Patents

Literature

110results about How to "Easy to forge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

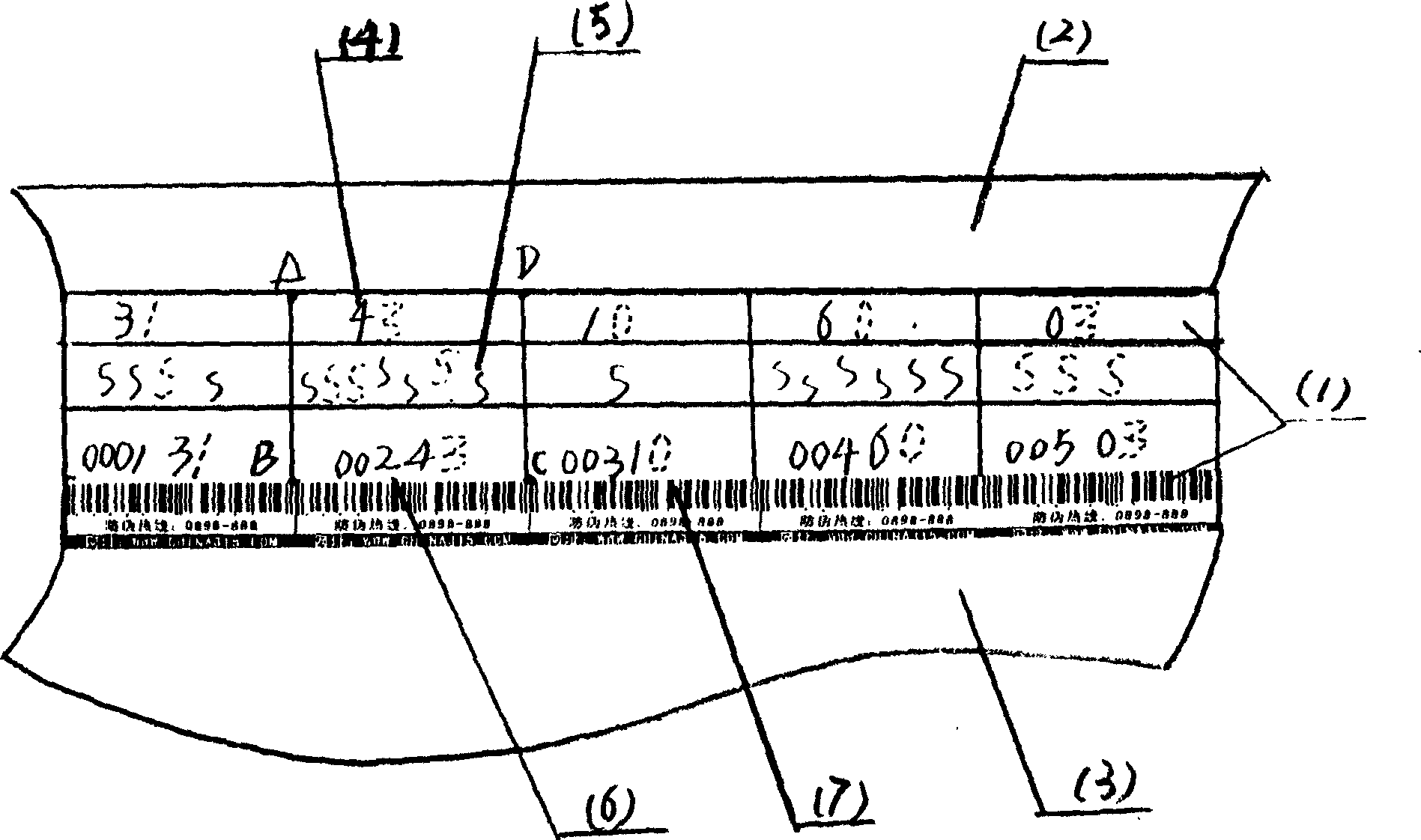

Uncovered counterfoil type double anti-fake structure, anti-fake method and manufacturing method

ActiveCN102930778AEasy to identifyEasy to forgeStampsRecord carriers used with machinesSoftware engineeringMechanical engineering

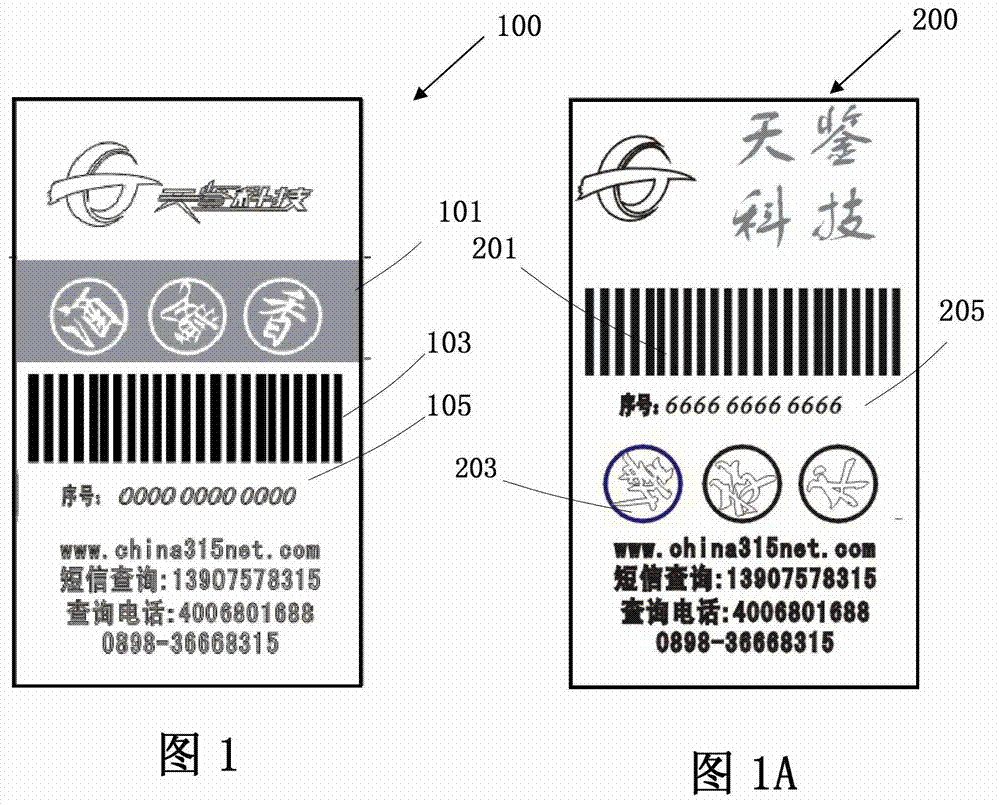

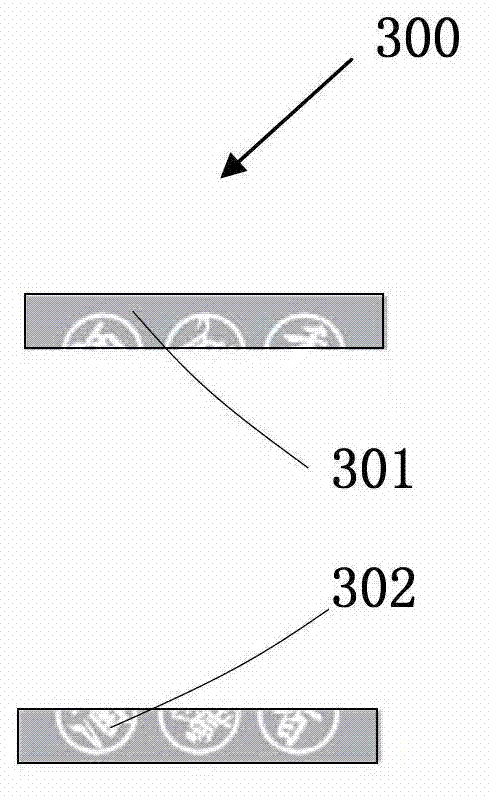

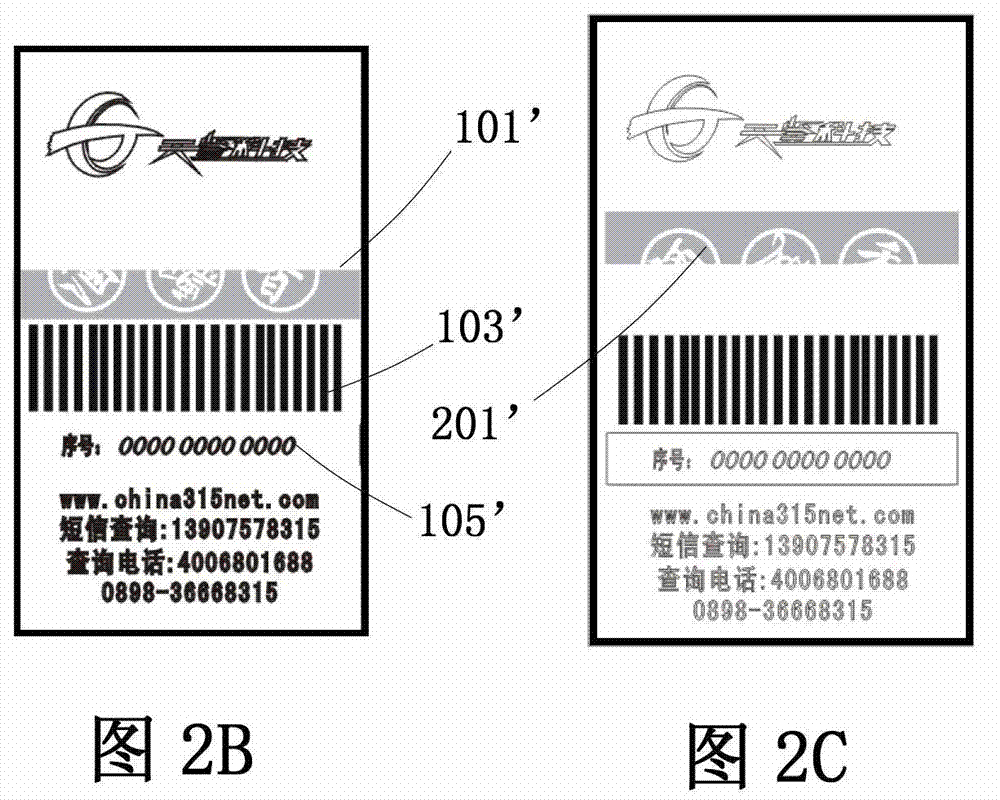

Disclosed are an uncovered counterfoil type double anti-fake structure, an anti-fake method and a manufacturing method. The anti-fake structure comprises a first text anti-fake layer and a second text anti-fake layer which is located below the first text anti-fake layer, the first text anti-fake layer can be uncovered and separated from the second text anti-fake layer, and the first text anti-fake layer and the second text anti-fake layer are in a text anti-fake structure which uses network to independently perform anti-fake query. According to the anti-fake method, two text anti-fake layers which can be uncovered and separated on the anti-fake structure are used to perform double anti-fake by the network. The anti-fake method includes that the authenticity of the anti-fake structure is inquired by the network according to information on the first text anti-fake layer, the first text anti-fake layer which is located above the second text anti-fake layer is uncovered to expose the second text anti-fake layer which is located below the first text anti-fake layer, and the authenticity of the anti-fake structure is inquired by the network according to information on the second text anti-fake layer of a counterfoil portion. The uncovered counterfoil type double anti-fake structure, the anti-fake method and the manufacturing method have the advantages that the anti-fake structure is achieved based on combination of an authentic text anti-fake technology and a modern network or communication technology, the recognition is easy, and the counterfeit is difficult.

