An amphibious unmanned ship refueling system and refueling method with adjustable fuel delivery rate

A refueling system and unmanned ship technology, which is applied in transportation and packaging, liquid distribution, conveying or transfer devices, packaging, etc., can solve problems such as complicated operation, dangerous refueling operation, and insertion into the fuel tank port, so as to improve the degree of automation and save energy. Labor costs, the effect of avoiding fuel spills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

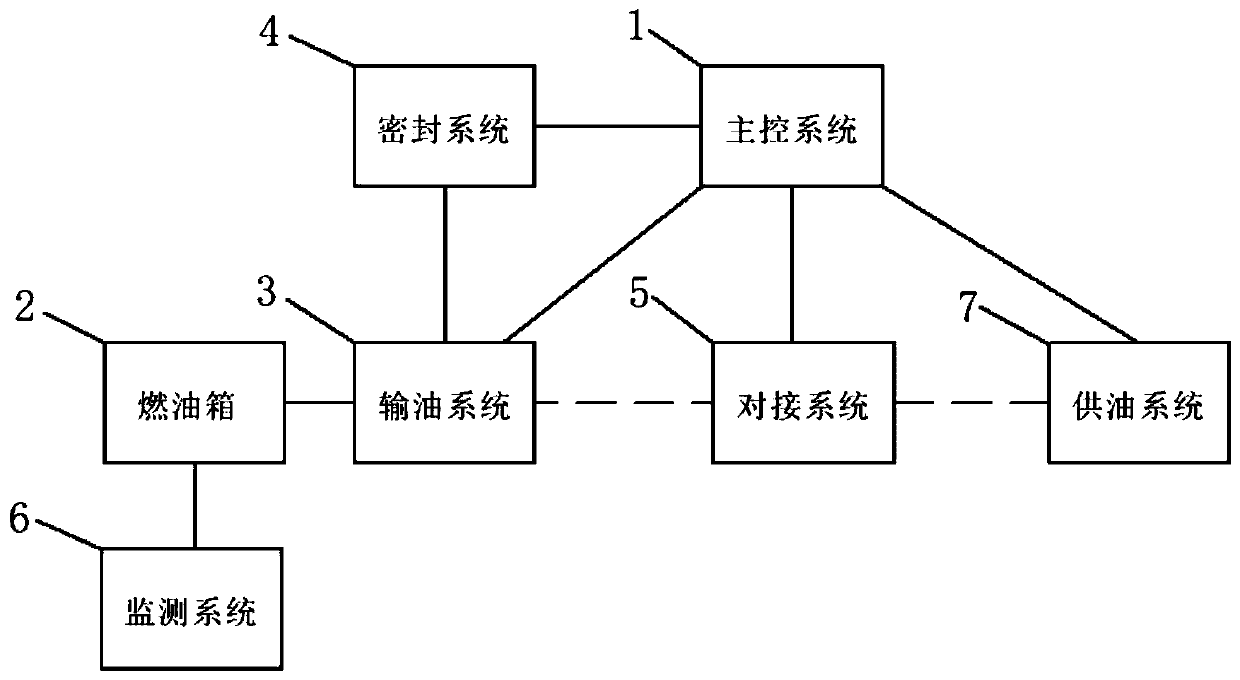

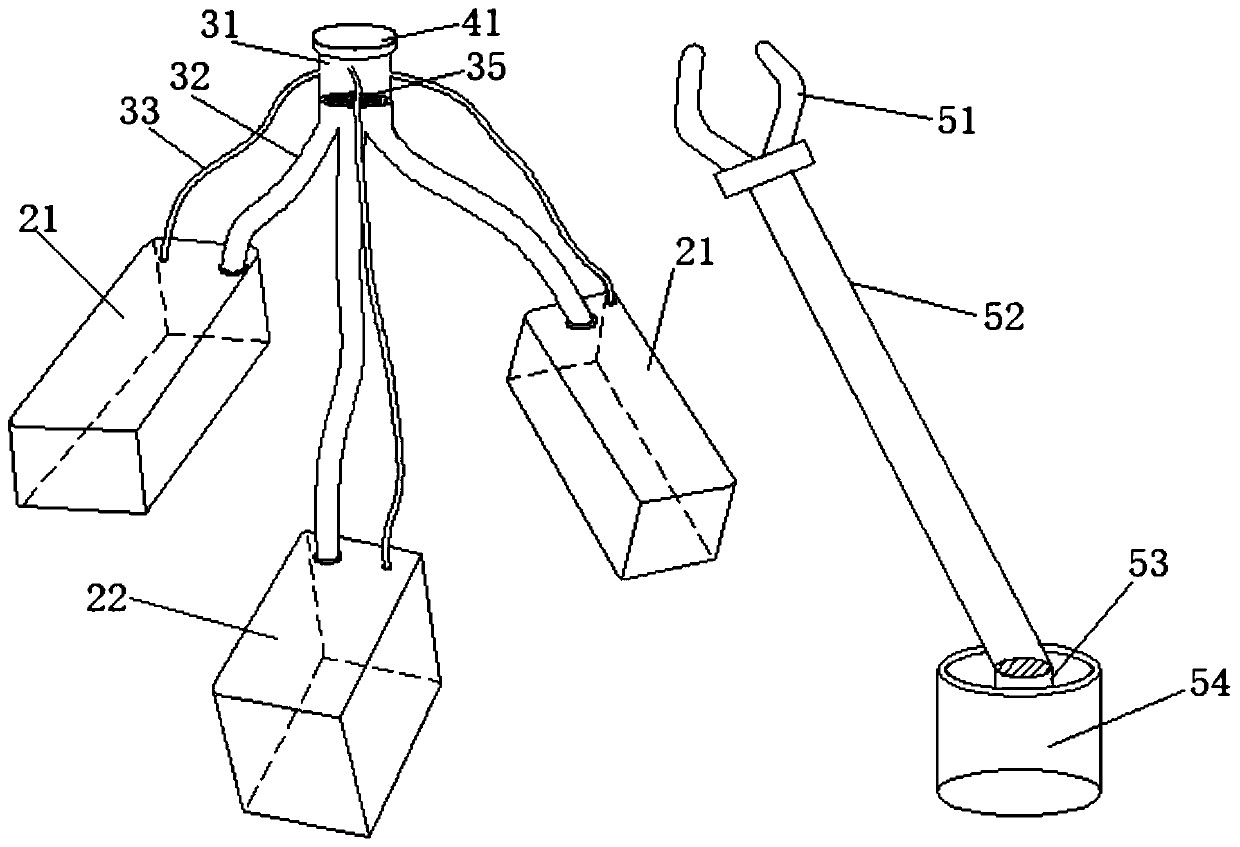

[0040] Embodiment 1 of the present invention provides an amphibious unmanned ship refueling system with adjustable oil delivery rate, such as figure 1 and figure 2 As shown, it includes a main control system 1, a fuel tank 2, a fuel delivery system 3, a sealing system 4, a docking system 5, a monitoring system 6 and a fuel supply system 7, wherein the fuel tank 2 is provided with at least two, and is connected with the delivery system The oil system 3 is connected, and the oil delivery system 3 includes a main filling port 31;

[0041] The sealing system 4 includes a sealing cover 41, the sealing cover 41 is used to seal the main oil filling port 31, and the main control system 1 controls the opening and closing of the sealing cover 41;

[0042]The main control system 1 inserts the refueling gun into the main refueling port 31 to realize refueling by controlling the docking system 5, and the monitoring system 6 monitors the oil quantity of the fuel tank 2 in real time and fe...

