Water surface garbage collector

A water surface garbage and concentrator technology, which is applied to the cleaning of open water surfaces, water conservancy projects, construction, etc., can solve the problems of manpower consumption and low efficiency, and achieve the effects of saving labor, maintaining cleanliness, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

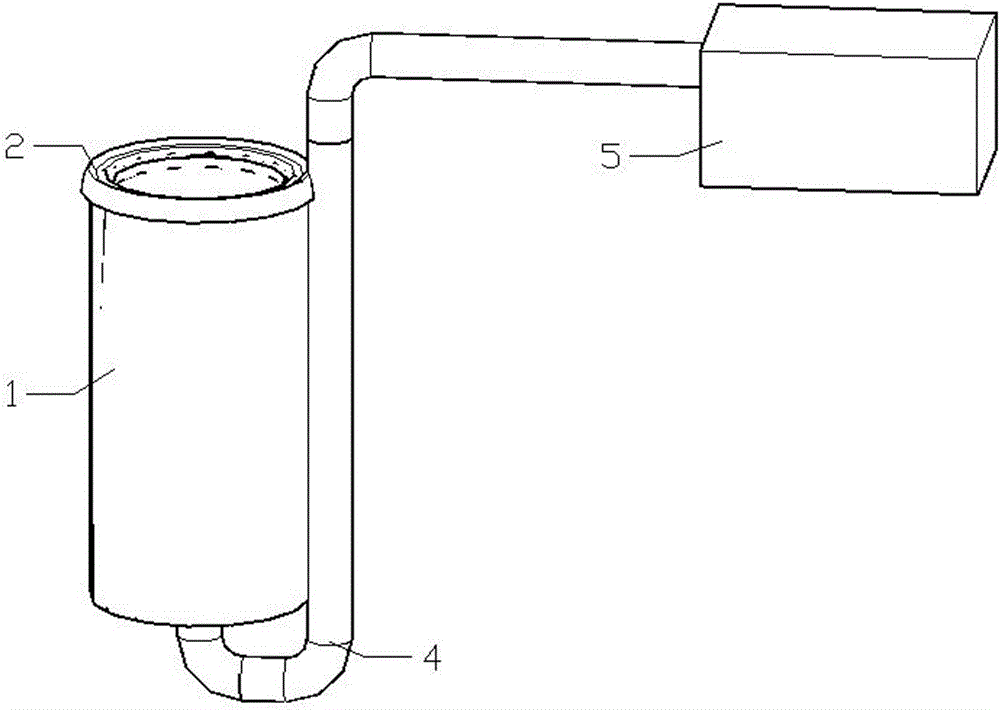

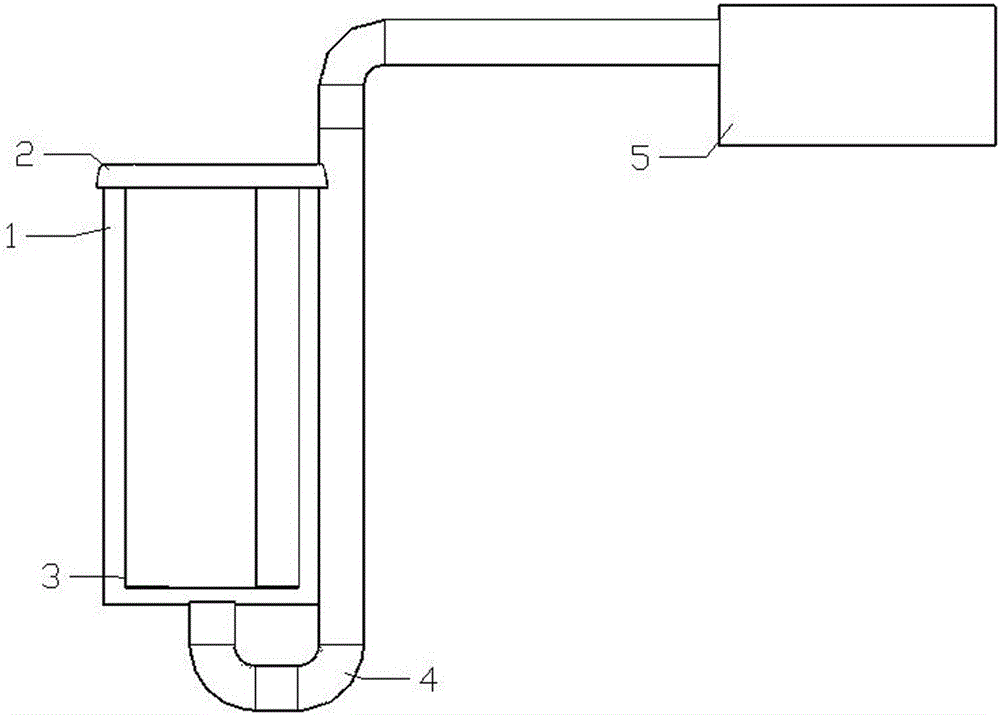

[0017] refer to figure 1 , figure 2 The present invention comprises a rubbish collection barrel 1, a barrel cover 2, a filter screen 3, a water suction pipe 4, and a water suction engine 5, wherein the barrel cover 2 is installed on the top of the garbage collection barrel 1, and the garbage collection barrel 1 is fixed on the side of the ship or on the shore. Make the mouth of the barrel 1cm below the water surface. The filter screen 3 is installed in the lower end of the bucket cover 2, filters out the water entering the garbage collection bucket 1, and keeps the garbage in the garbage collection bucket 1. The bottom end of the rubbish collection bucket 1 is provided with a water suction pipe 4, and the water suction pipe 4 is connected with a water pump 5.

[0018] When the water surface garbage concentrator works, the water pump 5 starts to suck out the water in the garbage collection bucket 1, so that the garbage collection bucket 1 generates attraction to the nearby w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com