Device and method for manufacturing a continuous strand for the tobacco industry

A technology of processing industry and loading device, applied in the device of tobacco rod or filter rod, tobacco rod or filter rod, continuous rod field, which can solve problems such as irregularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

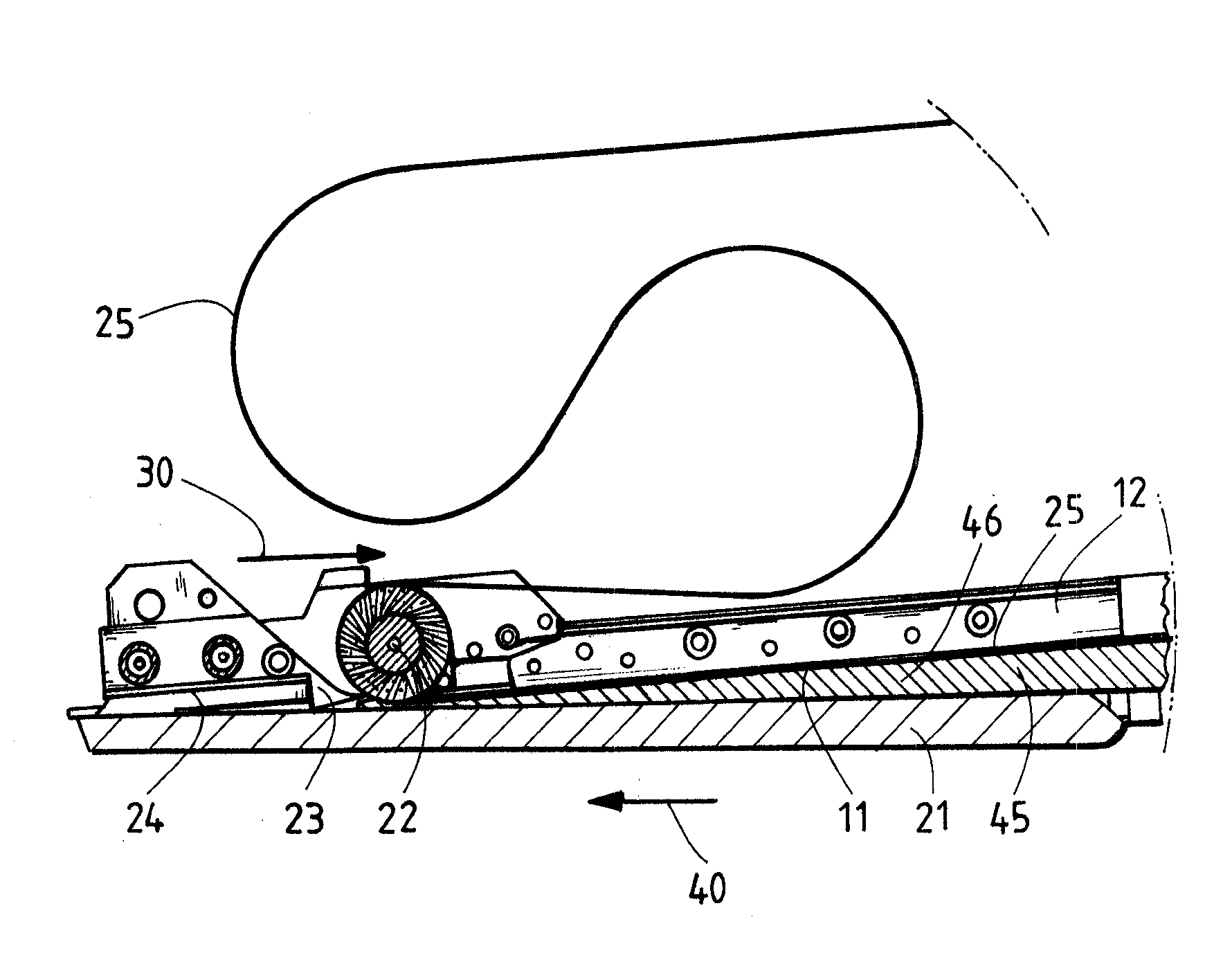

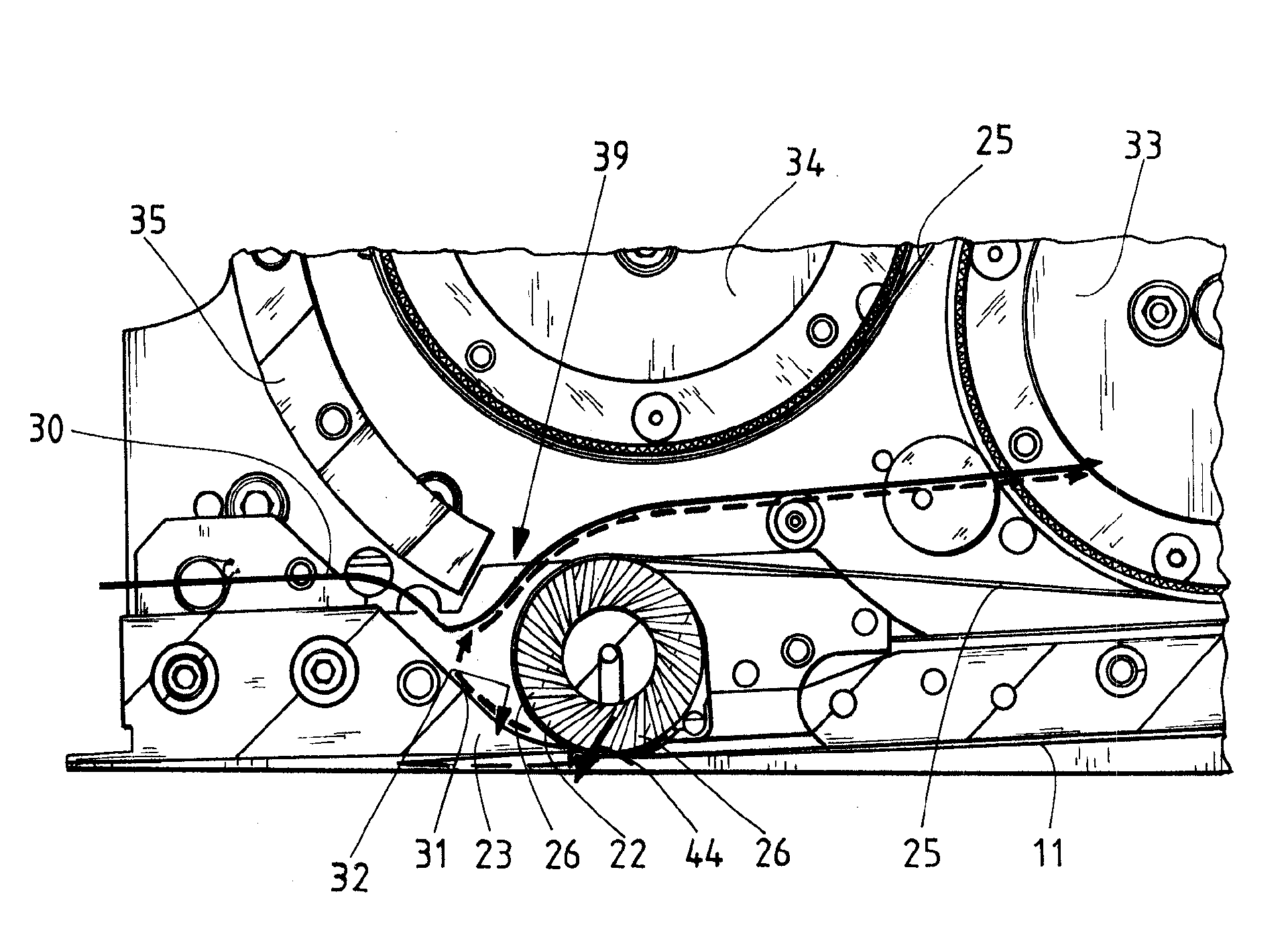

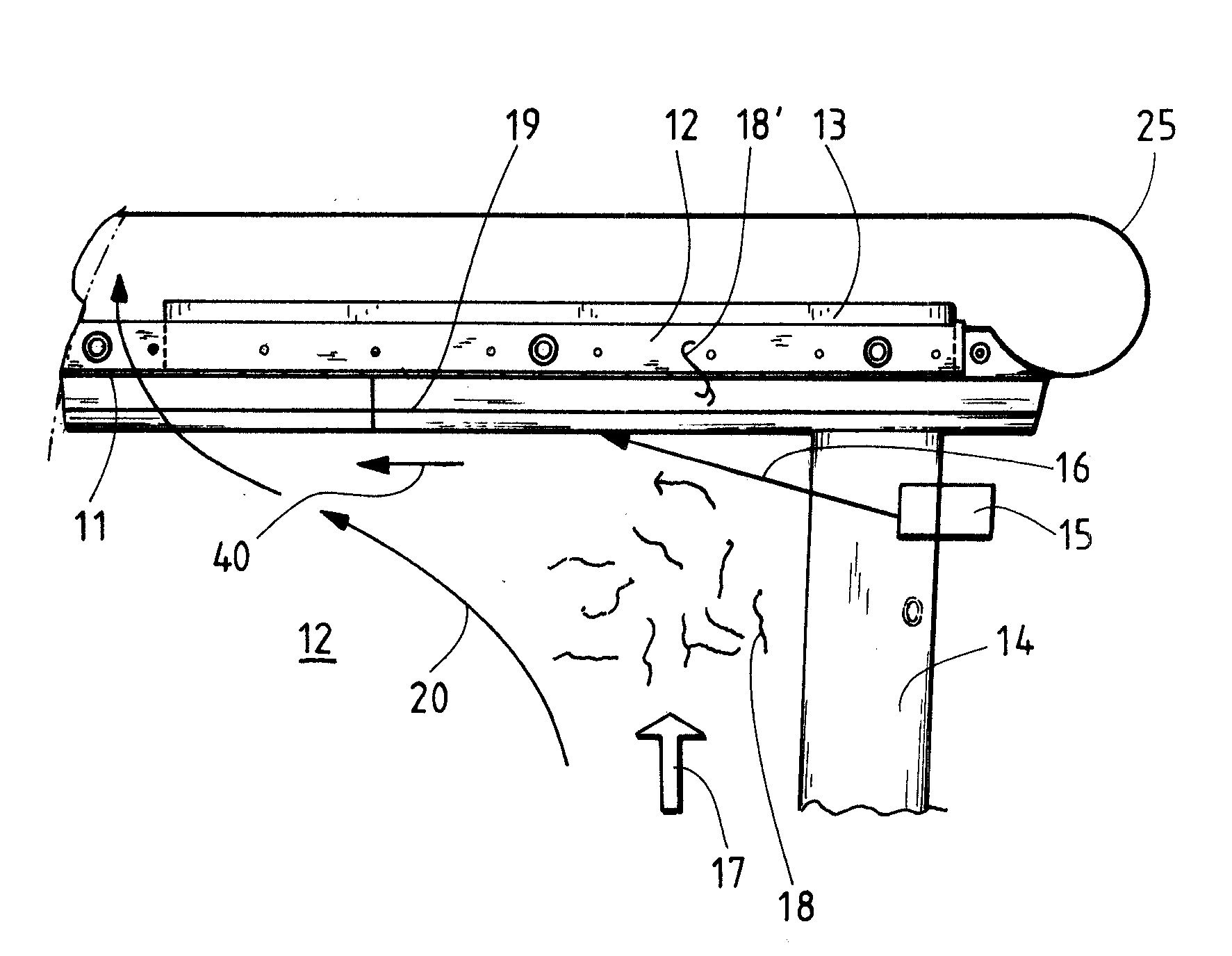

[0042] figure 1 A schematic view of the device according to the invention for forming continuous rods, in particular tobacco rods or filter rods, for the tobacco industry is shown schematically. In the description below, the starting point is a filter rod, wherein the invention is expressly not limited to the design of a filter rod. exist figure 1 not shown in the figure 2 Schematically using 18 or 18' as the filter material or strip material illustrated as fibers, in figure 1 The medium enters the suction shaft 10 from below and goes upwards to the suction rod conveyor 11 and is dissipated there or, in general terms, formed there.

[0043] The suction strip conveyor 11 comprises a suction belt 25 which is configured as a continuously rotating structure and is usually a fabric belt. Preference is given to using a fabric belt as described in German patent application DE 10 2010 003 287.5. The fabric belt here is a suction belt consisting of a fabric with warp threads and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com