Patents

Literature

56results about How to "Easy to transport away" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

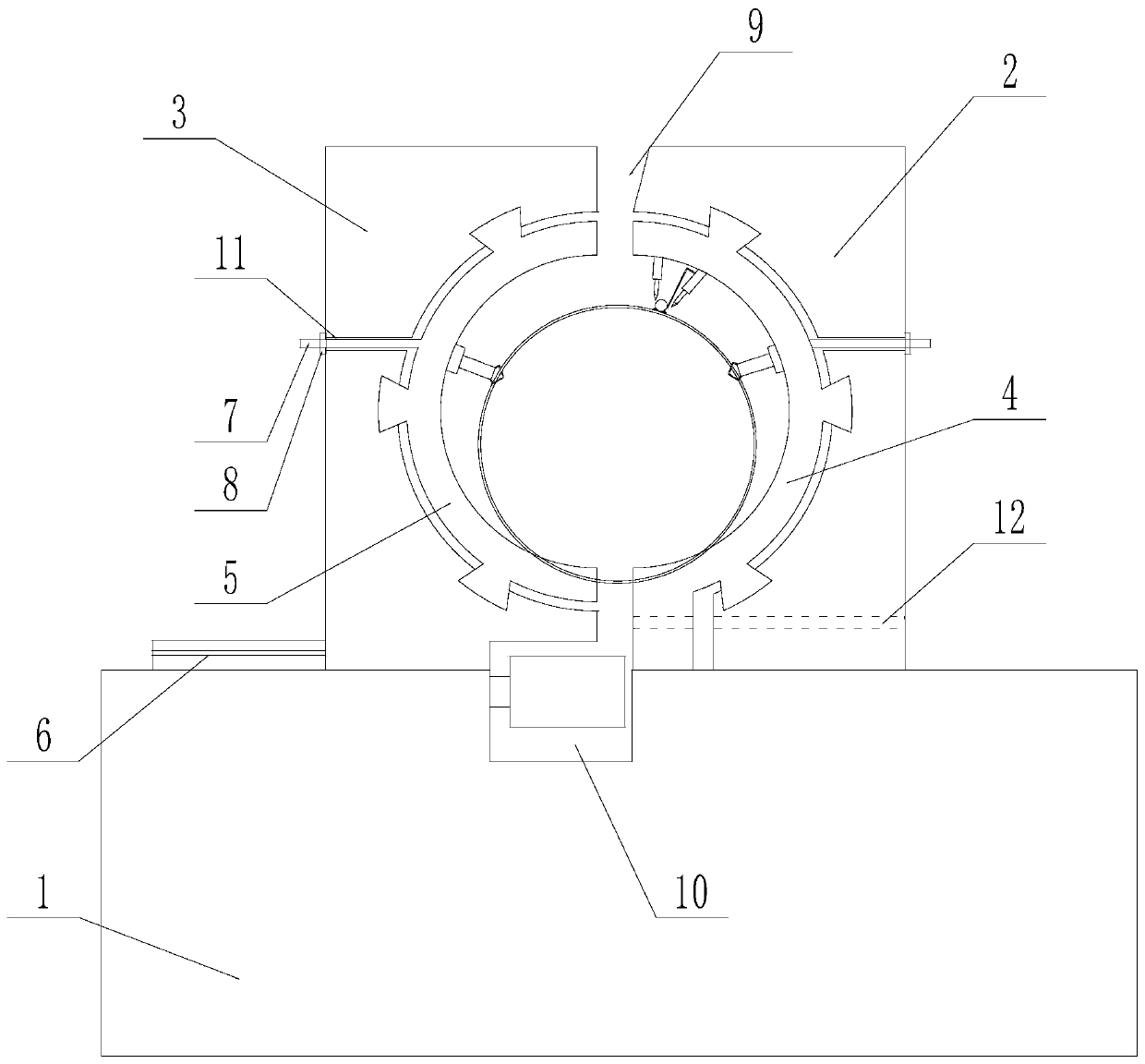

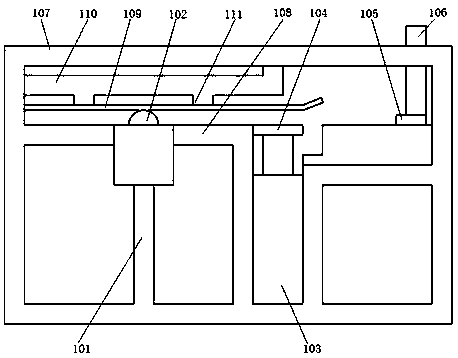

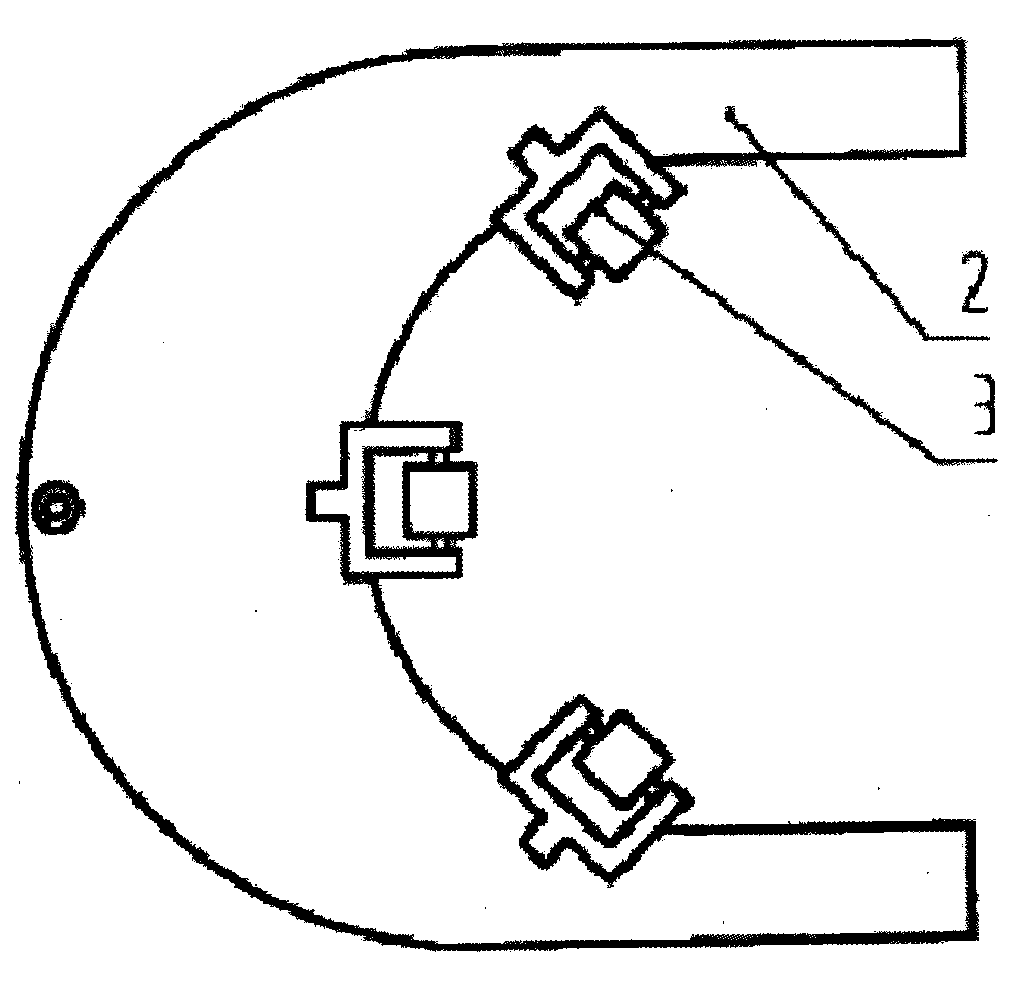

Intermittent washing and drying machine

InactiveCN105363716AEasy to transport awayHigh degree of automationDrying gas arrangementsCleaning using liquidsEngineeringMechanical engineering

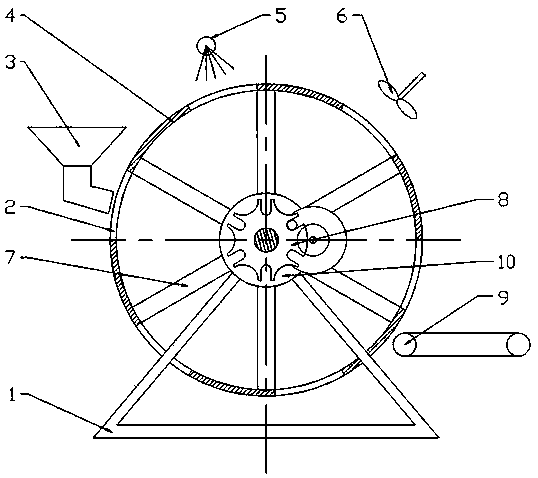

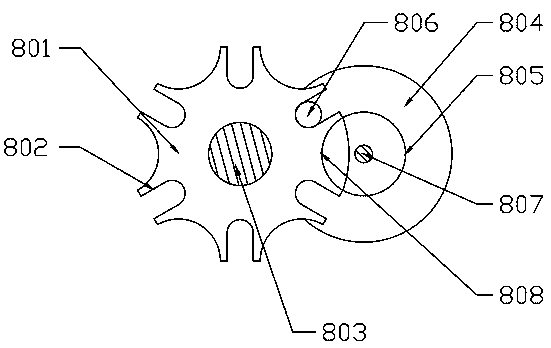

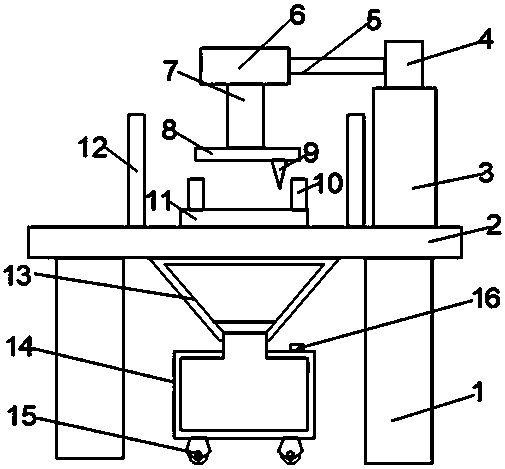

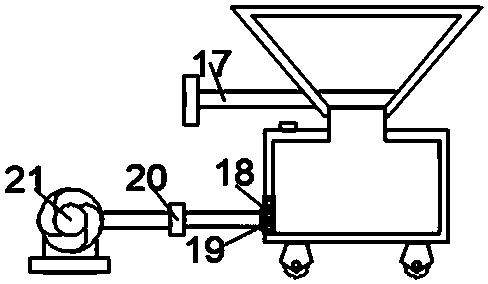

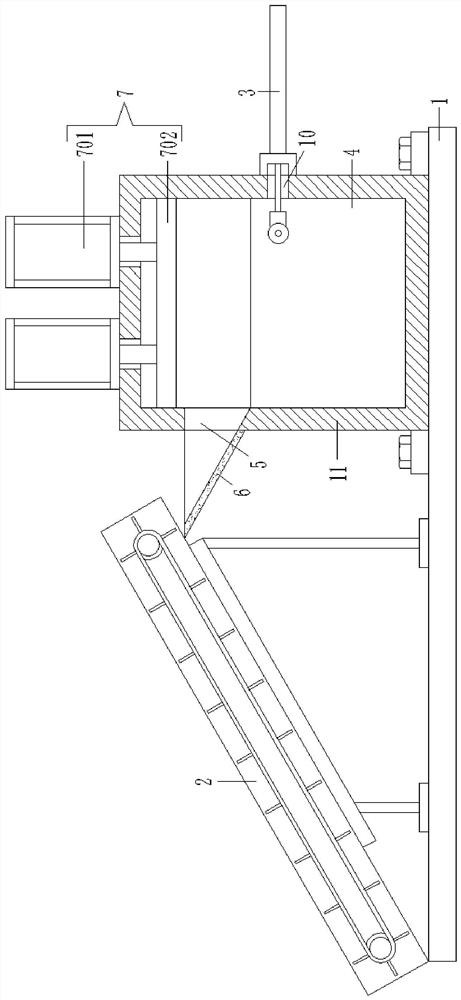

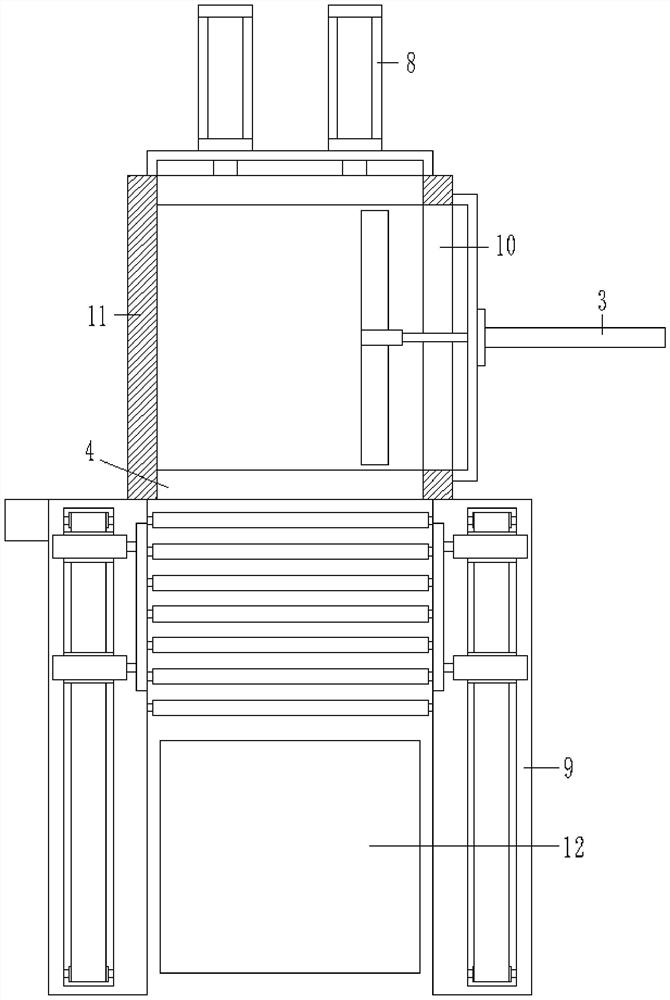

The invention discloses an intermittent washing and drying machine. The intermittent washing and drying machine comprises a rack and a working cavity, wherein a bearing shaft is fixed on the rack and is hinged to a fixed disc and a grooved wheel of a grooved wheel mechanism; partition plates are uniformly distributed and fixed at the periphery of the edge of the fixed disc; the outer ends of the partition plates are fixed to the inner wall of the working cavity; the partition plates are used for dividing the inside of the working cavity into fan-shaped sections isolated from each other; the number of the fan-shaped sections is equal to that of the partition plates; an opening is formed in the arc-shaped surface of each section; four openings are successively configured to be a feeding station, a washing station, a drying station and a discharging station; a feeding hopper is arranged at the feeding station; a washing water pipe is arranged at the washing station; a drying fan is arranged at the drying station; a shifting disc of the grooved wheel mechanism is matched with the grooved wheel; a shifting disc power shaft is fixed on the shifting disc; a circular pin is fixed on the shifting disc and is placed in a radial groove of the grooved wheel. The invention aims to provide an automatic washing and drying machine; the machine is capable of intermittently carrying out the four processes of feeding, washing, drying and discharging in stages, and is also capable of continuously working without halt.