Owner:TIANJIAN ANTI FORGERY SCI & TECH

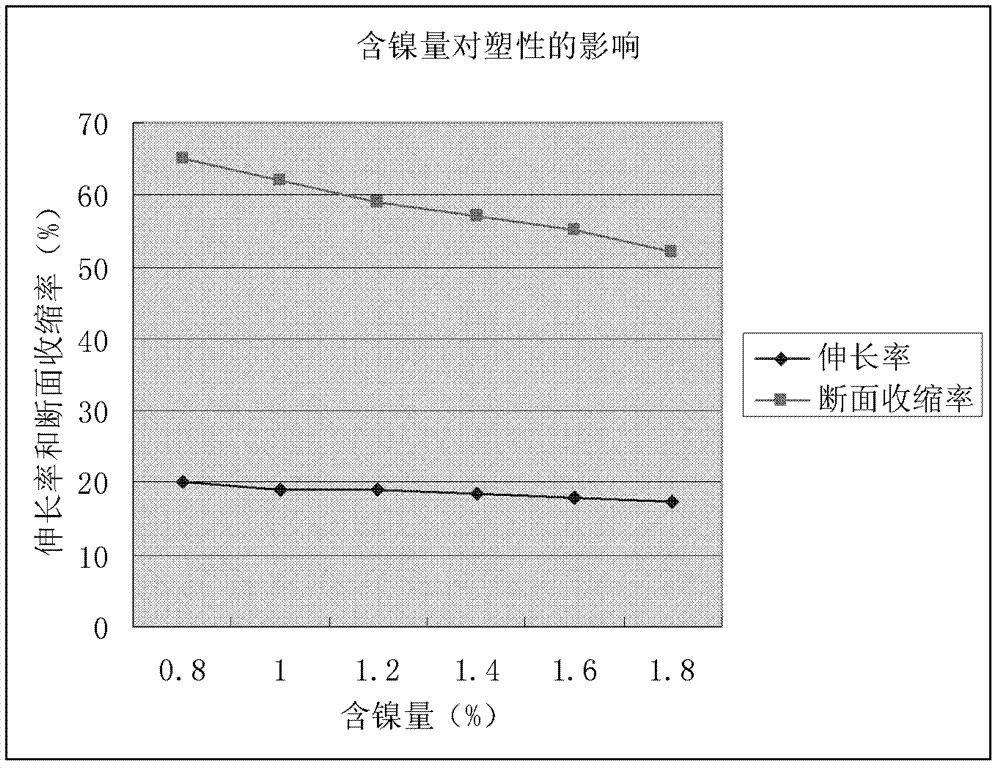

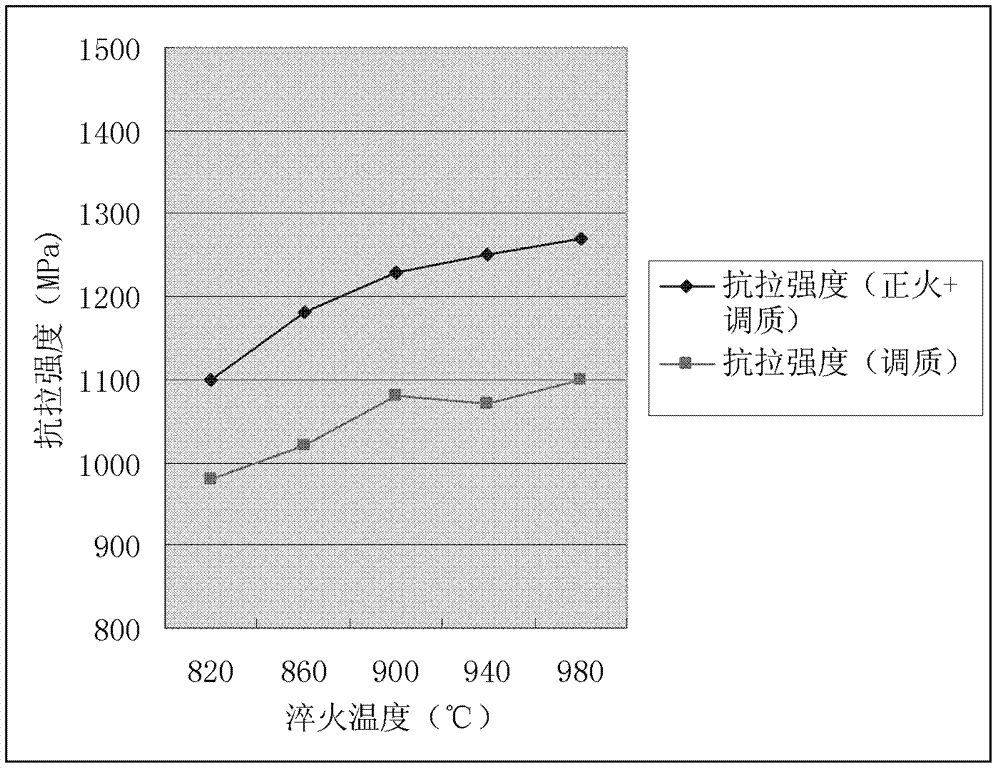

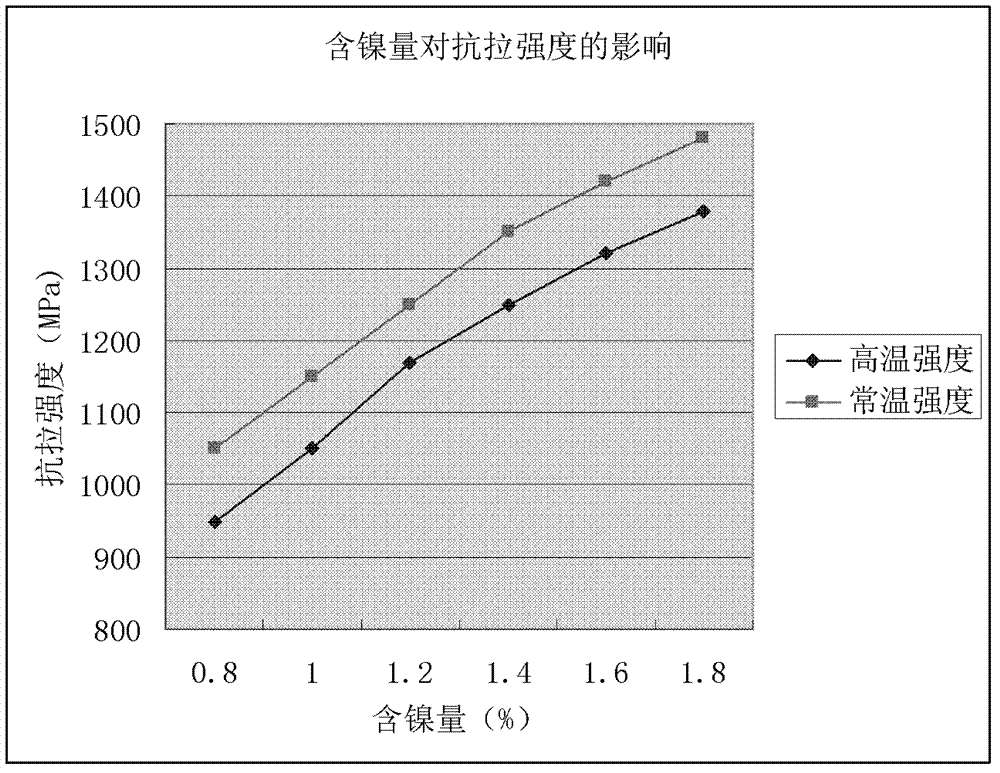

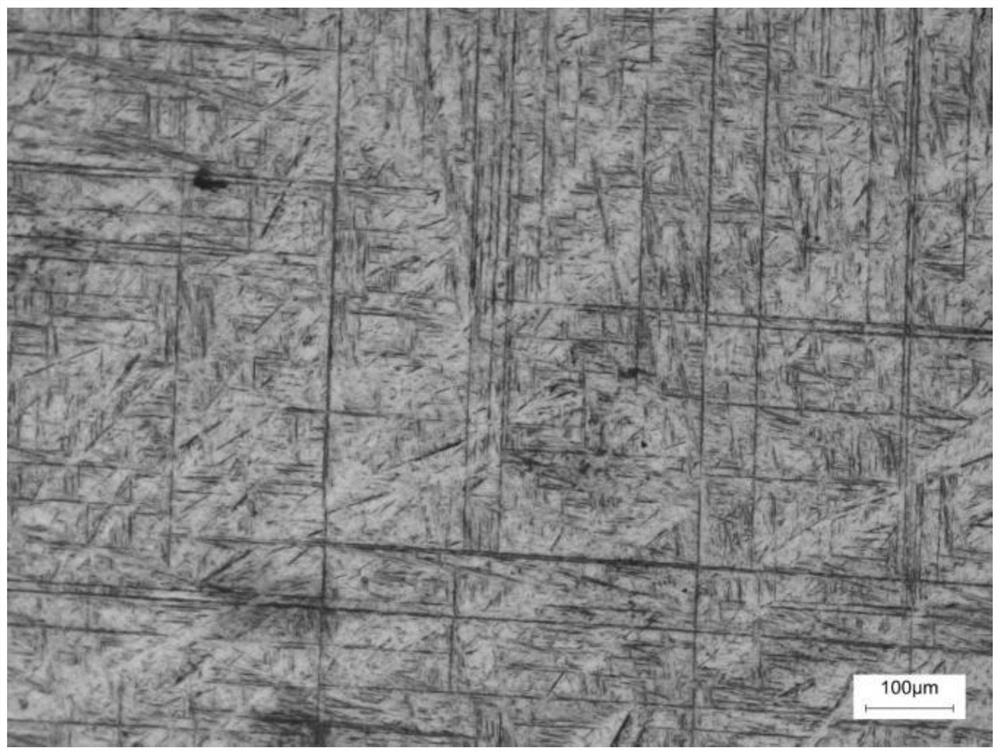

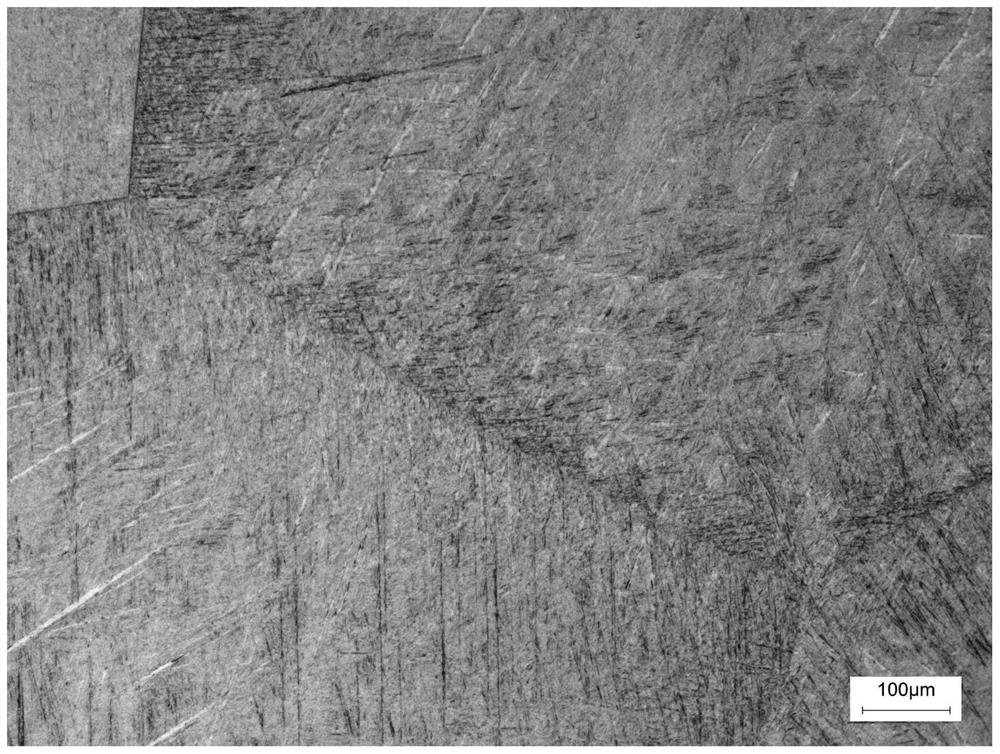

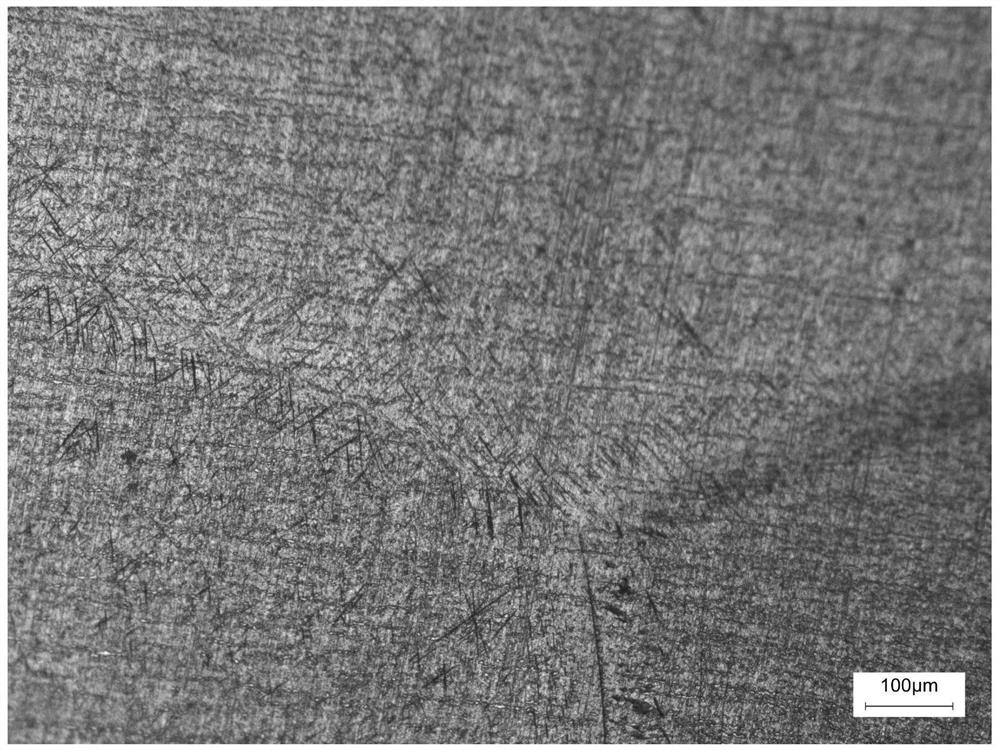

Alloy forged steel and its heat treatment method and use

ActiveCN102953008AGood comprehensive mechanical propertiesImprove hardenability and heat strength propertiesBraking membersAlloy elementCompound (substance)

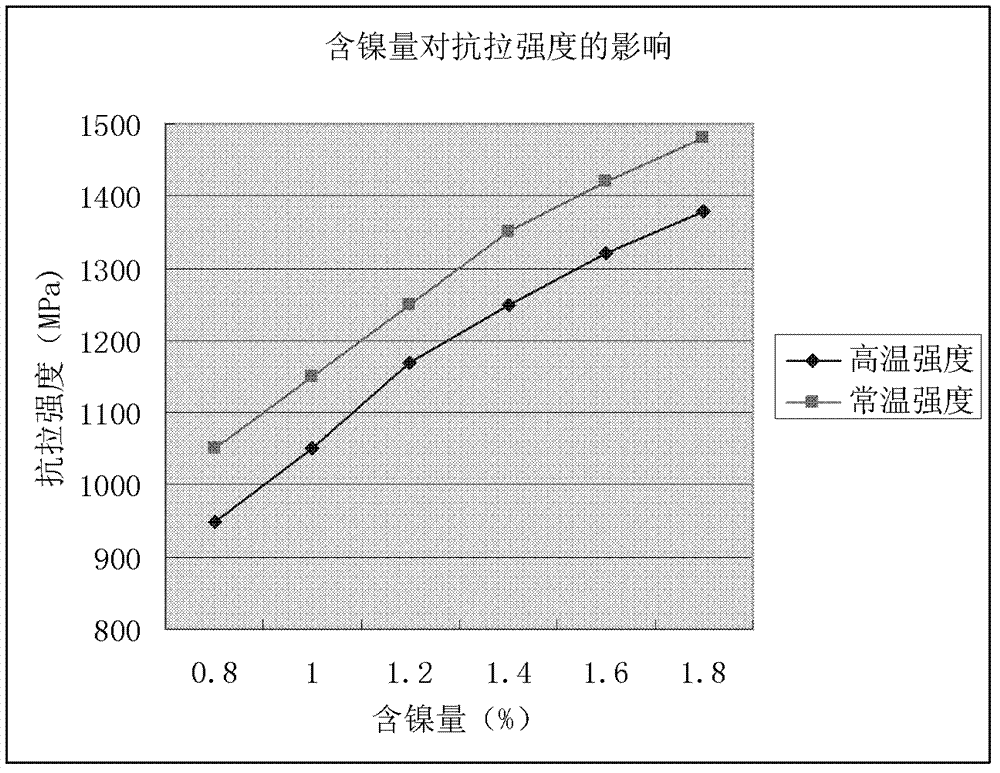

The invention provides an alloy forged steel and its heat treatment method and use. The alloy forged steel comprises: by mass, 0.26 to 0.35% of C, 0.15 to 0.39% of Si, 0.85 to 1.50% of Mn, less than or equal to 0.02% of P, less than or equal to 0.01% of S, 0.80 to 2.00% of Cr, 0.70 to 2.00% of Ni, 0.35 to 1.00% of Mo, and the balance Fe and other elements. Through reasonable proportioning of alloy elements such as Mn, Ni, Cr and Mo, and main chemical components such as C and Si in forged steel materials, through appropriate heat treatment processes, grains are refined; hardenability and heat intensity properties of the alloy forged steel are improved; normal temperature strength and high temperature strength of the alloy forged steel are greatly improved; and excellent comprehensive mechanical properties of the alloy forged steel are obtained.

