Coiled material automatic-changing system and waterproof coiled material hot-melting and laying locomotive

A technology of waterproof coiled materials and coiled materials, which is applied to tools used in roofing engineering, roofing, construction, etc. It can solve the problems of increasing labor costs, limited length of coiled materials, and affecting construction efficiency, so as to save labor costs and improve construction efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Preferred embodiments of the present invention will be described in more detail below. Although preferred embodiments of the present invention are described below, it should be understood that the present invention can be embodied in various forms and should not be limited by the embodiments set forth herein. Rather, these embodiments are provided so that this disclosure will be thorough and complete, and will fully convey the scope of the invention to those skilled in the art.

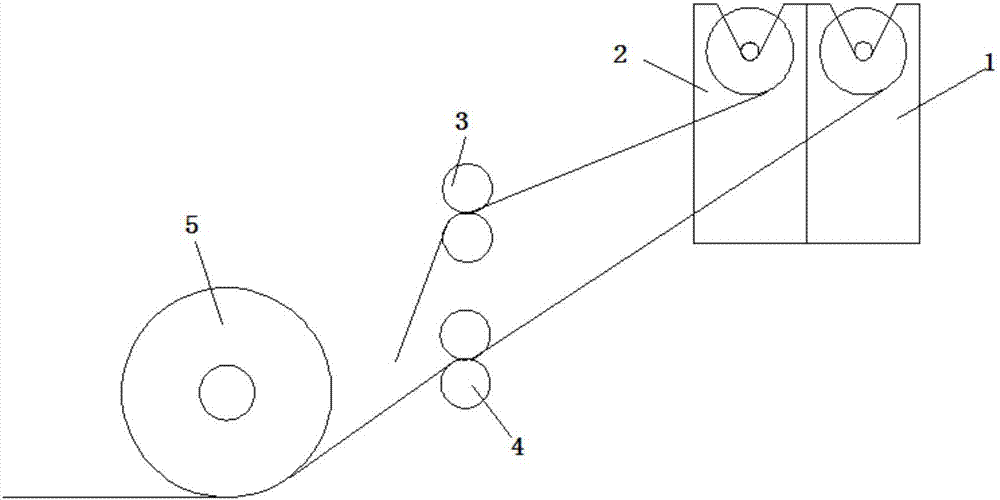

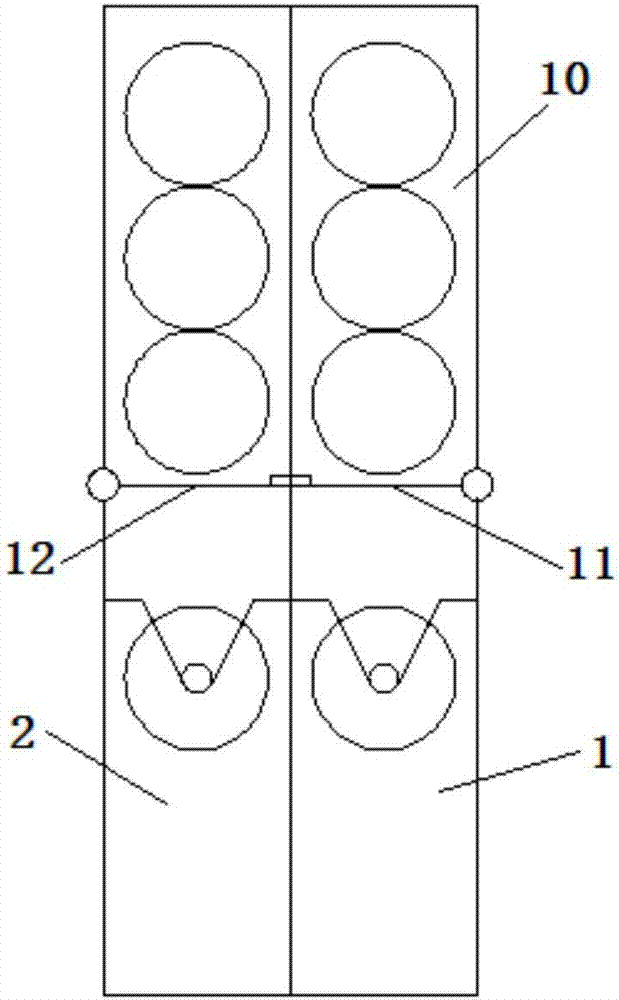

[0028] According to one aspect of the present invention, an automatic coil material changing system is provided, and the coil automatic material changing system includes:

[0029] The first coil support and the second coil support are used to place coils;

[0030] The first guiding device is used to tension and guide the waterproof coiled material discharged from the first coiled material support to under the paving roller;

[0031] The second guiding device is used to tension and guide the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com