Owner:CHONGQING SHUNTAI FOOD

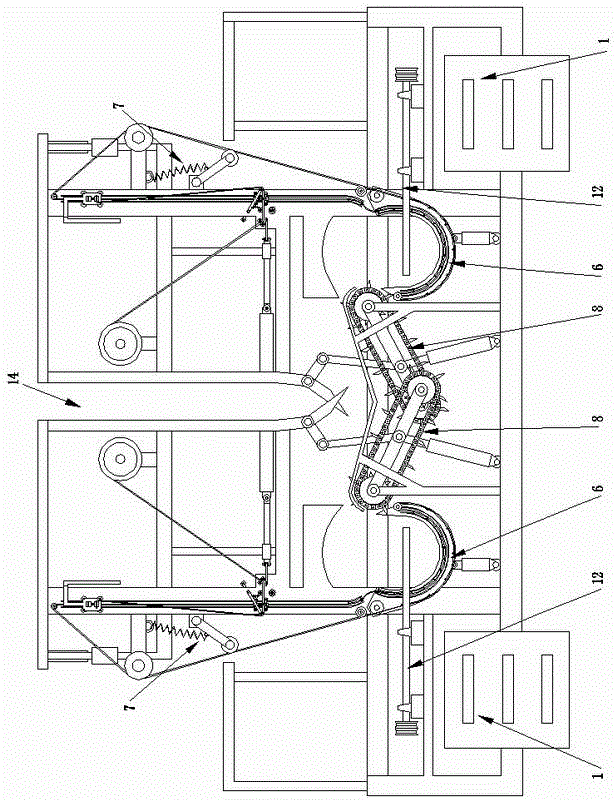

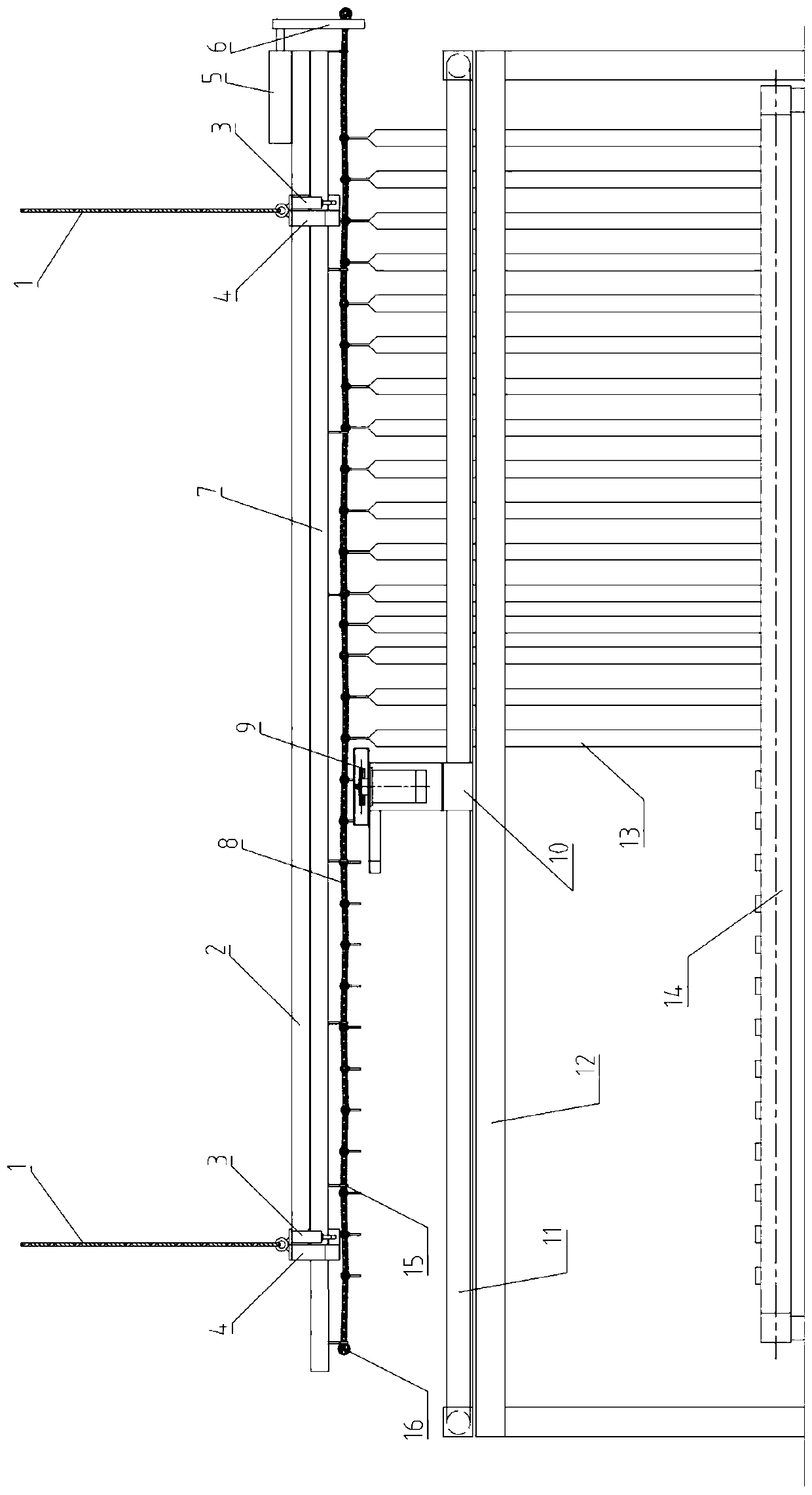

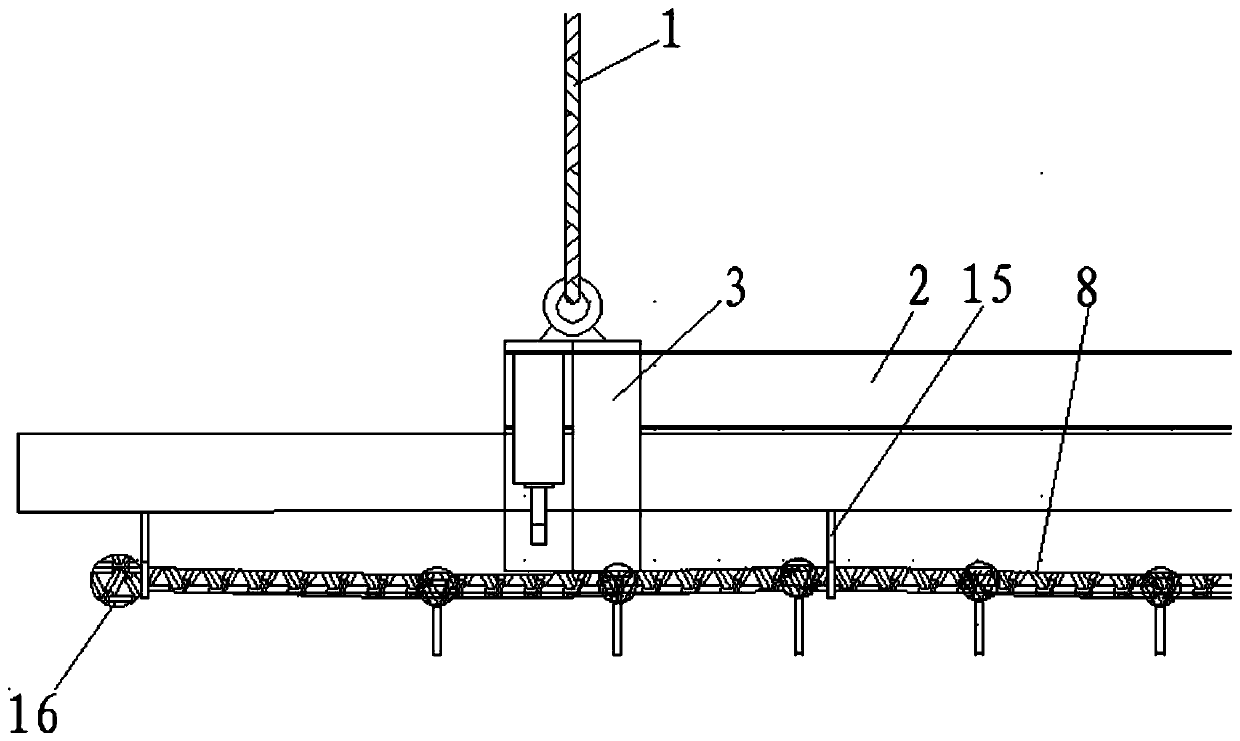

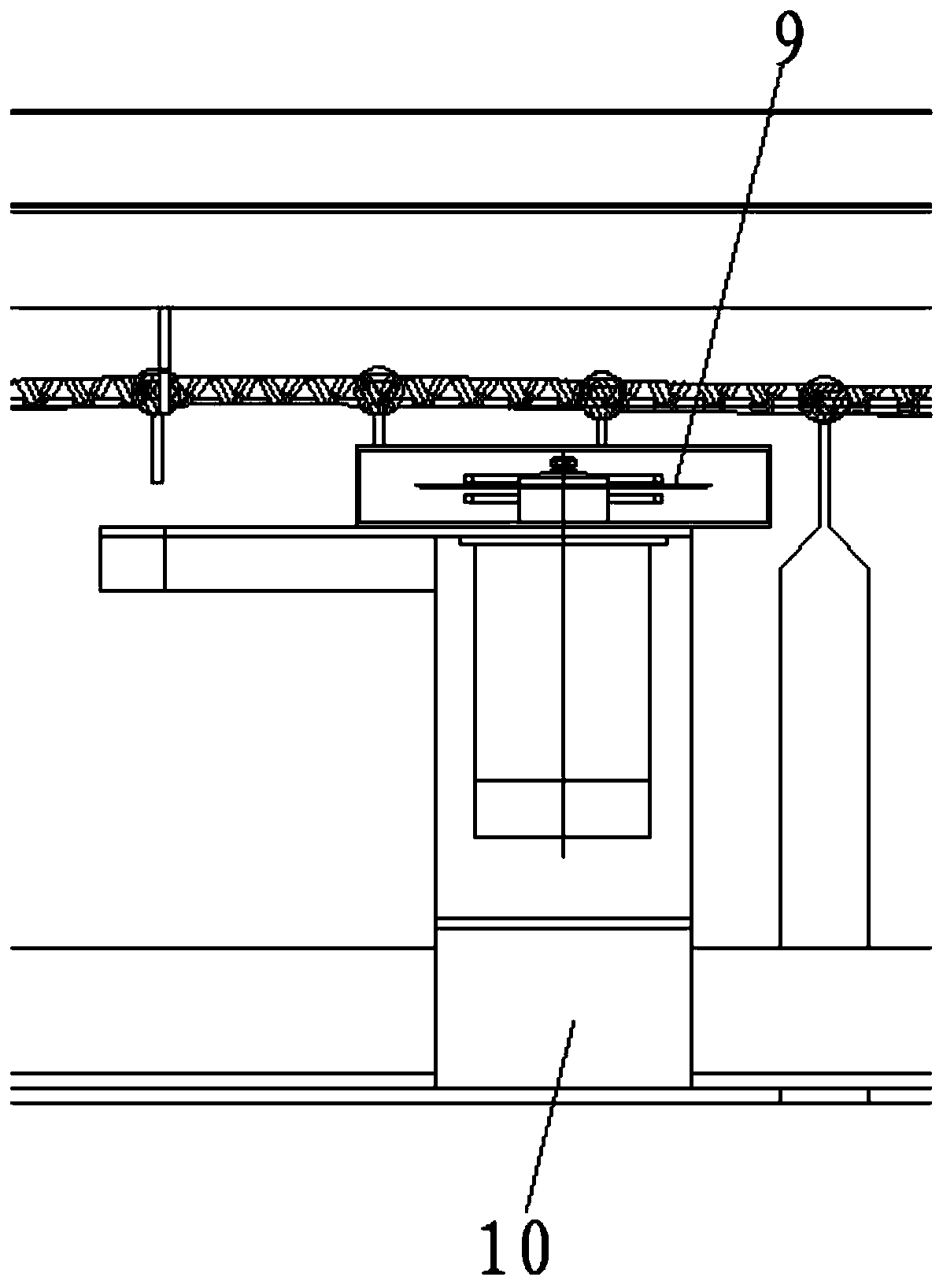

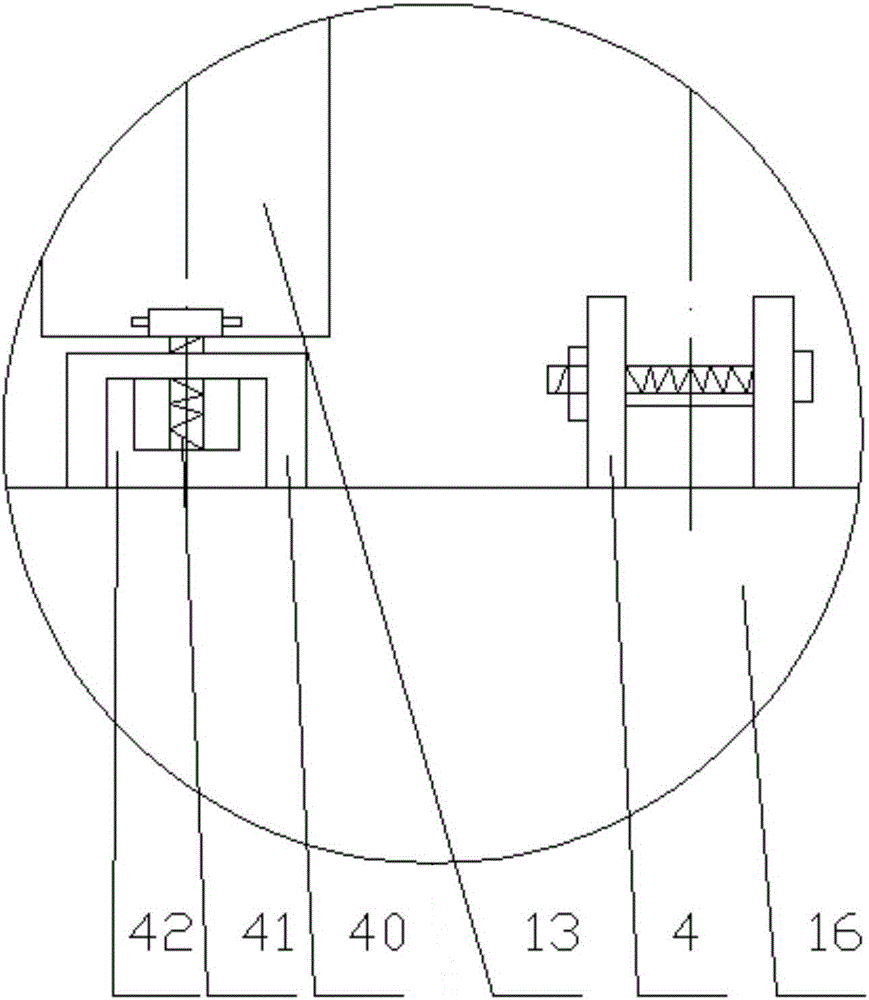

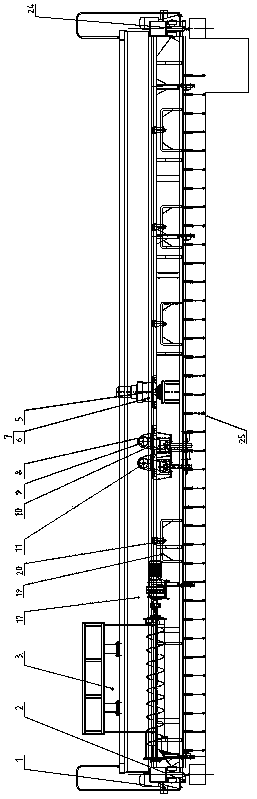

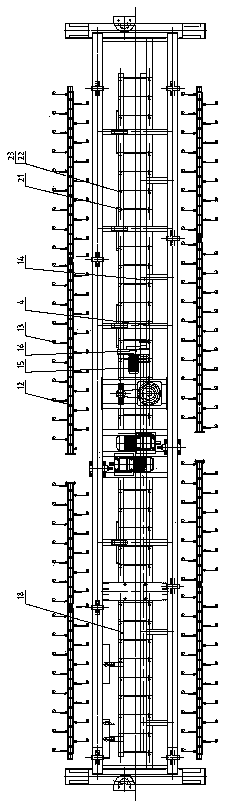

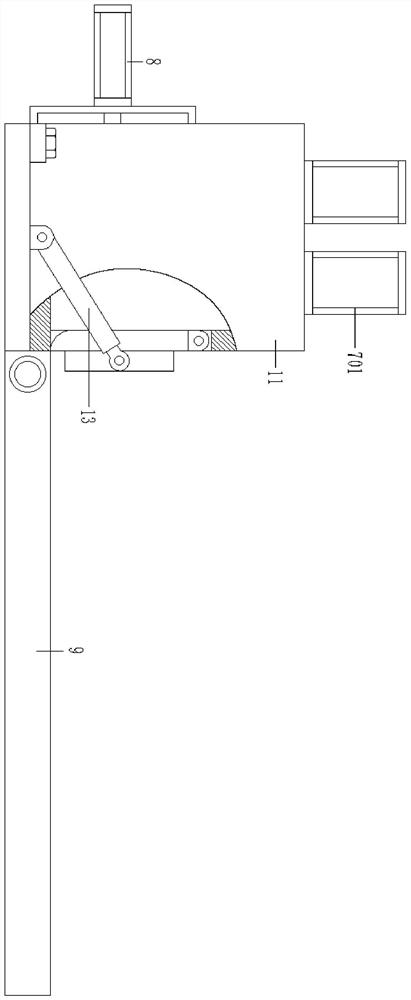

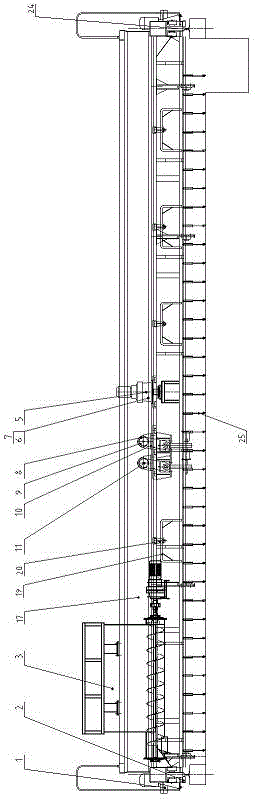

Reed/crop straw harvesting bundler

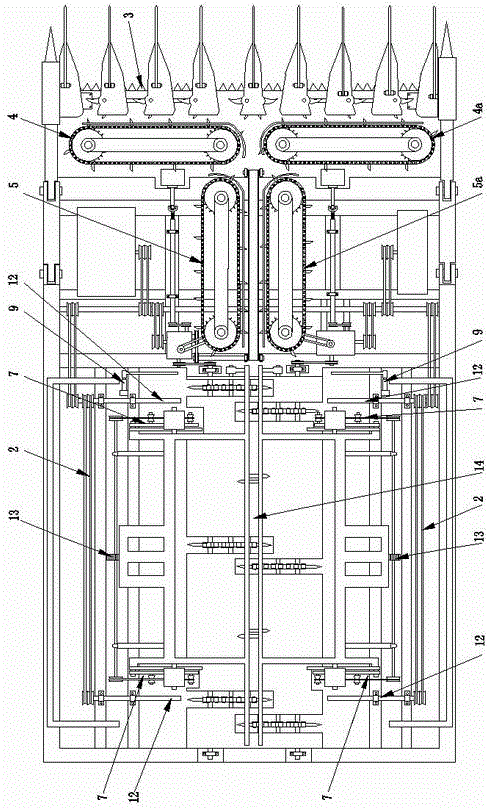

The invention discloses a reed / crop straw harvesting bundler, and belongs to the technical field of harvesters. The harvesting bundler mainly comprises a cutting knife mechanism, feeding mechanisms, distributing mechanisms, bundling mechanisms, rope conveying mechanisms, rope conveying gear mechanisms, aligning mechanisms, bundle conveying mechanisms and a lifting mechanism. The transverse feeding mechanisms, the longitudinal feeding mechanisms, the distributing mechanisms, the bundling mechanisms, the rope conveying mechanisms, the rope conveying gear mechanisms, the aligning mechanisms and the bundle conveying mechanisms are symmetric about the center of a travelling mechanism. After materials harvested by the harvesting bundler are conveyed to the distributing mechanisms by the feeding mechanisms, the left distributing mechanism and the right distributing mechanism alternately distribute the materials to the two bundling mechanisms, the materials are aligned by the aligning mechanisms and then bundled by the bundling mechanisms, the rope conveying mechanisms convey ropes, and the materials are manually fastened, conveyed out, loaded and carried away by the bundle conveying mechanisms. According to the harvesting bundler, harvesting is combined with bundling, harvesting operation is completed once, labor is saved, transportation is facilitated, production efficiency is improved, and production cost is reduced.