Embodiment 2

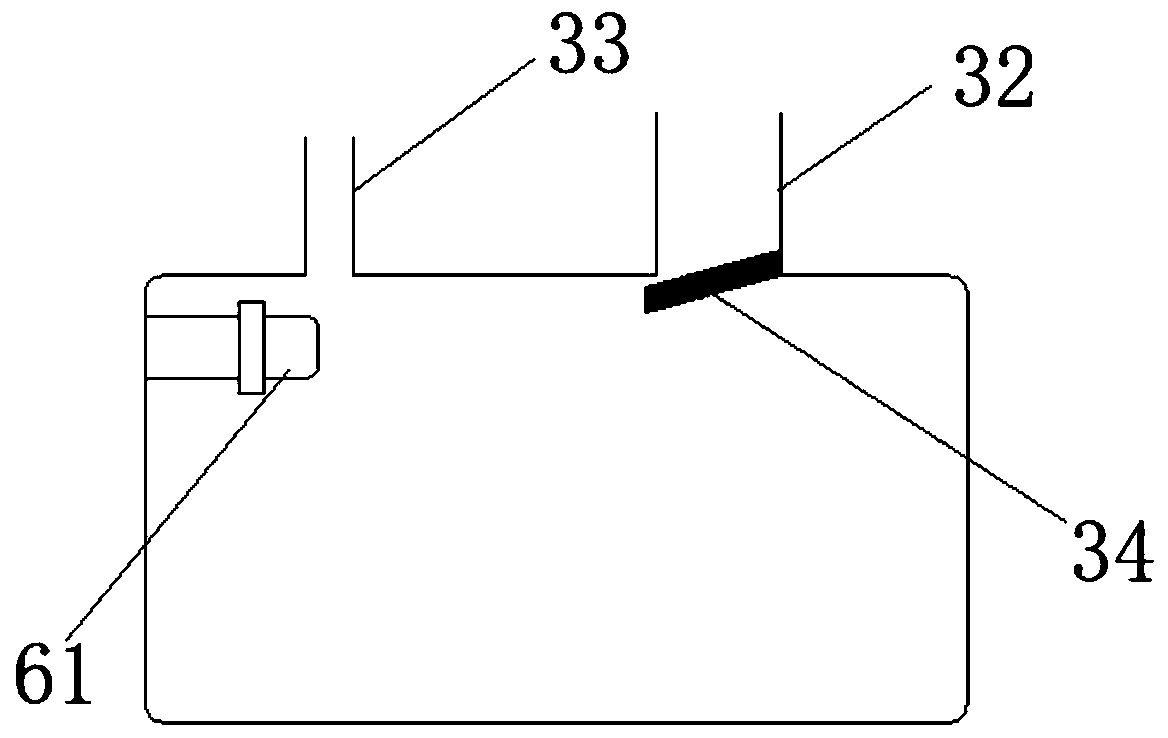

[0059] On the basis of the refueling system described in embodiment 1, this embodiment 2 also provides a method of using the refueling system to refuel an amphibious unmanned ship on land, such as Figure 6 As shown, it includes the following steps: under the control of the main control system 1, the sealing cover 41 is opened, and the docking system 5 inserts the refueling gun into the main refueling port 31; under the control of the main control system 1, the fuel tank 2 that needs to be refueled The electronically controlled baffle piece 34 is opened, and according to the number of opened electronically controlled baffle pieces 34 at this time, the fuel supply system 7 provides a corresponding fuel delivery rate and starts refueling; The amount is fed back to the main control system 1 to determine whether the refueling is completed; after the refueling is completed, under the control of the main control system 1, the docking system 5 takes out the refueling gun and restores ...

Embodiment 3

[0072] On the basis of the refueling system described in embodiment 1, this embodiment 3 also provides a method for refueling an amphibious unmanned ship when using the refueling system to navigate in waters, which is the same as the land refueling method described in embodiment 2 The main difference is: when refueling in waters, the hull is in a sailing state, and the fuel supply system 7 is set on the refueling ship, and the unmanned ship and the refueling ship need to remain relatively stationary to realize dynamic refueling.

[0073] Such as Figure 7 As shown, a refueling method provided by the embodiment of the present invention includes the following steps: the refueling ship is close to the amphibious unmanned ship, and the speed is adjusted to make the two relatively stationary; the stabilizing platform 54 is started, and the base 53 of the docking system 5 is stabilized; Under the control of the main control system 1, the sealing cover 41 is opened, and the docking s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com