Carrying device

A technology for a carrier and a carrier, applied in the field of transportation, can solve the problems of labor consumption, increase the difficulty of handling, and increase the cost of handling, and achieve the effects of saving labor, facilitating popularization and use, and reducing the difficulty of handling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

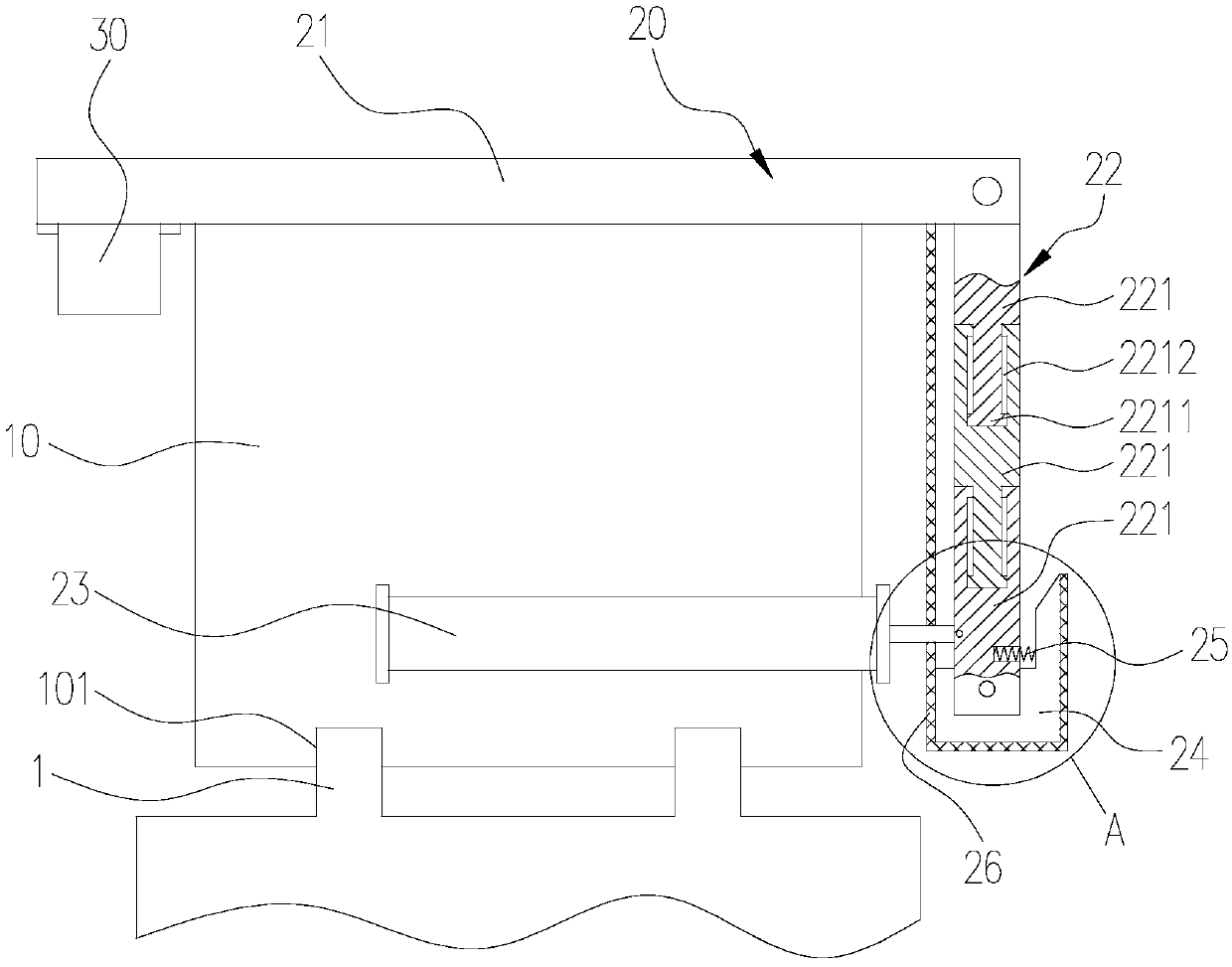

[0023] see figure 1 , figure 2 , the invention provides a carrying device, which is used for carrying a car. The carrier device includes a carrier 10 and a carrier assembly 20 mounted on the carrier 10 , and the transported vehicles complete loading and unloading work through the carrier assembly 20 .