Owner:韩志玉 +1

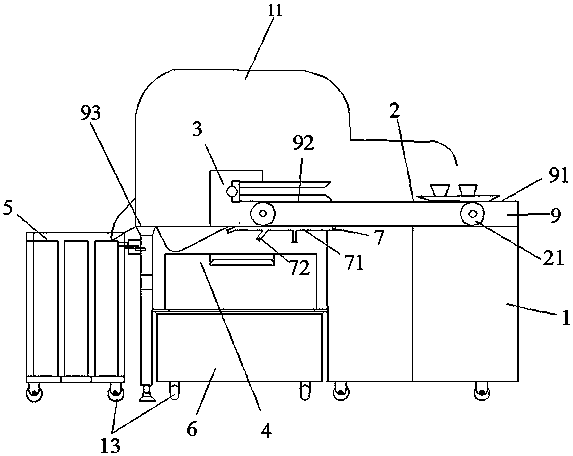

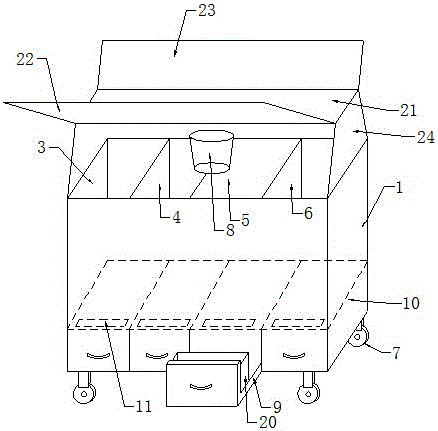

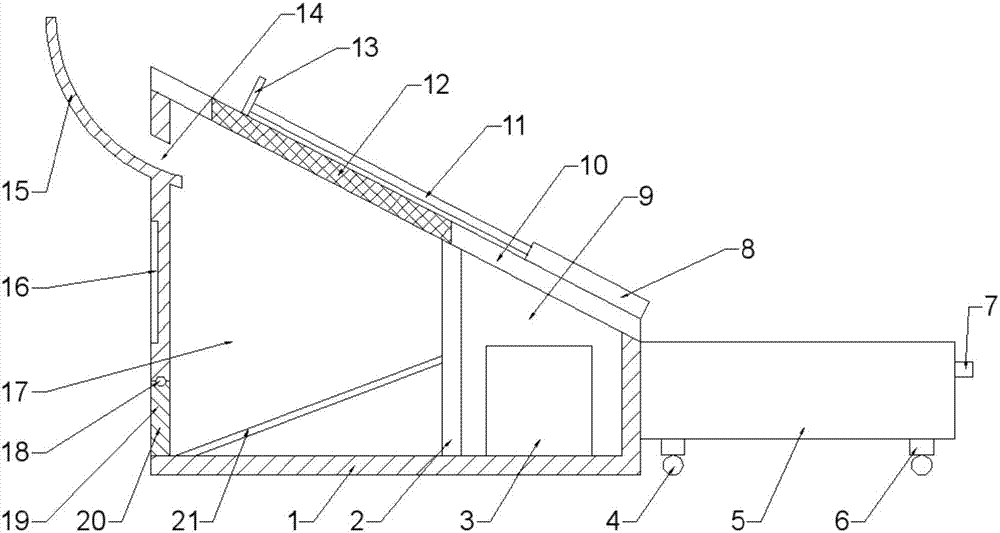

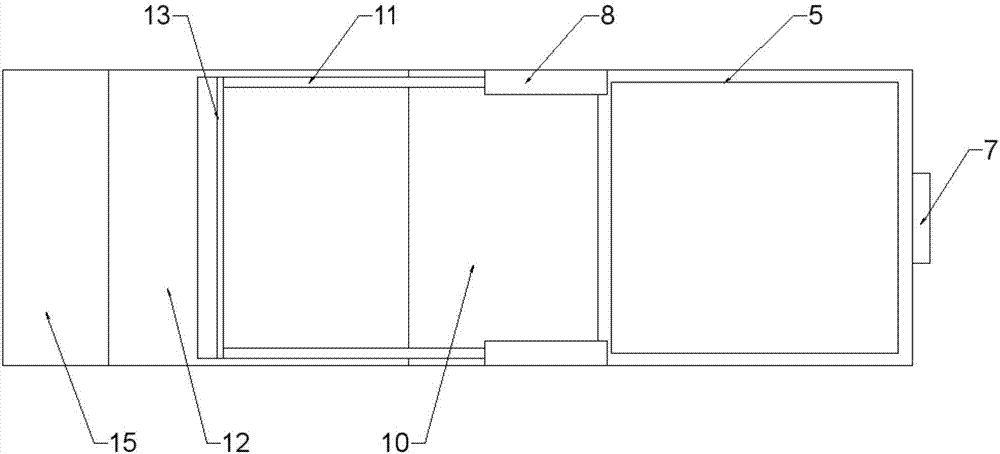

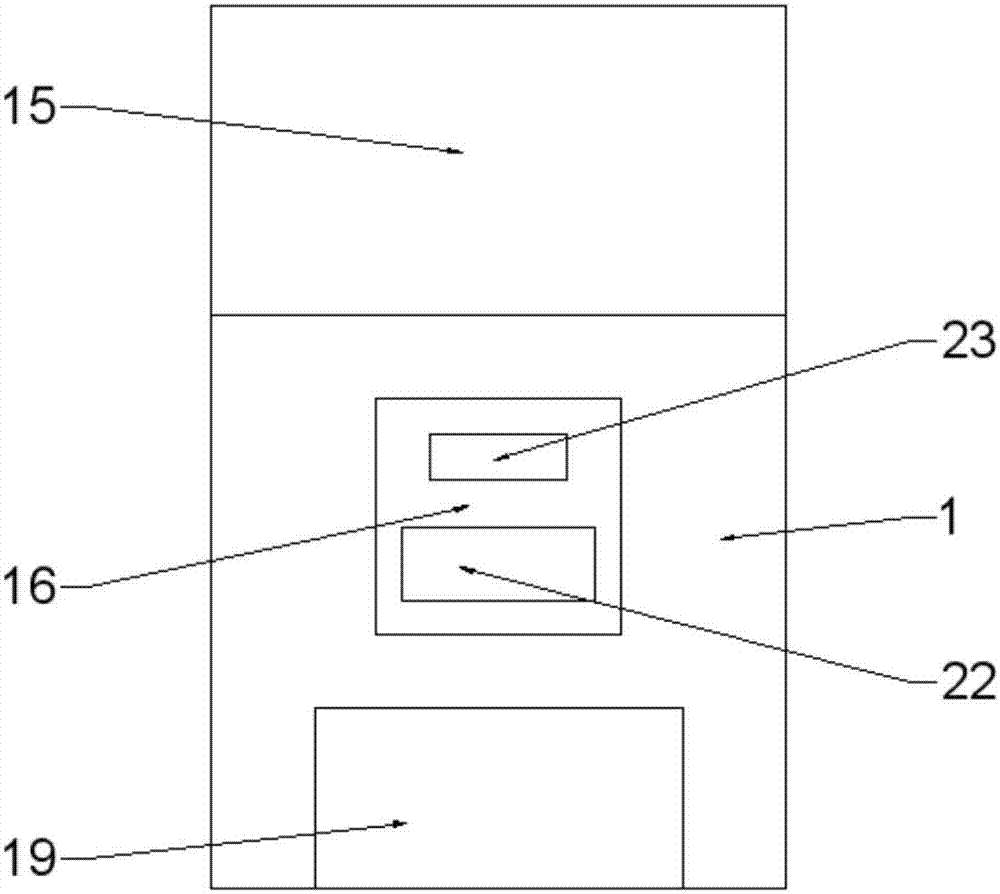

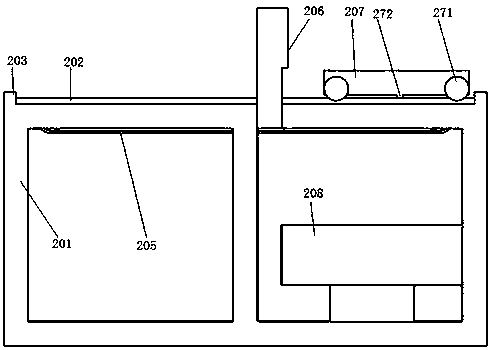

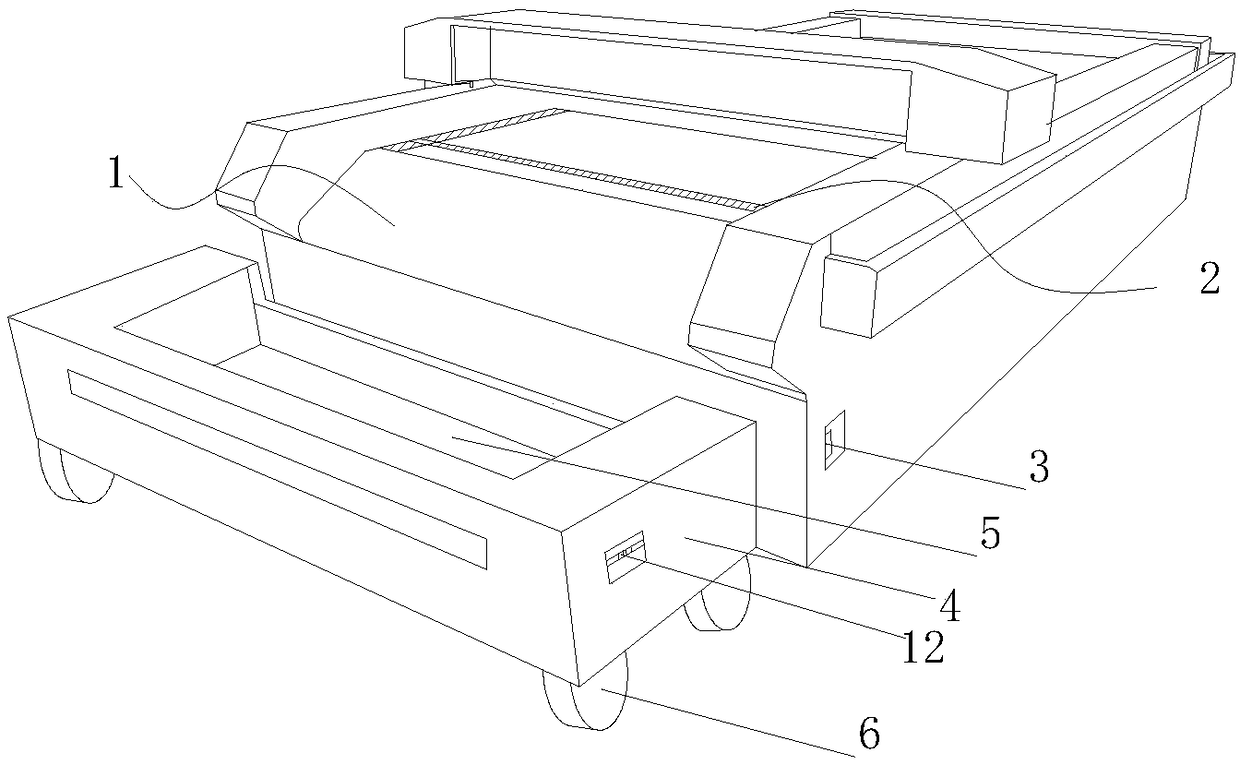

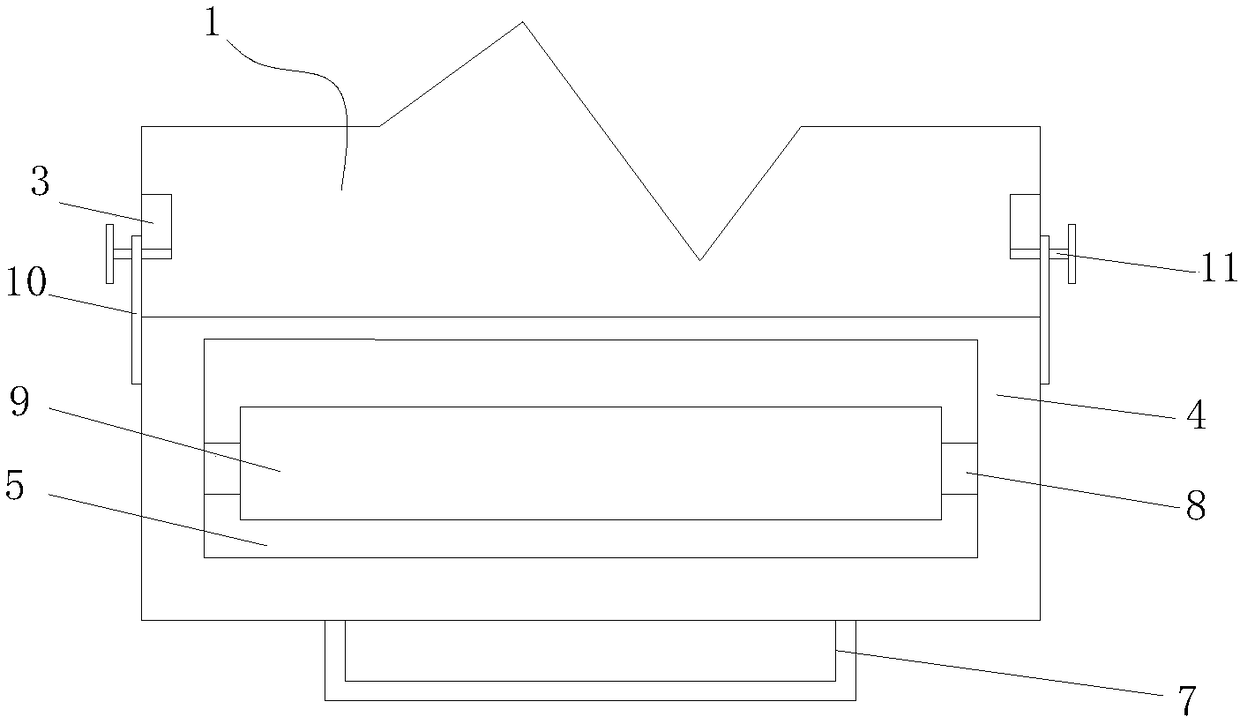

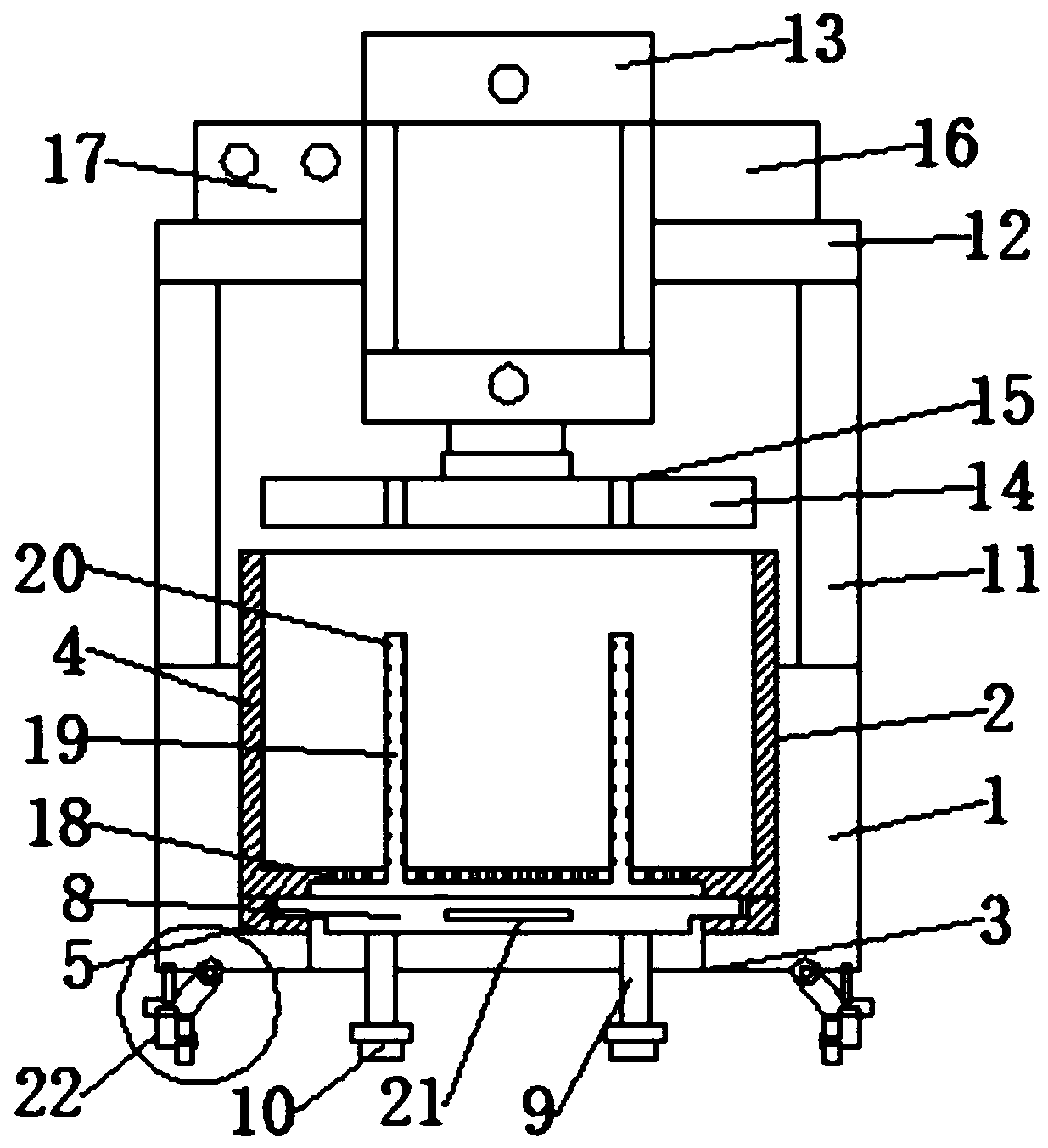

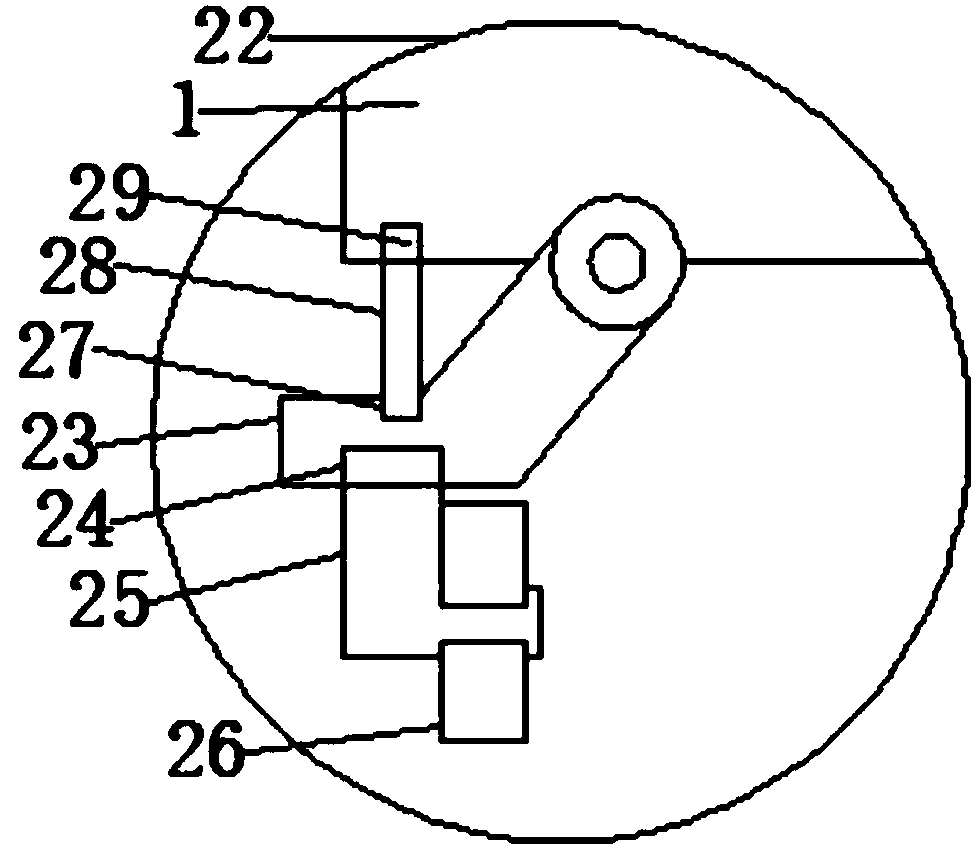

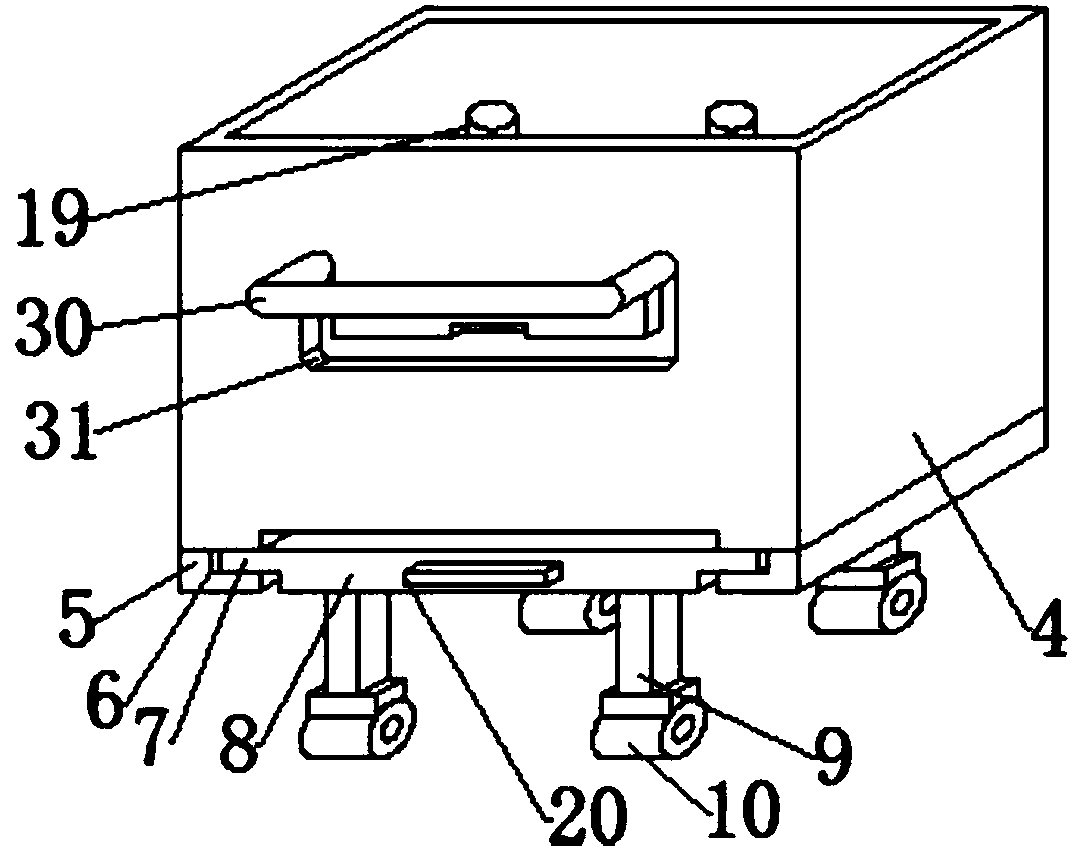

Canteen bowl and plate separating and cleaning machine

InactiveCN108577733AEasy to useEasy to transport awayTableware washing/rinsing machinesEngineeringSewage

The invention discloses a canteen bowl and plate separating and cleaning machine which comprises a base, a conveying mechanism, a turning and separating mechanism, a cleaning box, a dinner plate recycling basket, a dirt storage tank, a spray washing mechanism, a support, a work bench board, a supporting plate and a shielding cover, wherein the conveying mechanism can convey used dinner plates to abowl and plate separating position, bowls and dinner plates can be automatically separated under the action of a sensor and a driving motor on the turning and separating mechanism, the driving motoris in driving connection with the turning and separating mechanism, the bowls can fall into the cleaning box to be cleaned, the dinner plates are conveyed to the dinner plate recycling basket, bowl and plate separation is achieved, and the bowls are cleaned; the dirt storage tank is arranged at the lower end of the cleaning box, and leftover and sewage can be collected into the dirt storage tank;the cleaning box, the dirt storage tank and the dinner plate recycling basket are respectively and movably connected with the base and can be easily moved away and replaced when being filled up. The device is convenient to use, avoids the problems of low efficiency in manually collecting plates and long time consumption, is clean and tidy and is suitable for large canteens to recycle tableware.

Owner:SICHUAN HUIDATONG MACHINERY EQUIP MFG

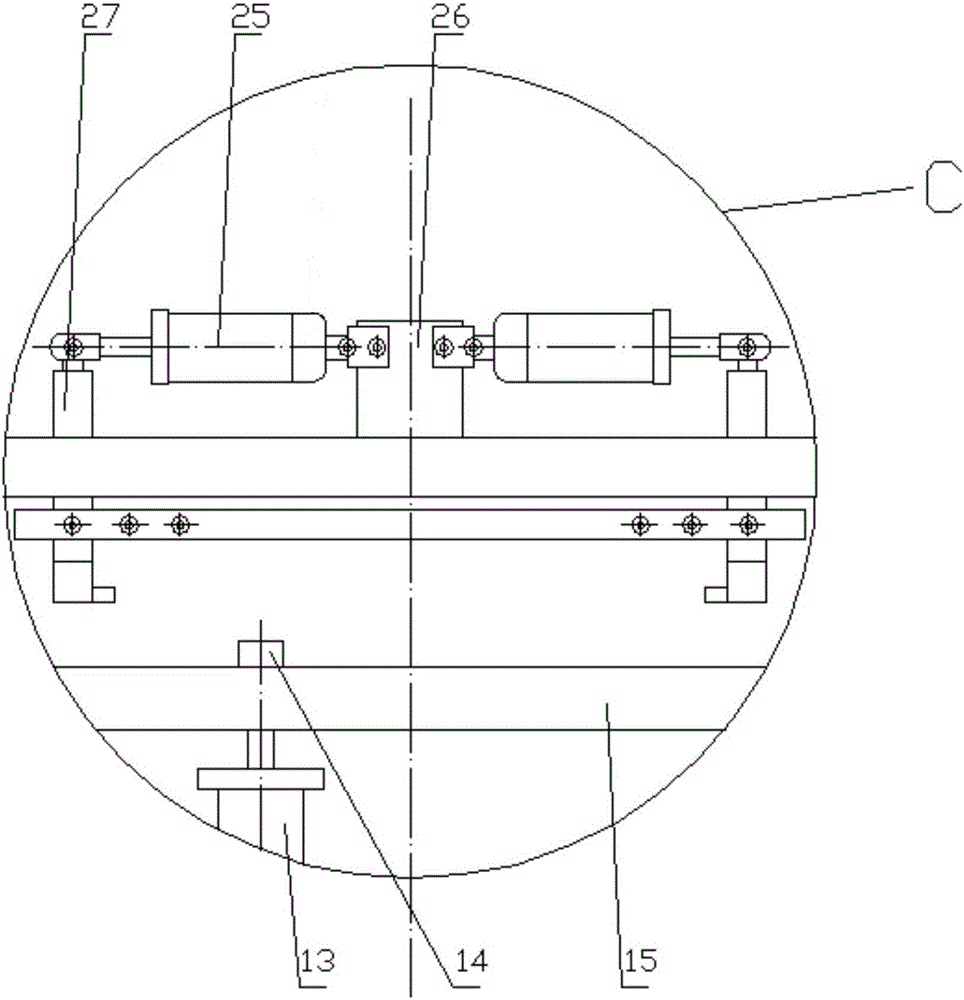

Power distribution cabinet assembling platform

The invention provides a power distribution cabinet assembling platform. The power distribution cabinet assembling platform includes an electric control cabinet, a base, lifting mechanisms, a turning mechanism, an operation platform and vertical arm mechanisms; supporting upright columns are connected onto the base; slide grooves are arranged on the supporting upright columns; the lifting mechanisms are vertically arranged at four corners of the base; the turning mechanism comprises a turning bracket, a rotating shaft, a connecting piece and a turning hydraulic jack, wherein the turning bracket is correspondingly clamped in the slide grooves in a sliding manner and is connected at the upper parts of the lifting mechanisms in a jacking manner, the rotating shaft is parallelly fixed at the lower part of the turning bracket and is clamped into the slide grooves in a sliding manner, and the turning hydraulic jack is connected at the middle of the turning bracket in a jacking manner through the connecting piece; the operation platform is fixed at the upper surface of the turning bracket; and the vertical arm mechanisms are arranged at two sides of the middle of the operation platform. With the power distribution cabinet assembling platform adopted, the positions of the side plates of a power distribution cabinet to be assembled can be determined, and complex steps for repeatedly adjusting a cabinet body to straighten the cabinet body in an assembling process can be omitted, and after the power distribution cabinet is assembled, the cabinet body of the power distribution cabinet can be automatically turned so as to be straightened, and manual lift can be omitted.

Owner:天津市建电实业有限公司

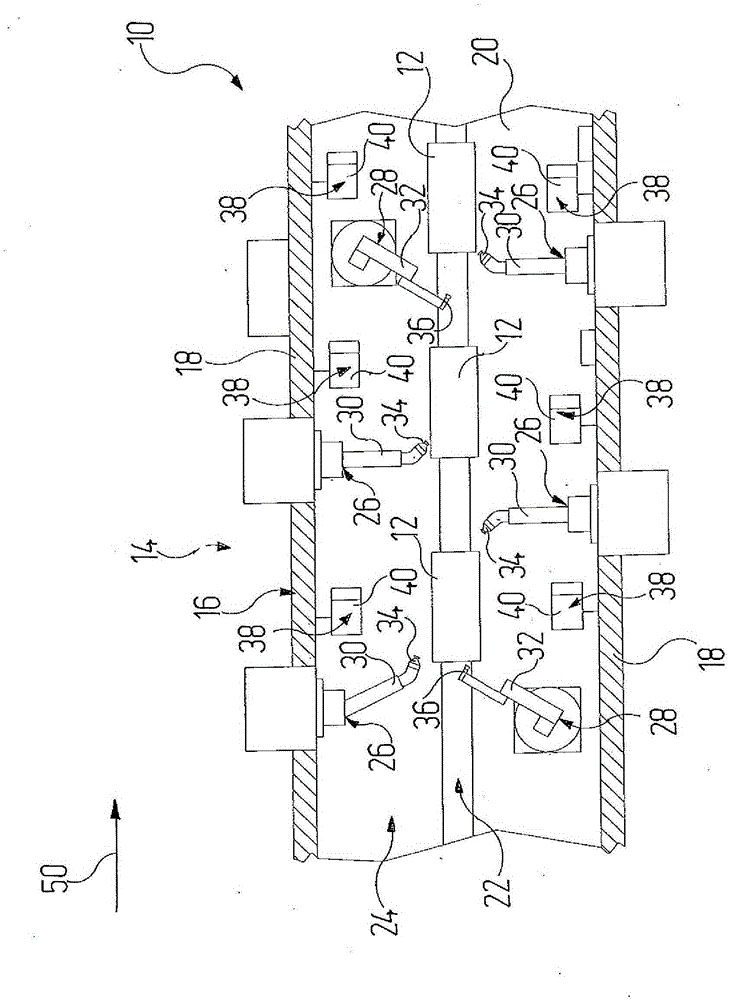

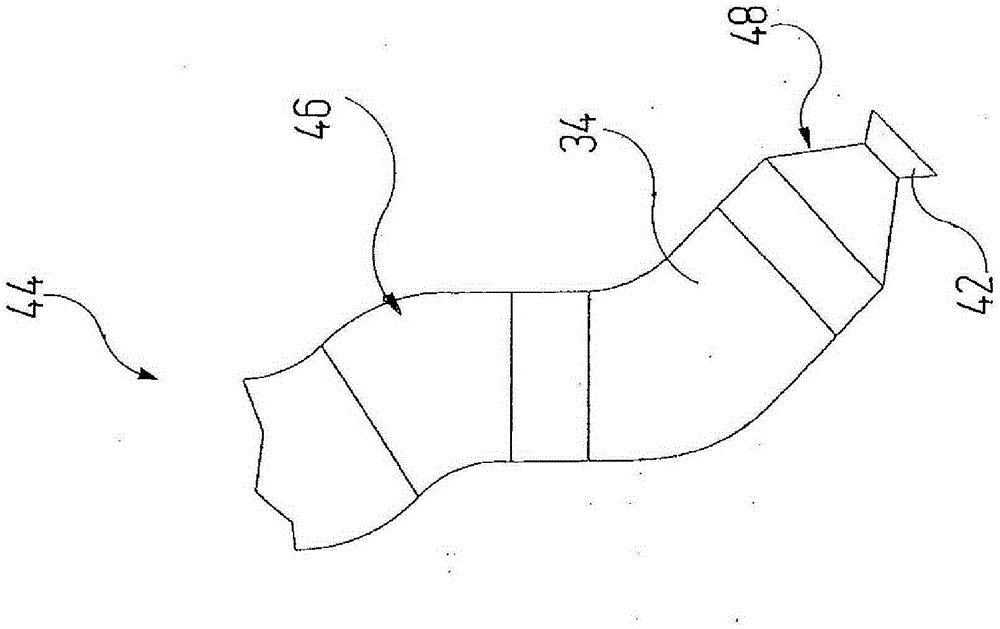

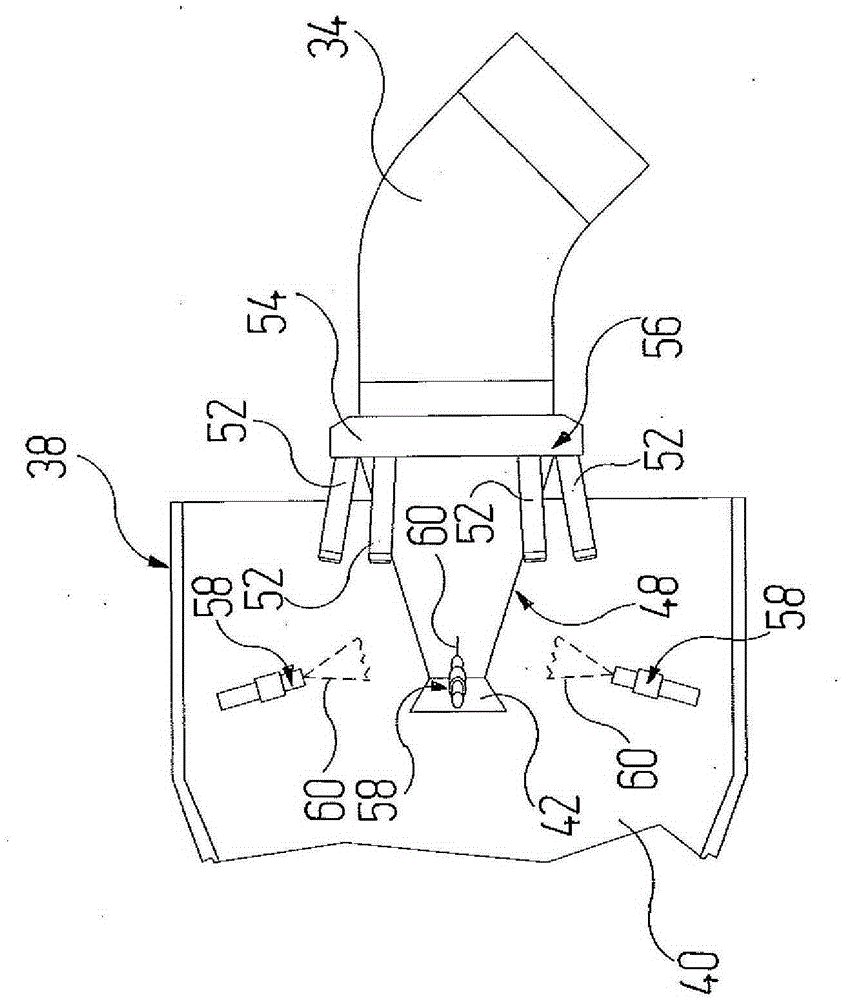

Cleaning process and cleaning device for one or more parts of an application system

InactiveCN105562383AEasy to transport awayEasy to cleanSpraying apparatusCleaning using gasesCleaning methodsMechanical engineering

The invention relates to a cleaning process for one or more parts of a cleaning application system (24). The cleaning process for one or more parts of the cleaning application system (24) by positioning one or more parts of the application system in a clewing chamber (40), spraying the one or more parts of the application system with a medium using a plurality of spray devices, with the medium being supplied to the spray devices from an assembly group. One or more parts of the application system (24) may be removed from the cleaning chamber, wherein during spraying the supply of media to the spray devices takes place in a sequence having a plurality of successive phases. At least two phases of the sequence differ in terms of the supply of the at least one medium to the spray devices. A cleaning device designed to carry out the cleaning process is also provided having a control device (76) for controlling the supply of the medium to the spray devices.

