Intermittent washing and drying machine

A washing and drying machine, intermittent technology, applied in the direction of drying machine, drying gas arrangement, drying, etc., can solve the problems of prolonging production cycle, increasing labor intensity, increasing production energy consumption, etc., to ensure continuity, increase The effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below by means of specific embodiments:

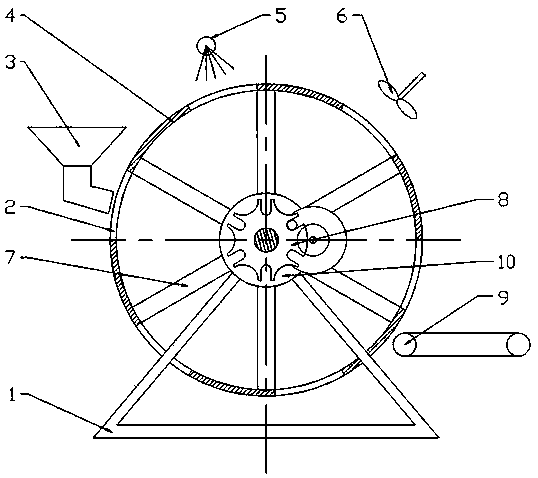

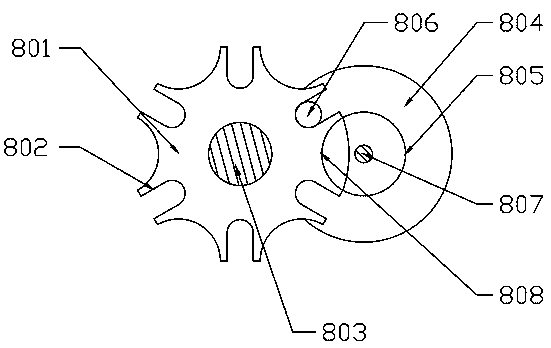

[0011] The reference signs in the drawings of the description include: frame 1, opening 2, feed hopper 3, working chamber 4, washing water pipe 5, drying fan 6, partition 7, sheave mechanism 8, sheave 801, radial groove 802, support shaft 803, dial 804, convex arc 805, round pin 806, dial power shaft 807, concave arc 808, conveyor belt 9, fixed plate 10.

[0012] Embodiment The intermittent washing and drying machine is basically as attached figure 1 And attached figure 2 As shown: including frame 1 and working chamber 4, support shaft 803 is fixed on frame 1, fixed disc 10 is hinged on support shaft 803, and the outer edge of fixed disc 10 is evenly distributed in the circumferential direction and fixed with 6 partitions 7, partitions The outer ends of 7 are fixed to the inner wall of the working chamber 4, and the partition 7 divides the inner space of the working ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com