and provide reference for the operation of other links.

Owner:SHENYANG POLYTECHNIC UNIV

Method for separating primary and secondary washed massecuite from high-grade washed massecuite

ActiveCN103642946BAffect product qualityGuarantee product qualitySugar juice purificationEngineeringComputer control

Owner:GUANGXI BOXUAN FOOD

Compensatory turning method for three-high stand

InactiveCN106825615AFlexible processImprove processing efficiencyTurning machinesMicrometerOperation mode

The invention discloses a compensatory turning method for a three-high stand, which comprises the steps of: controlling a tool to turn a small groove on the surface of a roll collar according to the following mode: selecting a turning tool which has a corresponding pass and is at an angle of 120 degrees, knocking the turning tool to an initial position, rotating the tool to rotate counter-clockwise by 58 degrees, manually feeding the tool by 1 to 2mm and then rotating the tool by 3 degrees to 5 degrees; retracting the tool to the initial position, measuring a micrometer size, calculating out a compensation route according to the measured micrometer size and a size of the tool, and carrying out compensatory tool feeding. Adoption of the method has the advantages of flexible operation mode, simple and efficient operation method, short operation time and high machining efficiency.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Imitation wild cultivation method of black fungus in jatropha curcas forest

InactiveCN101953271BEasy to controlSave resourcesHorticultureFertilizer mixturesMonopotassium phosphateInsect pest

The invention relates to an imitation wild cultivation method of black fungus in a jatropha curcas forest, which comprises the steps of bagging of prepared culture materials, sterilization, inoculation, production of fungus sticks, culture and fungus bed outdoor bag cultivation, and the prepared culture materials for producing the fungus sticks comprise the following components by weight percent:30%-75% of jatropha curcas branch powder, 15%-50% of sawdust or cotton seed hull or xylitol residue, 8%-30% of wheat bran or rice bran, 0.05%-1% of monopotassium phosphate, 0.2%-5% gypsum powder and 0.2%-5% of quick lime; and a fungus bed in the outdoor bag cultivation step is arranged in open space of the jatropha curcas forest. The black fungus planted by the method does not occupy farmland andcan save resources and well control the growth of mixed fungi and insect damages, and the black fungus has the advantages of good quality, good taste, high first-grade product rate, high biological efficiency and stable yield.

Owner:SHENZHEN XINHUA NANFANG BIOTECH

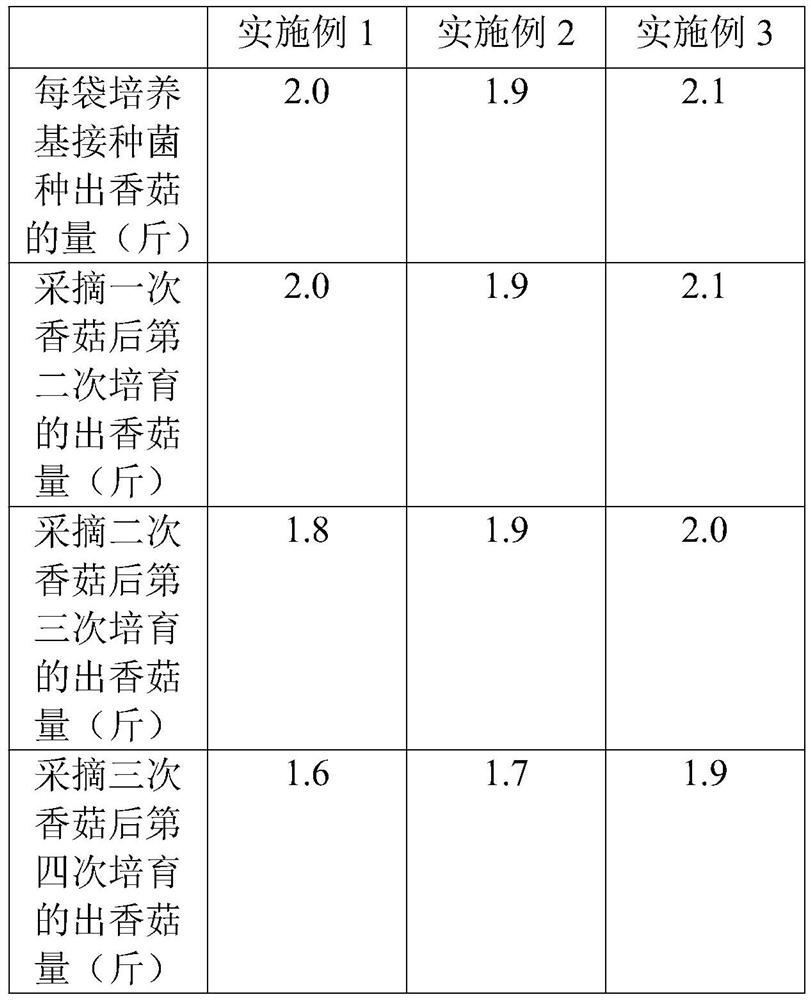

Shiitake mushroom culture medium and preparation method thereof

InactiveCN112673895AConvenient sourceImprove first-class rateCultivating equipmentsMushroom cultivationBiotechnologyEconomic benefits

The invention discloses a shiitake mushroom culture medium and a preparation method thereof. The shiitake mushroom culture medium is prepared from the following raw materials including, by weight, 60-85 parts of sawdust, 10-30 parts of wheat bran, 0.5-2 parts of gypsum and 0.5-2 parts of lime. Compared with the prior art, the raw material source of the shiitake mushroom culture medium is simple, the mushroom culture medium prepared by the raw materials is rich in nutritional ingredient, after the mushroom culture medium is used for preparing mushroom sticks, the fruiting rate is high, the fruiting amount of each bag of culture medium reaches 1.8 jin to 2.1 jin, the first-grade product rate of cultured shiitake mushrooms is high, and the fruiting frequency can reach four times, so that + the shiitake mushroom culture medium is low in cost and remarkable in economic benefit.

Owner:新乡市润辉生物科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com