A High-frequency Transformer Automatic Gluing Mechanism

A high-frequency transformer and encapsulation technology, applied in the manufacture of inductors/transformers/magnets, electrical components, metal processing, etc., can solve the problems of low production efficiency, unguaranteed production quality, low efficiency, etc., and reduce the labor of workers. Strength, improving production efficiency, and the effect of automated encapsulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Now, the present invention will be further described in detail in conjunction with the accompanying drawings and preferred embodiments.

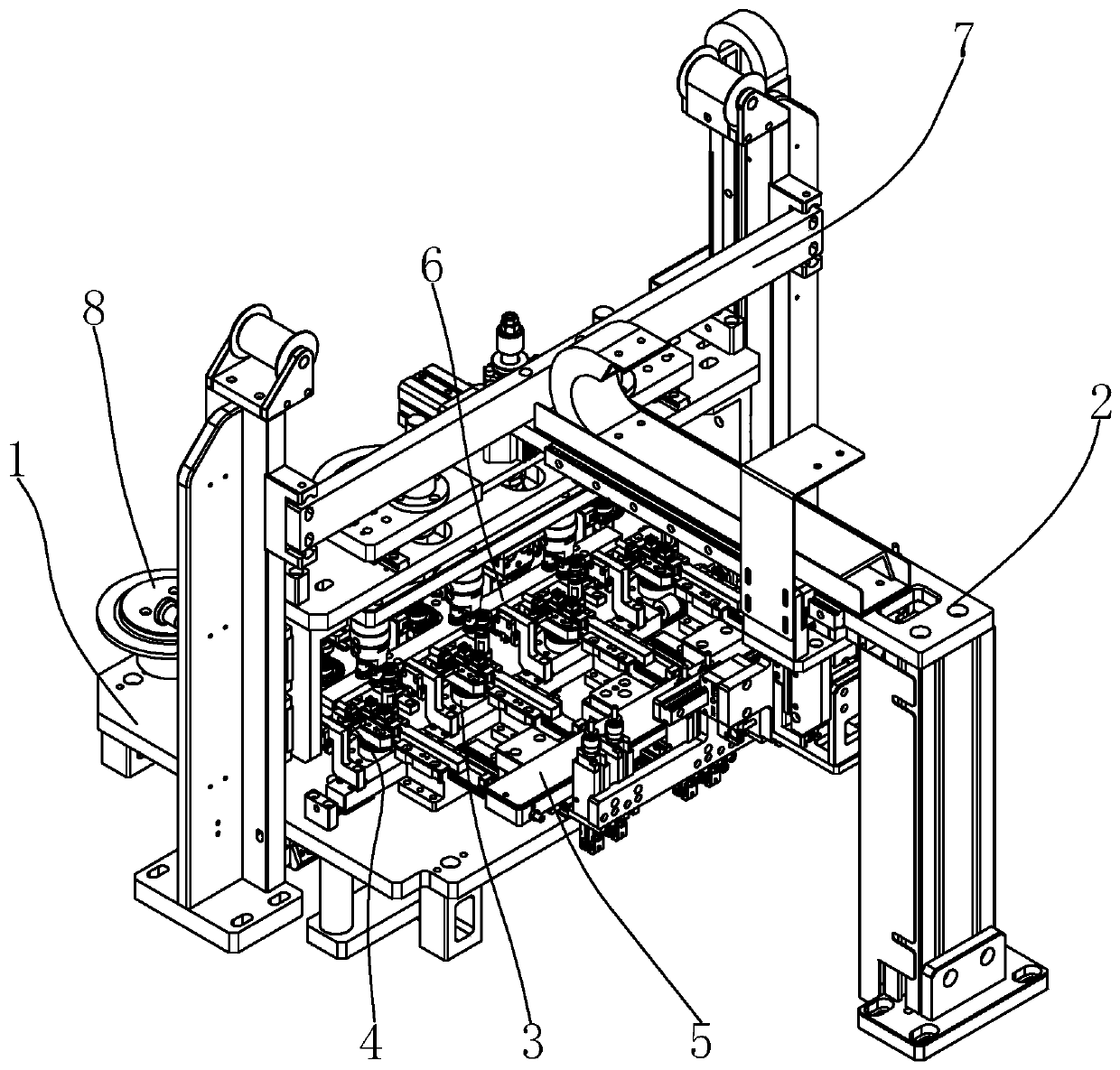

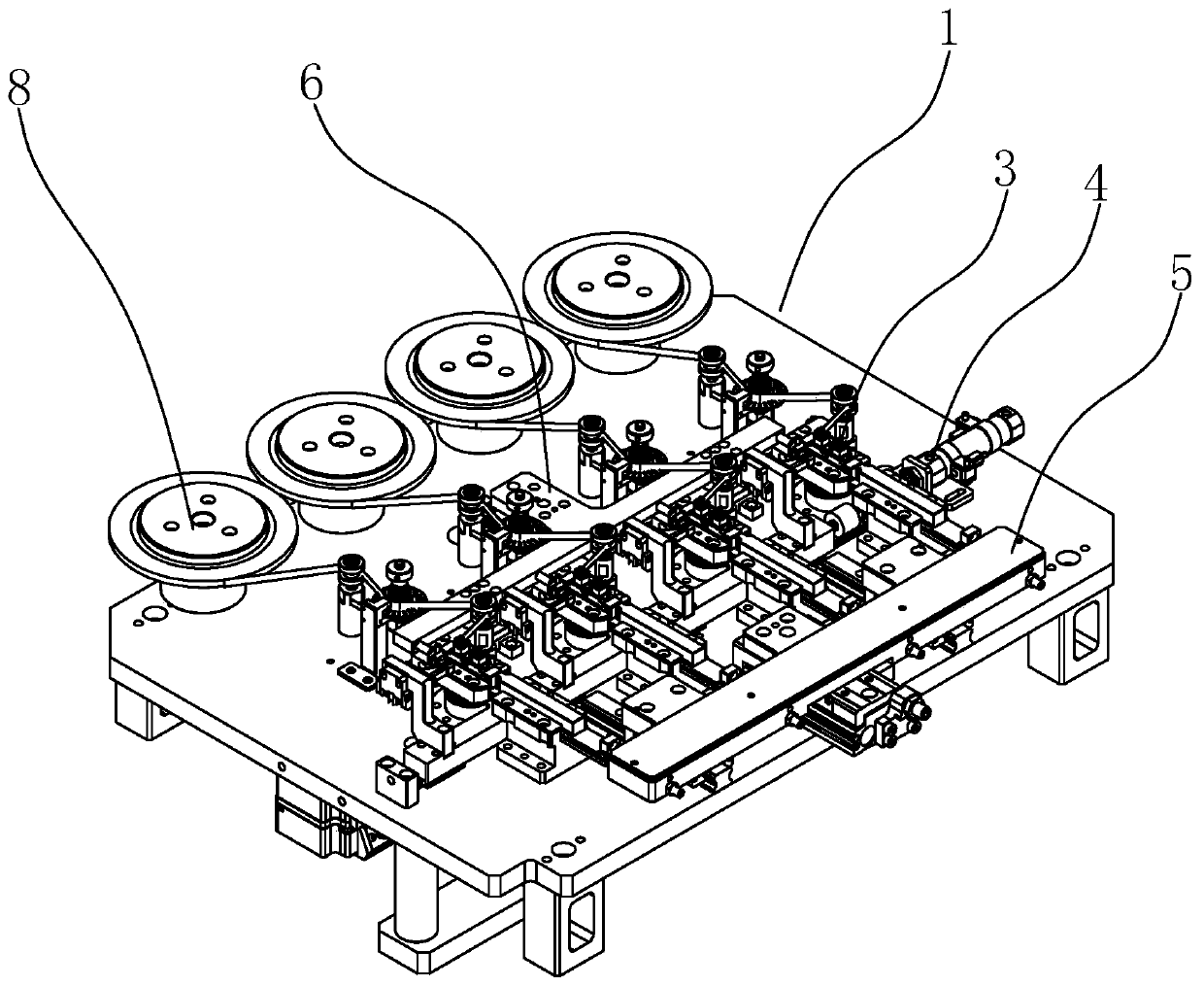

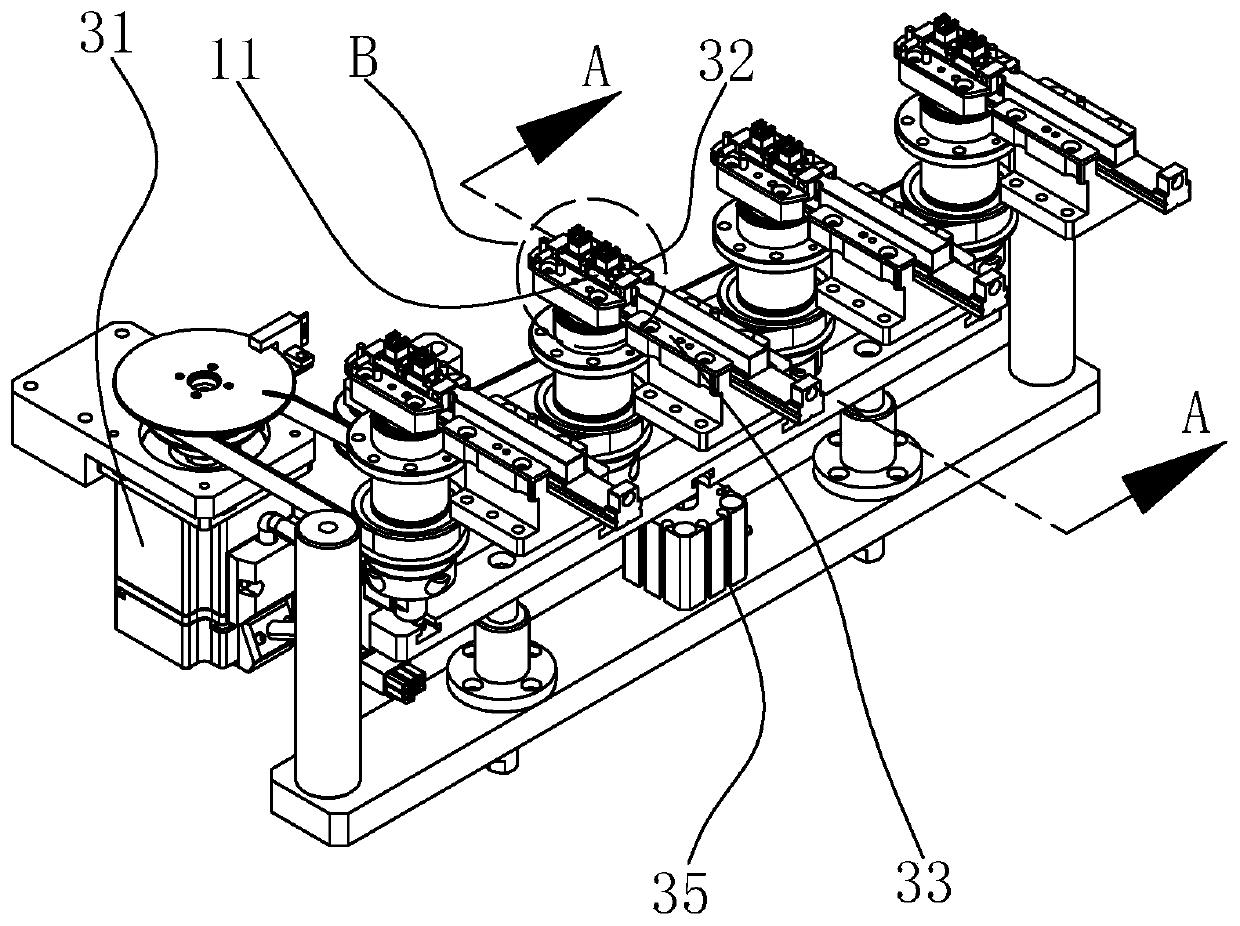

[0036] Please also refer to figure 1 and Figure 4 A high-frequency transformer automatic encapsulation mechanism, including a panel 1, a rotating assembly 3 fixed on the panel 1, a cutter assembly 4, a pull rod assembly 5 arranged at the front end of the rotating assembly 3, and a The ejector rod assembly 6 and the tape conveying assembly 8 also include a pressing assembly 7 arranged on the upper end of the rotating assembly 3 and a retrieving assembly 2 for picking and placing products, and the rotating assembly 3 is provided with two stations for placing products Block 11 is divided into station block one 11-1 and station block two 11-2. The rotating assembly 3 includes a rotating base 32, a first power member 31 that drives the rotating base 32 to rotate, and a sliding base 33 installed on the panel 1 in parallel with the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com