Owner:EISENMANN SE

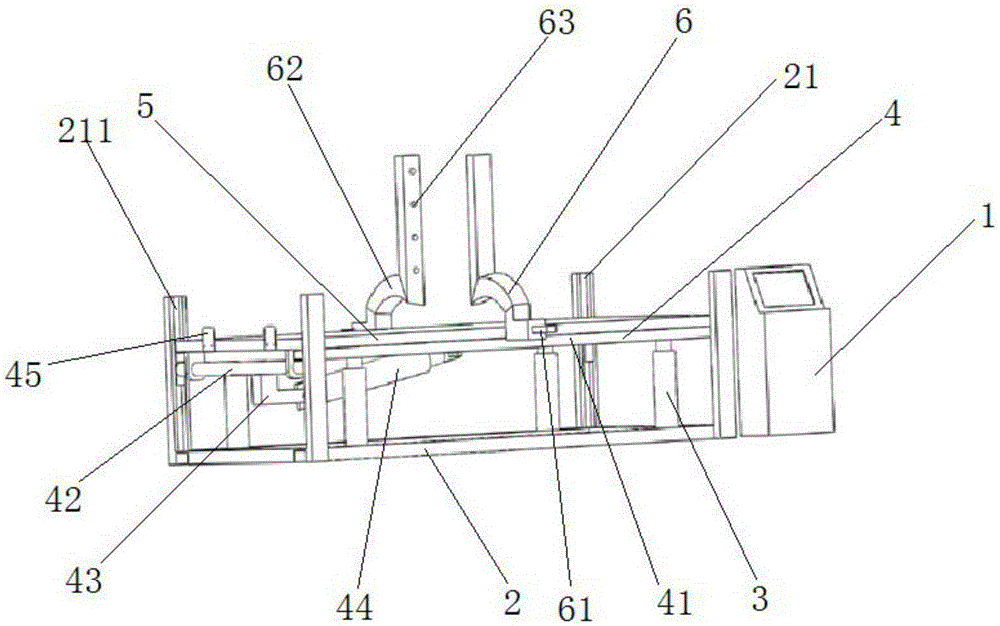

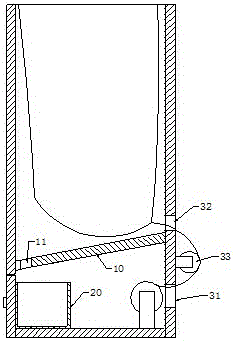

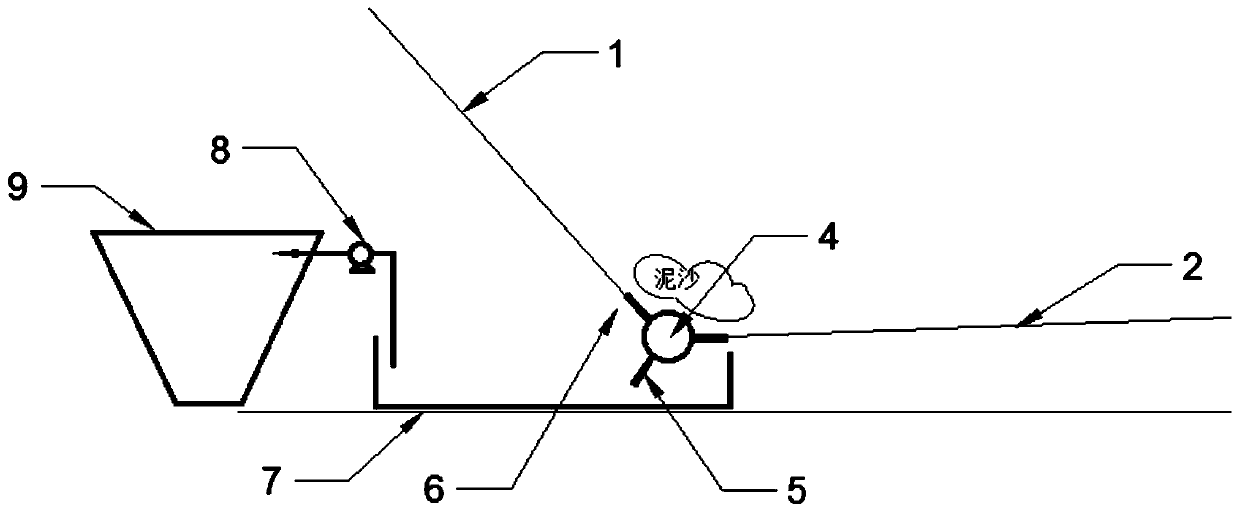

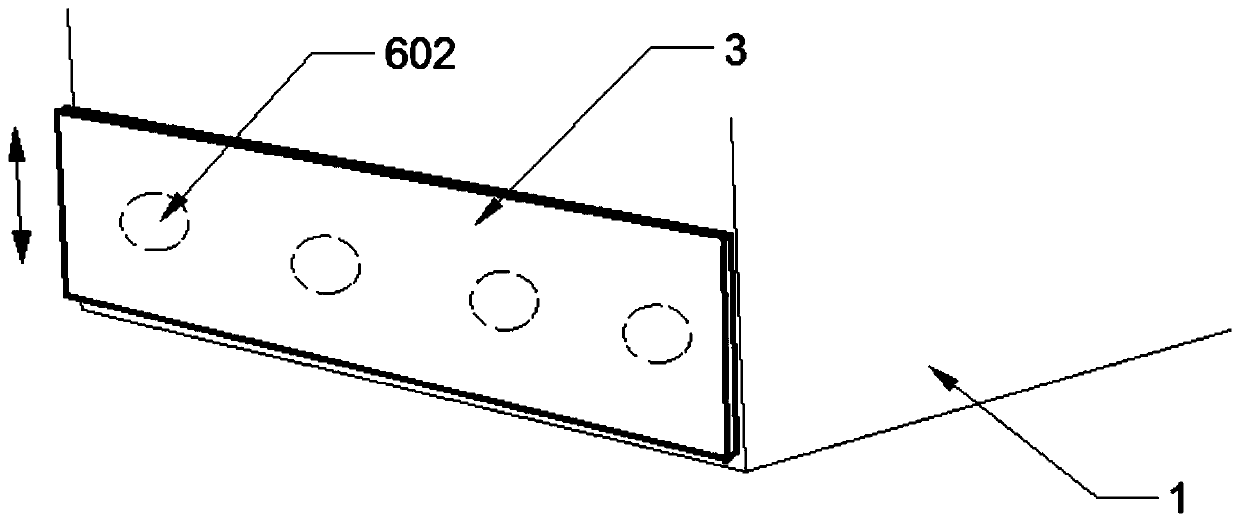

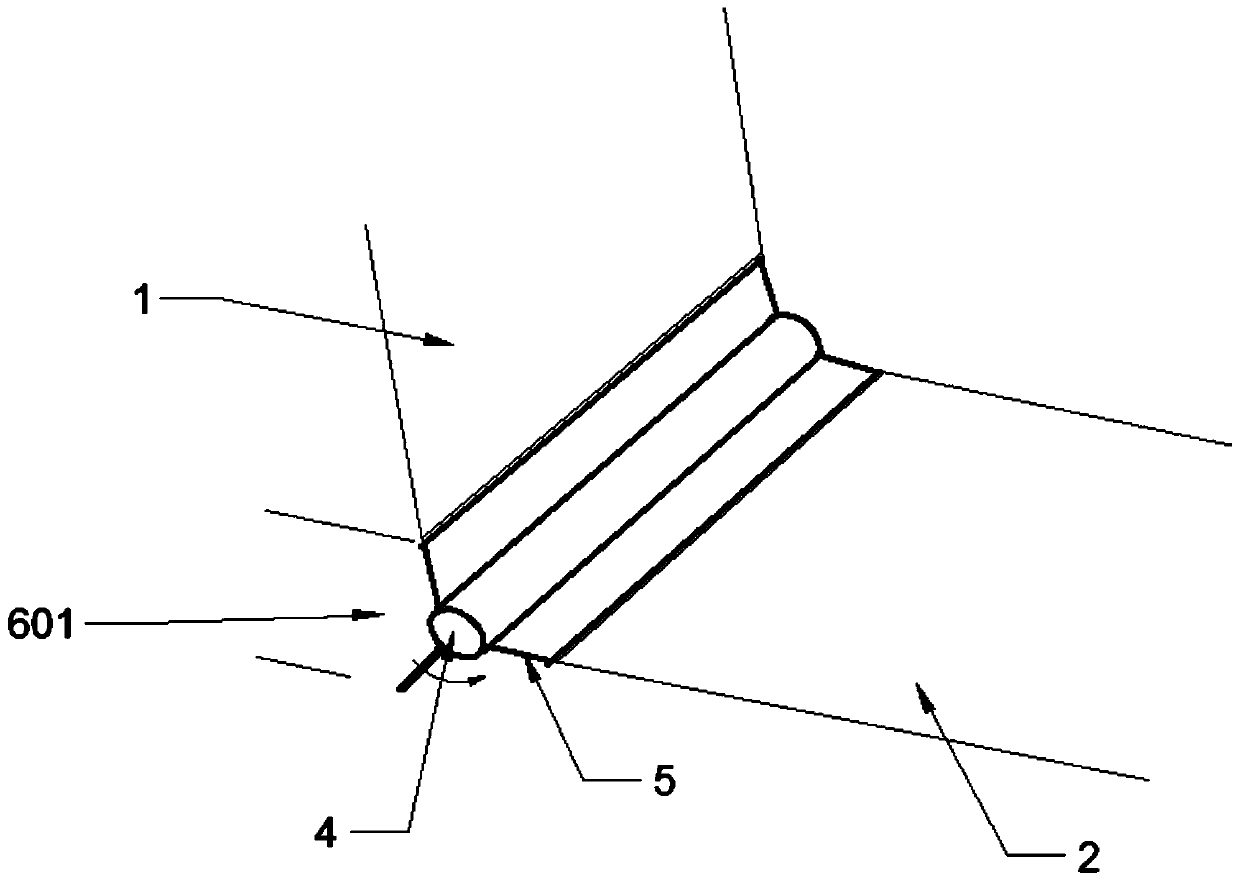

Cutting method and device and cutting method for hung kelp

ActiveCN111300510AEfficient cuttingRealize continuous cuttingMetal working apparatusStructural engineeringAsparagus schoberioides

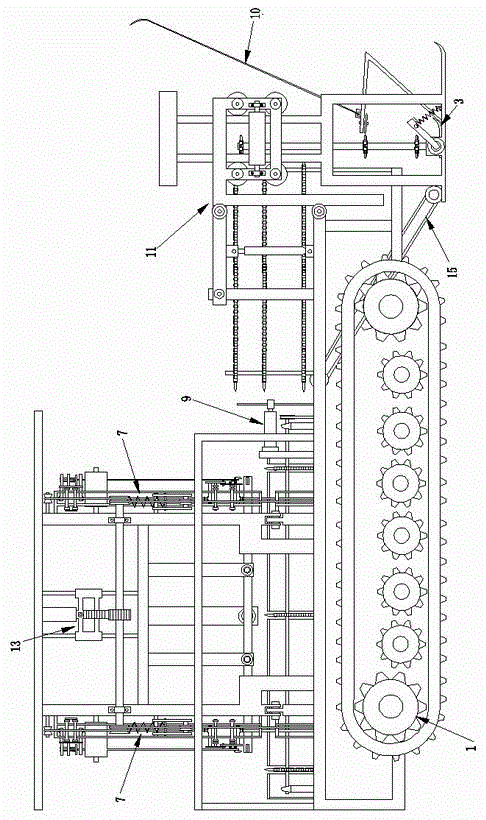

The invention relates to a cutting device for hung kelp. A seedling rope of the hung kelp is transversely hung below an airing rod through hooks, and the airing rod, the seedling rope and the kelp form a conveyed unit assembly; a lifting rod is transversely arranged, the two ends of the lifting rod are fixedly connected with the lower ends of lifting ropes, a clamping device is arranged at the endpart of the lifting rod, and the clamping device can clamp and fix the airing rod below the lifting rod; a seedling rope tensioning device is arranged at one end of the lifting rod, the moving part of the seedling rope tensioning device is connected with a guide clamping piece, and the guide clamping piece clamps one end of the seedling rope, and can straighten and tension the seedling rope; andthe conveyed unit assembly is conveyed right above a sliding table by the lifting rope and the clamping device, a horizontal cutting tool can transversely move along the sliding table, and the heightof the cutting tool is located at a kelp stalk part below a kelp hook, and corresponds to an asparagus filament part on the kelp. According to the cutting device for the hung kelp, the problem of winding of asparagus filaments is solved, continuous cutting is achieved, and meanwhile, mechanical cutting is achieved under the condition of the flexible seedling rope.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI +1

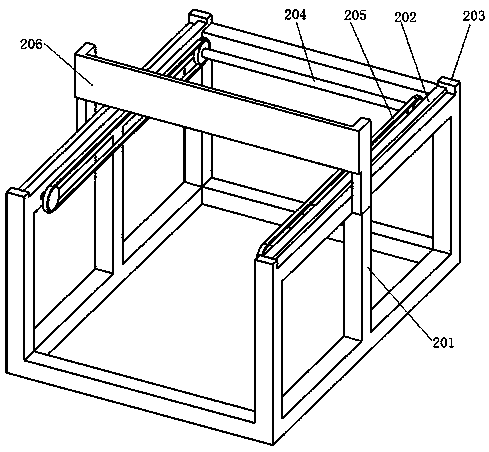

Automatic color plate stacking machine

ActiveCN105059993ARealize automatic stackingGuaranteed identityArticle deliveryStack machineEconomic benefits

The invention relates to an automatic color plate stacking machine. The stacking machine comprises a square machine frame, a lifting device, a conveying device, a clamping and horizontally-moving device and a swinging and rotating device. The lifting device is arranged on one lateral side of the square machine frame. The conveying device is arranged at the bottom of the square machine frame. The clamping and horizontally-moving device is arranged at the position, above the conveying device, of the lifting device. The swinging and rotating device is arranged outside the clamping and transversely-moving device. The lifting device can drive the clamping and horizontally-moving device to horizontally move up and down. The outer side of the clamping and horizontally-moving device is connected with the swinging and rotating device. The swinging and rotating device can swing and rotate up and down. When the clamping and horizontally-moving device and the swinging and rotating device are both in the horizontal state, the clamping and horizontally-moving device can horizontally move forwards and backwards on the swinging and rotating device. The stacking machine is scientific in design and can automatically complete stacking of a color steel machine. Manpower and material resources are greatly saved. The work efficiency is improved. The economic benefits of enterprises are improved.

Owner:天津市新宇彩板有限公司

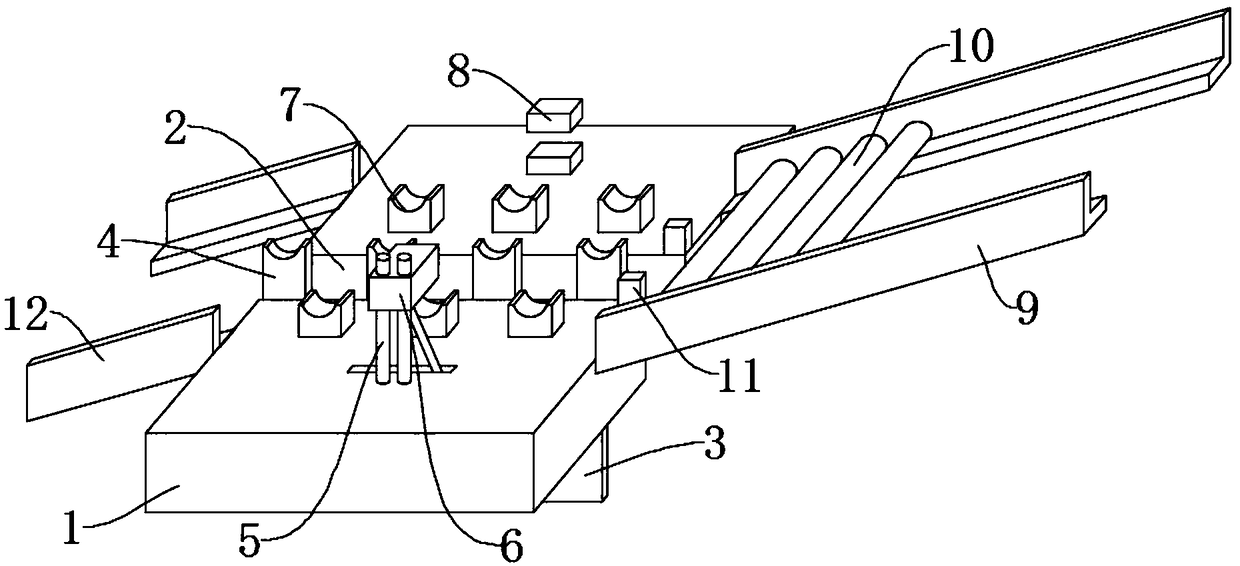

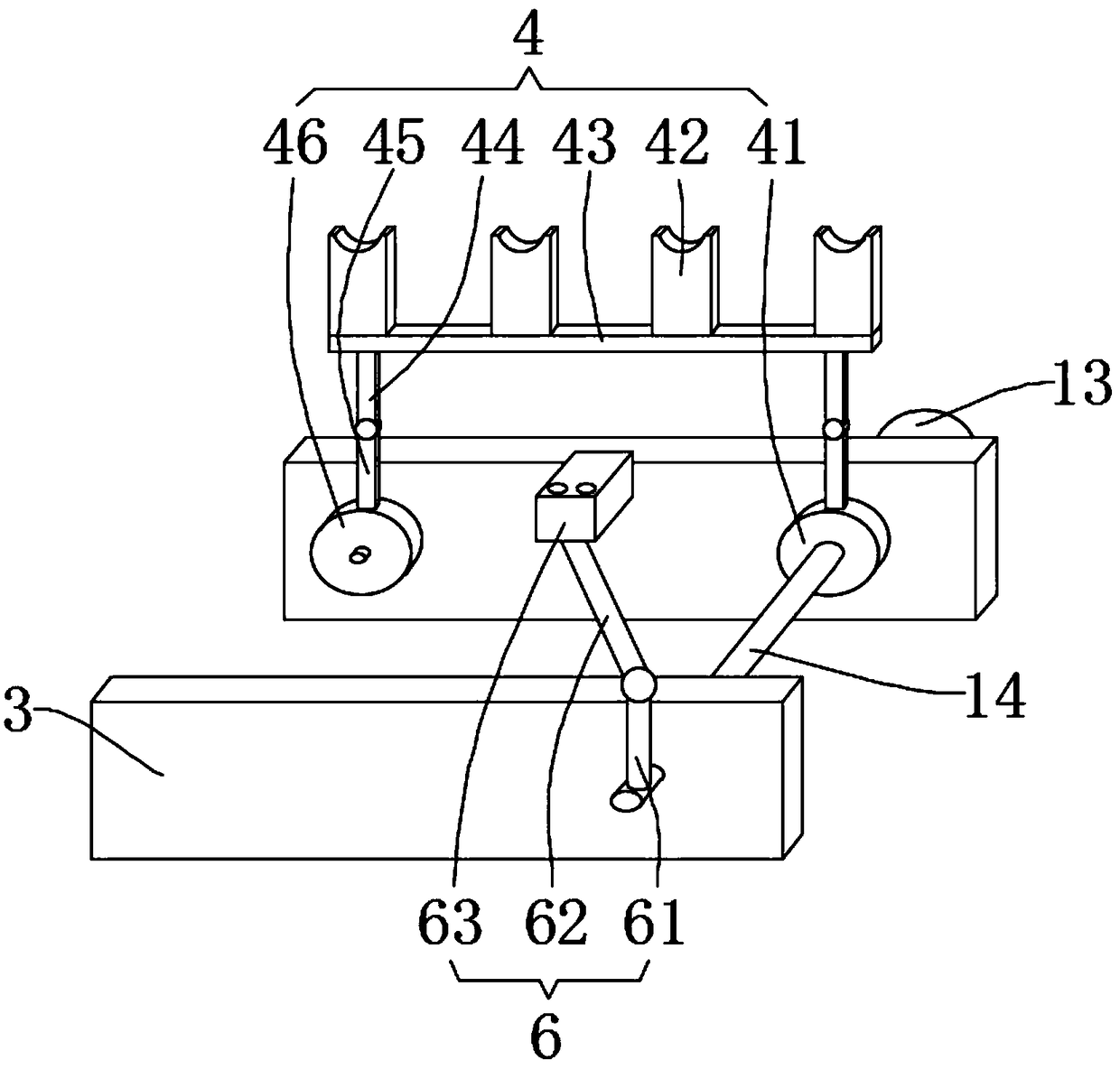

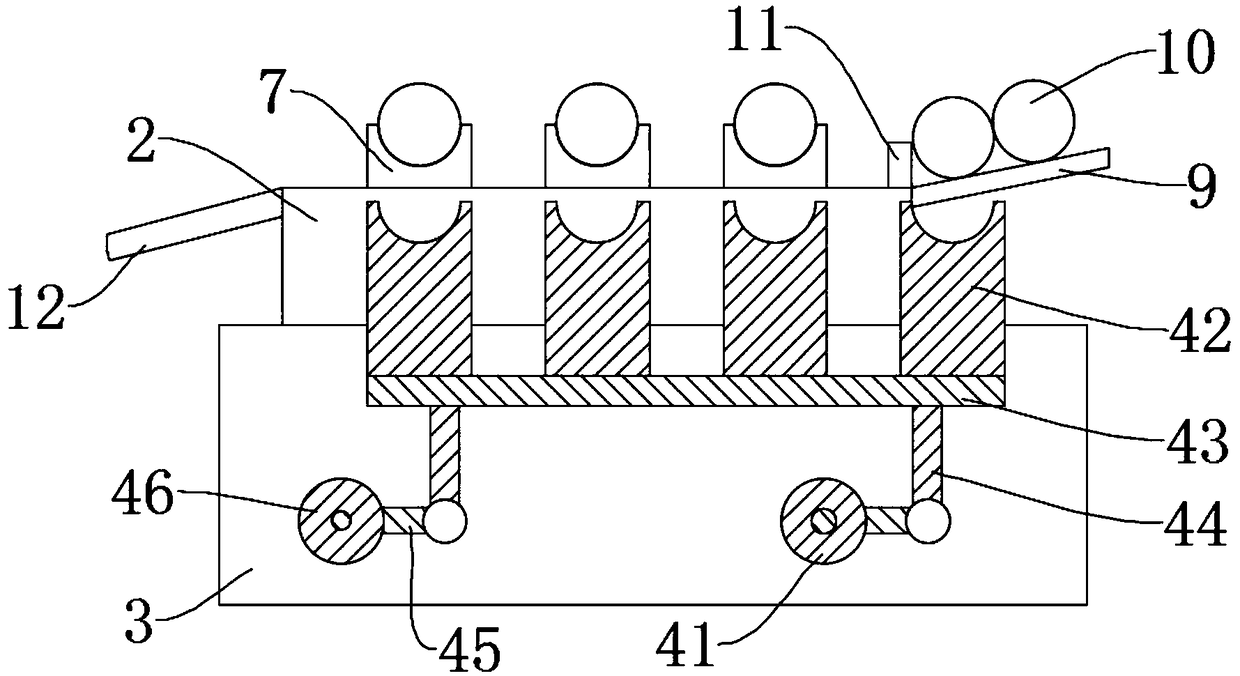

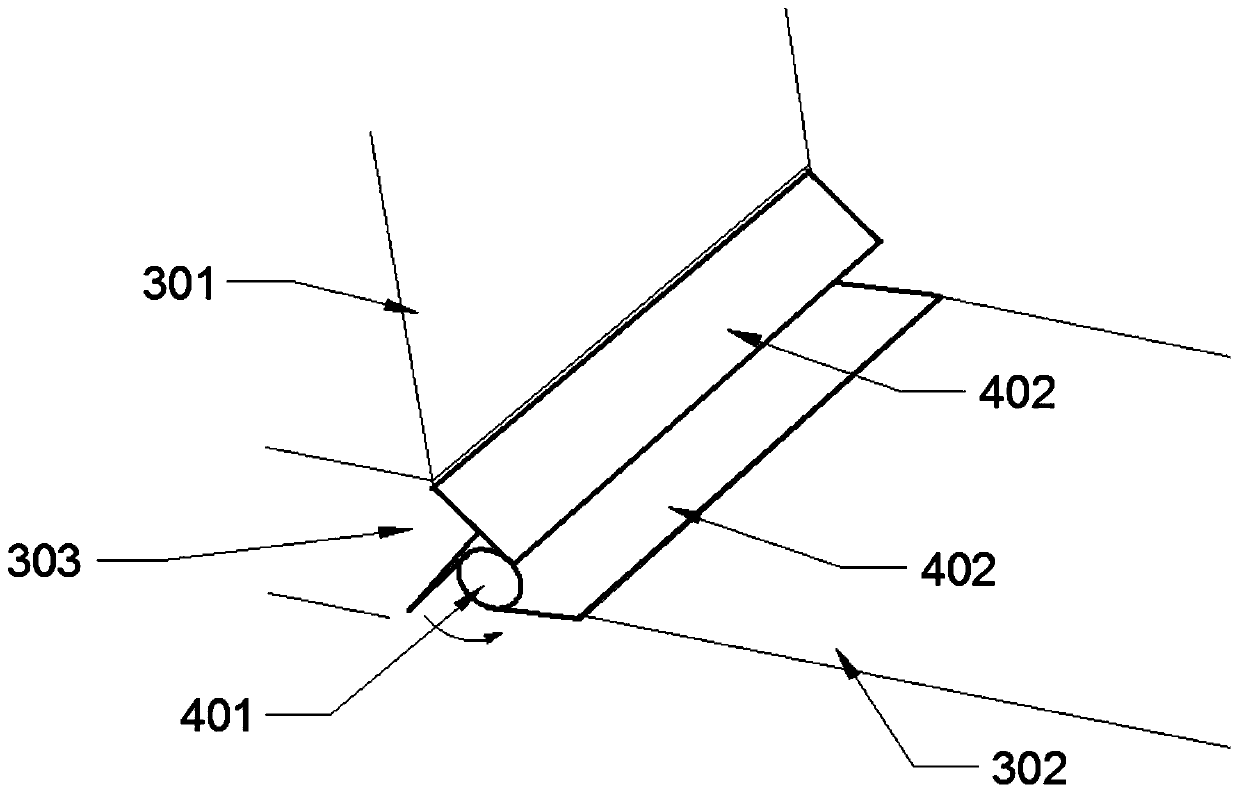

High-performance continuous forging and pressing device for alloy steel rods

ActiveCN109261883AEasy to forgeEasy to transport awayEngine componentsHandling devicesMotor driveMaterials science

The invention discloses a high-performance continuous forging and pressing device for alloy steel rods. The device includes a worktable, a sliding groove is formed in the worktable, a feeding groove is connected with one end of the sliding groove and contains the steel rods, the other end of the sliding groove is connected with a discharge groove, and a bearing platform is installed on the top ofthe sliding groove; fixing plates are installed on both sides of the bottom of the sliding groove, and a rotating shaft is rotatably sleeved with the fixing plates; a motor is installed on the fixingplate on one side of the sliding groove, an output shaft of the motor is connected with the rotating shaft, one end of the rotating shaft is provided with a conveying mechanism, the conveying mechanism is clamped into the sliding groove, a guide rail is installed on one side of the worktable, a clamping mechanism is installed between the guide rail and the other end of the rotating shaft, and a forging and pressing mechanism is installed on the other side of the worktable. The steel rods slide down along the feeding groove, the motor drives the rotating shaft to rotate, the conveying mechanismlifts the steel rods onto the bearing platform one by one, the rotating shaft drives the clamping mechanism to move at the same time, the clamping mechanism presses the steel rods on the bearing platform, and the forging and pressing mechanism conducts forging and pressing on the end face of each steel rod; after forging and pressing are finished, the clamping mechanism loosens the steel rods, and the conveying mechanism lifts the steel rods to the discharge groove.

Owner:安徽震祥精工科技有限公司

Special waste sorting vehicle for treatment rooms

The invention discloses a special waste sorting vehicle for treatment rooms. The special waste sorting vehicle comprises a vehicle body and a cover plate mechanism, wherein a household waste tank, an invasive medical waste tank, an ampoule waste tank and an infectious medical waste tank are arranged in the vehicle body; universal wheels are arranged at the bottom of the vehicle body and provided with brake devices; a sharp instrument box is arranged on a separating plate between the invasive medical waste tank and the ampoule waste tank; a waste bag accommodating cavity is formed in each waste tank; one bottom plate is fixedly connected with a front side plate of each waste bag accommodating cavity and adopts a drawer-type structure, and a waste bag is detachably mounted on the bottom plate by the aid of a rotating shaft; waste bag inlets and waste bag outlets are formed in the waste sorting vehicle. The special waste sorting vehicle is simple in structure and capable of facilitating waste sorting.

