Self-discharging type stamping and forming all-in-one machine

A technology of stamping forming and integrated machine, which is applied in the direction of metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of stamping accidents and low work efficiency, and achieve the effects of avoiding stamping accidents, saving time, and being easy to take

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

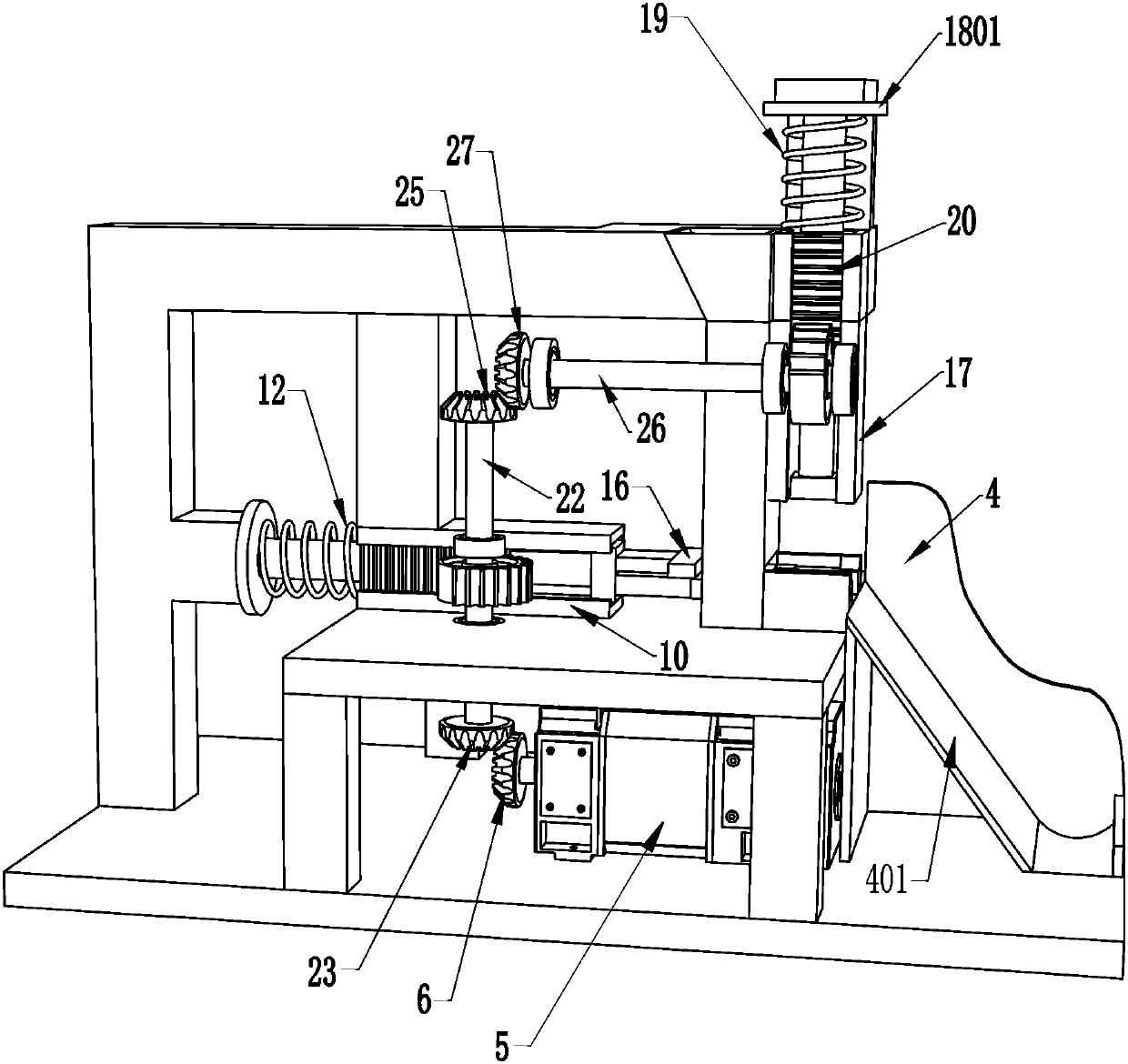

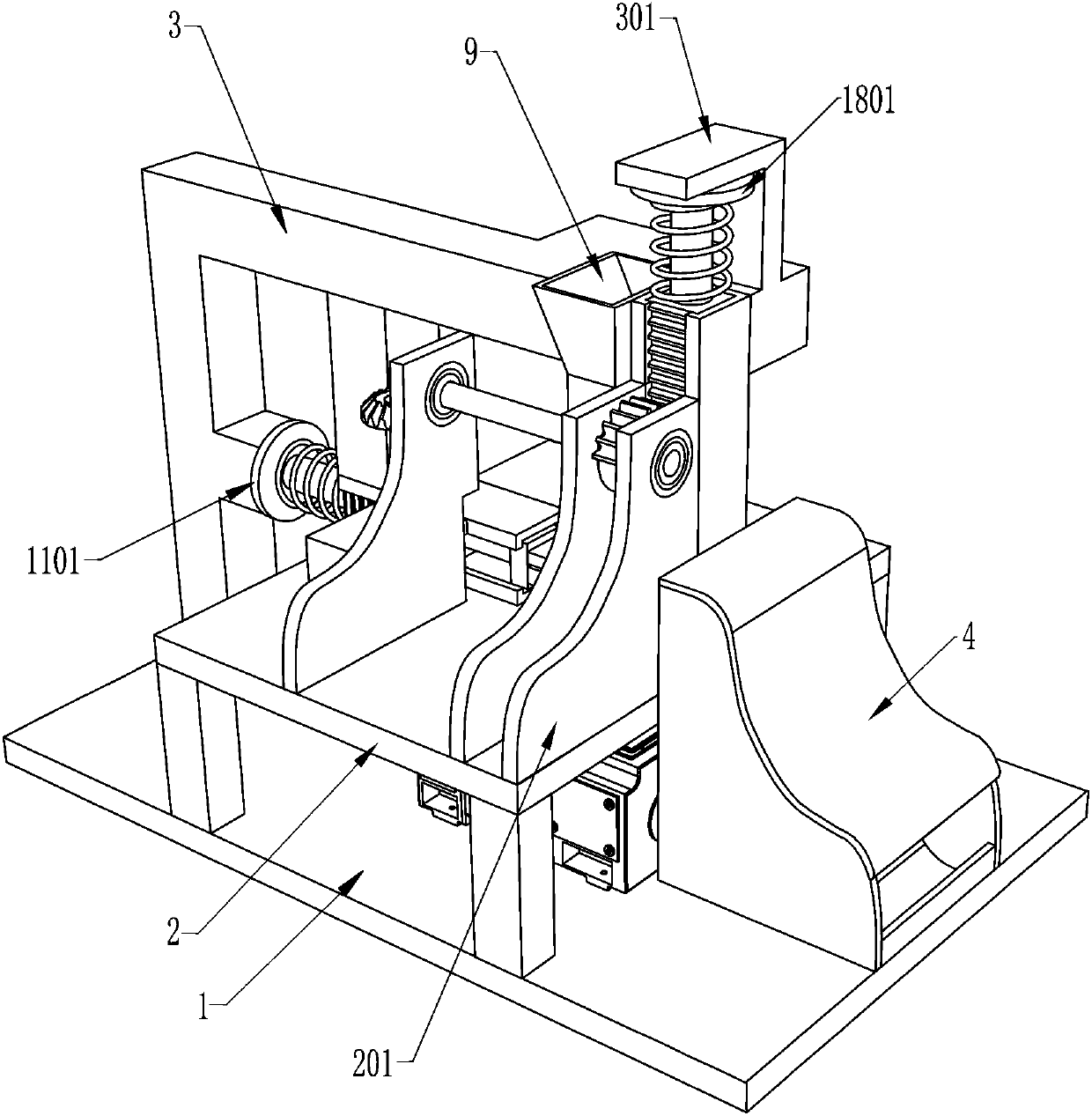

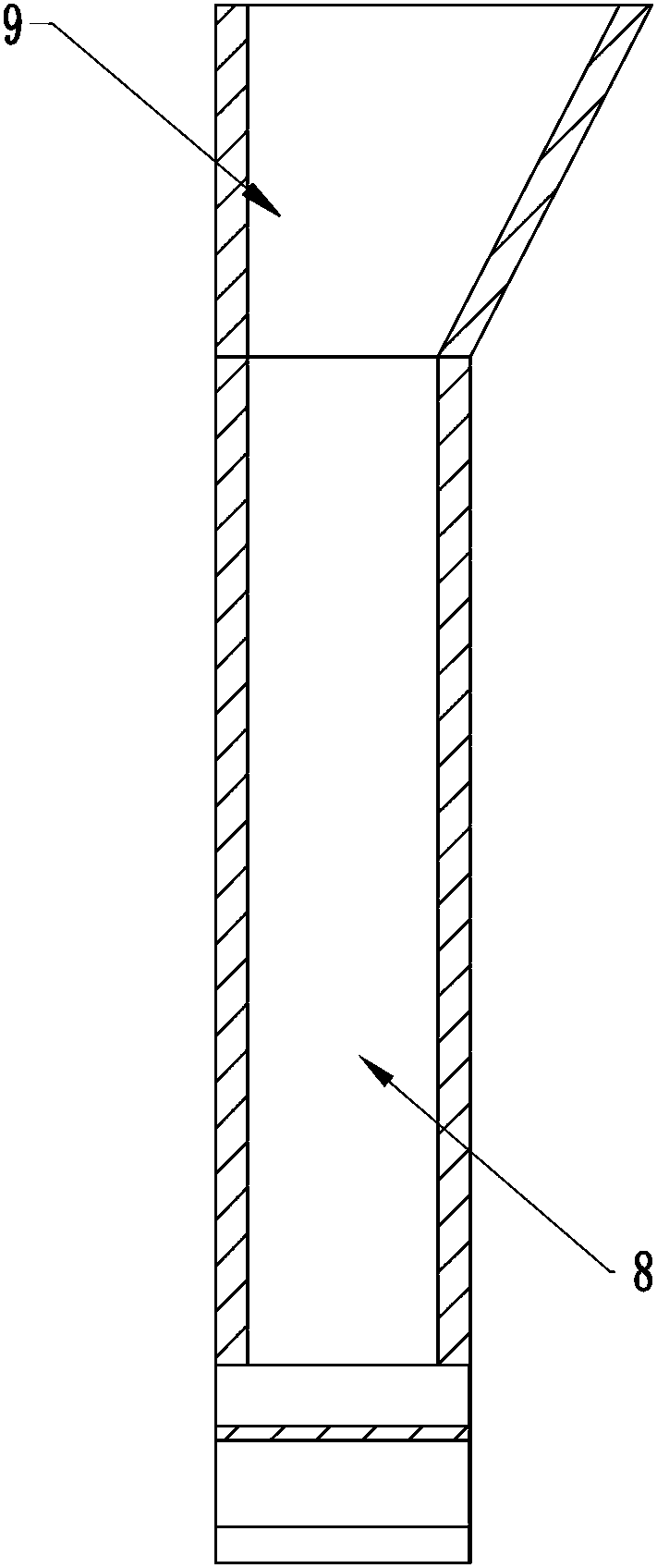

[0020] A self-unloading stamping and forming machine, such as Figure 1-4 As shown, it includes a chassis 1, a frame 2, a curved plate 201, a support column 3, an L-shaped block 301, a motor 5, a stamping frame 7, a discharge frame 8, a storage frame 9, a pushing mechanism and a bending mechanism , the chassis 1 is fixed with a frame 2, a support column 3 and a motor 5, the frame 2 is located on the right side of the support column 3, the motor 5 is located below the frame 2, and three arc-shaped plates 201 are fixedly connected to the top of the frame 2. Frame 2 left middle is fixedly provided with stamping frame 7, is provided with discharge frame 8 on the punch frame 7, and discharge frame 8 is connected with frame 2, and discharge frame 8 top is provided with material storage frame 9, and material storage frame 9 and The support column 3 is connected, and the frame 2 is provided with a pushing mechanism, which is used for unloading. The shape block 301 is provided with a ...

Embodiment approach 2

[0027] On the basis of Embodiment 1, if Figure 1-2 As shown, it also includes a box body 4 and a sloping plate 401 , the box body 4 is arranged on the right side of the top of the chassis 1 , the box body 4 is located on the right side of the frame 2 , and the box body 4 is provided with a sloping plate 401 .

[0028] The box body 4 can collect stamped workpieces, and people don't need to collect them all the time. The inclined plate 401 can effectively allow the workpieces to slide into the receiving box, which is convenient for taking.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com