Preparation method for ultra-pure 3Y yttria-stabilized zirconia

A technology of yttrium-stabilized zirconia and zirconium oxychloride, which is applied in zirconia and nanotechnology, can solve the problems of wide zirconia particle size distribution, application restrictions and limitations, and uneven distribution of crystal forms, so as to achieve sufficient and complete calcination and reaction Rapid, high-purity results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

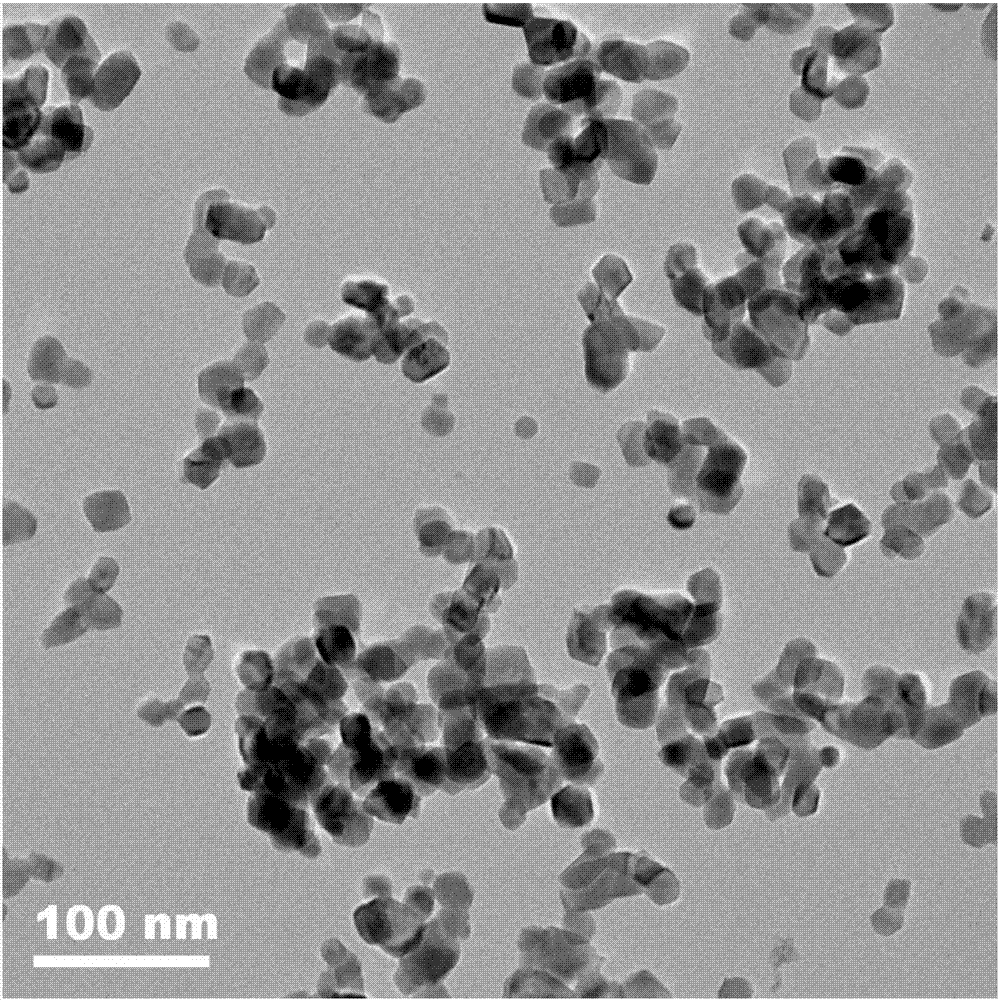

Image

Examples

Embodiment 1

[0024] A preparation method of ultra-high-purity 3Y yttrium-stabilized zirconia, comprising the following preparation steps:

[0025] (1) First add zirconium oxychloride and ultra-high-purity water into the reaction kettle at a mass ratio of 5:2 for dissolution, stir evenly, filter through a filter bag with a filter hole of 0.5um to remove impurities, and then remove impurities through a ceramic membrane. Obtain the zirconium oxychloride filtrate for subsequent use;

[0026] (2) get yttrium nitrate and ultrapure water to dissolve in the ratio of mass ratio 1:10, stir evenly, filter through the filter bag filter hole of 0.5um to remove impurities, and then remove impurities through ceramic membrane to get the yttrium nitrate filtrate for subsequent use;

[0027] (3) preparing mass concentration is 15% ultra-high-purity ammonia water, for subsequent use;

[0028] (4) The zirconium oxychloride filtrate prepared in step (1) and the yttrium nitrate filtrate prepared in step (2) ar...

Embodiment 2

[0035] A preparation method of ultra-high-purity 3Y yttrium-stabilized zirconia, comprising the following preparation steps:

[0036] (1) First add zirconium oxychloride and ultra-high-purity water into the reaction kettle at a mass ratio of 5:2 for dissolution, stir evenly, filter through a filter bag with a filter hole of 0.5um to remove impurities, and then remove impurities through a ceramic membrane. Obtain the zirconium oxychloride filtrate for subsequent use;

[0037] (2) get yttrium nitrate and ultrapure water to dissolve in the ratio of mass ratio 1:10, stir evenly, filter through the filter bag filter hole of 0.5um to remove impurities, and then remove impurities through ceramic membrane to get the yttrium nitrate filtrate for subsequent use;

[0038] (3) preparing mass concentration is 13% ultra-high-purity ammonia water, for subsequent use;

[0039] (4) The zirconium oxychloride filtrate prepared in step (1) and the yttrium nitrate filtrate prepared in step (2) ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com