Owner:AFFILIATED HOSPITAL OF NANTONG UNIV

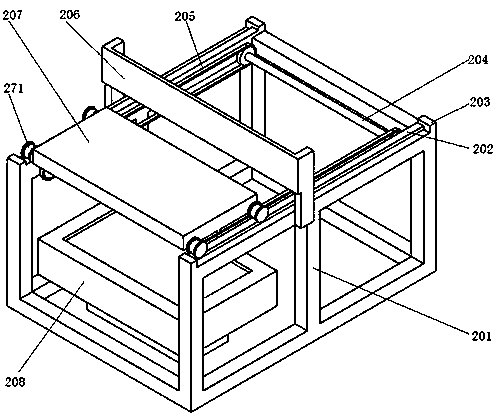

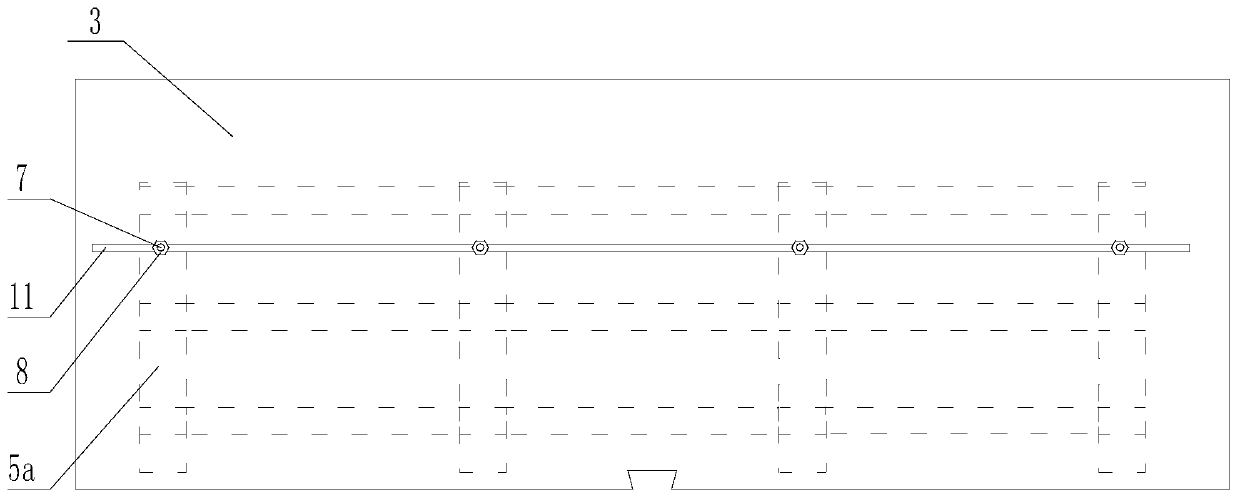

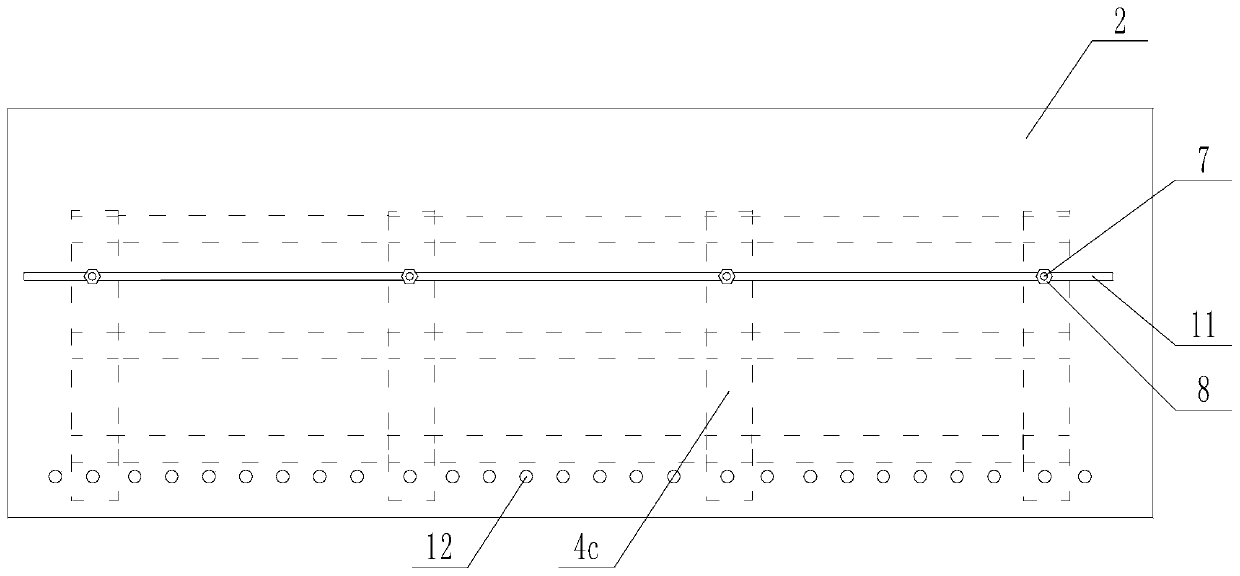

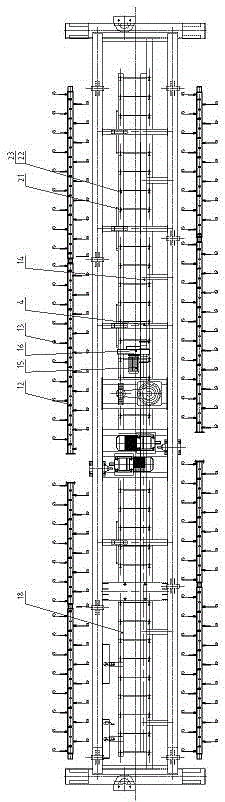

Spreading and turning type sludge treatment device

ActiveCN104355523AEven distribution of sludgeImprove work efficiencySludge treatment by de-watering/drying/thickeningSludgePulley

The invention relates to sludge treatment equipment, and particularly discloses a spreading and turning type sludge treatment device. The spreading and turning type sludge treatment device comprises a running frame formed by connection of two running supports and two connecting rods. The device is characterized in that the two connecting rods are connected through a plurality of evenly distributed support beams, small pulley assemblies are welded on the support beams, scraper beams are mounted at top ends of the small pulley assemblies, and scrapers are fixed on the scraper beams through hinge pins, cotter pins and gaskets; scraper motors are mounted on the support beams, swing rods are mounted on output shafts of the scraper motors and connected onto the scraper beams through rotating wheels, and sliding levers of the small pulley assemblies are connected onto the scraper beams through welding. The device can move transversely while moving longitudinally along a sludge tank, can spread sludge at any corner in the sludge tank, and can evenly distribute the sludge.

Owner:山东福航新能源环保股份有限公司

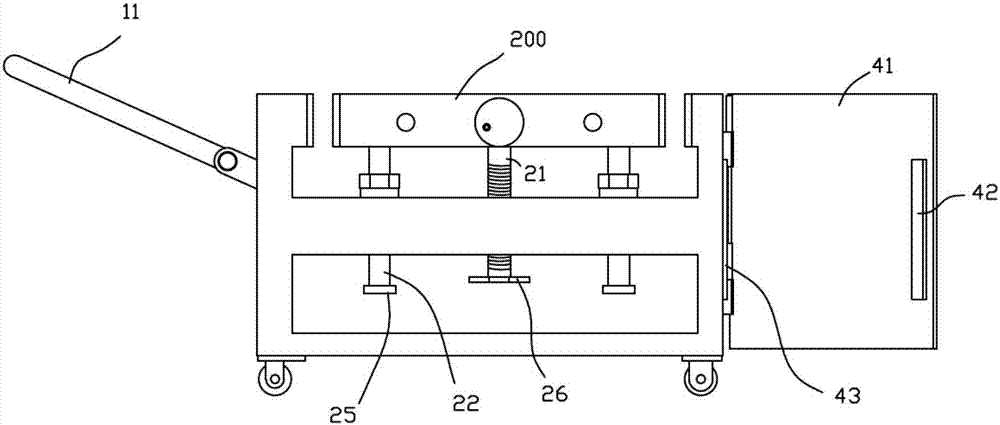

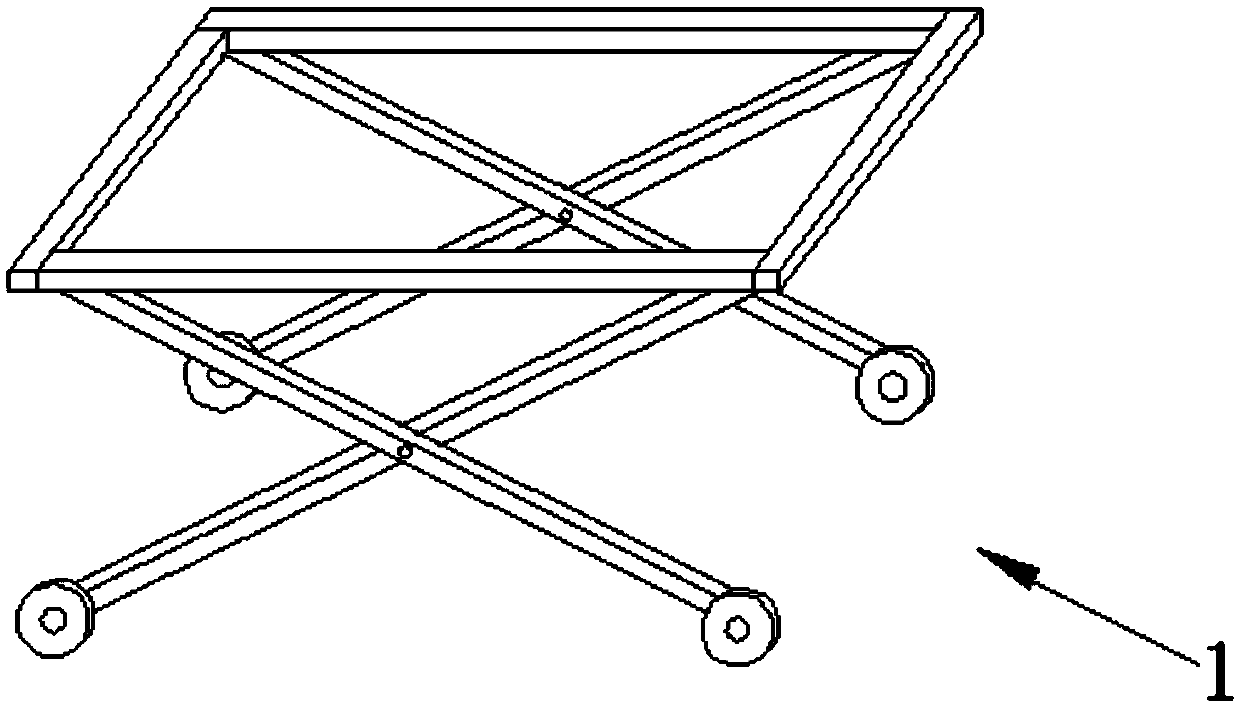

Carriage device for dyeing cloth basket

InactiveCN107117197AReduce labor intensityEasy to carry and transportSupporting partsHand carts with multiple axesEngineeringHandrail

The invention discloses a transporting device for printing and dyeing cloth baskets, which comprises a frame body, the bottom of the frame body is provided with rollers, the number of the roller wheels is four, and the front part of the frame body is provided with handrails; A support rod is arranged between the two side parts, and a height adjustment assembly is arranged above the support rod, and the height adjustment assembly includes a movable block, which can be adjusted in the vertical height direction; the movable The side of the block is provided with a horizontal clamping assembly, the horizontal clamping assembly includes a splint, and the splint can move horizontally; the tail of the frame is also provided with a baffle assembly, and the baffle assembly includes a baffle, so The baffle is hinged to the frame. It has designed a turnover vehicle specially used for carrying plastic baskets loaded with cloth. The vehicle is convenient and quick to transport and can effectively reduce the labor intensity of personnel.

Owner:HUZHOU YOUCHUANG TECH CO LTD

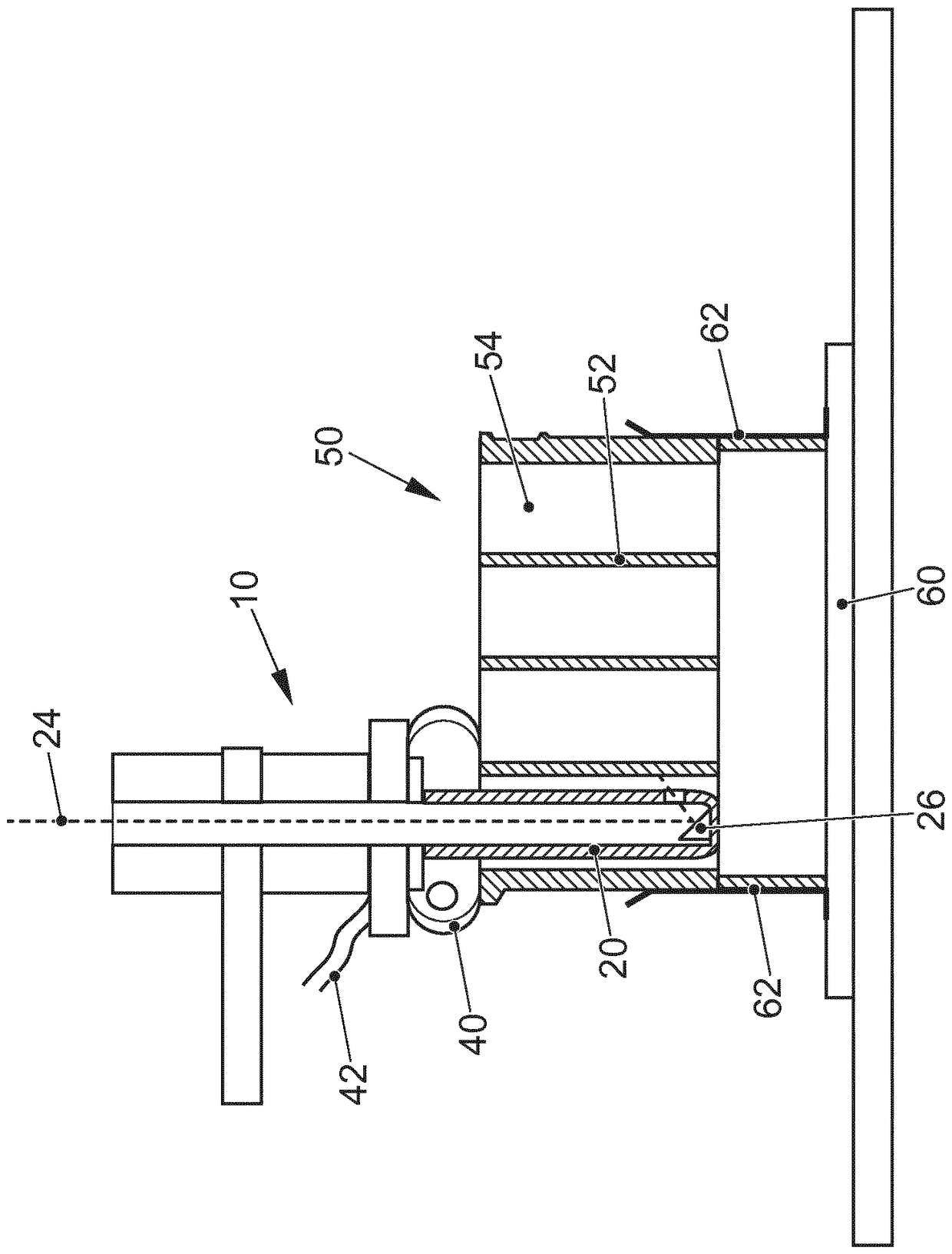

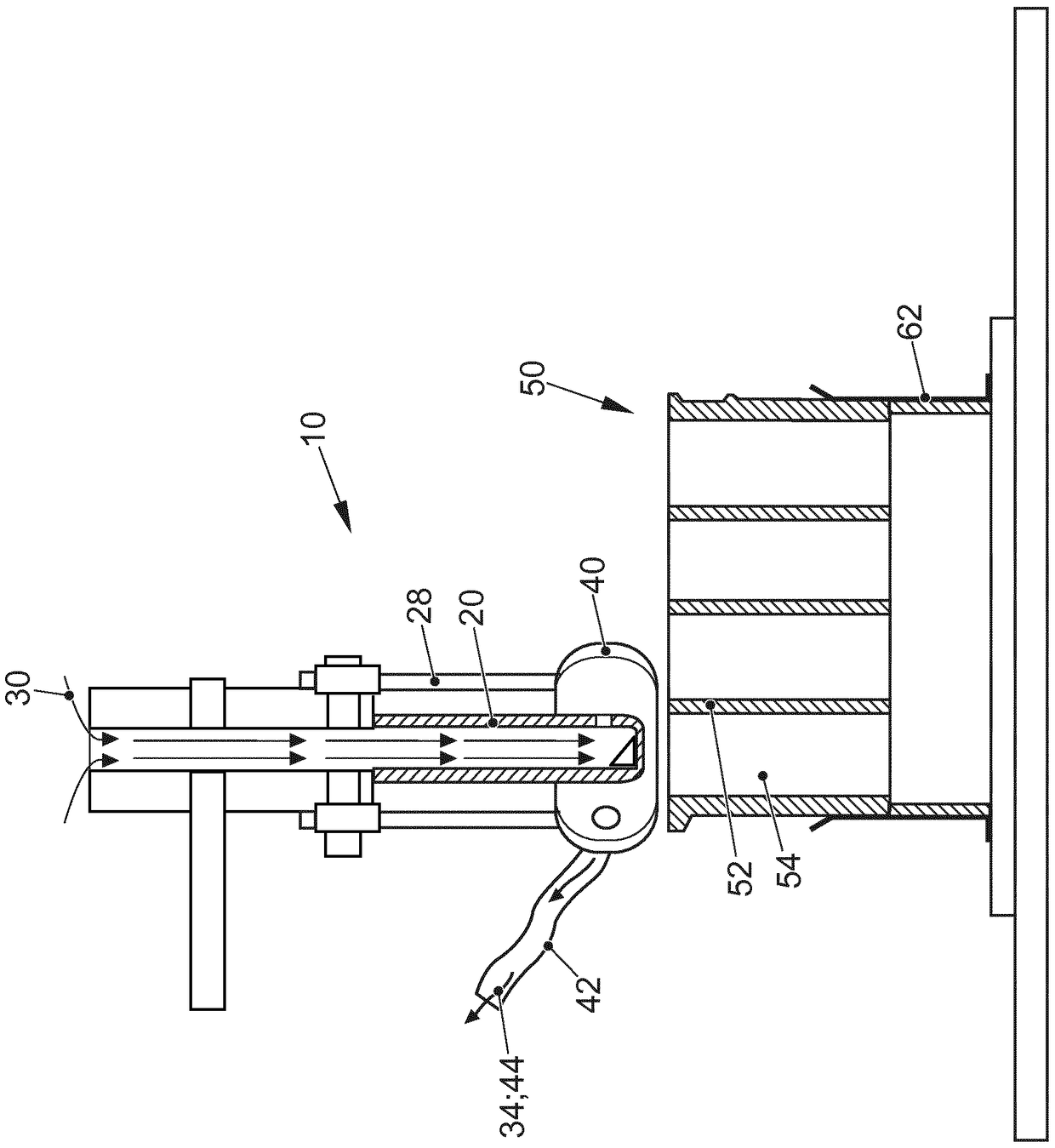

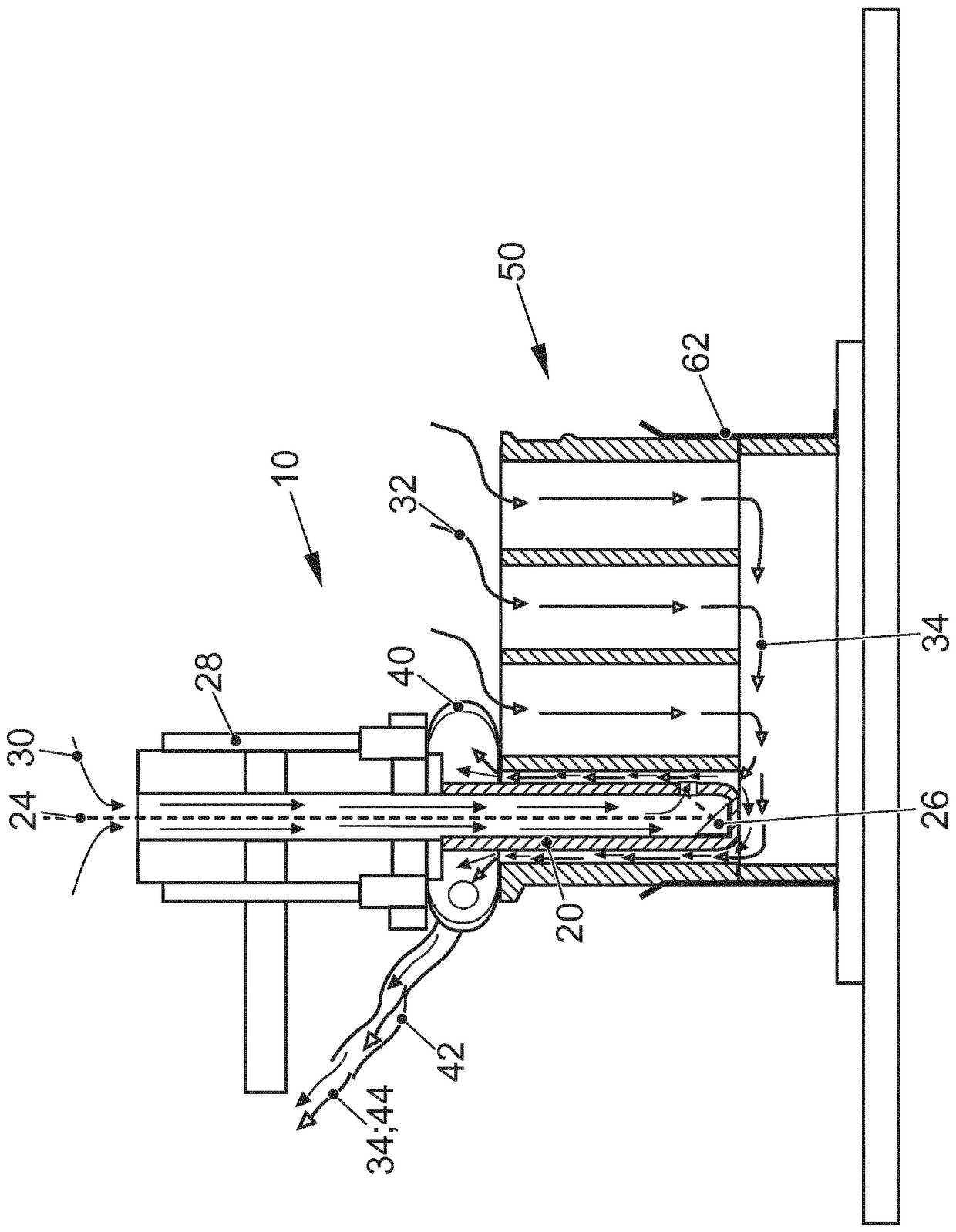

Method for surface machining, method for producing an engine block, device for surface machining and motor vehicle

ActiveCN109475968AEasy to drive toSuction volume flow reductionArc welding apparatusVehicle componentsInternal combustion engineMachine tool

The invention relates to a method for machining the surface of a cavity, particularly a piston track of a cylinder of an internal combustion engine block (50), according to which the cavity is provided, a machining tool (20) is inserted into the cavity, and the surface of the cavity is machined using the machining tool (20). Furthermore, a flushing gas (30) is introduced into the cavity and a suction system is connected to an opening in the cavity in order to suck out flushing gas (30) and particles that may have been produced during the machining.

Owner:VOLKSWAGEN AG

Bearing machining equipment with waste material collection function

InactiveCN108453296AEasy to transport awayAvoid injuryMilling equipment detailsMaintainance and safety accessoriesRotary stageResist

The invention discloses bearing machining equipment with a waste material collection function. The bearing machining equipment comprises a supporting frame, wherein the upper end of the supporting frame is fixedly connected with a supporting table; a supporting rod is mounted at the right end of the supporting table; a rotating table is mounted at the upper end of the supporting rod; one end of the rotating table is connected with a cantilever; a variable-frequency speed adjuster is mounted at the end, which is far away from the rotating table, of the cantilever; the lower end of the variable-frequency speed adjuster is fixedly connected with a guide column; the lower end of the guide column is connected with a fixed block; a milling cutter is mounted at the lower end of the fixed block; two clamping blocks are symmetrically mounted below the milling cutter; the lower ends of the clamping blocks are connected with a fixed seat. The bearing machining equipment disclosed by the inventioncan resist scrap iron in a bearing machining process through a baffle plate, so as to prevent the scraps from injuring people; the scrap iron can be collected through a material feeding hopper and acooling tank; a fan can cool the scrap iron through a ventilating mesh; an air discharging pipe can be removed through an insertion slot, so that the scrap irons can be transported away more conveniently when being accumulated to a certain extent.

