Method for surface machining, method for producing an engine block, device for surface machining and motor vehicle

An engine block and surface machining technology, which is applied in the fields of surface machining, manufacturing of engine blocks, devices for surface machining and motor vehicles, can solve high investment costs, high energy consumption, large operating costs, etc. problems, to achieve the effect of saving operating costs, improving efficiency, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

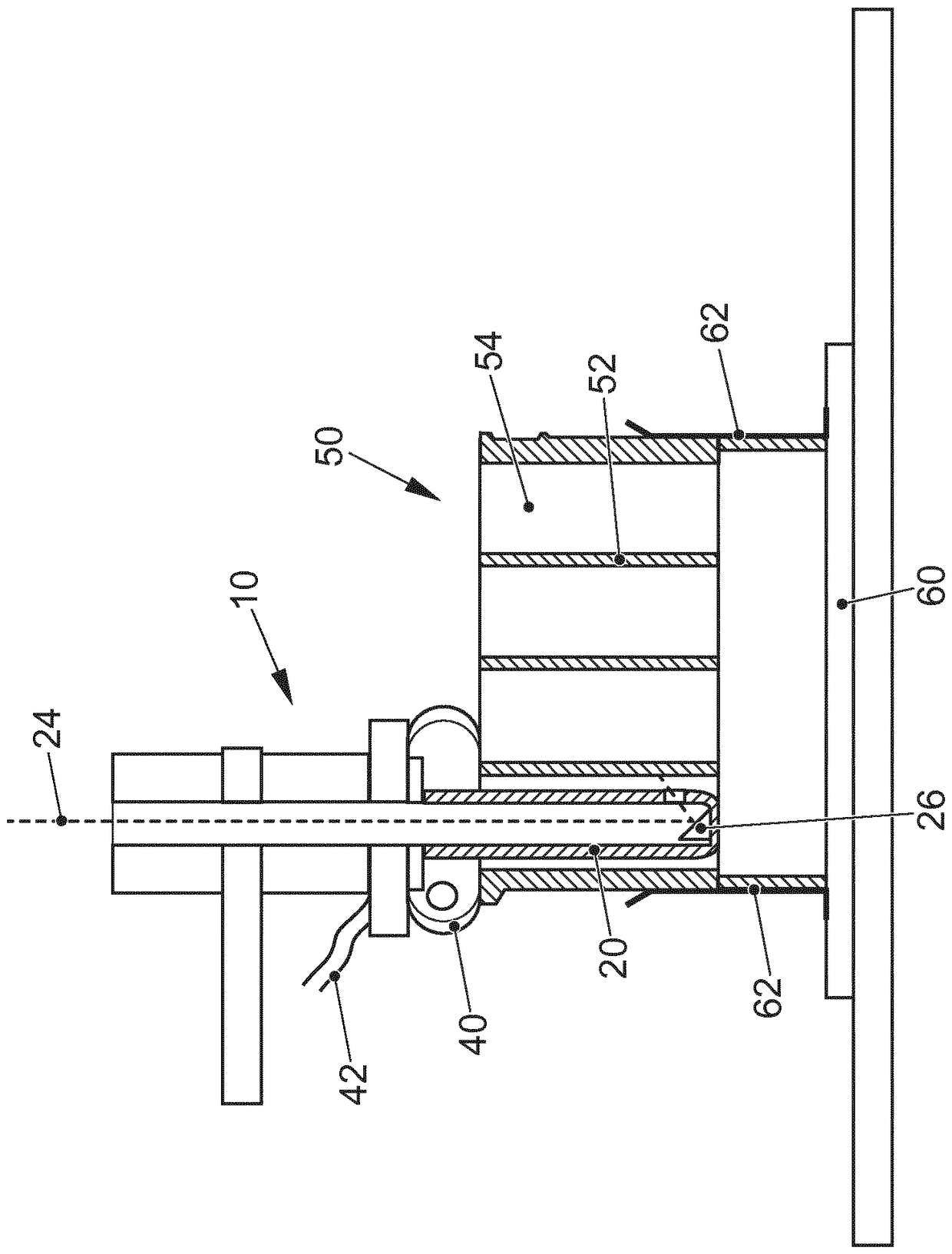