[0024] The vehicle 10 is movably arranged on the road. In this embodiment, the vehicle 10 is an unmanned transport vehicle. Specifically, the lower end surface of the carrier 10 is concavely provided with two slide grooves 101, and the road surface is convexly provided with two guide rails 1 matching with the slide grooves 101, and the carrier 10 is erected on the guide rails 1 through the slide grooves 101. While the tool 10 is moving, the guide rail 1 is slidably connected with the slide groove 101 .

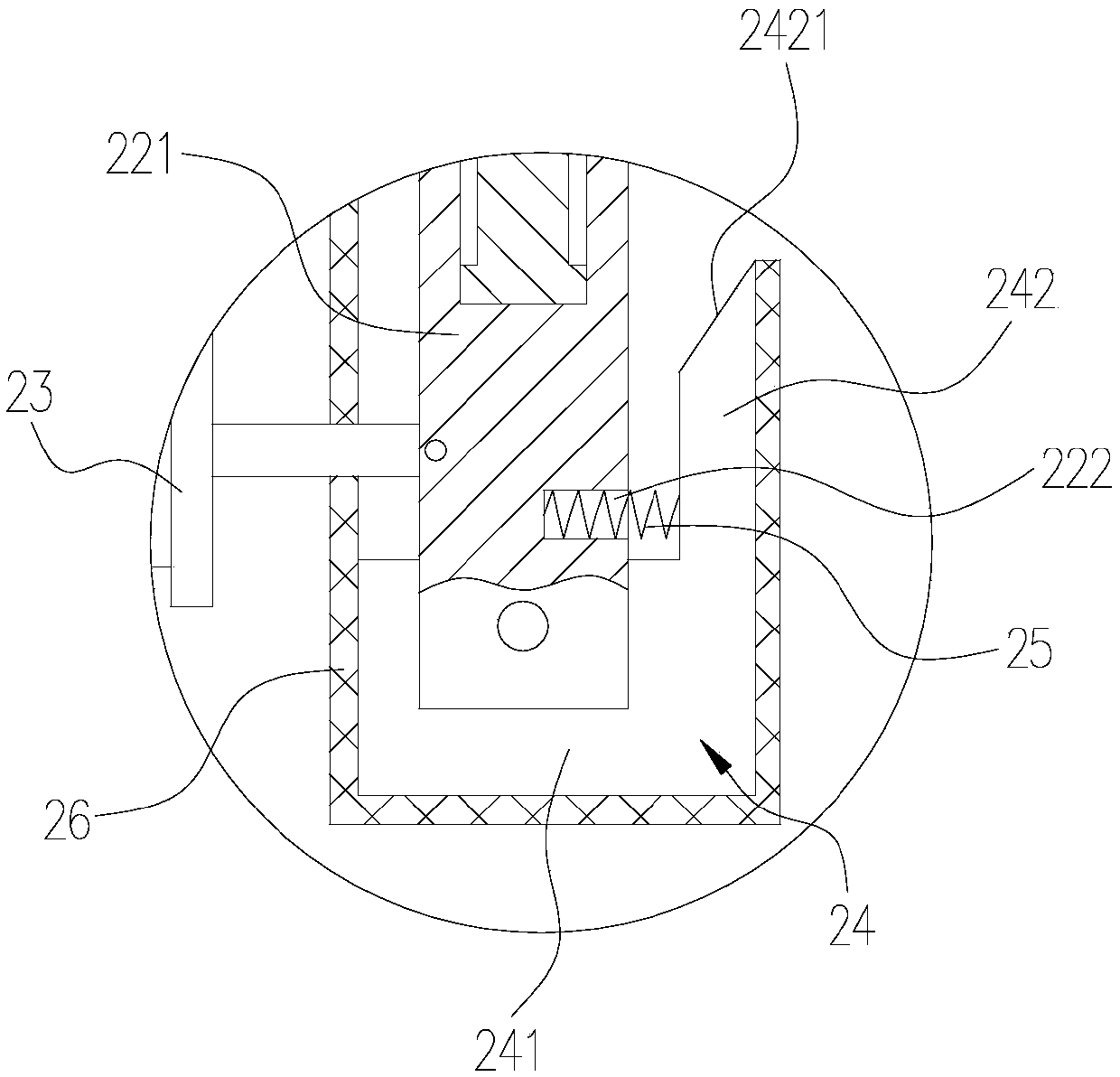

[0025] The carrying component 20 includes a load board 21 , a telescopic mechanism 22 , a supporting mechanism 23 , a guide plate 24 , an elastic member 25 and a telescopic...

