Novel efficient board single-side putty applying machine

A putty-scraping, high-efficiency technology, applied to the device and coating of the surface coating liquid, can solve the problems of high labor intensity, high cost of board making, time-consuming and labor-intensive quality, etc., and achieve stable and reliable operation, convenient operation, adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

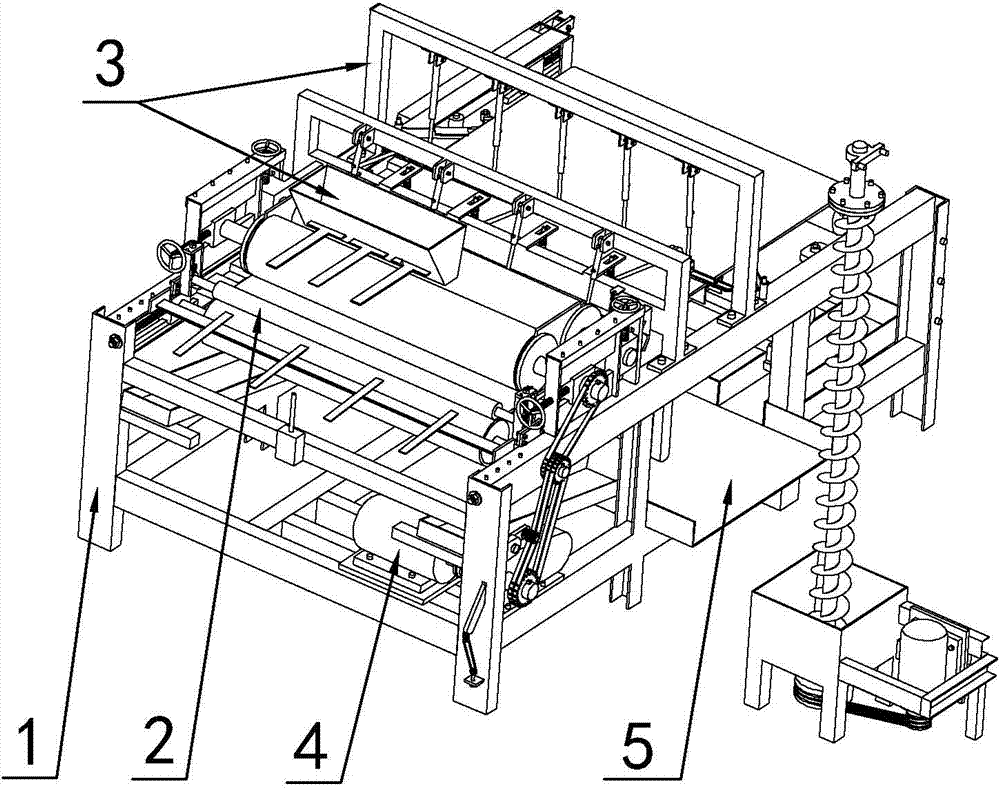

[0040] For the convenience of those skilled in the art to understand, the following in conjunction with the attached Figure 1-12 , to further specifically describe the technical solution of the present invention.