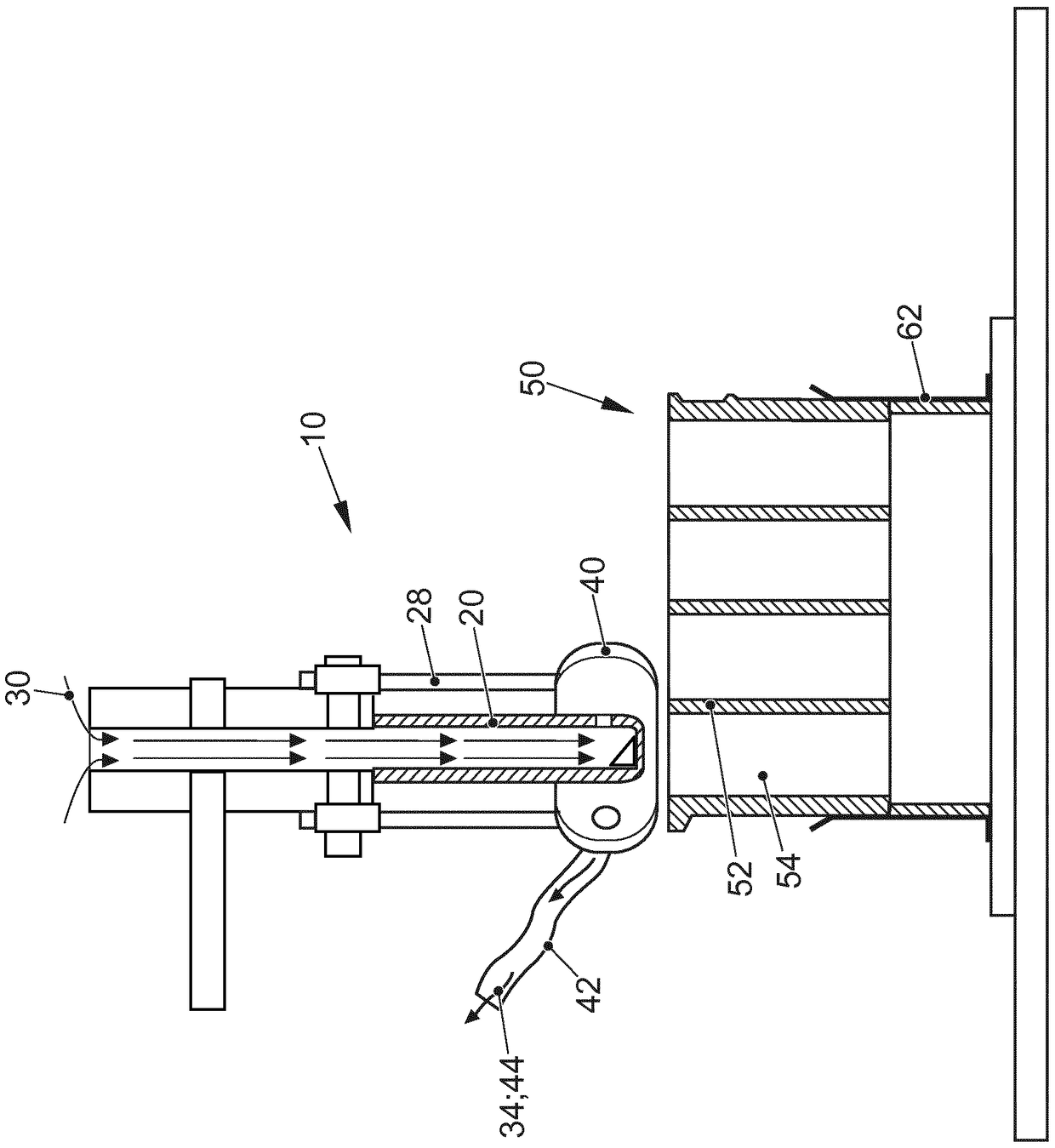

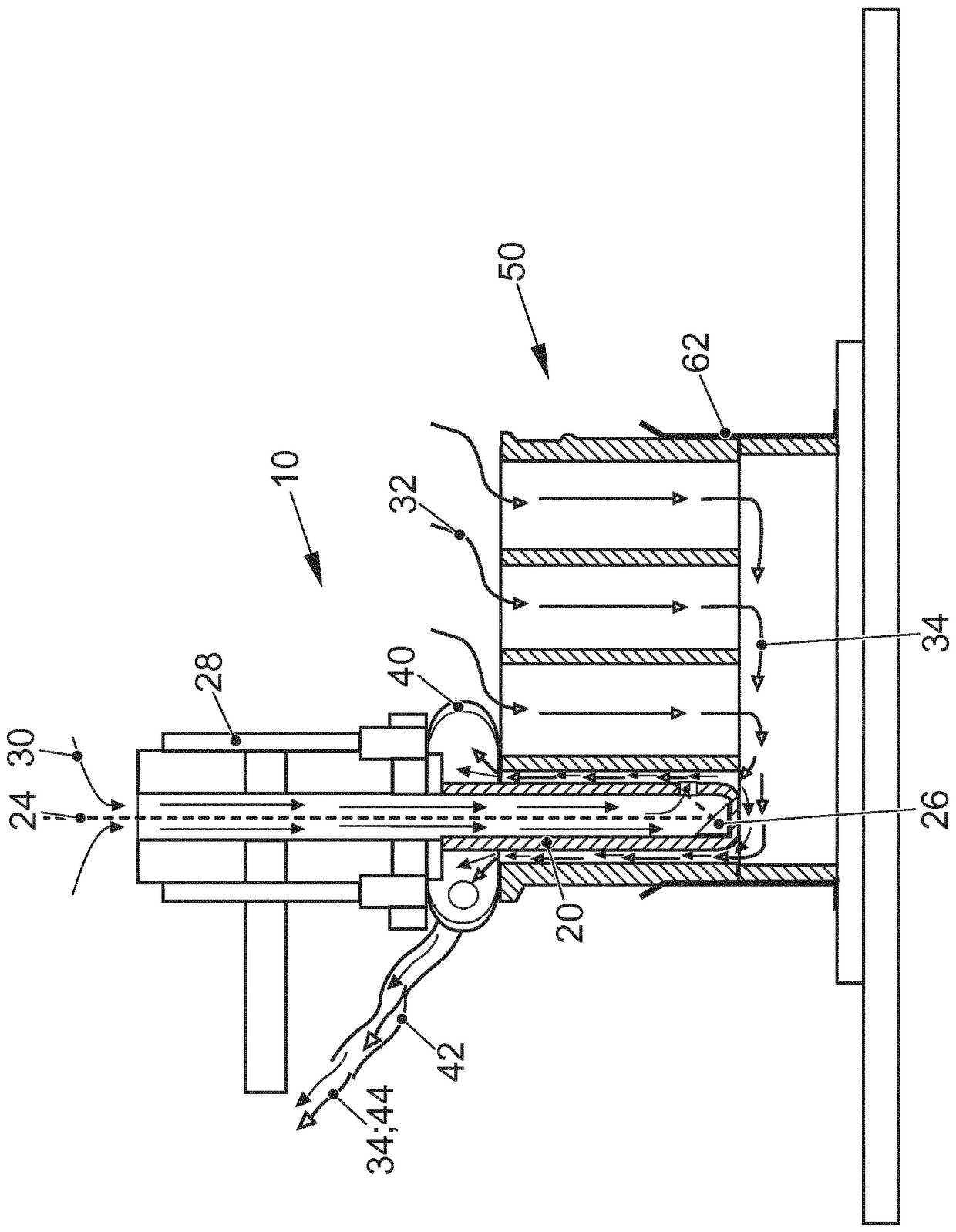

[0061] figure 1 A section through a device 10 for surface machining according to the invention is shown. It includes a machining tool 20 , also called an inner machining head, which is embodied in the form of a hollow rod. The machining tool 20 can be guided vertically by means of a guide device 28 in order to facilitate its introduction into a hollow cavity, for example a cylinder 54 of an engine block. A purge gas flow aligned along the longitudinal axis of the machining tool 20 and extending from top to bottom in the direction of the side of the machining tool 20 that can be driven into the cylinder takes place in the interior of the machining tool 20 . Arranged at the lower end of the processing tool 20 is a reflector 26 , also referred to as a deflection prism, which is suitable for reflecting the laser beam, which is also guided from above through the processing tool 20 , and directing it via the outlet to the cylinder 54 The piston travels at the surface of the track ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com