Smashing and calcining device for lead waste

A technology of a calcining device and a pulverizing device is applied in the direction of improving process efficiency, which can solve the problems of resource and time consumption, incomplete calcination, etc., and achieve the effect of less time consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

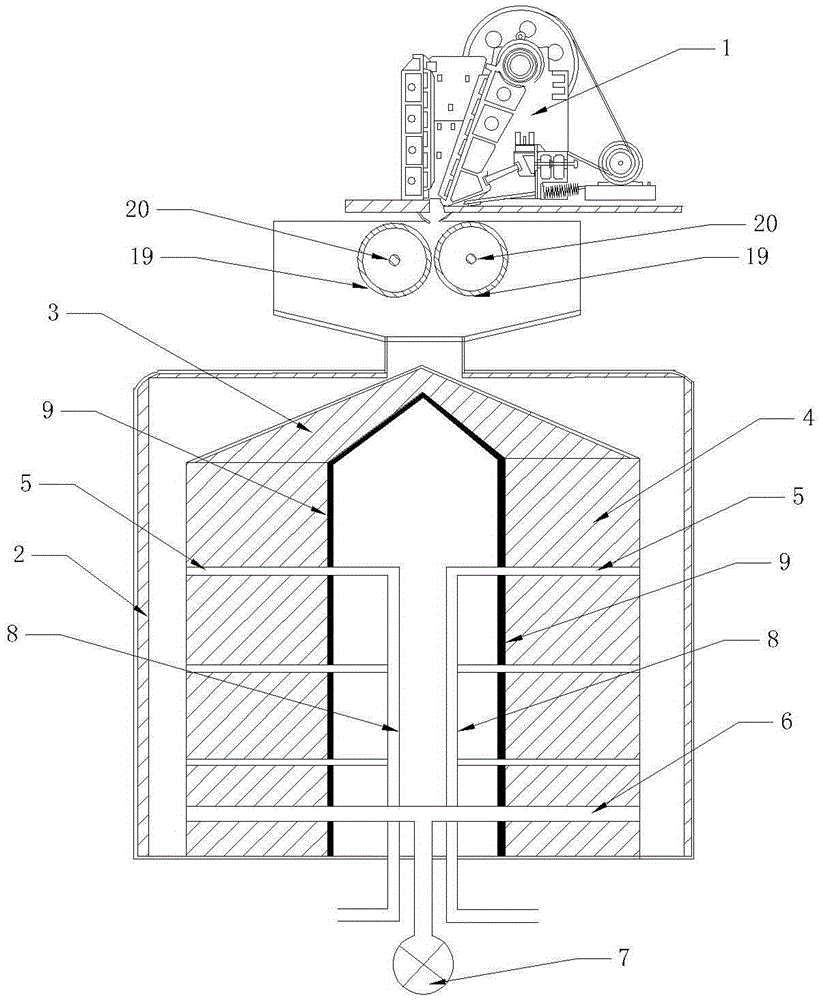

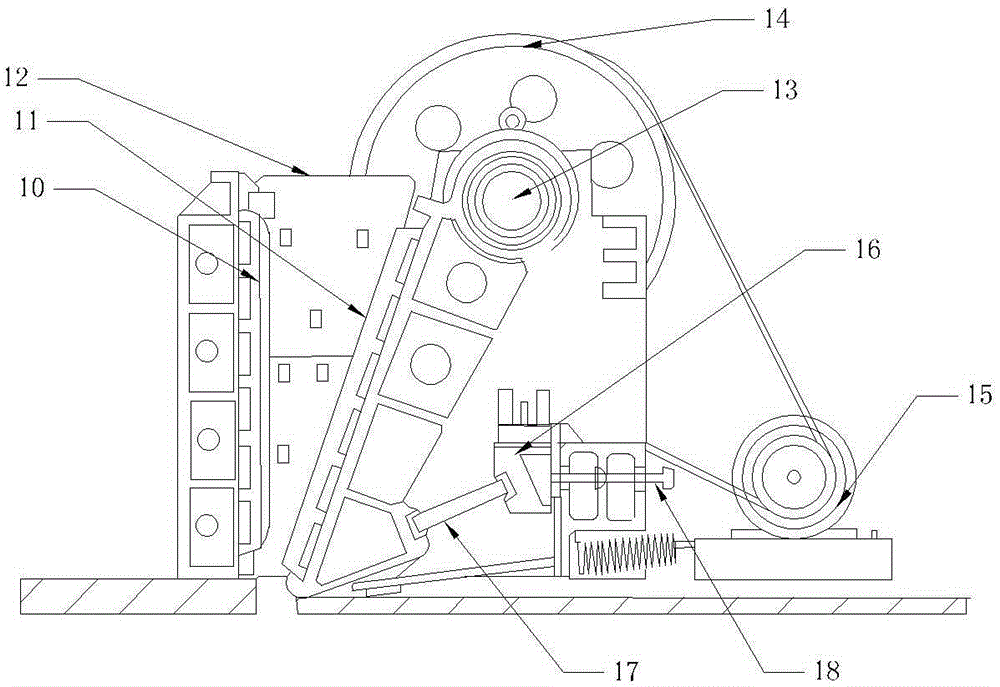

[0023] Such as figure 1 and figure 2 A crushing and calcining device for lead waste shown includes a crushing device 1, a crushing device and a calcining device; the crushing device 1 and the calcining device are respectively located above and below the crushing device; The feed port is docked, and the crushing device and the calcination device are connected by pipelines; the calcination device includes a calcination furnace, a combustion assembly and a material distribution assembly arranged inside the calcination furnace, and a layer of refractory bricks 2 is arranged on the inner wall of the calcination furnace. The door is arranged at the bottom; the distribution assembly 3 is conically arranged on the upper part of the combustion assembly.

[0024] In this embodiment, the combustion assembly includes a refractory wall 4 cast from refractory materials, a gas preset pipeline 5, and an air pipeline 6; one end of the gas preset pipeline 5 and the air pipeline 6 is cast in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com