Owner:YANCHENG SANCHUAN BEARING MFG

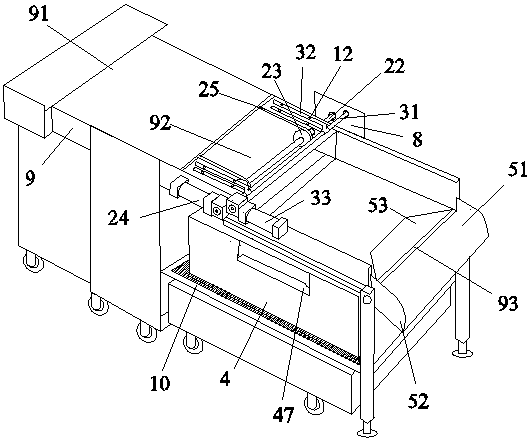

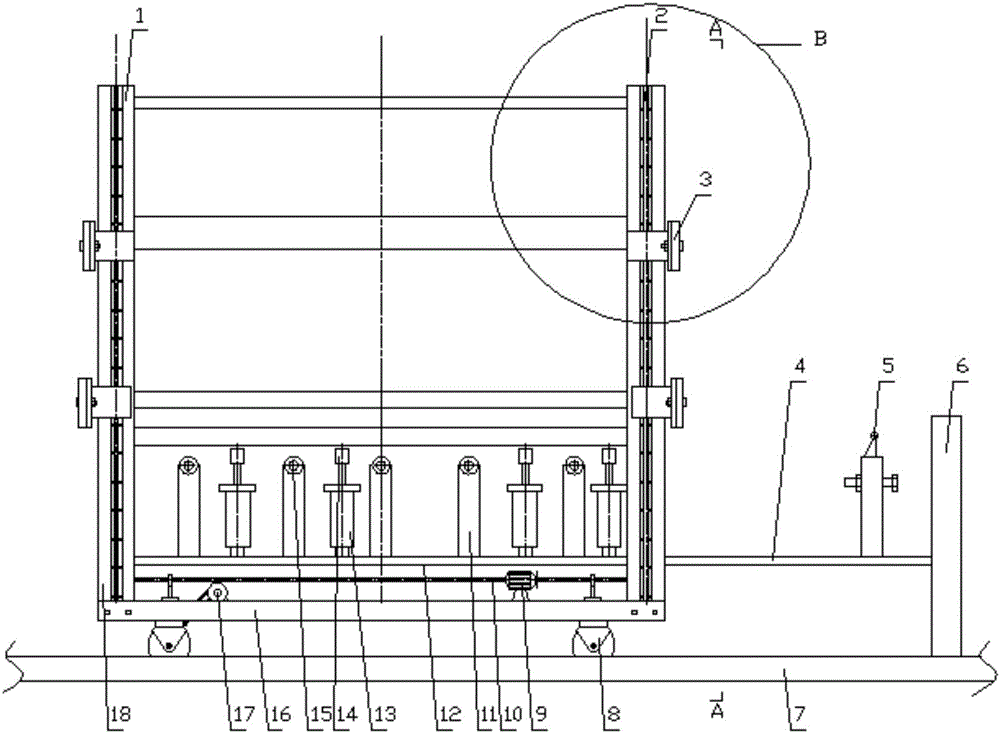

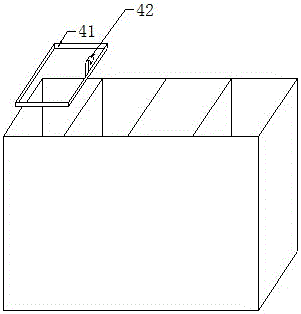

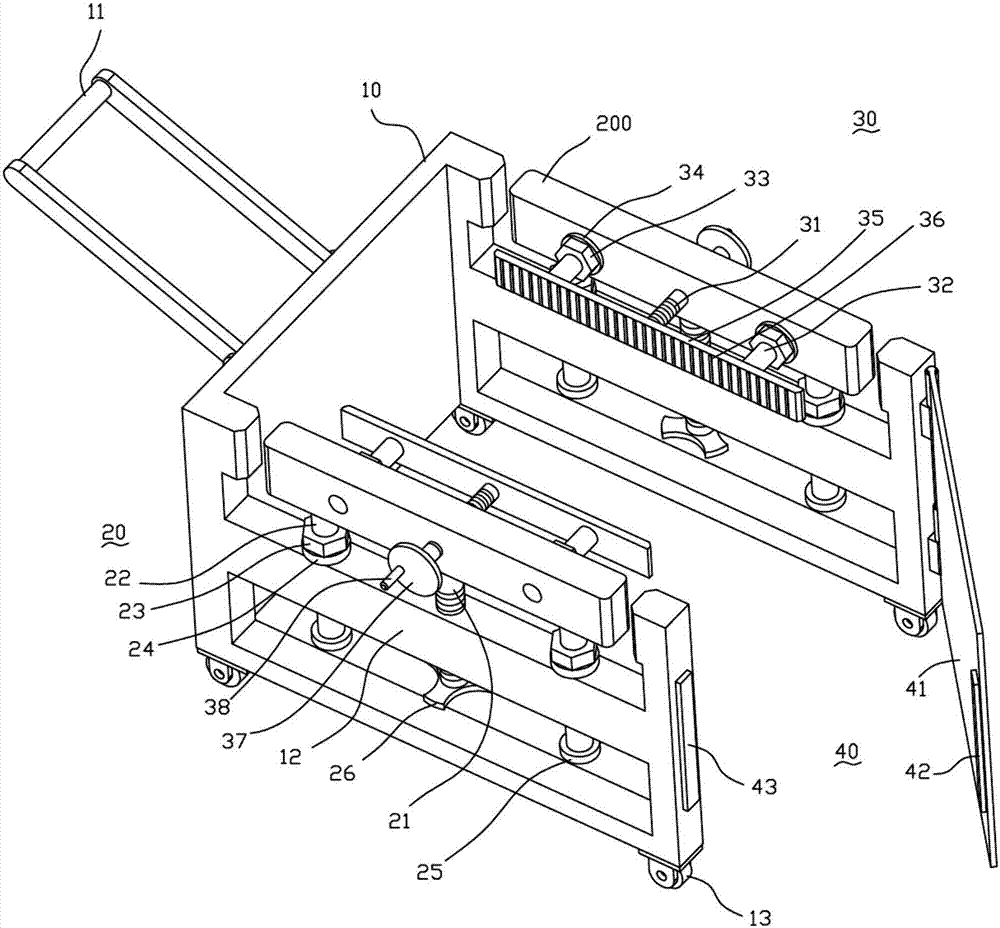

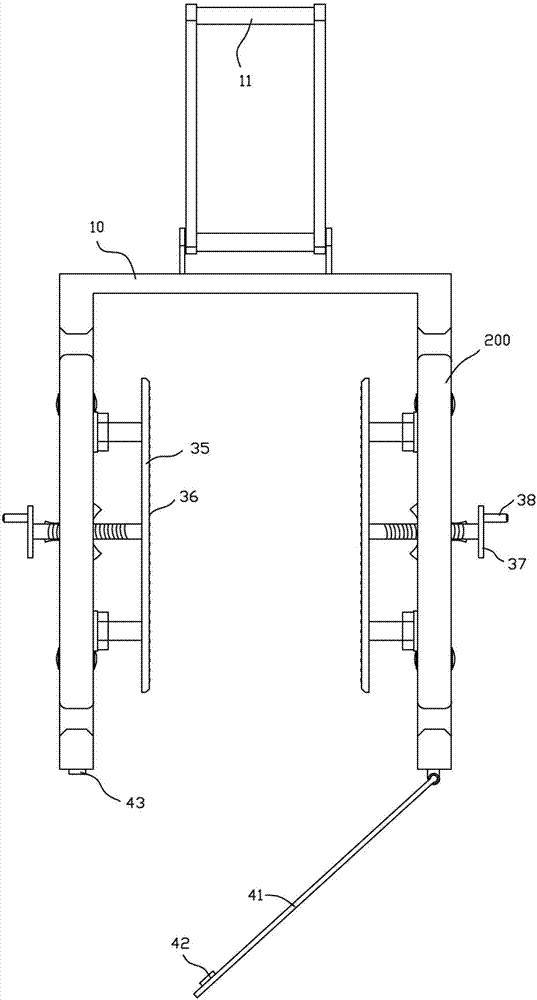

Material collecting mechanism of sanding machine

InactiveCN105563312AIt is convenient for the forklift to load and transport the platesEasy to take awayGrinding machine componentsElectrical and Electronics engineeringEngineering

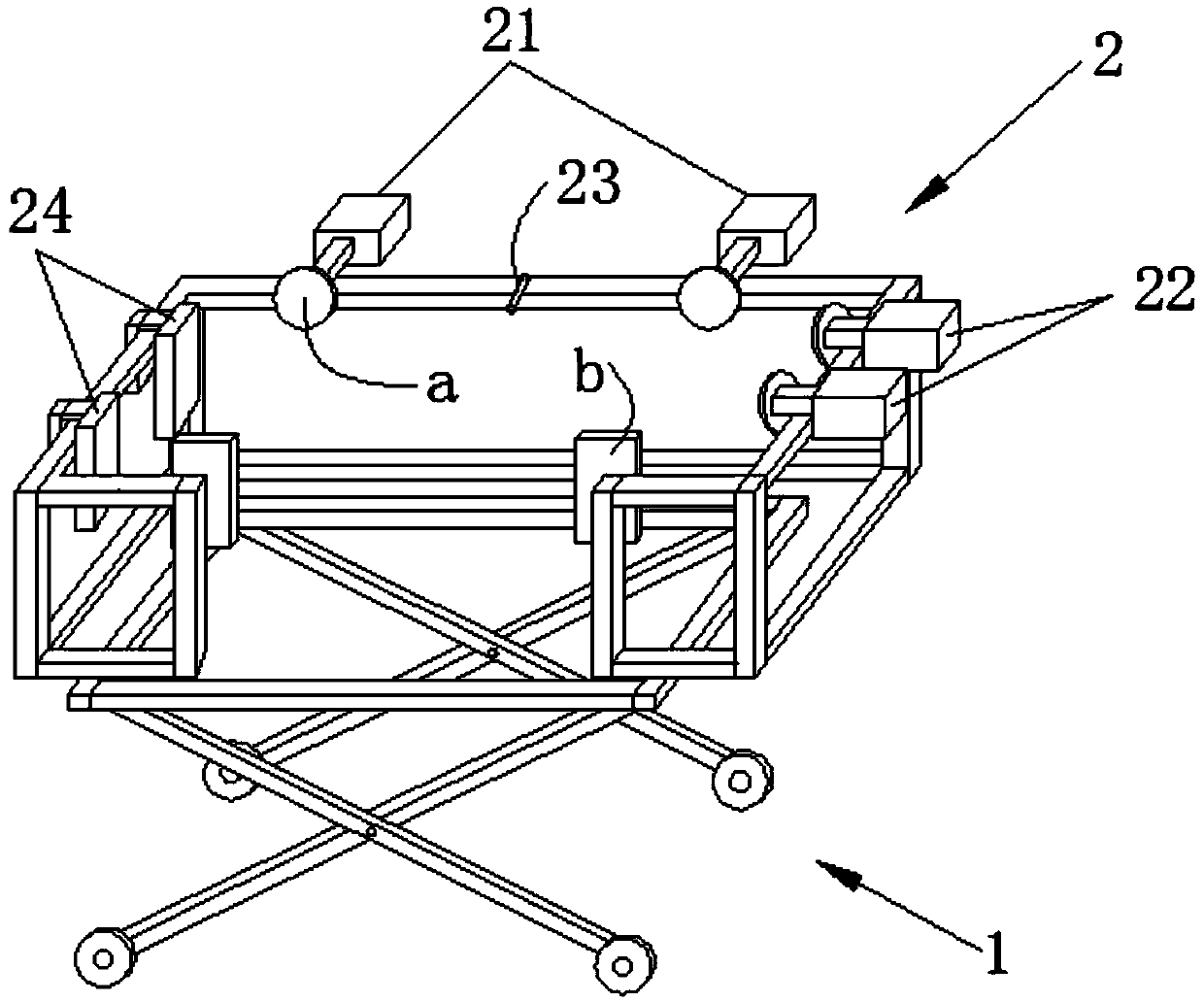

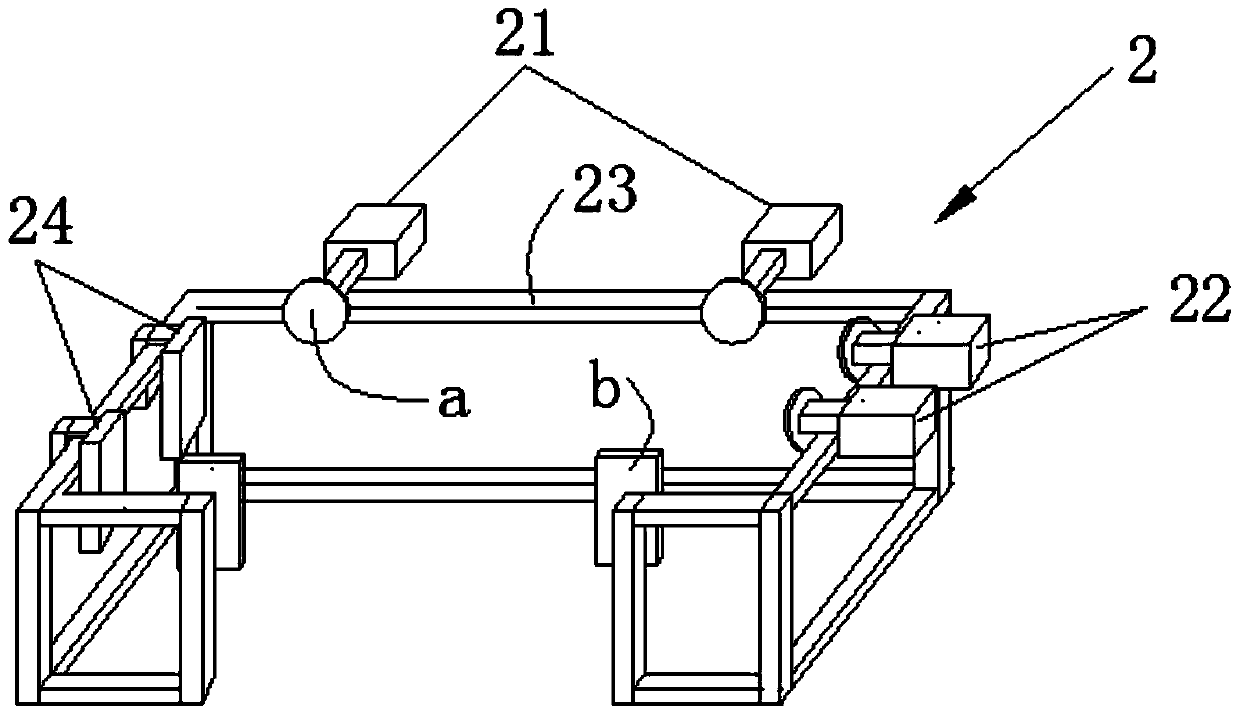

The invention provides a material collecting mechanism of a sanding machine. The material collecting mechanism is arranged at the discharging end of the sanding machine and comprises a lifting device. The material collecting mechanism further comprises a material collecting frame provided with a cavity for containing panels. The lifting device is arranged in the cavity. The material collecting frame is provided with first alignment devices and second alignment devices. The first alignment devices and the second alignment devices do a forward or backward movement towards the center of the cavity in the horizontal direction. The included angle between the first alignment devices and the second alignment devices in the horizontal direction is 90 degrees. The first alignment devices and the second alignment devices are located on the same horizontal plane. The first alignment devices, the second alignment devices and the material collecting frame are matched to finish the alignment work of the panels. Compared with the prior art, the first alignment devices and the second alignment devices push long edges and opposite edges of the panels, and under the cooperation of the material collecting frame, the panels are aligned.

Owner:ANHUI ANSU WORLD HOME CO LTD

Collection device for cutting iron chips

PendingCN107285068AEnergy savingSolve the spatter of iron filingsConveyorsLoading/unloadingElectric driveScrap

The invention relates to a collection device for cutting iron chips, and relates to the field of mechanical equipment. According to the collection device for the cutting iron chips, compared with the prior art, the characteristics of being clean and environment-friendly, and energy-saving are achieved through adopting electric drive, and in addition, the iron chips are collected through a magnetic bottom plate, and the problem of splashing of the iron chips during a production process is effectively solved; meanwhile, the device is provided with a waste bin and a waste basket, the waste basket facilitates a user to carry away the generated iron chips at any time, the waste bin is capable of conveniently collecting the iron chips left on the magnetic bottom plate, and a better utilization effect is achieved; and in addition, the device is provided with a control panel, and the user can control running of the device according to an actual need, so that use efficiency of the device is increased.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

Wood board discharging and stacking mechanism

InactiveCN108687873AGuaranteed surface qualityDoes not cause tiltStacking articlesDischarging equipmentMechanical engineering

Owner:惠忠州

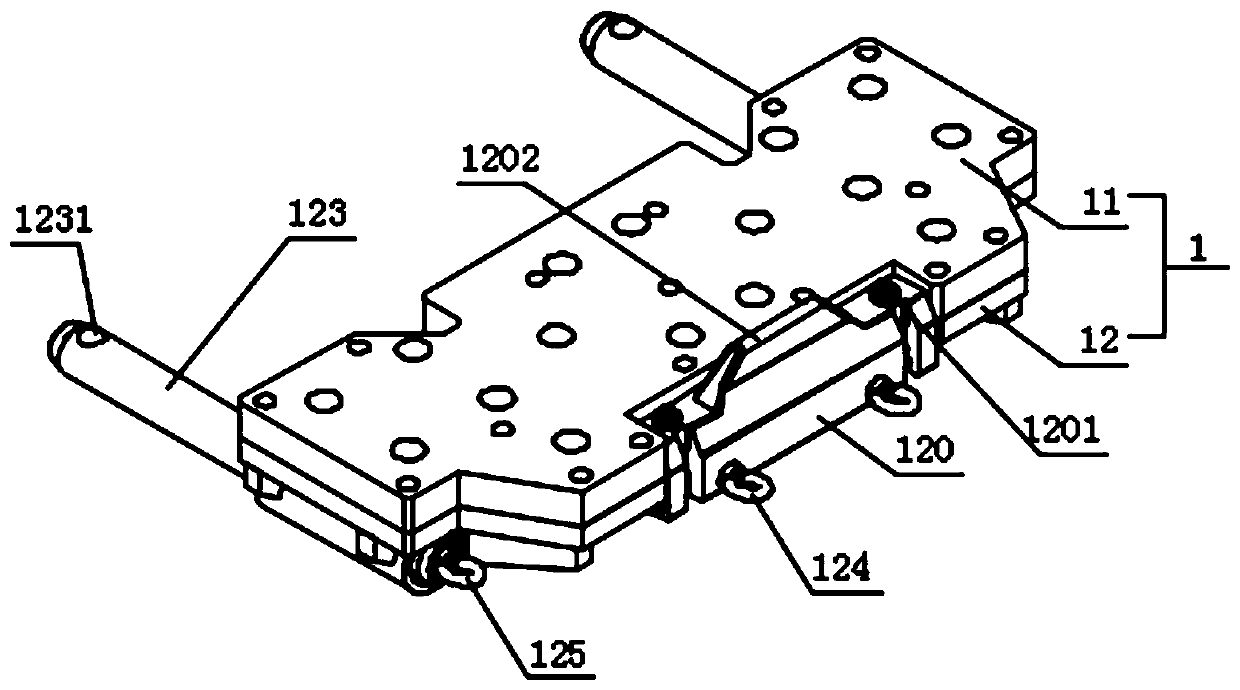

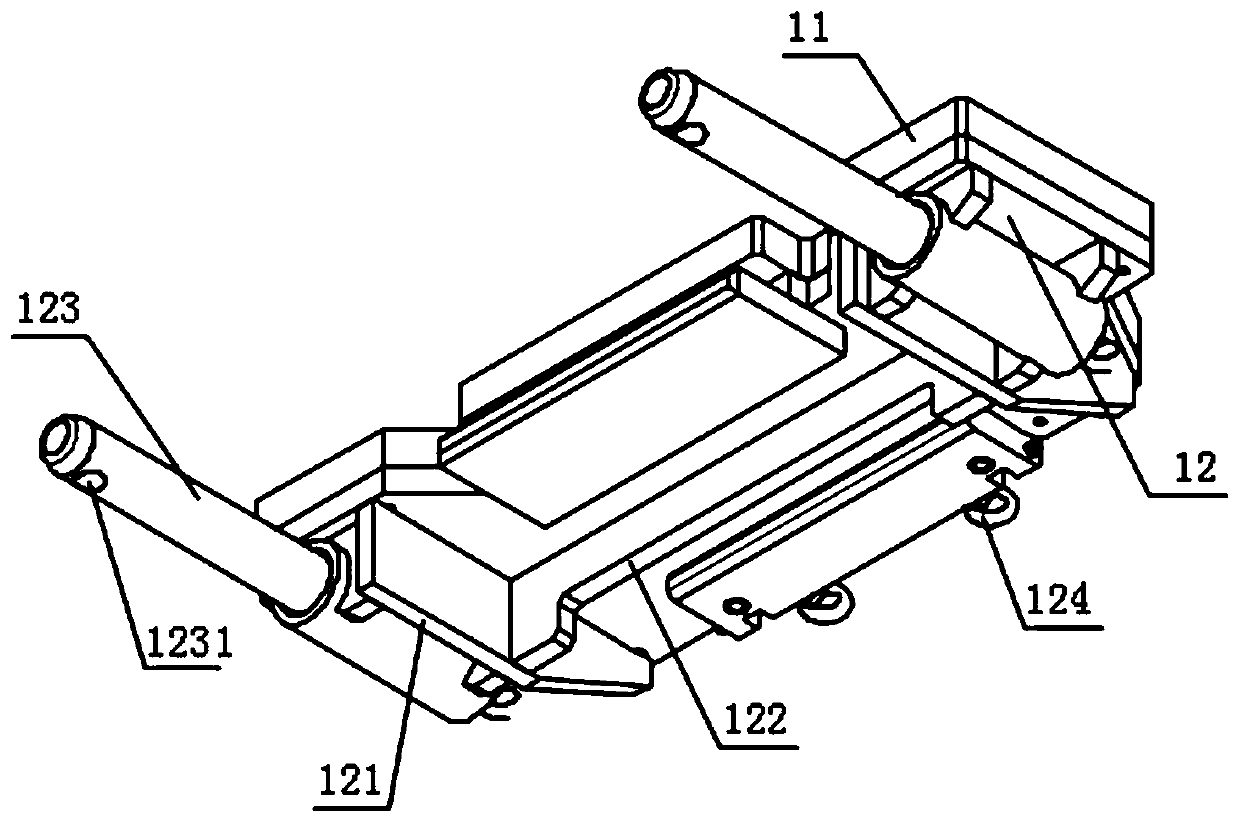

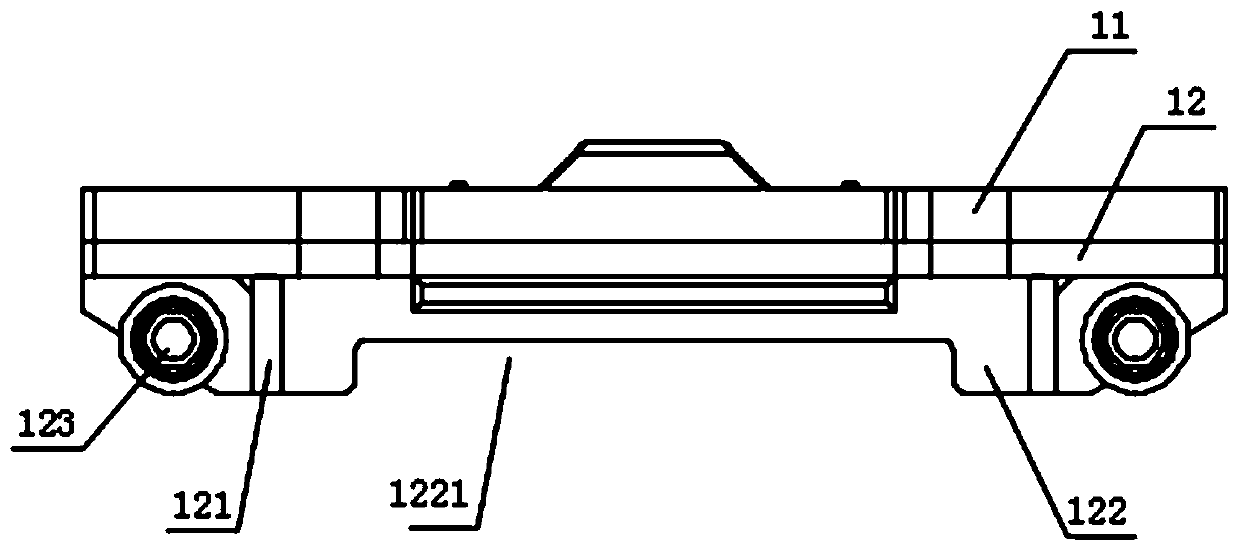

Clamping and pushing tool for lengthening AGV loading vehicle

PendingCN110843961AEasy to installEasy to disassembleHand carts with multiple axesVehicle frameLoad carriage

The invention belongs to the technical field of AGV loading vehicles, and particularly relates to a clamping and pushing tool for lengthening an AGV loading vehicle. The clamping and pushing tool comprises a lengthening assembly and a cart matched with the lengthening assembly; the lengthening assembly comprises a mounting base, a bearing plate is detachably mounted on the mounting base, a plurality of connecting rods which are parallel to one another are fixedly connected to the front end of the mounting base, and a pin hole is formed in the front end of each connecting rod; and the cart comprises a frame, a plurality of wheels are rotatably mounted on the lower portion of the frame, and the mounting seat is movably connected to the upper portion of the frame. The problem that a single person cannot replace a tool to transport a large workpiece is solved.