Embodiment 2

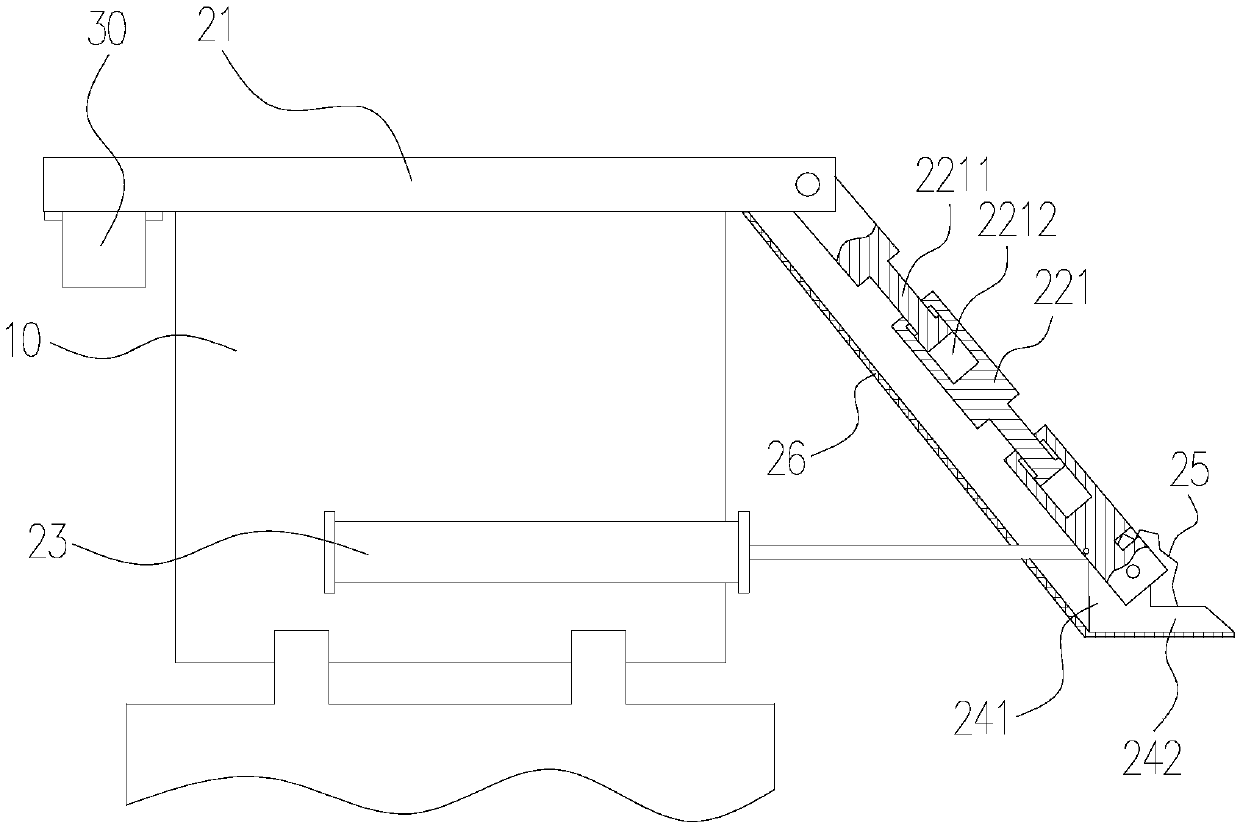

[0038] see Figure 4 The difference between the carrying device provided in the second embodiment and the carrying device in the first embodiment lies in that the supporting mechanism 23 of the second embodiment has a different structure.

[0039] Specifically, in this embodiment, the supporting mechanism 23 includes a motor (not shown) fixedly installed on one side of the carrier 10, a gear 231 installed on the output shaft of the motor, and a rack meshed with the gear 231 232. The motor is a forward and reverse motor, the rack 232 is slidingly connected to the carrier 10 , and one end of the rack 232 is rotationally connected to the telescopic plate 221 on the telescopic mechanism 22 away from the carrying plate 21 . When in use, start the motor, the motor drives the gear 231 to rotate, and then the gear 231 drives the rack 232 to slide relative to the carrier 10. It is stretched or shortened under the action, thereby making the guide plate 24 open or close synchronously. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com