Juice extraction structure and juice extraction machine adopting same

A technology for juicing and fixing structure, which is applied in the field of juicing structure and its juicer, can solve the problems of affecting the normal juicing of food, blocking the outlet of juice, destroying the nutrients of juice, etc., and achieves high processing efficiency and high juice yield. The effect of reducing vibration and noise, and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in combination with specific embodiments.

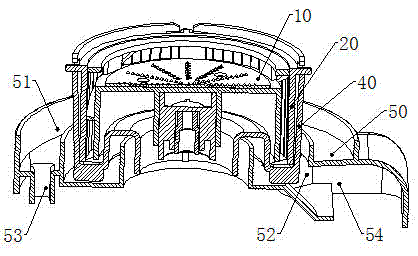

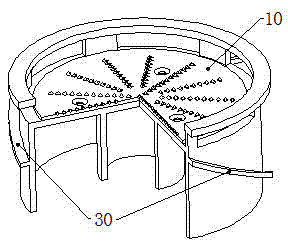

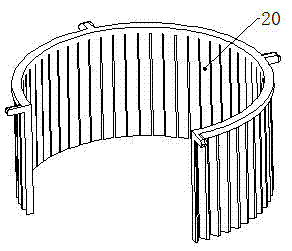

[0023] like Figure 1 to Figure 4 Shown is the embodiment of the juicing structure of the present invention and the juice extractor thereof, the juicing structure includes a cutter head frame 10 and a slag separation frame 20 sleeved on the outside of the cutter head frame 10, the cutter head frame 10 and the slag separation frame 20 There is a slag discharge structure 30 that moves relatively to the slag separation frame 20. The speed difference between the slag discharge structure 30 and the slag separation frame 20 is 5-45rpm. There is a gap d between them, 0<d≤1.5mm.

[0024] Wherein, the slag discharge structure 30 is at the same speed as the cutter head frame 10, while the cutter head frame 10 rotates, the slag discharge structure 30 rotates at the same speed and scrapes and discharges the pomace attached to the slag separation frame 20; and the slag discharge struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com