U-shaped internal-combustion rotating limekiln capable of recovering CO2

A rotary kiln and lime kiln technology, applied in the kiln field, can solve the problems of unutilized waste heat, waste of energy and resources, etc., and achieve the effects of novel design, improved product quality and reasonable structure

Inactive Publication Date: 2012-11-21

赵光辉

View PDF1 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The existing flame-insulated rotary lime kiln includes a rotary kiln body and a transmission mechanism. The rotary kiln body is inclined. The limestone falls into the calcination chamber through the high-end feeding port of the rotary kiln body, and is heated by the coal furnace at one end of the kiln body. , the lime is directly discharged from the low-end outlet, and the lime is discharged with heat, and a large amount of carbon dioxide is also discharged into the air. There are defects that the waste heat cannot be used, and energy and resources are wasted.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

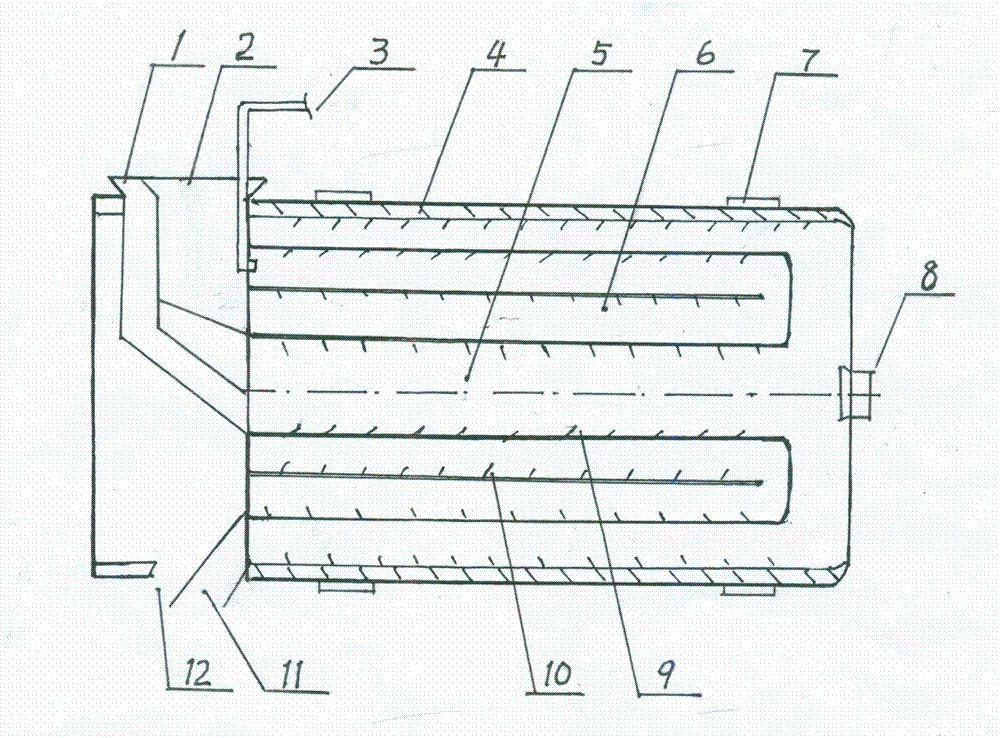

[0010] The invention creates the ability to recycle CO 2 Example 2 of the U-shaped internal combustion rotary lime kiln, see figure 1 , its structure includes: in the structure of embodiment 1, a pulverized coal burner or a gas burner is used to set at the tuyere 8, and the limestone in the calcination chamber 6 is calcined.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention belongs to the field of kiln, and provides a u-shaped internal-combustion rotating limekiln capable of recovering CO2. The limekiln is characterized in that the rotary kiln is horizontal, a u-shaped muffle heating furnace and a u-shaped calcining chamber are adjacently arranged inside the rotary kiln, blades are arranged on the inner wall of the muffle heating furnace and the inner wall of the calcining chamber, and a carbon dioxide collector is arranged through a limestone feeding inlet to communicate with the calcining chamber. Compared with present muffle rotary limekilns, the u-shaped internal-combustion rotating limekiln capable of recovering CO2 has significant advantages of reasonable structure, energy conservation, and emission reduction, and can recover and utilize materials and improve product quality.

Description

technical field [0001] The invention belongs to the technical field of kilns, and relates to a rotary lime kiln with partitions, in particular to a kiln capable of recovering CO 2 U-shaped internal combustion rotary lime kiln. Background technique [0002] The existing flame-trap rotary lime kiln includes a rotary kiln body and a transmission mechanism. The rotary kiln body is inclined. The limestone material falls into the calcination chamber through the high-end feed port of the rotary kiln body, and is heated by the coal furnace at one end of the kiln body. , The lime is directly discharged from the low-end outlet, and the lime is discharged with heat, and a large amount of carbon dioxide is also discharged into the air. There are defects that the waste heat cannot be used, and energy and resources are wasted. Contents of the invention [0003] The inventor has been engaged in the practice of lime firing for many years, and found that the existing flame-trap rotary lim...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B2/10

CPCY02P40/40

Inventor 赵光辉赵政

Owner 赵光辉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com