Power distribution cabinet assembling platform

A technology for power distribution cabinets and platforms, applied in switchgear, electrical components, etc., can solve the problems of low work efficiency, consuming a lot of manpower and material resources, and high labor intensity, saving manpower and material resources, eliminating manual lifting, and facilitating transportation. effect of walking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0019] The present invention will be described in detail below with reference to the accompanying drawings and examples.

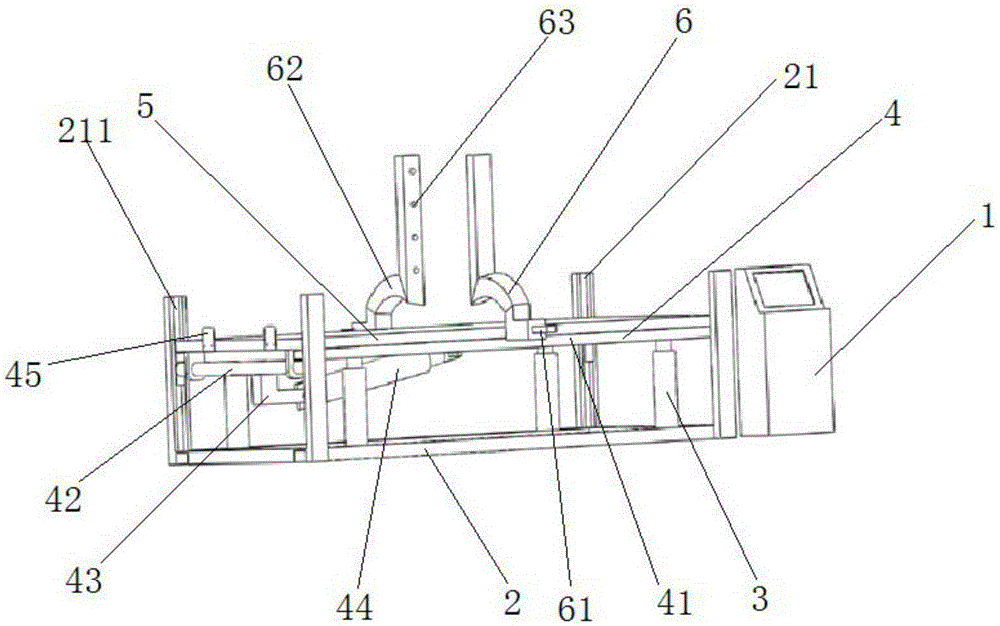

[0020] Such as figure 1 As shown, the present invention provides a power distribution cabinet assembly platform, including an electric control cabinet 1, a box-shaped base 2, a lifting mechanism 3, a turning mechanism 4, an operating platform 5 and a vertical arm mechanism 6, the base 2 The four corners are vertically connected with support columns 21, the support columns 21 are provided with longitudinally extending chute 211, and the lifting mechanism 3 controlled by the electric control cabinet 1 is vertically arranged at the four corners of the base 2, The turning mechanism 4 includes a square-shaped turning bracket 41, a rotating shaft 42, a connecting piece 43, and a turning hydra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com