Fluidized calcination device and method for treating high-iron low-aluminum coal series kaolinite

A technology of coal-based kaolin and calcination equipment, which is applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., and can solve problems such as non-circulation, small production scale, and long residence time of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

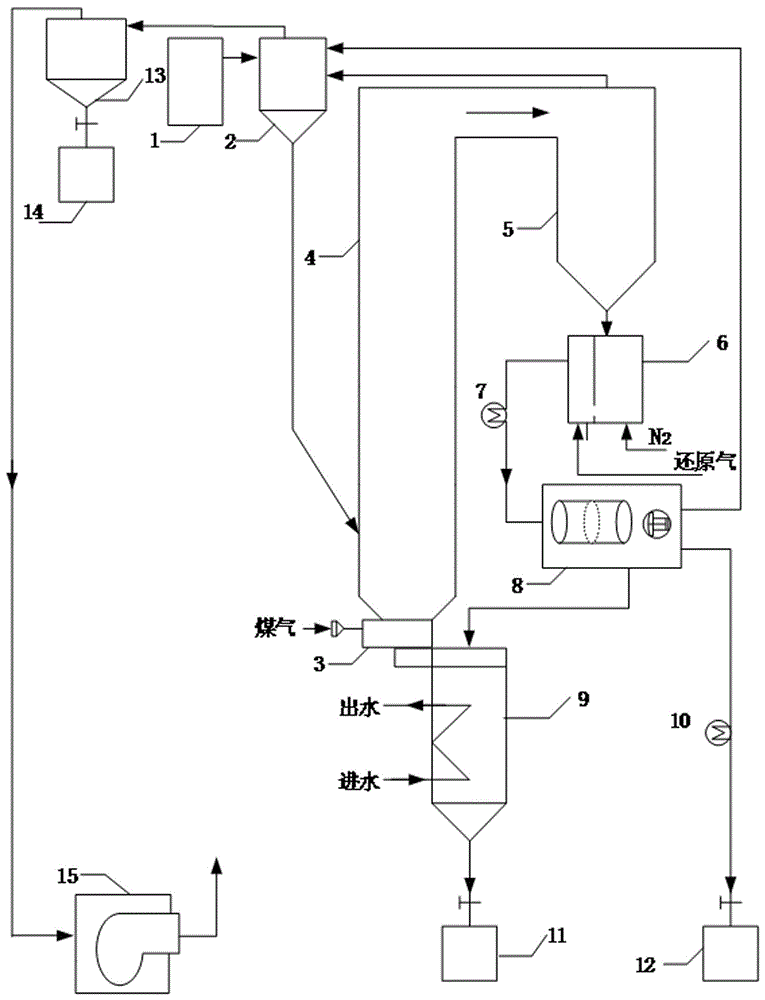

[0048] The structure of the fluidized calcination device for processing high-iron and low-aluminum coal series kaolin is as follows: figure 1 As shown, it includes feeding bin 1, gas burner 3, suspension preheater 4, suspension calciner 5, cyclone separator (two primary cyclone separators and secondary cyclone separator 13), iron removal reducer 6, Electromagnetic iron remover 8, whiteness monitor, material cooler 9 and Rhodes fan 15; the outlet of feeding bin 1 is connected with the feed port of primary cyclone separator 2, and the discharge port of primary cyclone separator 2 is connected with The feed port at the bottom of the suspension preheater 4 is connected, the top of the suspension preheater 4 is connected with the top of the suspension calciner 5 through the upper channel, and the discharge port at the bottom of the suspension calciner 5 is connected to the feed port of the iron removal reducer 6 Connected, the discharge port on the side of the iron removal reducer ...

Embodiment 2

[0073] The structure of the fluidized calcination device for processing high-iron and low-aluminum coal series kaolin is the same as that in Example 1, except that:

[0074] (1) The volume ratio of the suspension preheater to the suspension calciner is 1:0.6;

[0075] (2) The diameter-to-height ratio of the large cylinder is 1:4, and the diameter-to-height ratio of the small cylinder is 1:2;

[0076] (3) The ratio of the height of the connecting port to the height of the small cylinder itself is 1:3; the volume ratio of the large cylinder to the small cylinder is 1:0.4; the volume ratio of the primary cyclone separator to the secondary cyclone separator is 1 :3;

[0077] Method is with embodiment 1, and difference is:

[0078] (1) Control the temperature of the material at 1000°C and in a suspended state;

[0079] (2) Control the material temperature in the suspension calciner at 700°C;

[0080] (3) A reduction reaction occurs between the reducing gas and the calcined mate...

Embodiment 3

[0091] The structure of the fluidized calcination device for processing high-iron and low-aluminum coal series kaolin is the same as that in Example 1, except that:

[0092] (1) The volume ratio of the suspension preheater to the suspension calciner is 1:0.1;

[0093] (2) The diameter-to-height ratio of the large cylinder is 1:3, and the diameter-to-height ratio of the small cylinder is 1:1;

[0094] (3) The ratio of the height of the connecting port to the height of the small cylinder itself is 1:5; the volume ratio of the large cylinder to the small cylinder is 1:0.2; the volume ratio of the primary cyclone separator to the secondary cyclone separator is 1 :5;

[0095] Method is with embodiment 1, and difference is:

[0096] (1) Control the temperature of the material at 1300°C and in a suspended state;

[0097] (2) Control the material temperature in the suspension calciner at 1000°C;

[0098] (3) A reduction reaction occurs between the reducing gas and the calcined mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com