An intelligent soft measurement method for sizing rate of sizing

A soft measurement and sizing technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem of difficulty in meeting the requirements of fierce competition in product quality and production efficiency, large environmental impact, and large impact on test results, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

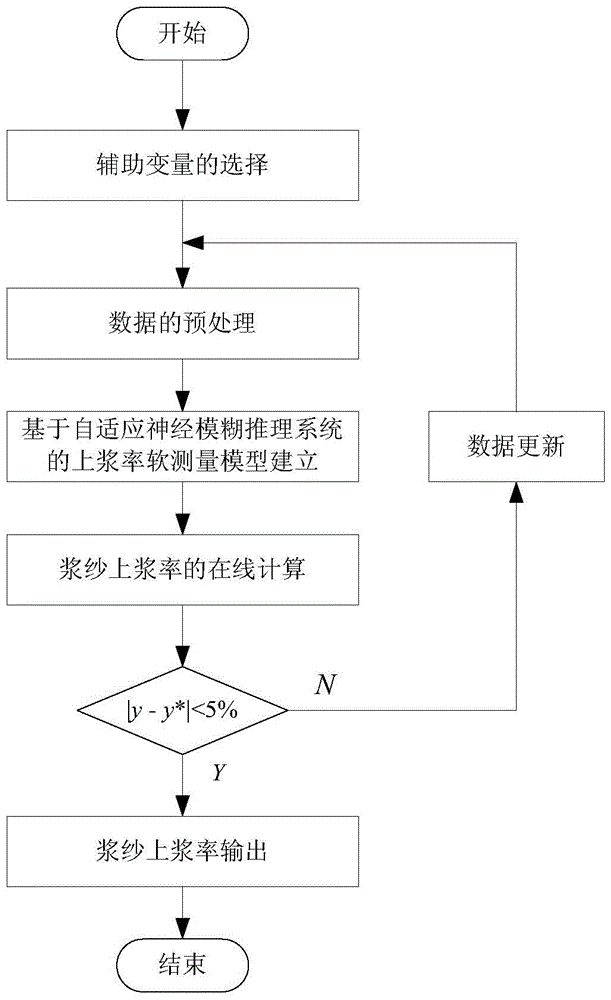

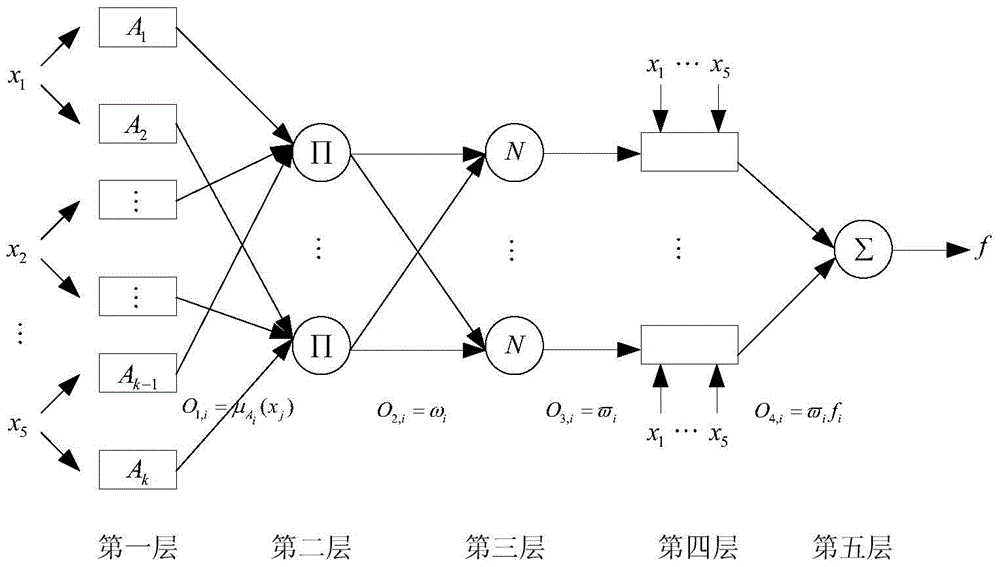

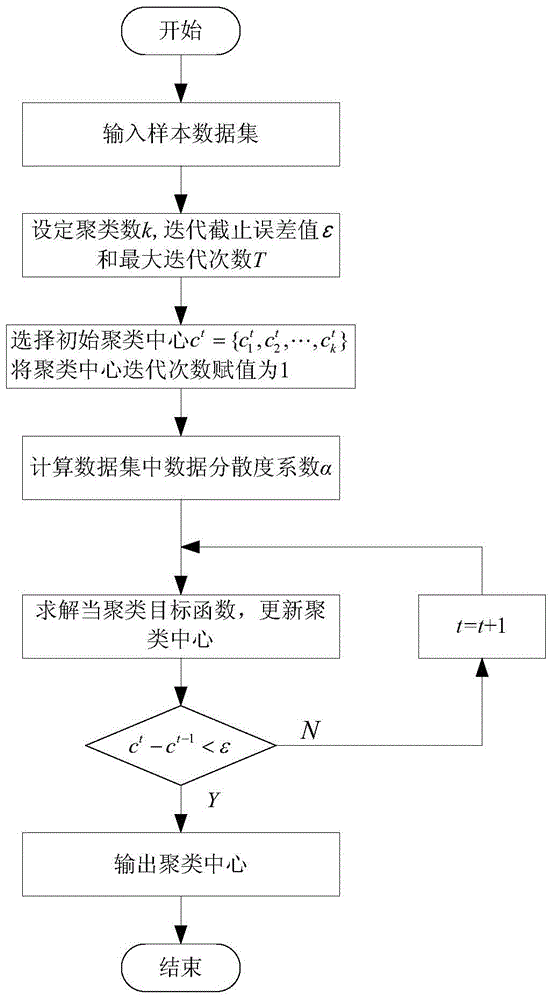

[0071] The soft measurement method for sizing rate of sizing given in this embodiment is applied to the online detection of quality indicators in the textile sizing production process. Sizing machine equipment includes warp creel, sizing tank (mainly composed of drawing roller, guide roller, submerged roller, low pressure sizing roller, submerged roller, high pressure sizing roller), wet splitting, drying room, headstock (mainly composed of tension roller, guide roller, waxing, split rod, telescopic reed, flat yarn roller, length measuring roller, dragging roller, winding tension roller, guide roller, weaving shaft), data acquisition card and computer; sizing The transmission part of the machine adopts frequency conversion control and computer centralized control; the data acquisition card is connected to the density meter and the computer thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com