Mixing type lime kiln with raw material graded treatment function

A graded treatment and lime kiln technology, applied in the field of lime production, can solve the problems of increased fuel consumption, resource waste, and prolonged limestone calcination time, and achieve the effects of reducing resource consumption, improving production efficiency, and reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

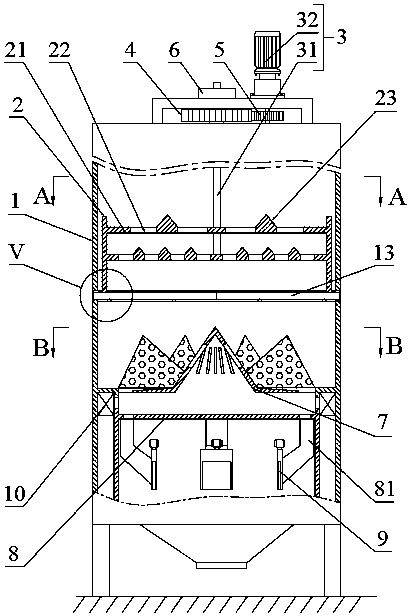

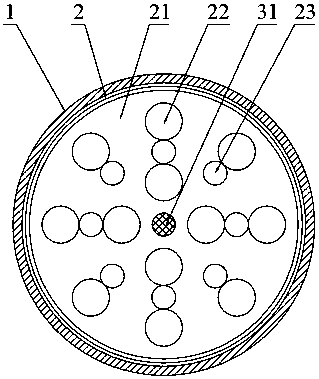

[0032] like Figure 1-4 As shown, the mixing type lime kiln with the function of raw material classification processing includes a kiln body 1, and the kiln body 1 is provided with a distributing mechanism 2, and the distributing mechanism 2 is provided with at least two layers of distributing materials parallel to each other. plate 21, the distribution plate 21 is provided with a number of through holes 22 for the passage of raw materials, along the top to the bottom of the distribution mechanism 2, the through holes 22 on two adjacent distribution plates 21 gradually decrease, the The material distributing mechanism 2 is connected with a driving mechanism 3, and the driving mechanism 3 drives the material distributing mechanism 2 to rotate, so that raw materials are dispersed on different material distributing plates 21 according to different volumes.

[0033]In the mixed-material lime kiln with the function of raw material grading treatment in this embodiment, the multi-lay...

Embodiment 2

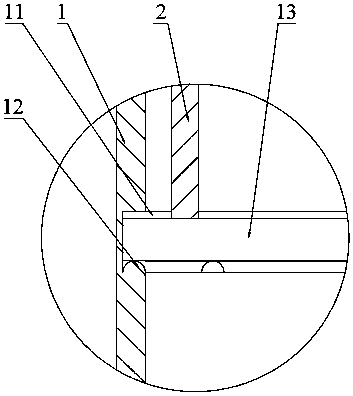

[0041] like Figure 1-4 As shown, the mixing type lime kiln in this embodiment has the function of classifying and processing raw materials. 1. The inner wall is provided with a chute 11, one end of the limit rod 13 is detachably connected to the material distribution mechanism 2, and the other end is slidably arranged in the chute 11.

[0042] The mixing type lime kiln with the function of classifying raw materials in this embodiment adopts the structural form of setting a limit rod 13 at the bottom of the material distribution mechanism 2, so that the material distribution mechanism 2 is connected with the kiln body 1, and the structure is relatively simple and easy. The material distribution mechanism 2 is limited inside the kiln body 1, so that the material distribution mechanism 2 is in stable contact with the inner wall of the kiln body 1 during the rotation process, so as to ensure the smooth progress of the calcination process.

Embodiment 3

[0044] like Figure 1-4 As shown, the structure of the mixing lime kiln with raw material classification processing function of this embodiment is the same as that of Embodiment 2, the difference is that: the bottom of the chute 11 is provided with several bumps 12, and the top surface of the bumps 12 is in the shape of In the shape of an arc, the limiting rod 13 moves along the sliding groove 11 and passes through each of the protrusions 12 in turn.

[0045] In the mixed-material lime kiln with the function of raw material grading treatment in this embodiment, a bump 12 is provided at the bottom of the chute 11 in the kiln body 1, so that when the limit rod 13 passes through the bump 12, the material distribution mechanism 2 moves along the The displacement of the kiln body 1 in the height direction causes the material distribution mechanism 2 to vibrate during the rotation process, which speeds up the grading process of raw materials according to different volumes. The rela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com