Owner:CRRC QISHUYAN INSTITUTE CO LTD +1

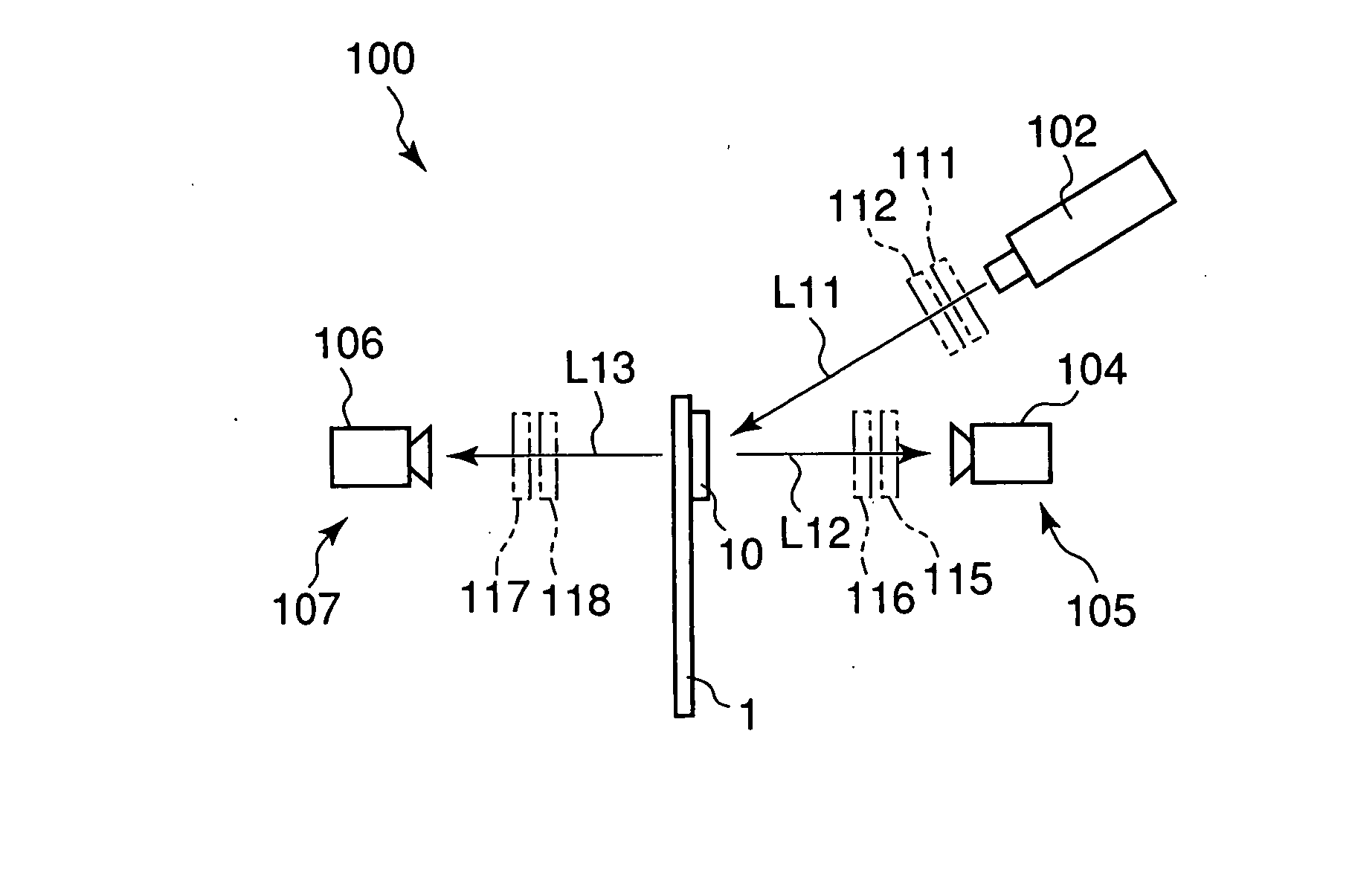

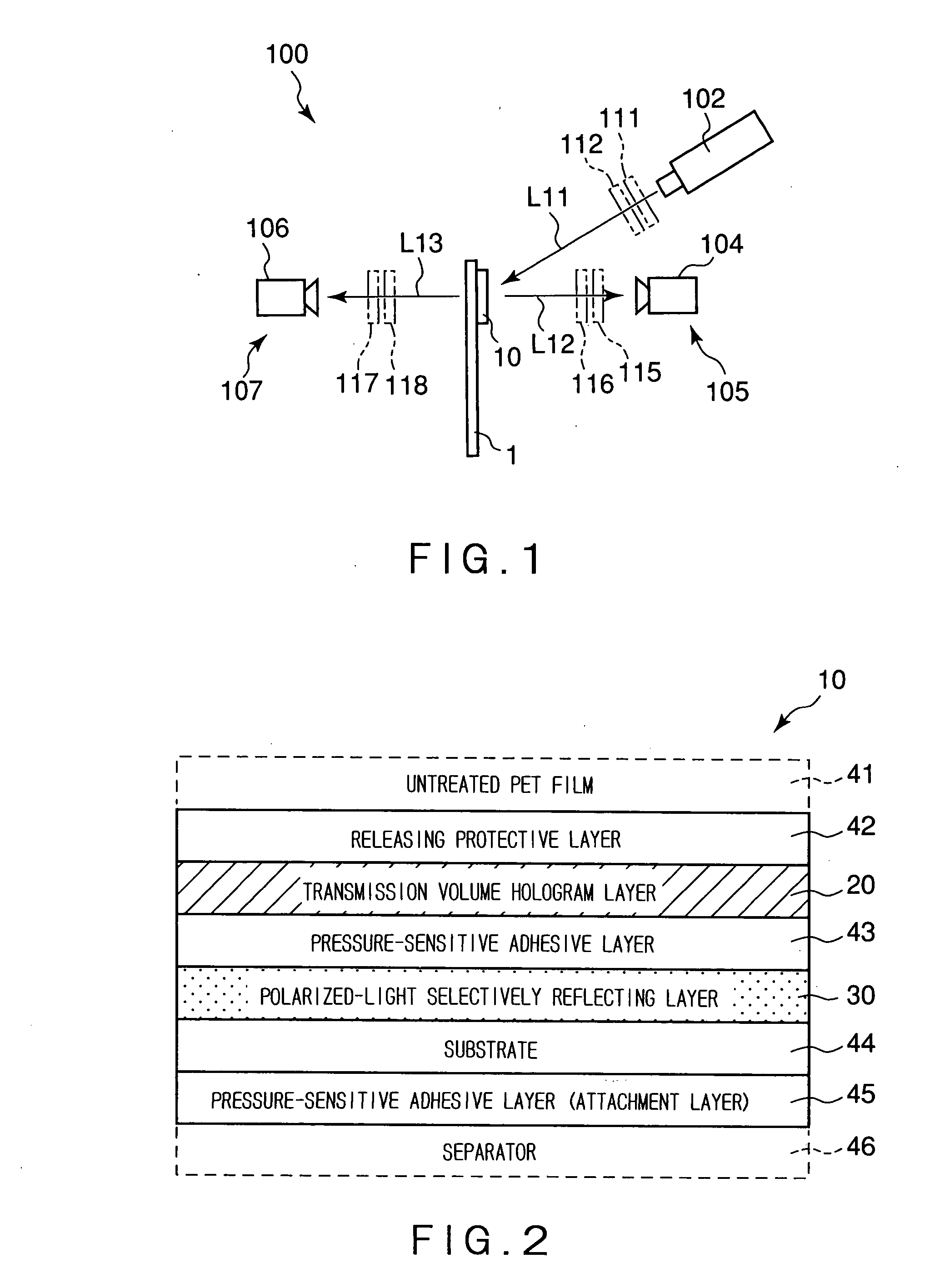

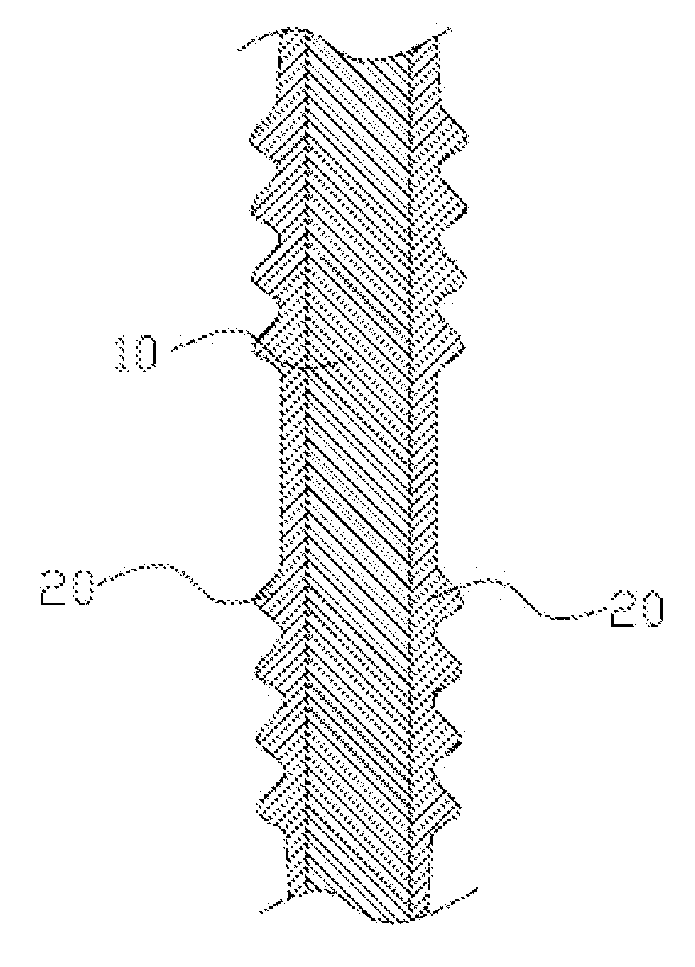

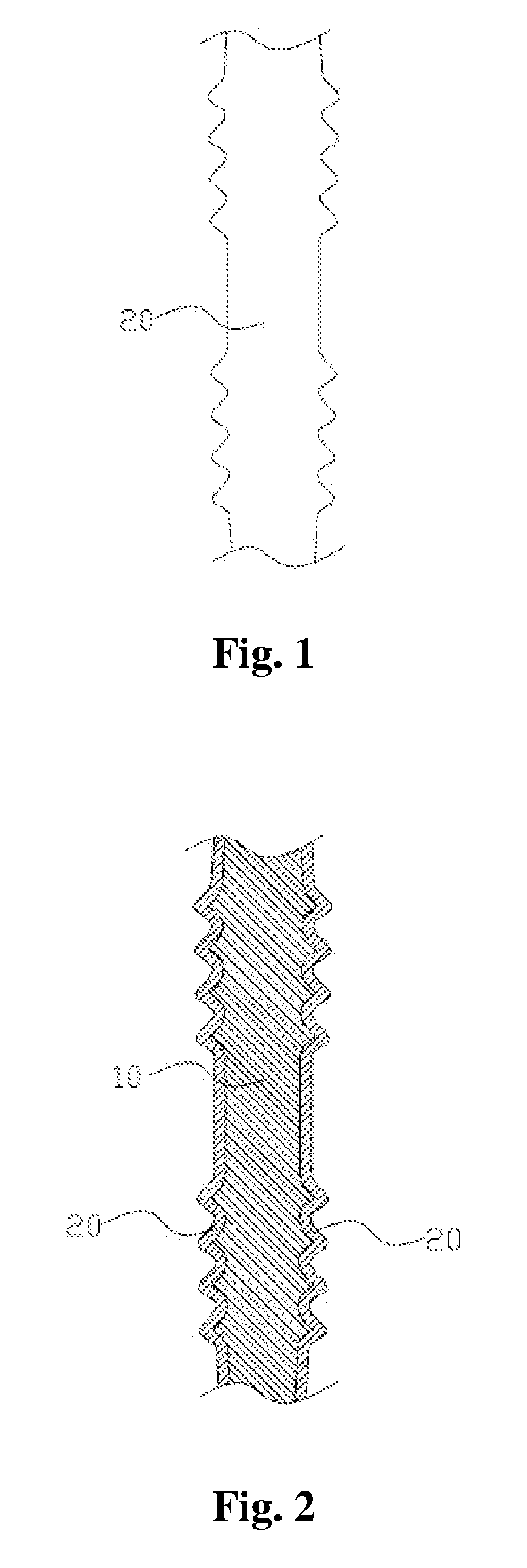

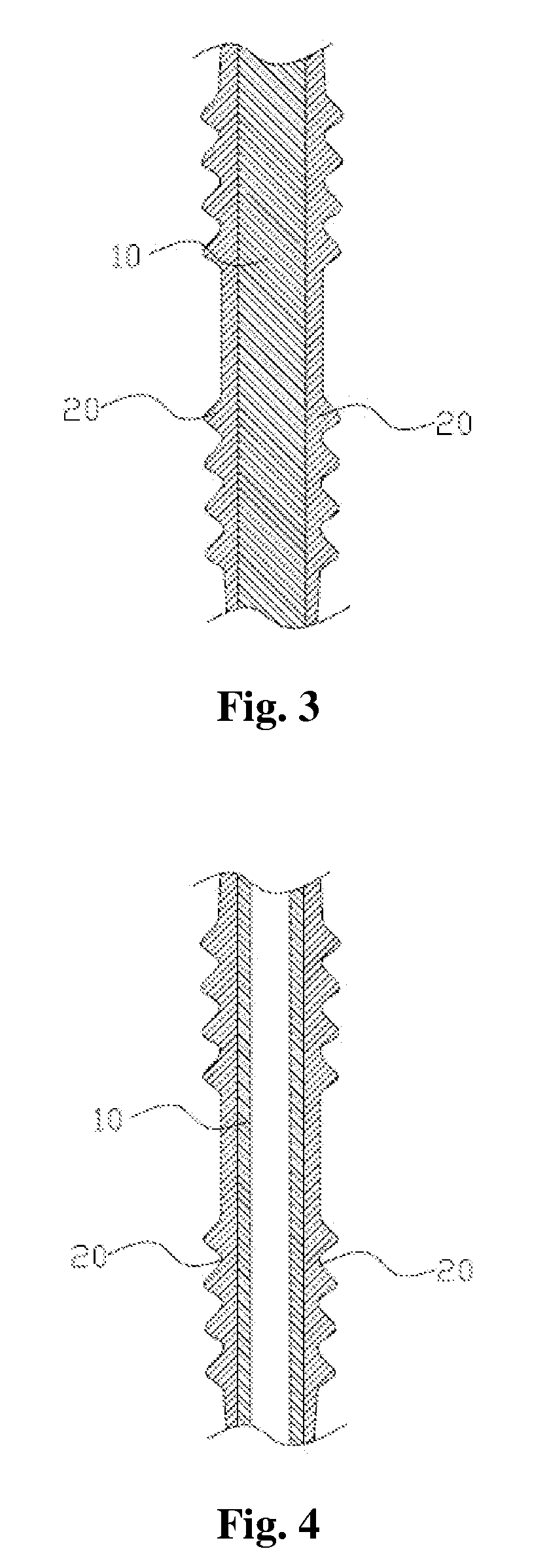

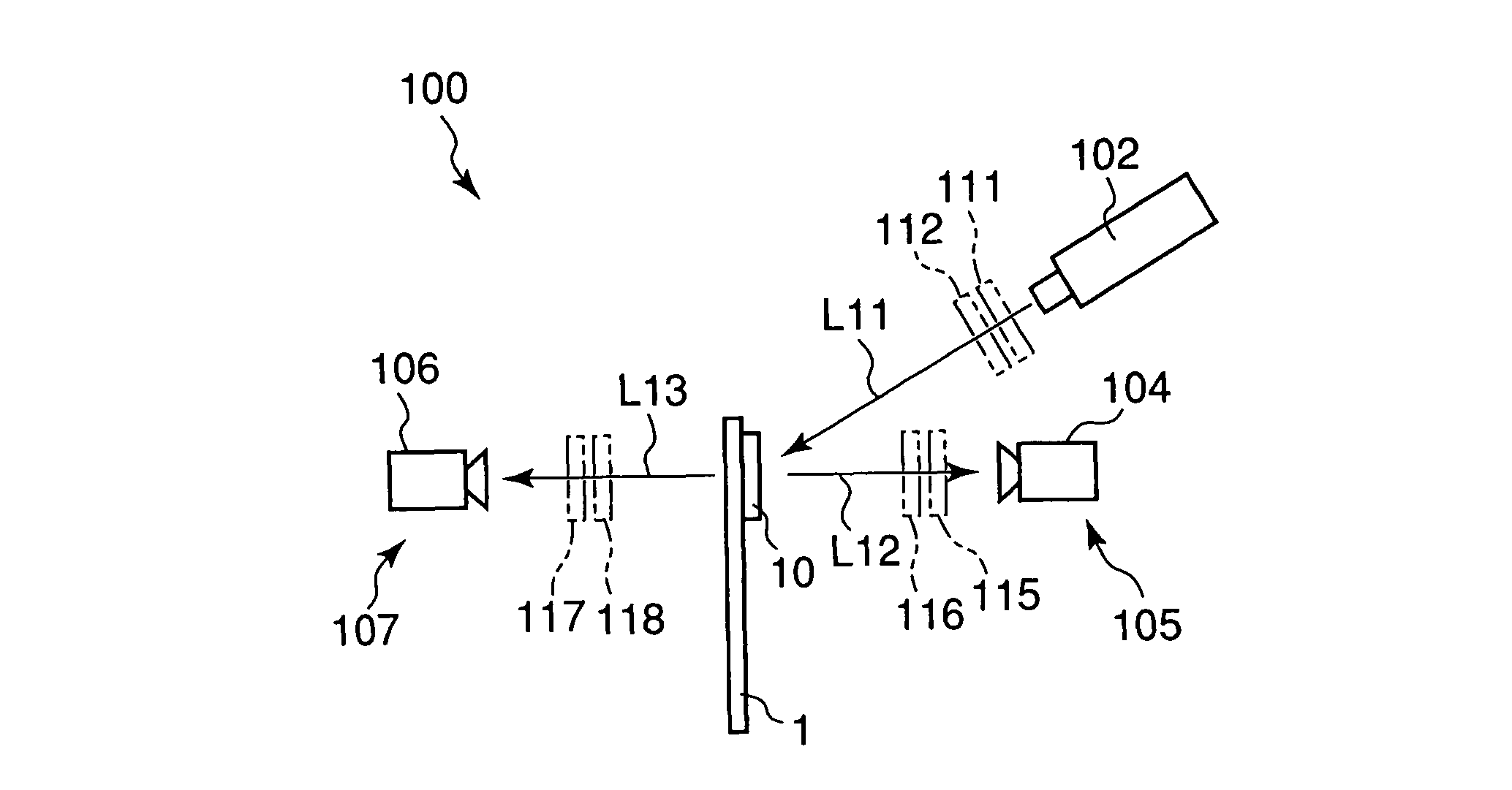

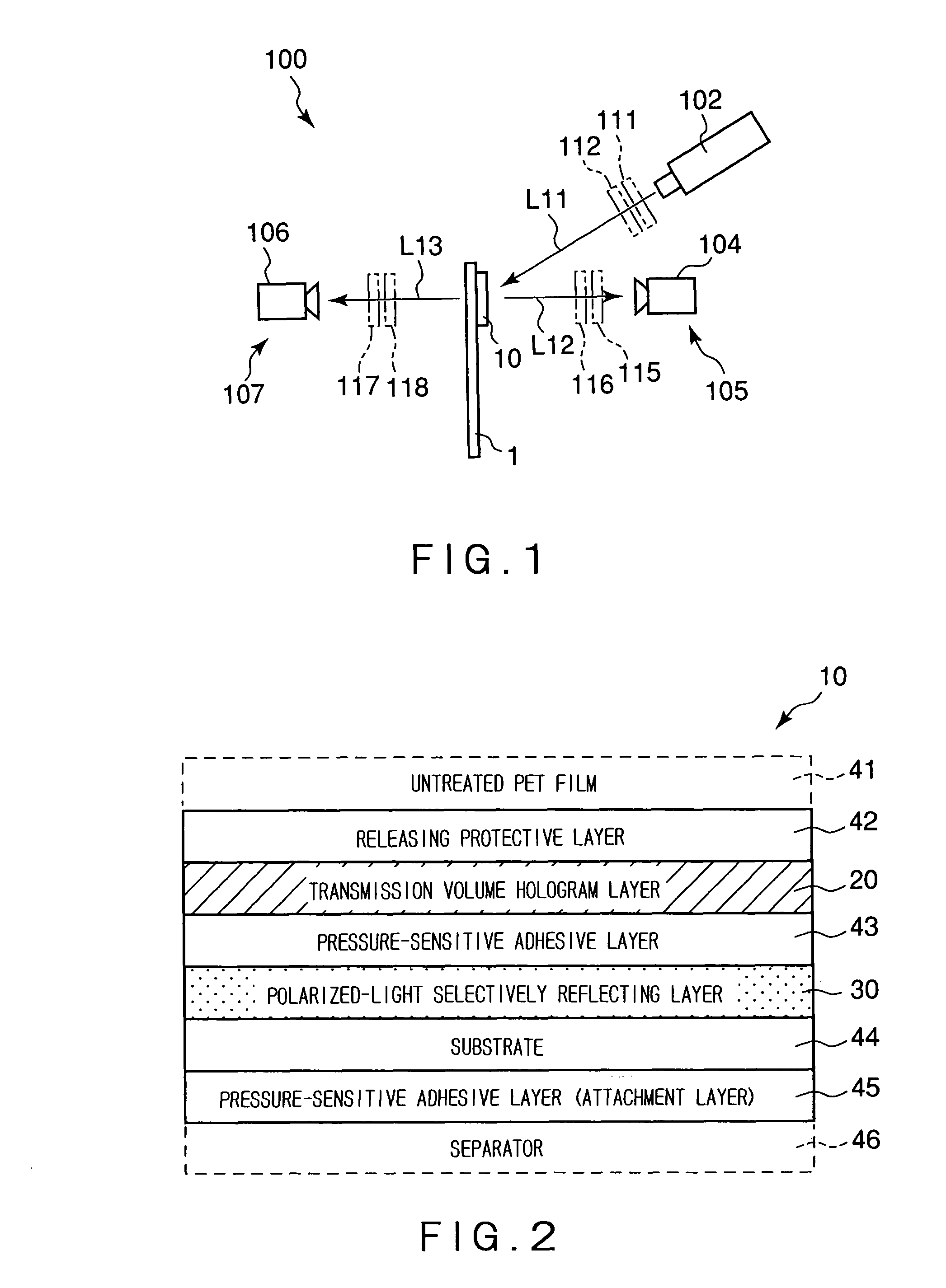

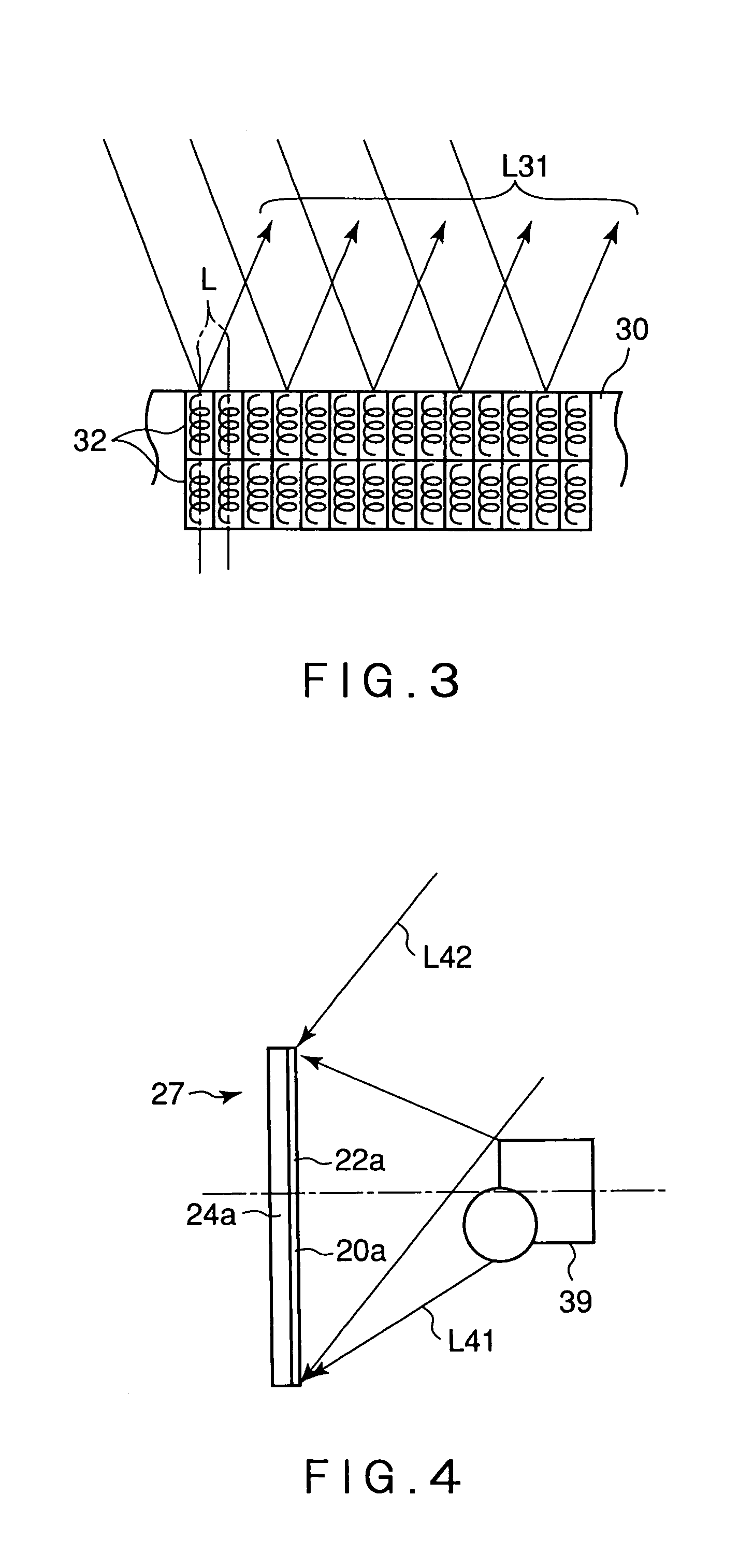

Authenticity indicator

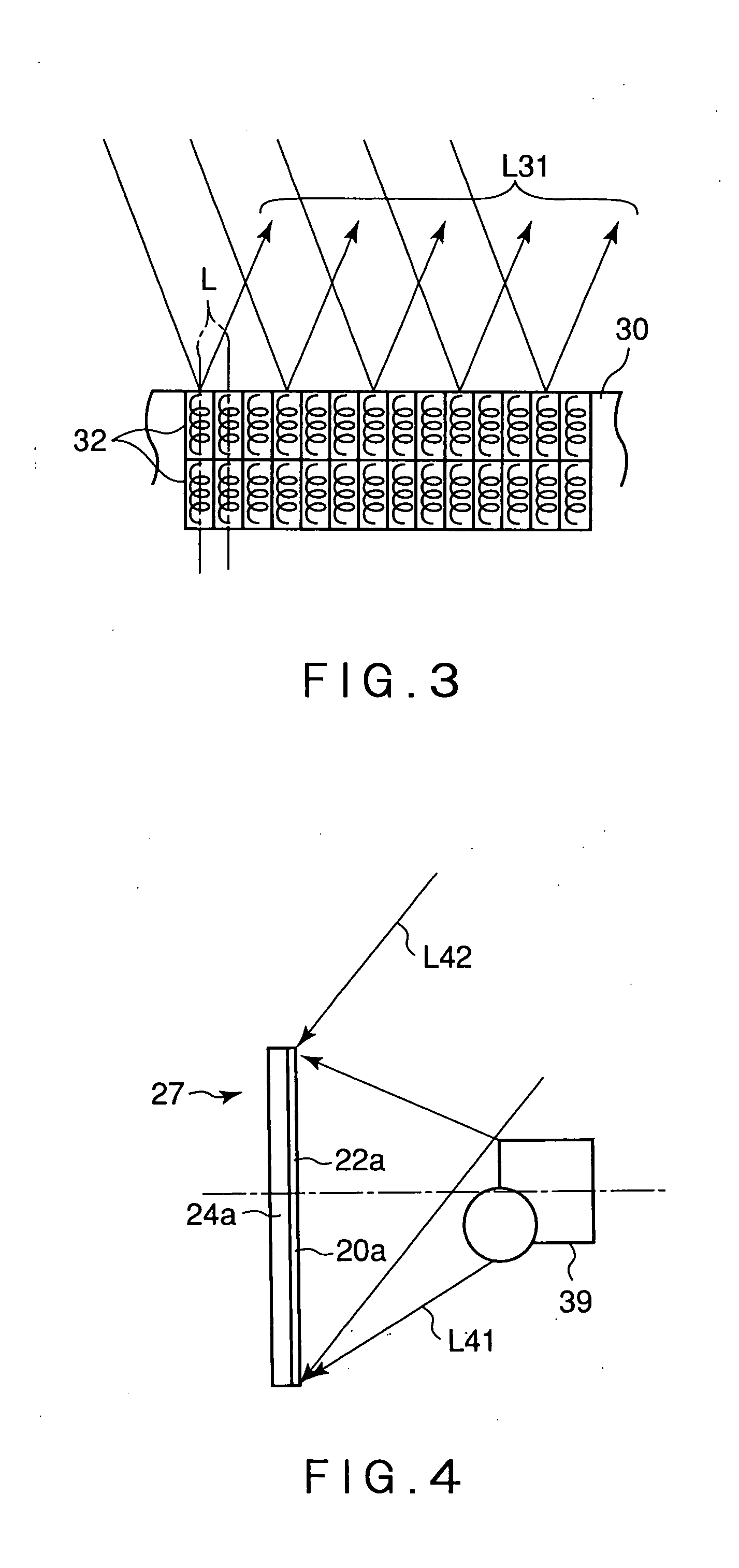

ActiveUS20070291339A1Accurate authenticityHigh accuracyOther printing matterPaper-money testing devicesVolume hologramOptoelectronics

An authenticity indicator that is difficult to be forged and whose authenticity can be confirmed easily and accurately is provided. The authenticity of the authenticity indicator 10 can be checked by making light enter the authenticity indicator 10 from front side and observing the light emerging from the front side or rear side. The authenticity indicator comprises a polarized-light selectively reflecting layer 30 that reflects a specified polarized component of incident light, and a transmission volume hologram layer 20 disposed on the front side of the polarized-light selectively reflecting layer 30. According to this authenticity indicator, its authenticity can be checked accurately by making use of its first authenticity recognition function attributed to the diffracting action of the transmission volume hologram layer and its second authenticity recognition function attributed to the polarized-light selectivity of the polarized-light selectively reflecting layer.

