Method for regulating basicity of sintered ore

An adjustment method and technology of alkalinity, applied in the field of sinter alkalinity adjustment, can solve the problems of low accuracy, fluctuation of sinter alkalinity, unstable composition, etc., to improve the qualification rate and first-class product rate, and stabilize sinter ore. Quality, effect of stabilizing sinter alkalinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

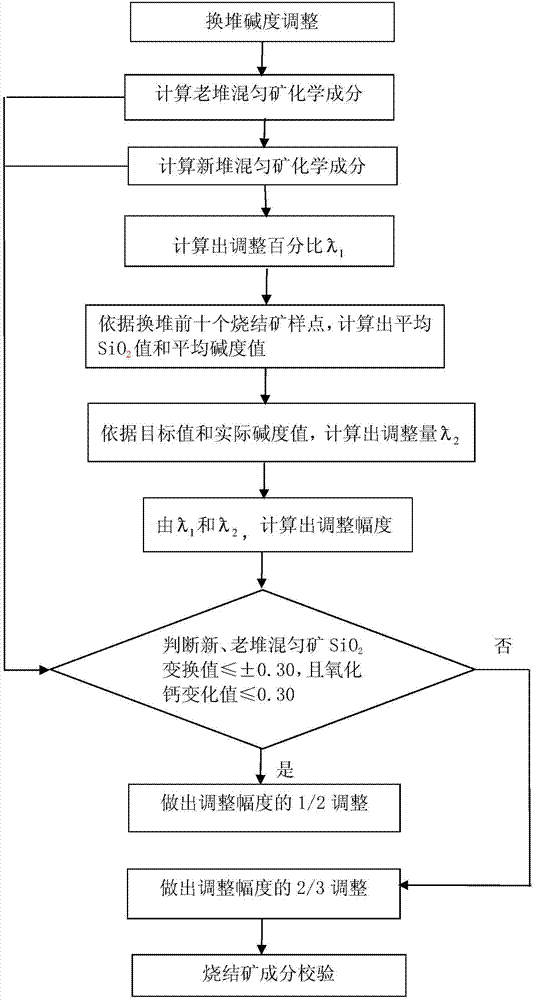

[0062] In order to further understand the content, features and effects of the present invention, the following embodiments are given as examples, and detailed descriptions are as follows with accompanying drawings:

[0063] See figure 1 with figure 2 , The present invention provides a method for adjusting the alkalinity of sintered ore, which includes the following steps:

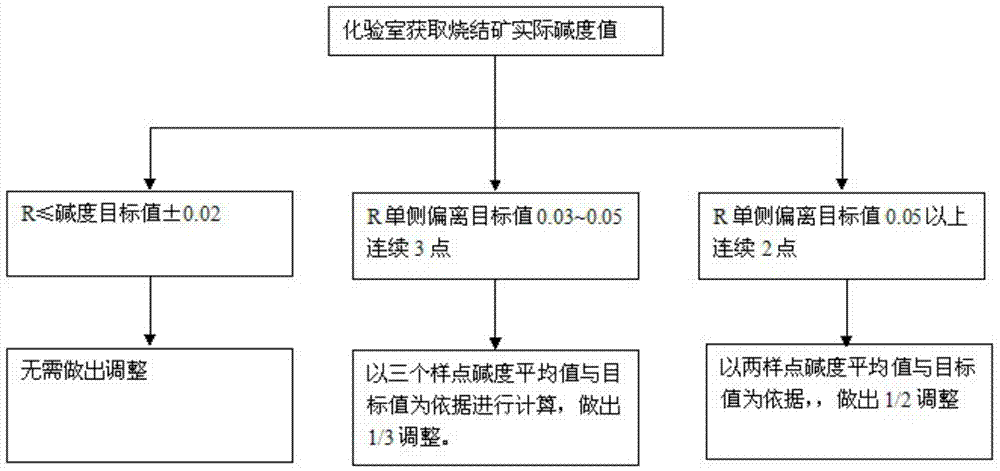

[0064] 1) Daily alkalinity adjustment

[0065] In daily production, the alkalinity of sinter inevitably fluctuates. First find out the reason for the change and judge it to be SiO 2 It is also the change in alkalinity caused by the change of CaO. If it is caused by the change of CaO, adjust it according to the following formula to adjust the limestone for flux.

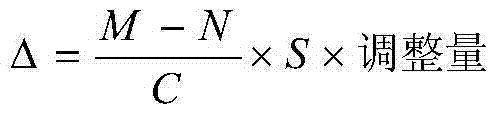

[0066] The adjustment formula is:

[0067]

[0068] Δ—Adjust the percentage of material ratio

[0069] M—Alkalinity target value

[0070] N—average alkalinity value (actual)

[0071] C—Limestone CaO%

[0072] S—average SiO 2 %(actual)

[0073] The adjustment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com