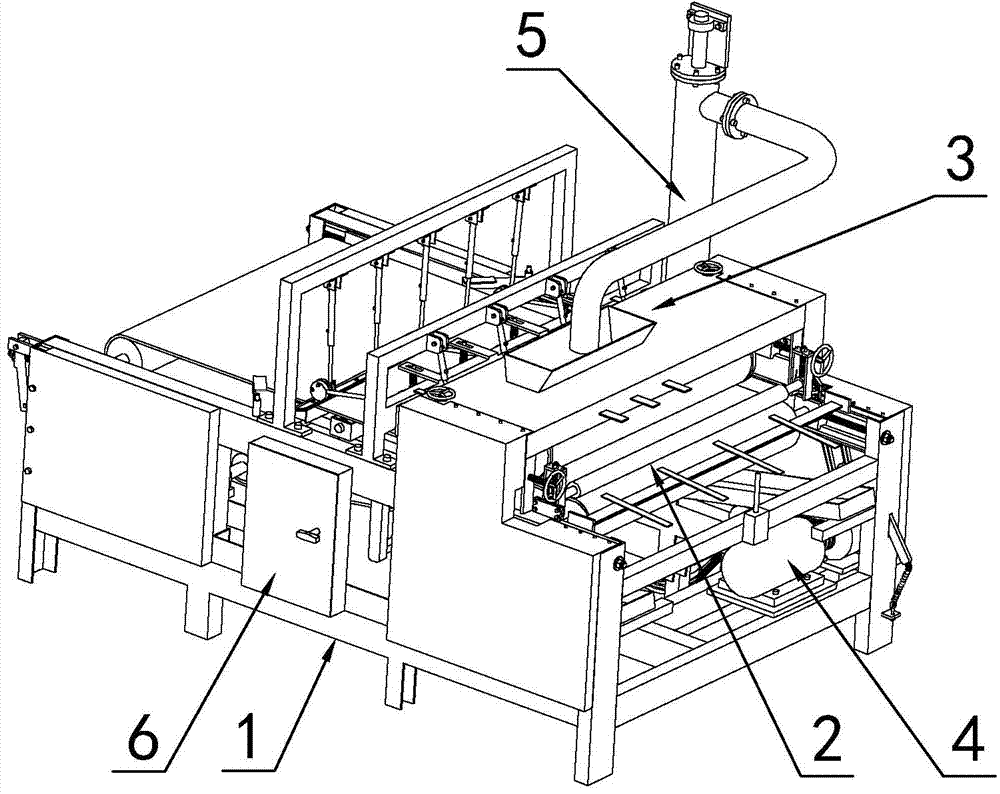

[0041] A new high-efficiency single-sided puttying machine for plates, including a frame 1, a transmission mechanism 2, a scraping mechanism 3, and a power mechanism 4. The frame 1 includes channel steel, angle steel, steel plate, and square steel. The frame 1 adopts welding It is fixedly connected by means of bolt connection, and the frame 1 is used for bearing and fixedly connecting the transmission mechanism 2, the scraping mechanism 3, and the power mechanism 4.

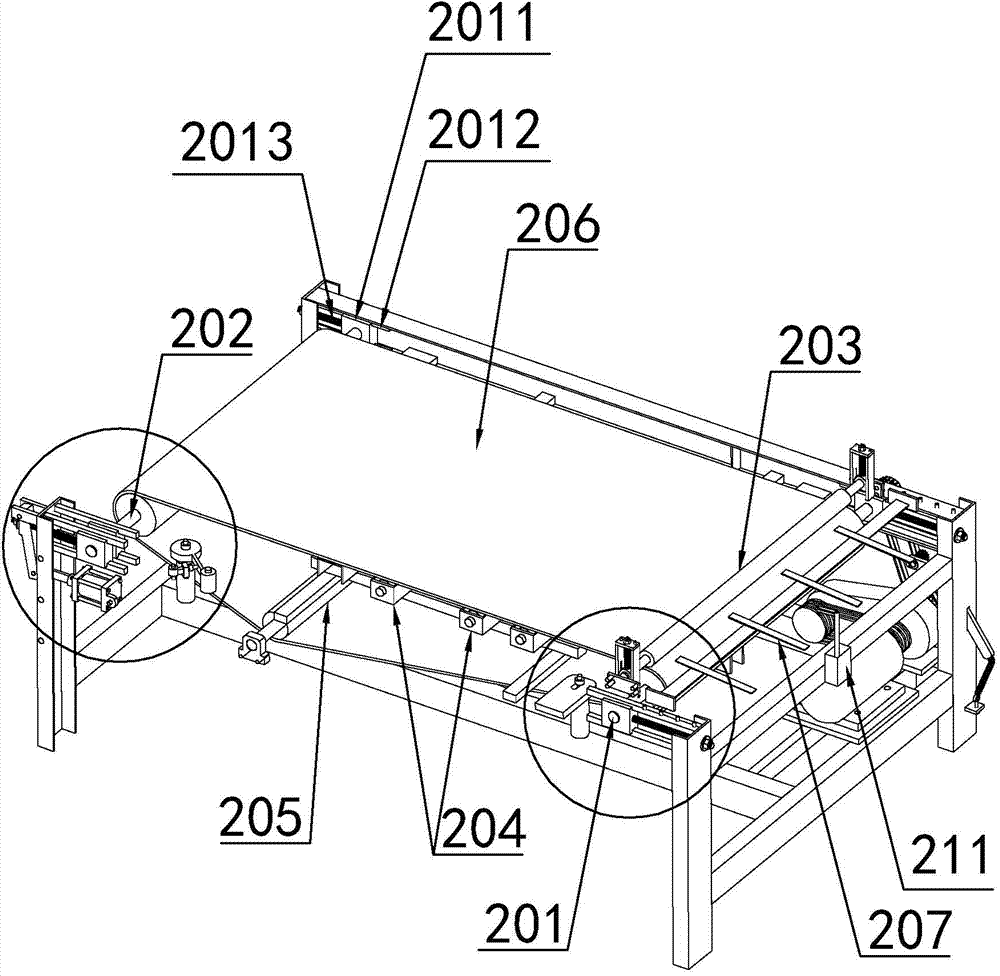

[0042] Described transmission mechanism 2 comprises driving roller 201, driven roller 202, pinch roller 203, idler roller 204, tension roller 205, conveyor belt 206, and described driving roller 201, driven roller 202, tension roller 205 tops are provided with There is a conveyor belt 206, the drivin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com