Owner:DAI NIPPON PRINTING CO LTD

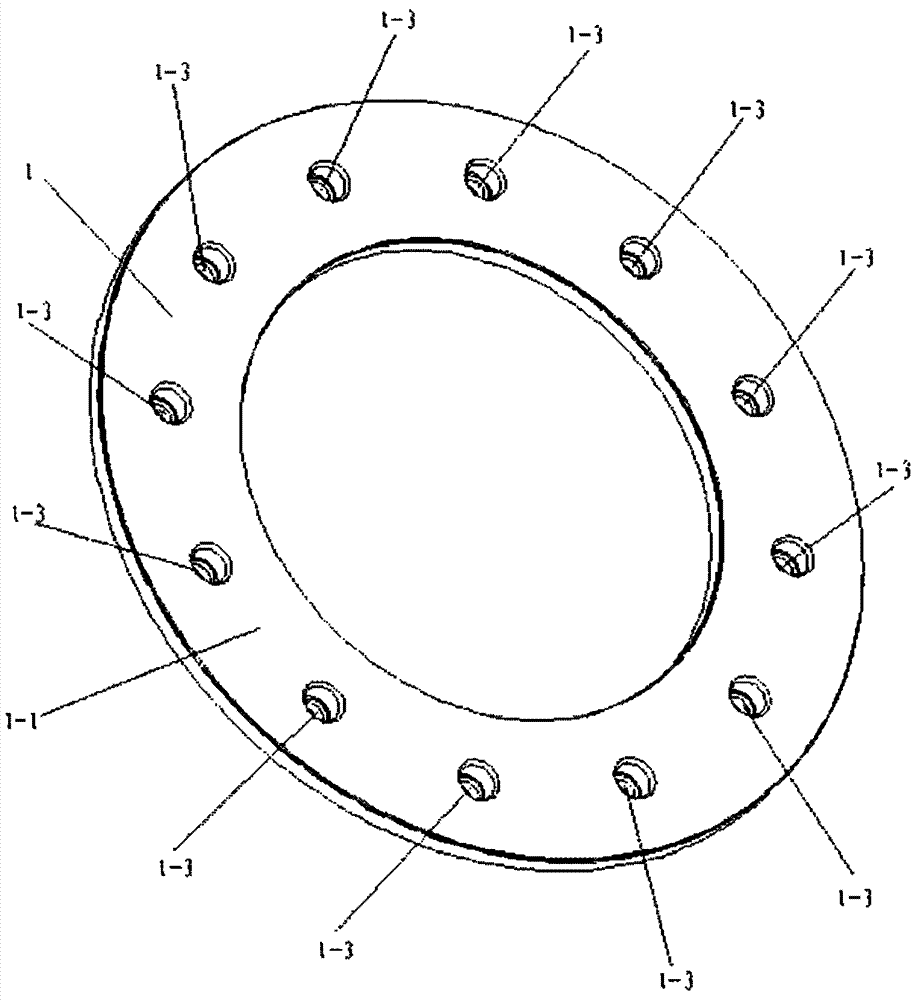

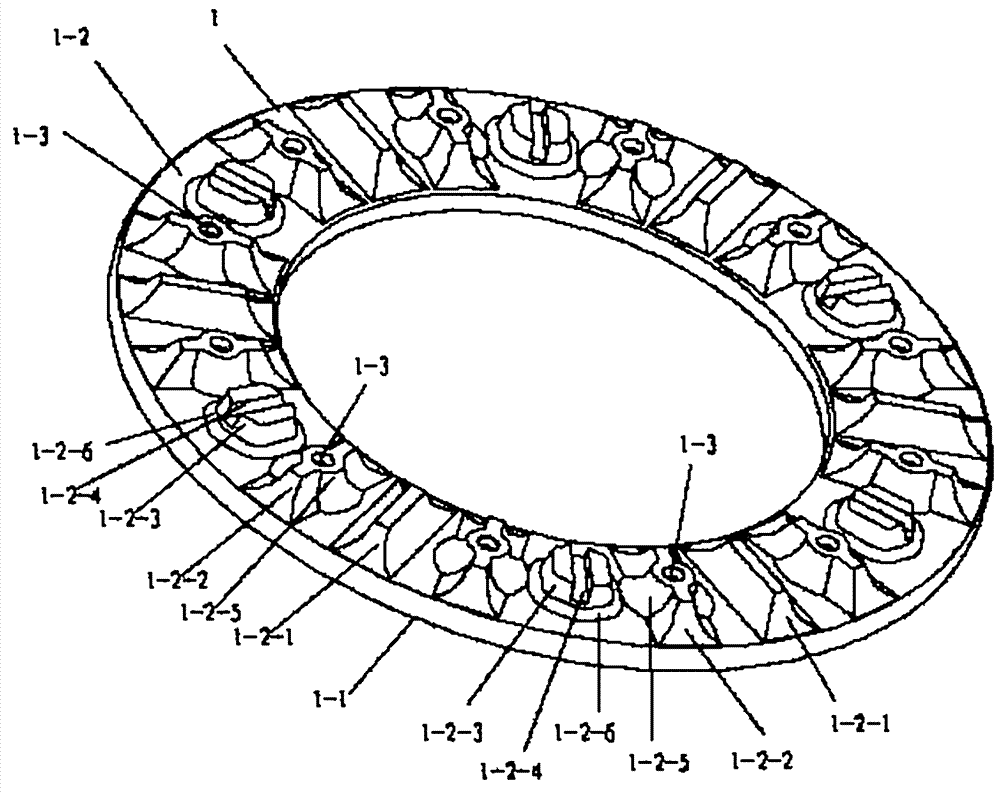

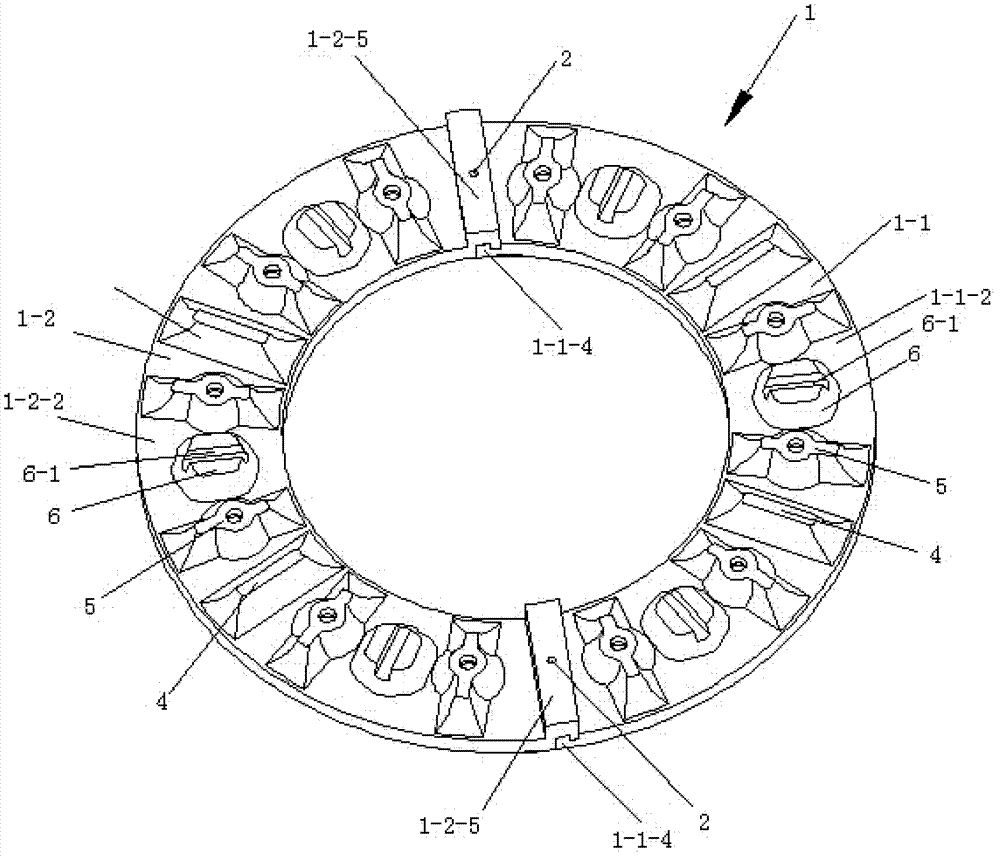

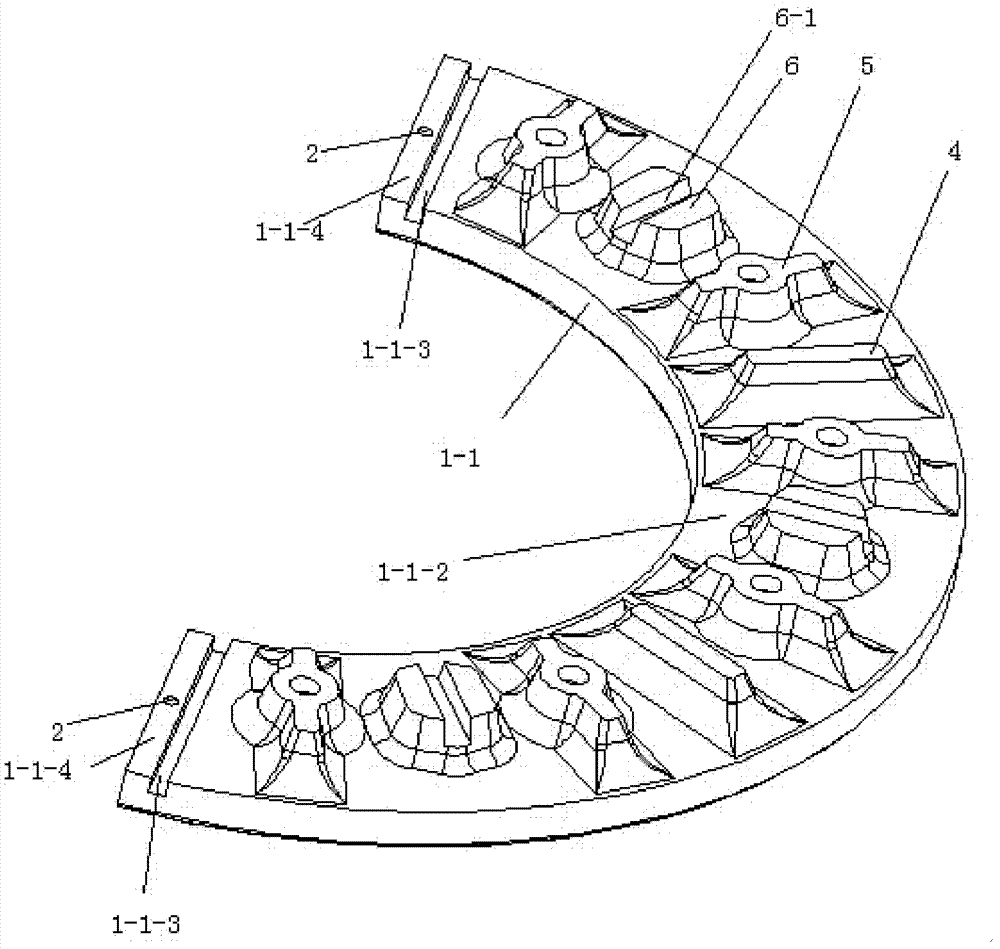

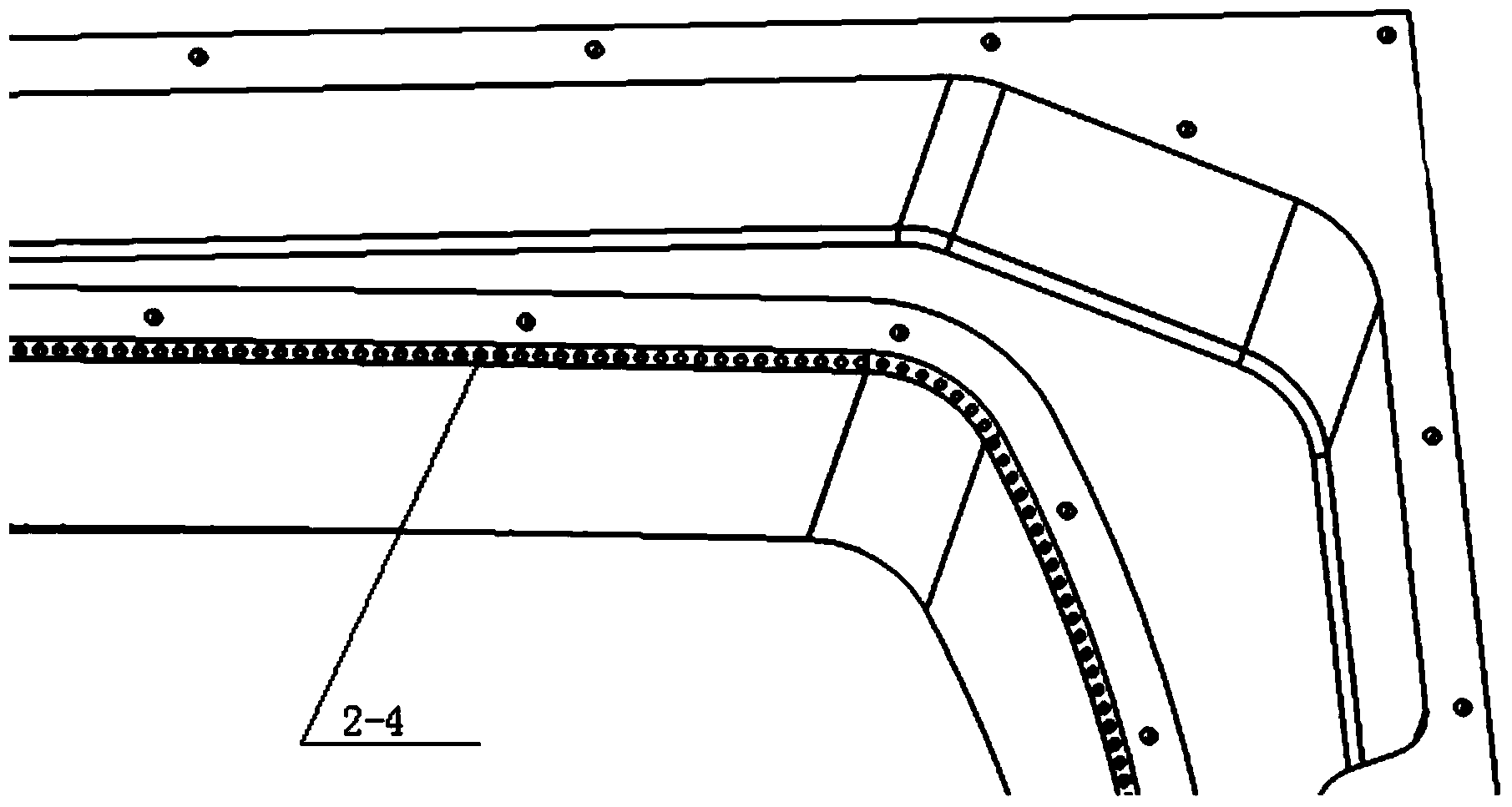

Brake disc of high-speed train

ActiveCN102900793ASpeed up circulationImprove cooling effectBraking discsEngineeringMechanical engineering

The invention discloses a brake disc of a high-speed train. The brake disc is provided with a disc body with a center hole. The disc body is provided with a friction surface and an inner side surface positioned on the back of the friction surface, a plurality of mounting holes are uniformly distributed on the disc body, a plurality of first radial platy radiating ribs, a plurality of second radial platy radiating ribs and a plurality of bosses are integrally forged on the inner side surface of the disc body, side surfaces of the first radial platy radiating ribs, side surfaces of the second radial platy radiating ribs and side surfaces of the bosses have draft angles, the mounting holes penetrate through the second radial platy radiating ribs, and radial keyways are arranged on the bosses. The brake disc is good in radiating effect, simple in forging forming and high in strength.