Owner:TIANJIN LONYU SCI & TECH PROGRESS

Sludge collecting vehicle with spiral separation mechanism

ActiveCN111501644AAchieve separationEasy to transport awaySludge treatmentRoad cleaningMechanical engineeringSludge

The invention discloses a sludge collection vehicle with a spiral separation mechanism. The sludge collection vehicle comprises a vehicle body, a sludge collecting mechanism which is arranged on the vehicle body, is close to the ground and is used for collecting sludge on the ground when the vehicle body runs; a stirring pool which is arranged in the vehicle body, the stirring pool is connected with the sludge collecting mechanism through a water inlet pipe provided with a water pump, and the stirring pool is further connected with the sludge-water separating mechanism through a water outlet pipe provided with a water pump; a mud-water separation mechanism, wherein the mechanism is arranged in the vehicle body and comprises an inner wall of a hollow inverted-cone-shaped structure. A feeding hole communicated with the water outlet pipe is formed in the top of the inner wall; the water outlet direction of the feeding hole is tangent to the cross section of the inner wall where the feeding hole is formed; the inner wall is provided with a plurality of meshes, muddy water sprayed out of the feeding port spirally flows downwards along the inner wall, the muddy water is made to move in acentrifugal mode, water in the muddy water is thrown out of the meshes, and sludge left after flood disasters on streets is collected.

Owner:广东润威建设工程有限公司

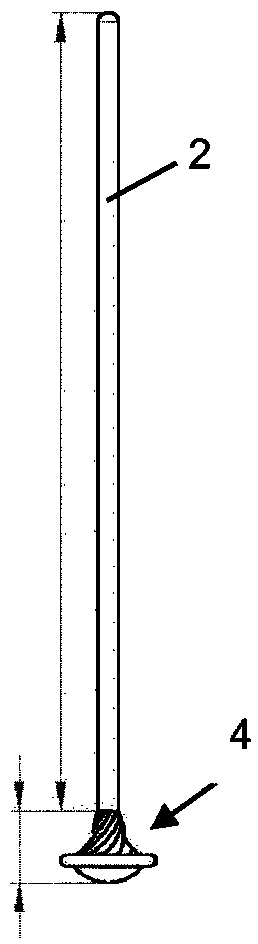

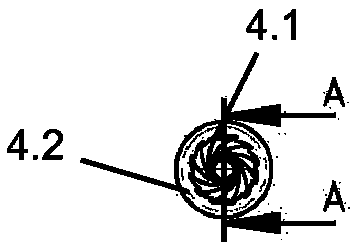

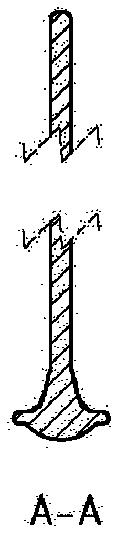

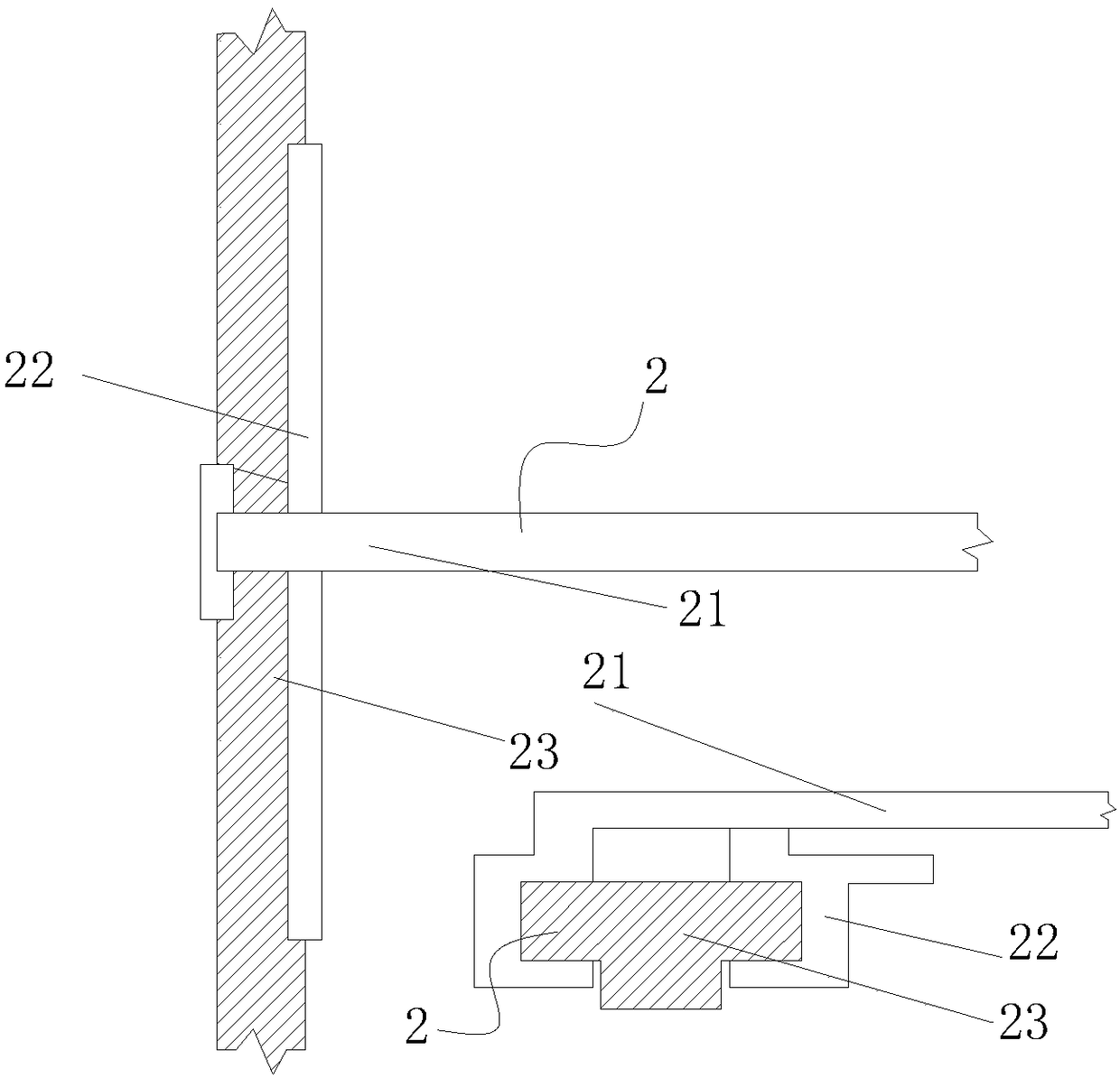

Surgical milling cutter

InactiveCN109475359AConvenient spacingSolve the lack of cooling capacityDiagnosticsSurgeryMilling cutterFlemming body

The invention relates to a surgical milling cutter which is designed to remove bone and / or cartilage tissue, comprising a shaft (2) which extends along a longitudinal axis, can rotate about same, andcan be releasably connected to a drive device and which has a proximal end that can be rotationally fixed to a drive unit and a distal end lying opposite the proximal end. A milling surface (4.1) which circumferentially surrounds the shaft (2) and extends on the distal end along the longitudinal axis of the shaft (2) is formed at the distal end, said milling surface protruding radially from the shaft and having a milling surface maximum radius R1. The aim of the invention is to prevent unwanted damage to delicate body structures. This is achieved by an atraumatic design in that a protective assembly is provided on the distal end. The protective assembly has a distal support surface and a protective assembly maximum radius R2 in order to form a protective ring (4.2) which surrounds the milling surface maximum radius R1 in a circular manner.

Owner:SKAJSTER FAMILIENSTIFTUNG

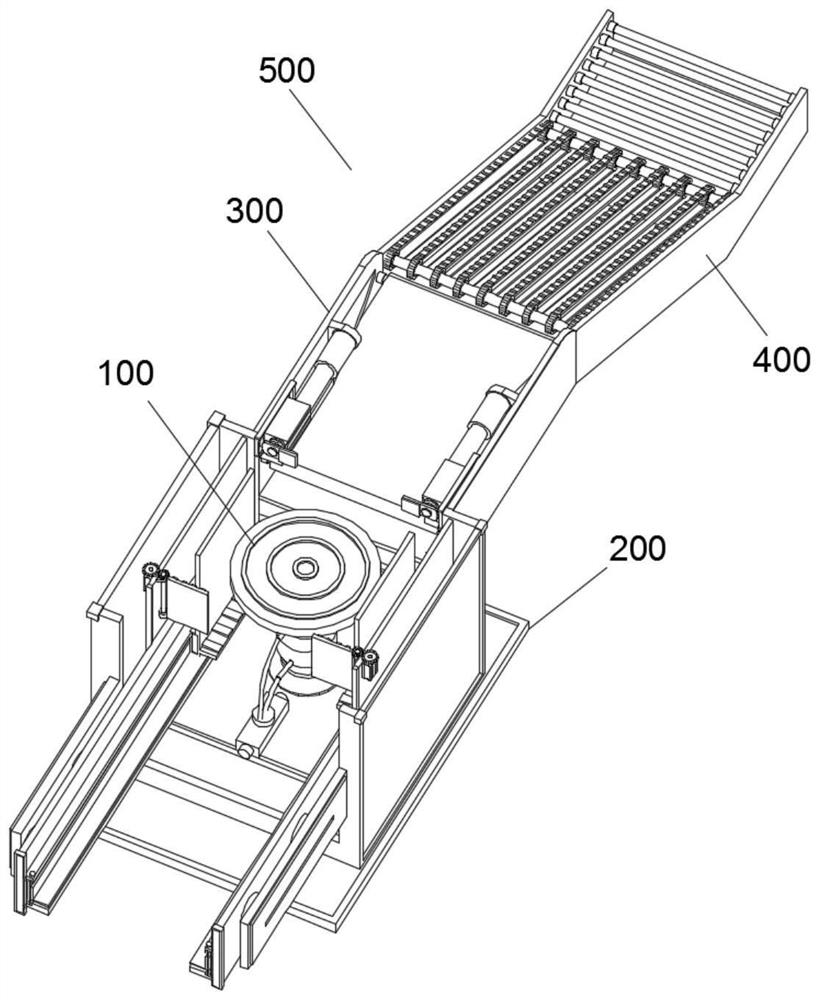

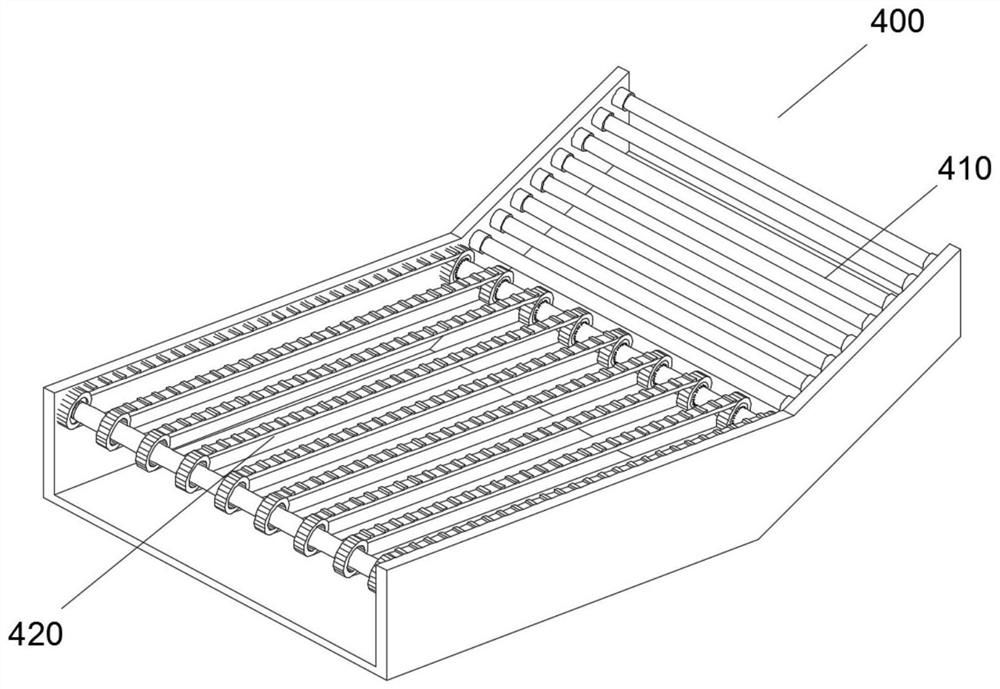

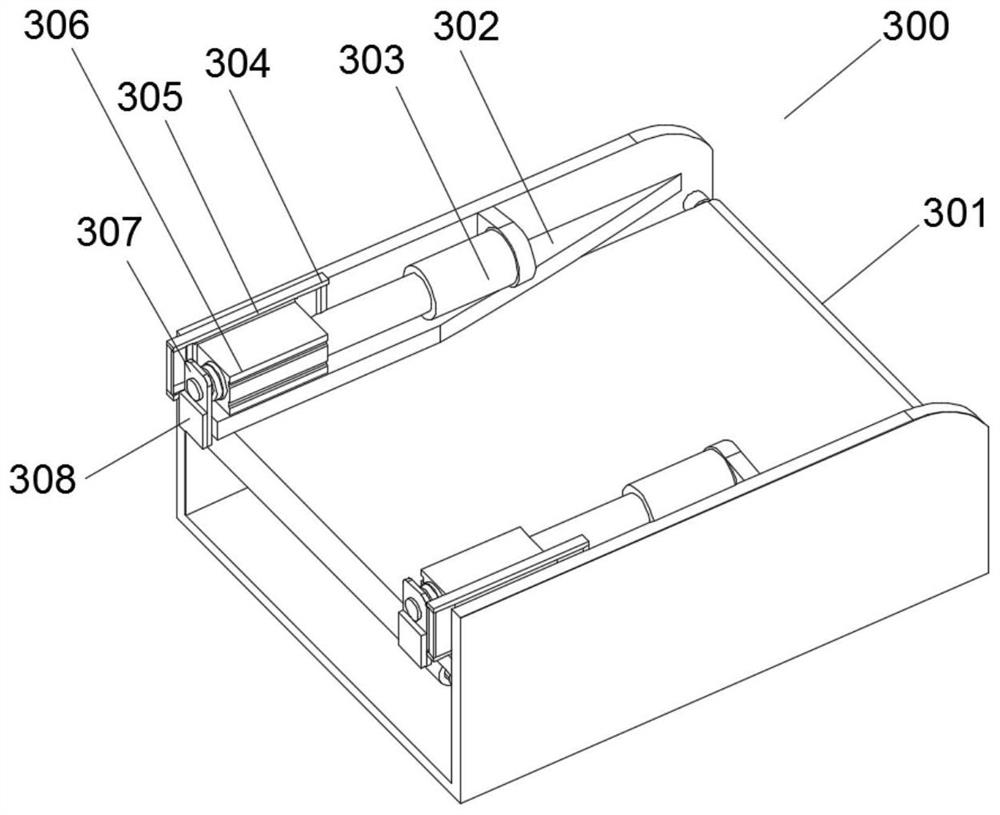

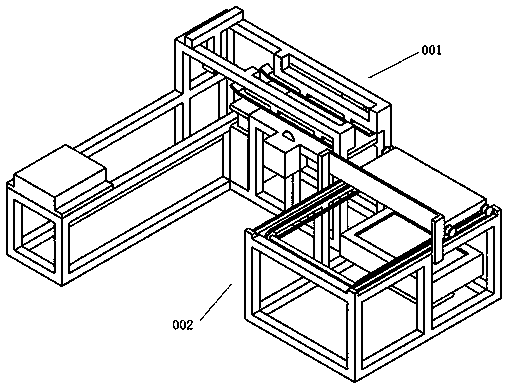

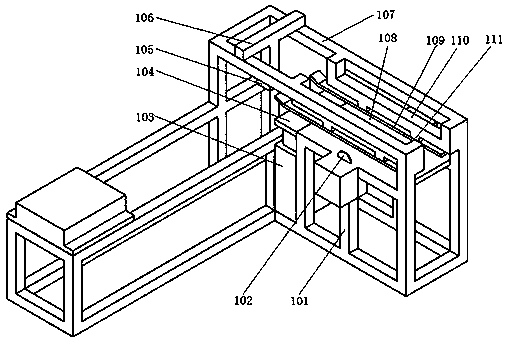

Automatic stacking and conveying equipment for plates

PendingCN114701865AWide range of applicationsLow costConveyorsStacking articlesEngineeringMechanical engineering

The invention discloses automatic stacking and conveying equipment for plates, and relates to the technical field of plate processing equipment.The automatic stacking and conveying equipment comprises an automatic stacking and conveying equipment body, a climbing device is installed at the right end of the automatic stacking and conveying equipment body, the left end of the climbing device is fixedly connected with an aligning device, and a stacking device is installed at the left end of the aligning device; a lifting device is installed on the inner wall of the bottom of the stacking device and further comprises a first roller conveying belt, one end of the first roller conveying belt is fixedly connected with a crawler belt conveying belt, the aligning device further comprises a second conveying belt, a centering plate is installed on the inner wall of one side of the aligning device, and the inner wall of one side of the aligning device is fixedly connected with an air cylinder. And a sliding rail is mounted on the inner wall of one side of the aligning device. The plate stacking device has the advantages that the plate stacking device is suitable for plates of different materials, the plates can be conveniently and automatically stacked, conveying is convenient, the aligning degree during stacking is improved, and the plate machining efficiency and stability are improved.

Owner:广东易典智能设备有限公司

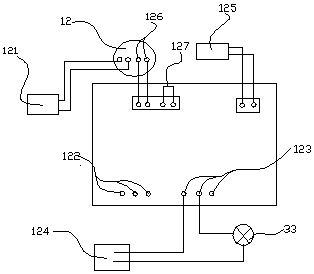

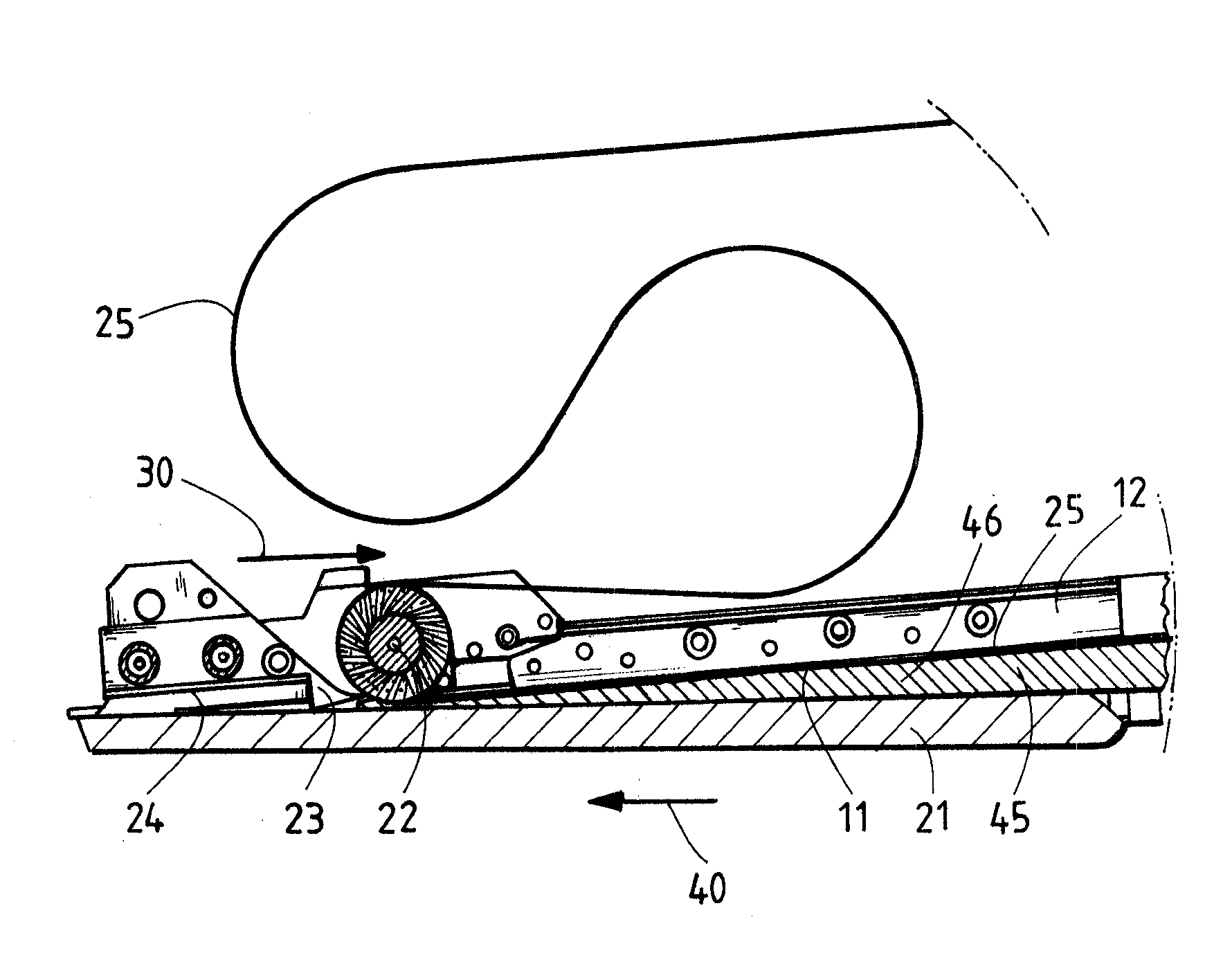

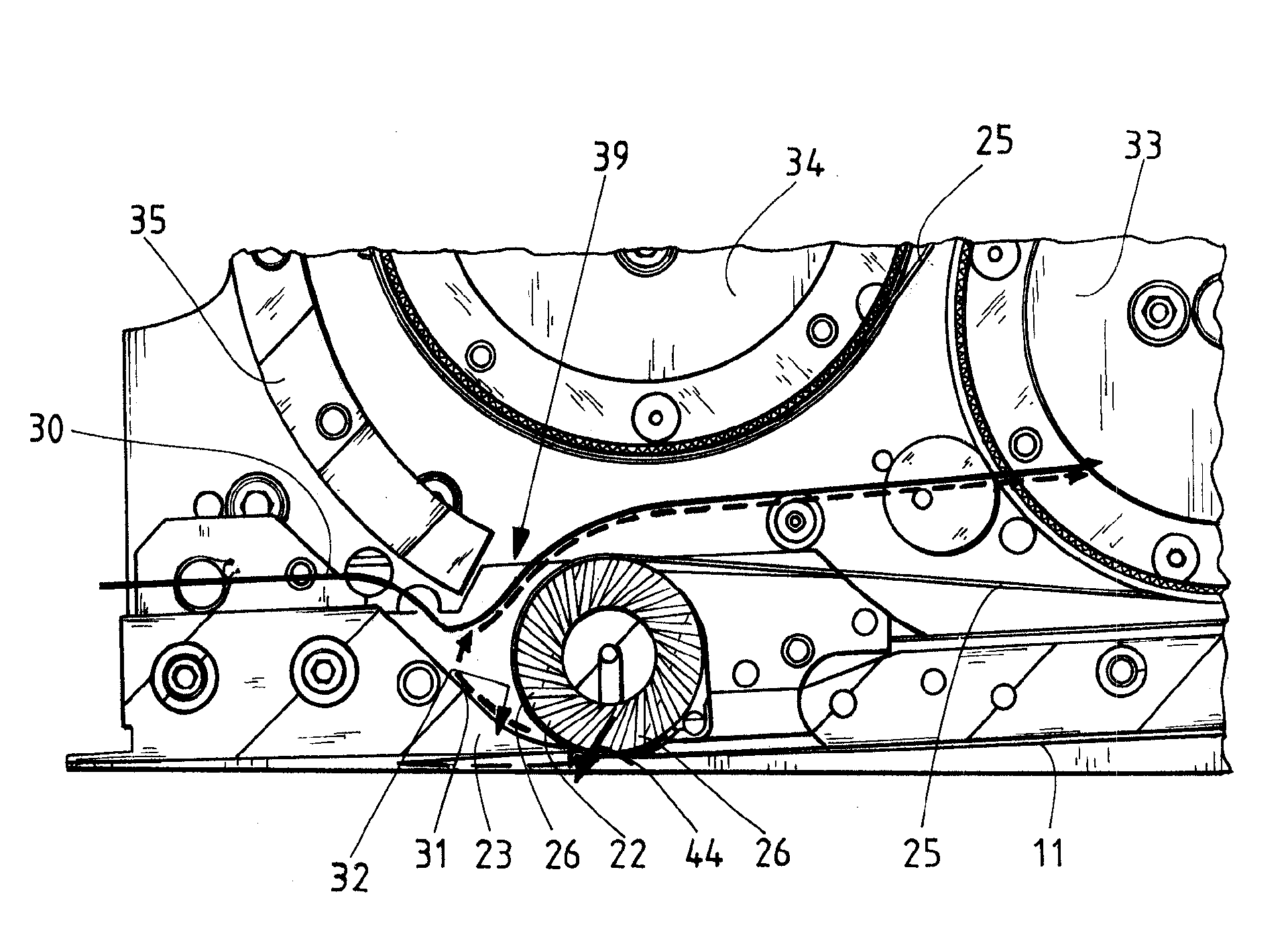

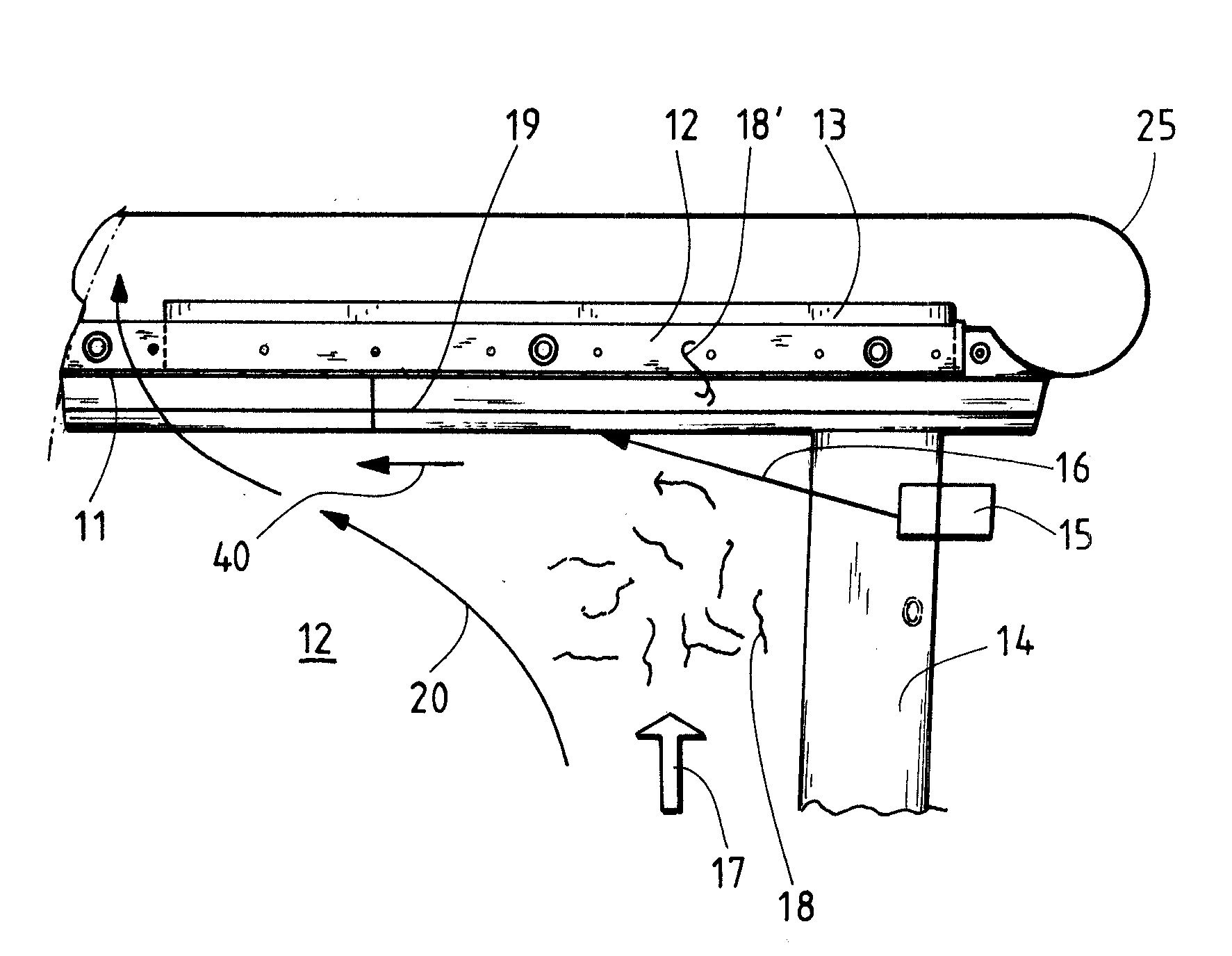

Device and method for manufacturing a continuous strand for the tobacco industry

InactiveCN102406232AAccelerated disengagementEasy to disengageCigarette manufactureTobacco smoke filtersEngineeringNozzle

The invention relates to manufacturing a continuous strand for the tobacco industry, the device has a suction strand conveyor (11) staying in active connection with a suction chamber (12) along a manufacturing path (38). The conveyor (11) is guided around a pressure disk (22) in a strand inlet region of lower and upper dimensioning devices (21, 24) forming the strand. A compressed air nozzle (36) is arranged upstream of the disk (22) in a region of the conveyor (11) on a side of the conveyor (11). The disk (22) includes air ducts (26) with openings on a circumferential surface of the disk. The ducts are inclinedly arranged in an angle to a radial of the disk and in or against a strand conveyor direction. An independent claim is also included for a method for manufacturing a continuous strand for a tobacco industry.

Owner:HAUNI MASCHINENBAU AG

Copper waste recycling device

PendingCN112454969AEasy to transportReasonable structural designPressesProcess efficiency improvementStructural engineeringWaste material

The invention discloses a copper waste recycling device. The device comprises a bottom plate, a feeding mechanism and a box body are arranged at the top of the bottom plate, a feeding port is formed at the upper end of the left side wall of an inner cavity of the box body, a material guiding nozzle is arranged below the right end of the feeding mechanism, the material guiding nozzle is fixedly connected with the box body, and an extruding mechanism is arranged at the top of the box body; door opening windows are symmetrically formed at the bottoms of the front side wall and the rear side wallof the inner cavity of the box body, a storage notch is formed in the right side wall of the inner cavity of the box body, a material uniformizing mechanism is arranged on the right side wall of the box body, the left end of the material uniformizing mechanism extends into the inner cavity of the box body through the storage notch, a pushing mechanism is arranged on the rear side wall of the box body, and a material moving mechanism is arranged at the front side of the box body; and a tray is arranged at the front side of an inner cavity of the material moving mechanism, and a power door assembly is arranged at the right side of the box body. The copper waste recycling device is reasonable in structural design, copper waste can be conveniently and rapidly extruded and shrunk to form block-shaped objects, occupied space is reduced, the copper waste can be conveniently carried away, recycled and reused, and the manual work difficulty is reduced.

Owner:安徽瀚中菲欧新材料有限公司

A flood control dam with mud-water separation device

ActiveCN111485534BAchieve separationEasy to transport awayBarrages/weirsClimate change adaptationEnvironmental engineeringFlood control

Owner:广东润威建设工程有限公司

Corner cutting device for non-woven fabric processing

The invention discloses a corner cutting device for non-woven fabric processing. The cutting device comprises a non-woven fabric cutting machine body, fixing grooves are respectively formed in the left and right sides of the non-woven fabric cutting machine, and a non-woven fabric anti-displacement pressing device is arranged on the upper surface of the non-woven fabric cutting machine body; according to the corner cutting device, a collecting box is extra arranged on the basis of the non-woven fabric cutting machine body, a rotary shaft slidably connected with a motor is arranged inside the collecting box, and the front end of a non-woven fabric is stuck to a shaft sleeve of the rotary shaft so that the processed non-woven fabric products can be rolled up when the rotary shaft rotates; pulleys are arranged at the lower end of the collecting box, the heavy products can be conveniently transported, the non-woven fabric anti-displacement pressing device is arranged on the upper end of the non-woven fabric cutting machine body, and a barrier strip can avoid slight displacement of the non-woven fabric and can move to a suitable position through sliding for pressing and displacement prevention.

Owner:ANHUI CAREMIC CONSULTING CO LTD

Transverse edge cutting and stacking device of plywood edge cutting machine

InactiveCN108687889AQuality assuranceAvoid scratchesOther plywood/veneer working apparatusVertical edgeEngineering

The invention discloses a transverse edge cutting and stacking device of a plywood edge cutting machine. The transverse edge cutting and stacking device of the plywood edge cutting machine comprises atransverse edge cutting device and a stacking device. When plywood enters the part between a pressing strip and a tabletop, a lifting table descends, the plywood smoothly enters the part between thepressing strip and the lifting table, and after most of the plywood enters the part between the pressing strip and the lifting table, the lifting table ascends, the plywood is tightly pressed throughthe pressing strip and the lifting table, the situation that corner angles of cut vertical edges of the plywood are scratched is avoided, and the plywood quality is guaranteed; and after the plywood is subjected to edge cutting, the plywood is pushed to the movable supporting plate, then, the movable supporting plate moves rightwards, a template falls onto a stacking lifting table due to stoppingof a discharging baffle, no relative movement exists between the pushed plywood and plywood below the pushed plywood, and the surface quality and tidy panel stacking of the plywood are guaranteed.

Owner:惠忠州

A paving and throwing type sludge treatment device

ActiveCN104355523BEvenly distributedEfficient dryingSludge treatment by de-watering/drying/thickeningSludgePulley

The invention relates to sludge treatment equipment, and particularly discloses a spreading and turning type sludge treatment device. The spreading and turning type sludge treatment device comprises a running frame formed by connection of two running supports and two connecting rods. The device is characterized in that the two connecting rods are connected through a plurality of evenly distributed support beams, small pulley assemblies are welded on the support beams, scraper beams are mounted at top ends of the small pulley assemblies, and scrapers are fixed on the scraper beams through hinge pins, cotter pins and gaskets; scraper motors are mounted on the support beams, swing rods are mounted on output shafts of the scraper motors and connected onto the scraper beams through rotating wheels, and sliding levers of the small pulley assemblies are connected onto the scraper beams through welding. The device can move transversely while moving longitudinally along a sludge tank, can spread sludge at any corner in the sludge tank, and can evenly distribute the sludge.

Owner:山东福航新能源环保股份有限公司

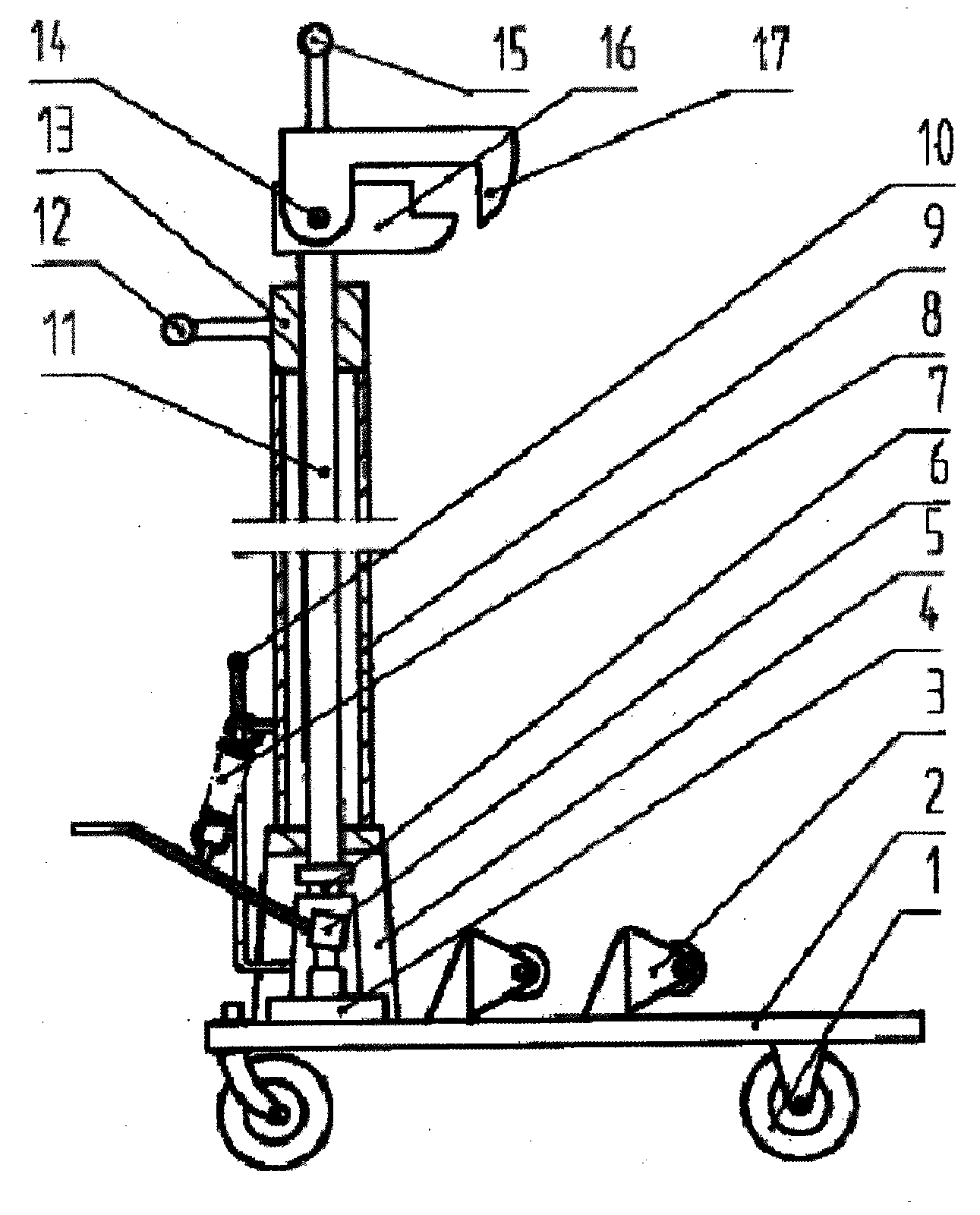

Trolley used in department store

InactiveCN103802869ASolve the problem of turnoverEasy to transport awayHand carts with multiple axesVehicle frameShortest distance

The invention discloses a trolley used in a department store. The trolley used in a department store is characterized in that the trolley comprises a trolley frame, wheels and a pushing handle, wherein a guide pipe support is arranged on the rear portion of the trolley frame, a jack is arranged below the guide pipe support, a lifting operating rod is arranged on one side of the jack, a return spring is arranged on the lifting operating rod of the jack, a pressure relief handle is arranged on the jack, a guide pipe is arranged on the guide pipe support, a lifting rod is arranged in the center of the guide pipe, the lower portion of the lifting rod is connected with the jack, and a goods locking device is arranged on the upper portion of the lifting rod. According to the trolley used in the department store, transferring of goods can be achieved effectively, goods can be carried away conveniently, the labor intensity is low, and the trolley is more suitable for short-distance transferring of goods in workshops, goods yards and the like.

Owner:上海南汇石森百货烟糖经营部

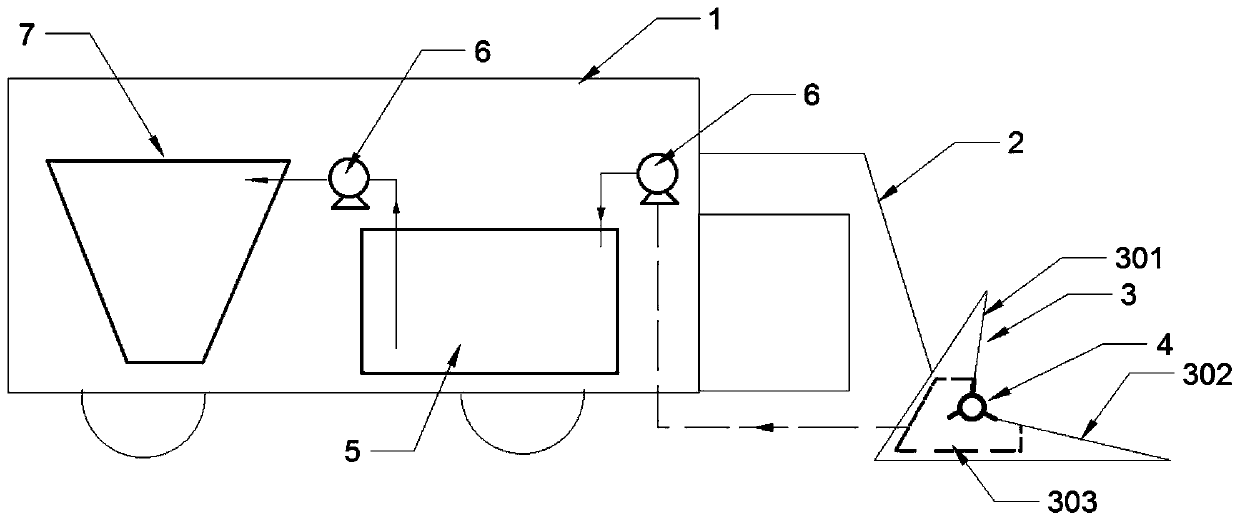

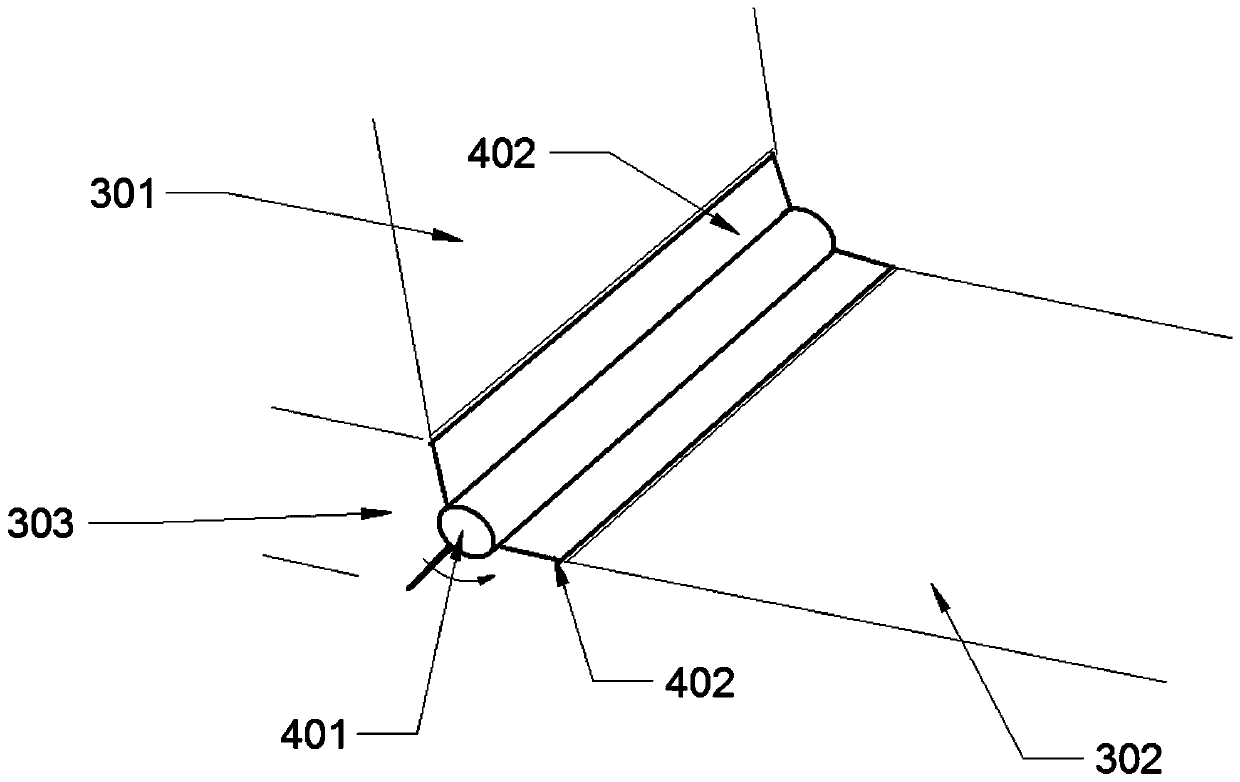

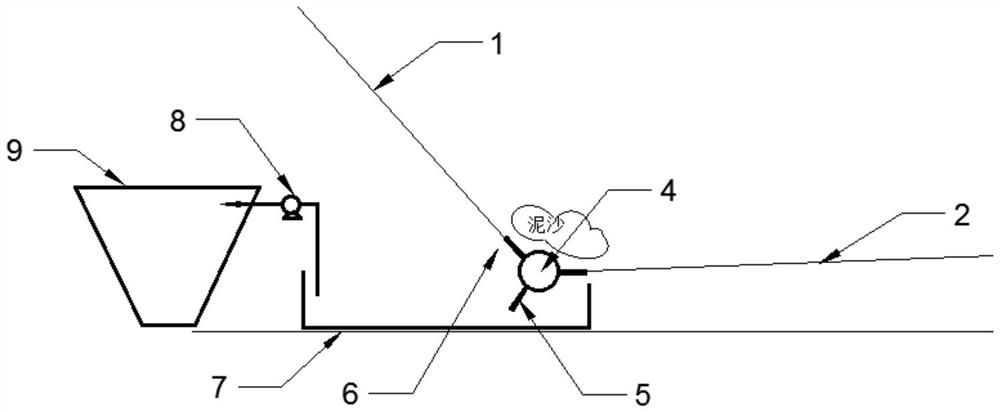

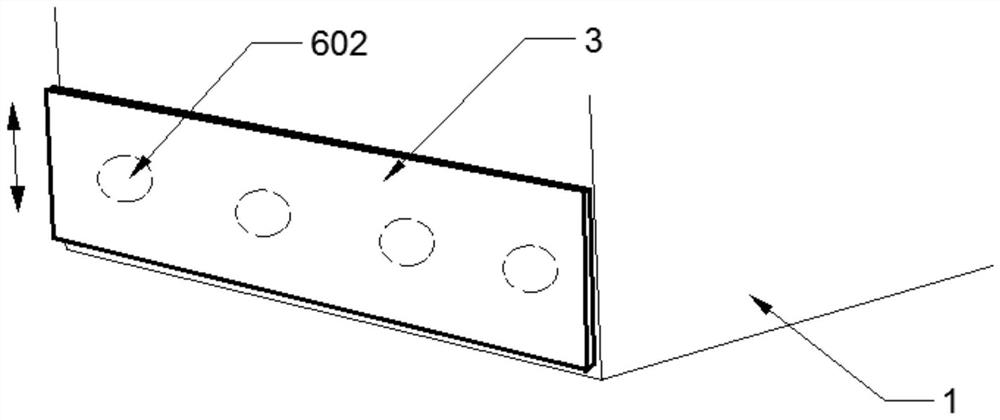

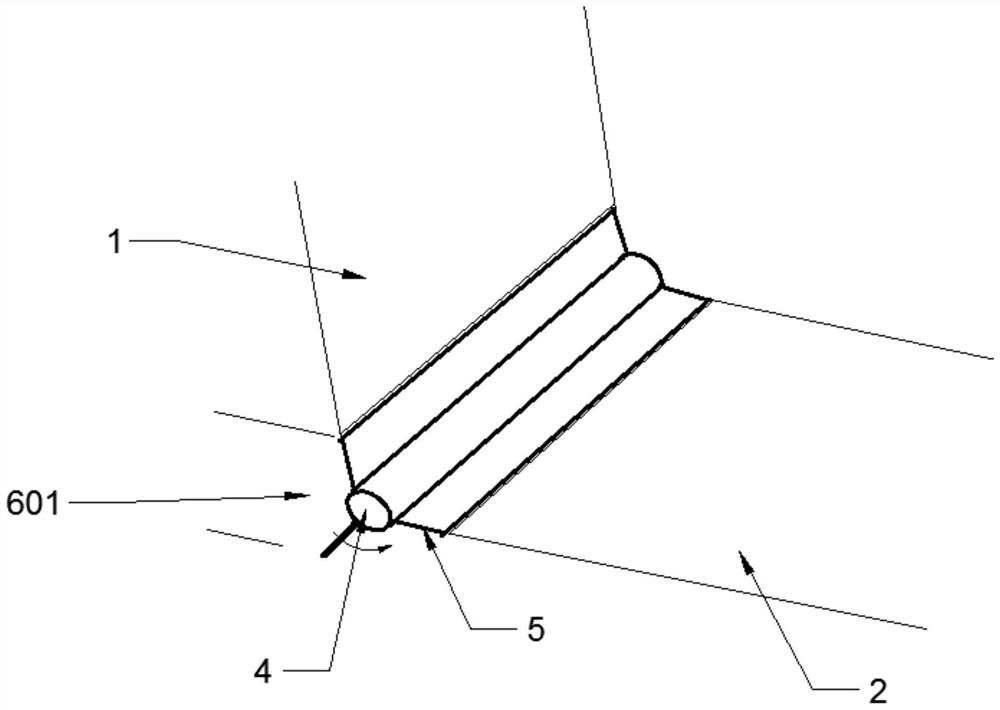

Flood control dam with mud-water separation device

ActiveCN111485534AAchieve mud-water separation effectAchieve separationBarrages/weirsClimate change adaptationFlood controlGeotechnical engineering

The invention discloses a flood control dam with a mud-water separation device. The flood control dam comprises a dam body, a mud guiding device, a stirring pool and the mud-water separation device. The dam body comprises a bottom face and an upstream face. A dam opening is formed in the included angle position between the bottom face and the upstream face. The mud guiding device comprises a drivedevice and a water intercepting valve connected with the drive device. The water intercepting valve is located at the dam opening and shields the dam opening when the water intercepting valve is closed. The stirring pool communicates with the dam opening and is connected with the mud-water separation device through a pipeline provided with a water pump. The mud-water separation device comprises an inner wall arranged to be of a hollow inverted-cone-shaped structure. A feeding port of the mud-water separation device is located in the top of the inner wall, and the water outlet direction of thefeeding port is tangent to the cross section of the mud-water separation device where the feeding port is located. A plurality of meshes are formed in the inner wall, mud water sprayed out of the feeding port spirally flows downwards along the inner wall, the mud water is made to do centrifugal motion, water in the mud water is thrown out of the meshes, and sediment accumulated at the bottom of the dam is collected.

Owner:广东润威建设工程有限公司

Solid-liquid separation device of swill

InactiveCN108187382AEasy to transportEasy to transport awayStationary filtering element filtersClamp connectionPulp and paper industry

The invention discloses a solid-liquid separation device of swill. The device comprises a support seat, wherein support blocks are arranged at both sides of the bottom end of a storage barrel, each support block is in clamped connection with a bottom plate through a first clamping groove and a first clamping block, a support leg is arranged at each corner of the bottom of the bottom plate, a firstroller is arranged at the bottom of each support leg, a bracket is arranged at each corner of the top end of the support seat, the top of each bracket is fixedly connected with the bottom of the topplate, and a pressing plate is arranged at the output end of a cylinder. The storage barrel is placed in a groove, so that workers can conveniently mount and dismount the storage barrel and transportswill; the bottom plate and the storage barrel can be conveniently clamped by support blocks, the bottom plate is rapidly mounted at the bottom of the storage barrel, the bottom plate can be driven bythe first rollers to move, and the workers can transport the swill conveniently and carry away the swill after solid-liquid separation; the swill can be compressed by the pressing plate, and outflowof a liquid in the swill is accelerated.

Owner:范科晨

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com