Owner:CRRC CHANGZHOU TECH MARK IND CO LTD +1

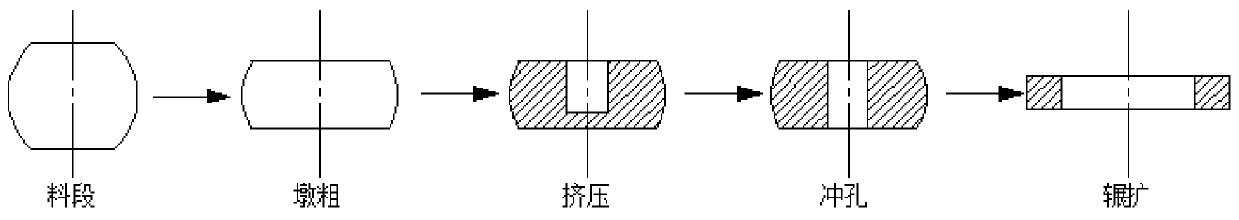

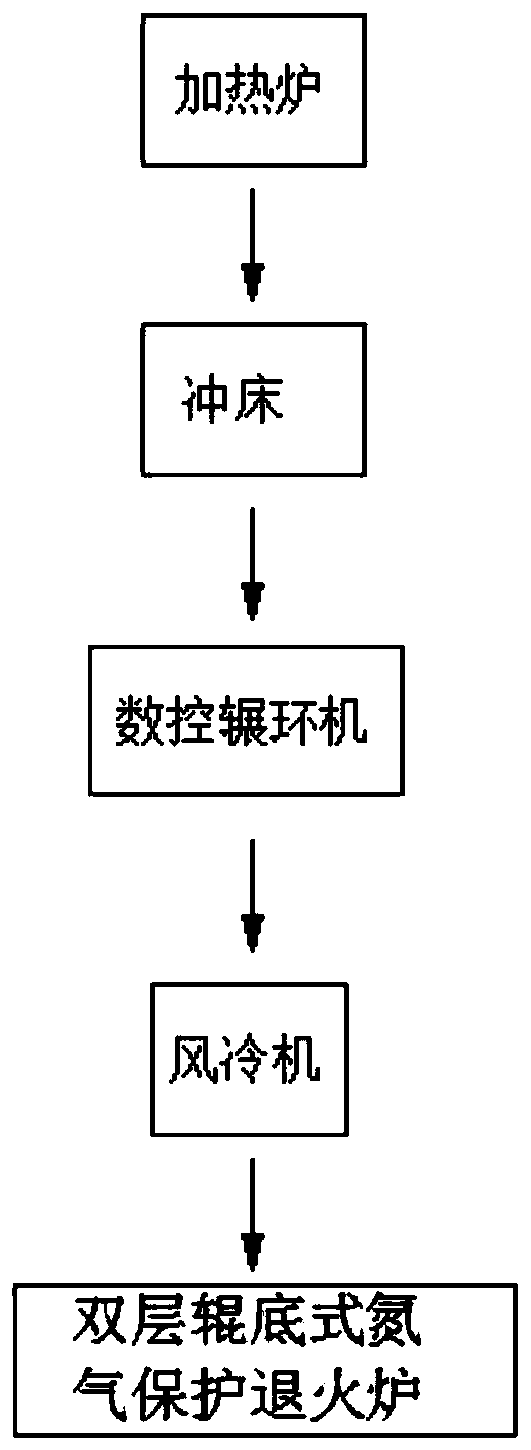

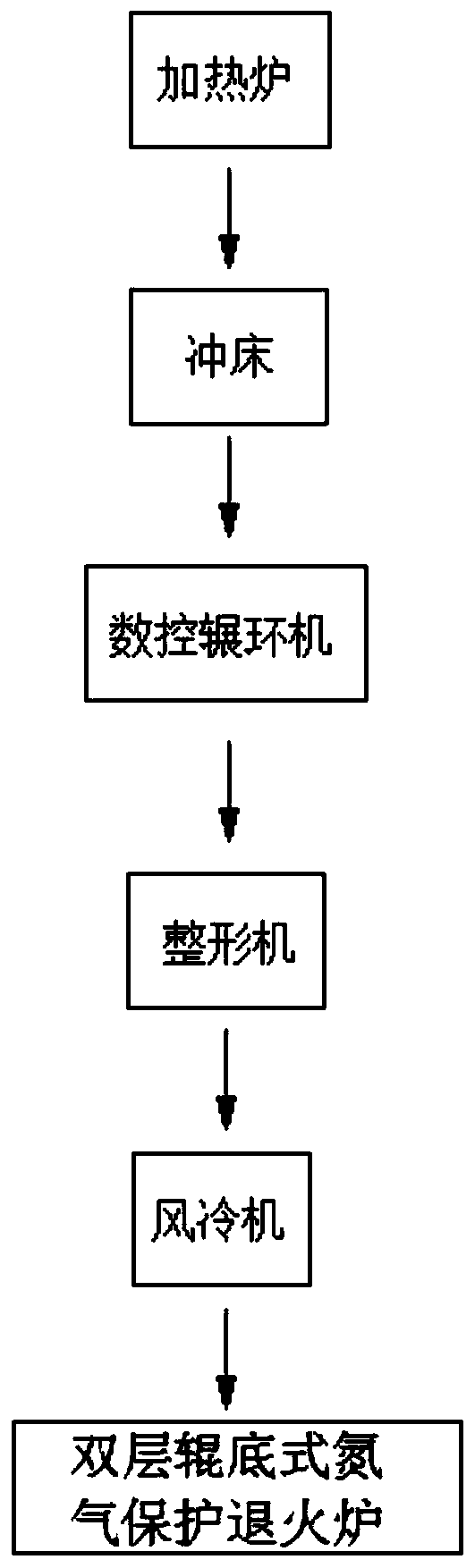

Bearing ring forging machining process and machining system

PendingCN109909437AHigh strengthHigh precisionMetal-working apparatusBearing componentsNumerical controlPunching

The invention discloses a bearing ring forging machining process and machining system, and relates to the technical field of bearing ring forging machining. The process includes the following steps that firstly, a steel material section of a high-carbon chromium bearing is heated to 1130 DEG C to 1180 DEG C; secondly, the heated material section is forged in the axial direction, and a material section subjected to upsetting is obtained; thirdly, the material section subjected to upsetting is extruded so that the middle portion of the material section subjected to upsetting can be indented, theindented portion of the middle portion of the material section is punched through, and a material section subjected to axial punching is obtained; fourthly, ring rolling is conducted on the materialsection, subjected to axial punching, through a numerical control ring rolling machine, and a ring is obtained; fifthly, the ring is air-cooled for 6 min to 8 min to 600 DEG C or below; and sixthly, spheroidizing annealing is conducted on the air-cooled ring through a double-layer roller hearth type nitrogen protection annealing furnace. The machining system comprises a heating furnace, a punchingmachine, the numerical control ring rolling machine, an air cooling machine and the double-layer roller hearth type nitrogen protection annealing furnace. By means of the bearing ring forging machining process and machining system, the surface roughness degree of the bearing ring can be decreased, no decarburized layers are generated after spheroidizing annealing, and therefore the cutting machining allowance is reduced, steel is saved, and the raw material utilization rate is increased.

Owner:临清市同兴轴承锻造有限公司

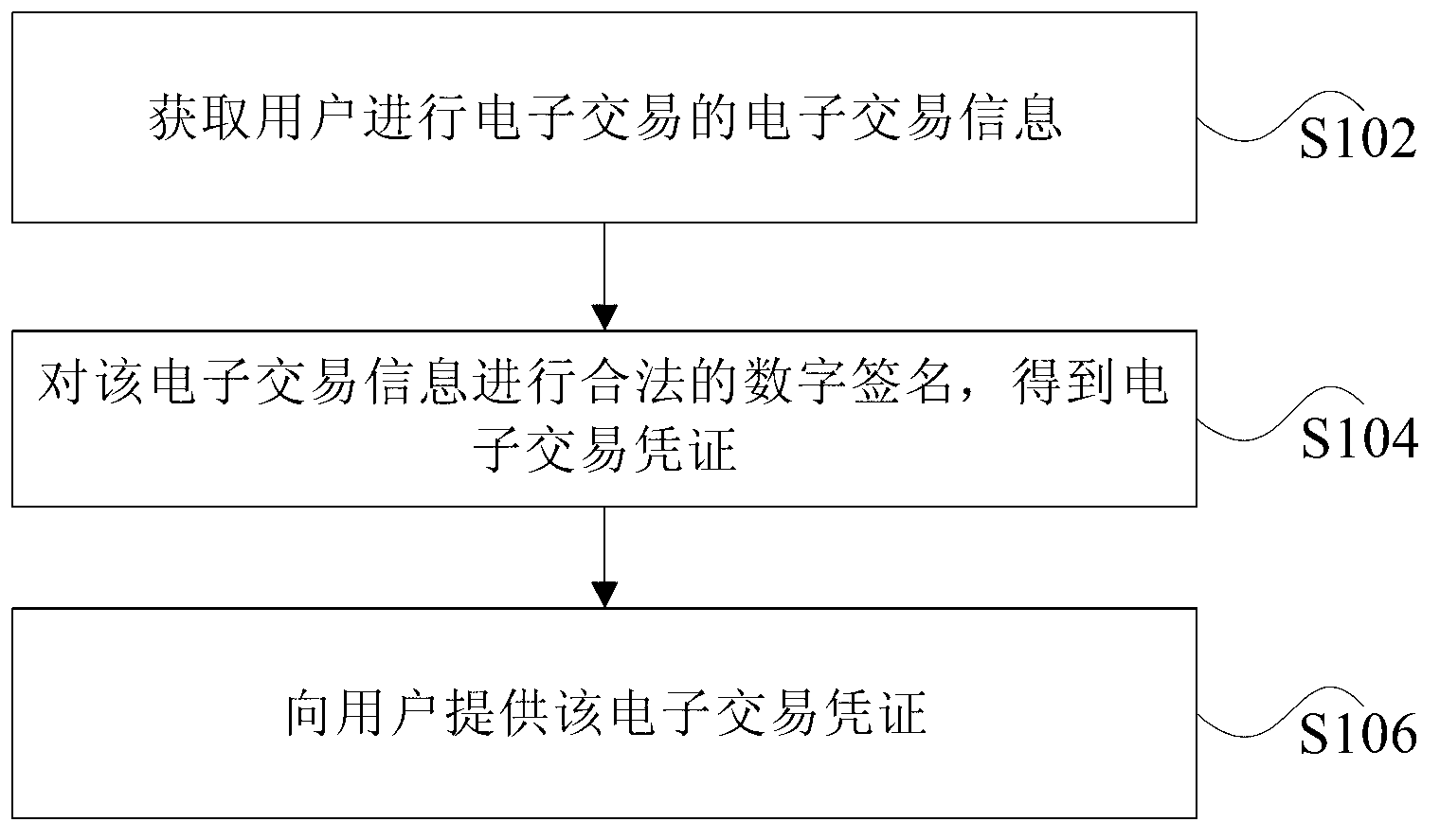

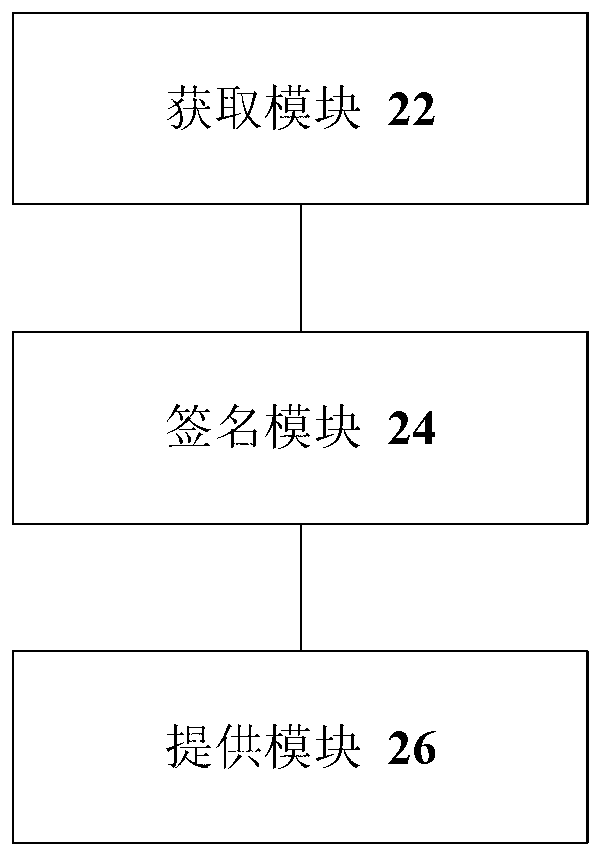

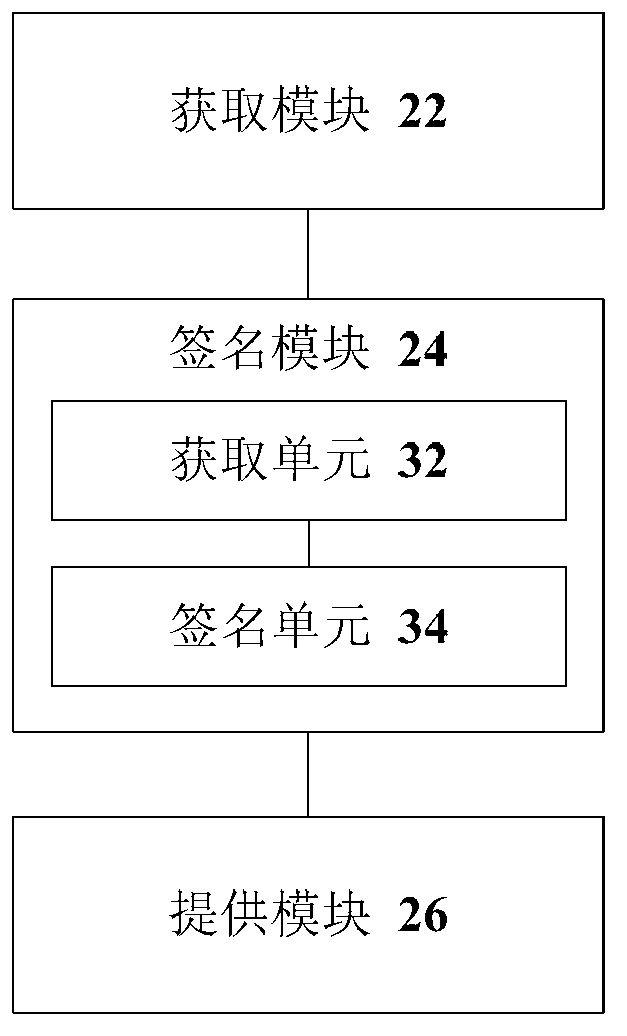

Processing method and device for electronic trading information

InactiveCN103268558AGuarantee authenticityGuaranteed non-repudiationCommerceNon-repudiationData mining

The invention discloses a processing method and device for electronic trading information. The processing method comprises the following steps of obtaining the electronic trading information of electronic trading conducted by a user, conducing legal digital signature on the electronic trading information, obtaining an electronic trading certificate, and providing the electronic trading certificate for the user. The processing method and device for the electronic trading information solves the problem that the electronic trading information is prone to being forged or tampered, and ensures authenticity and non-repudiation of the electronic trading information.

Owner:FUJIAN ETIM INFORMATION & TECH

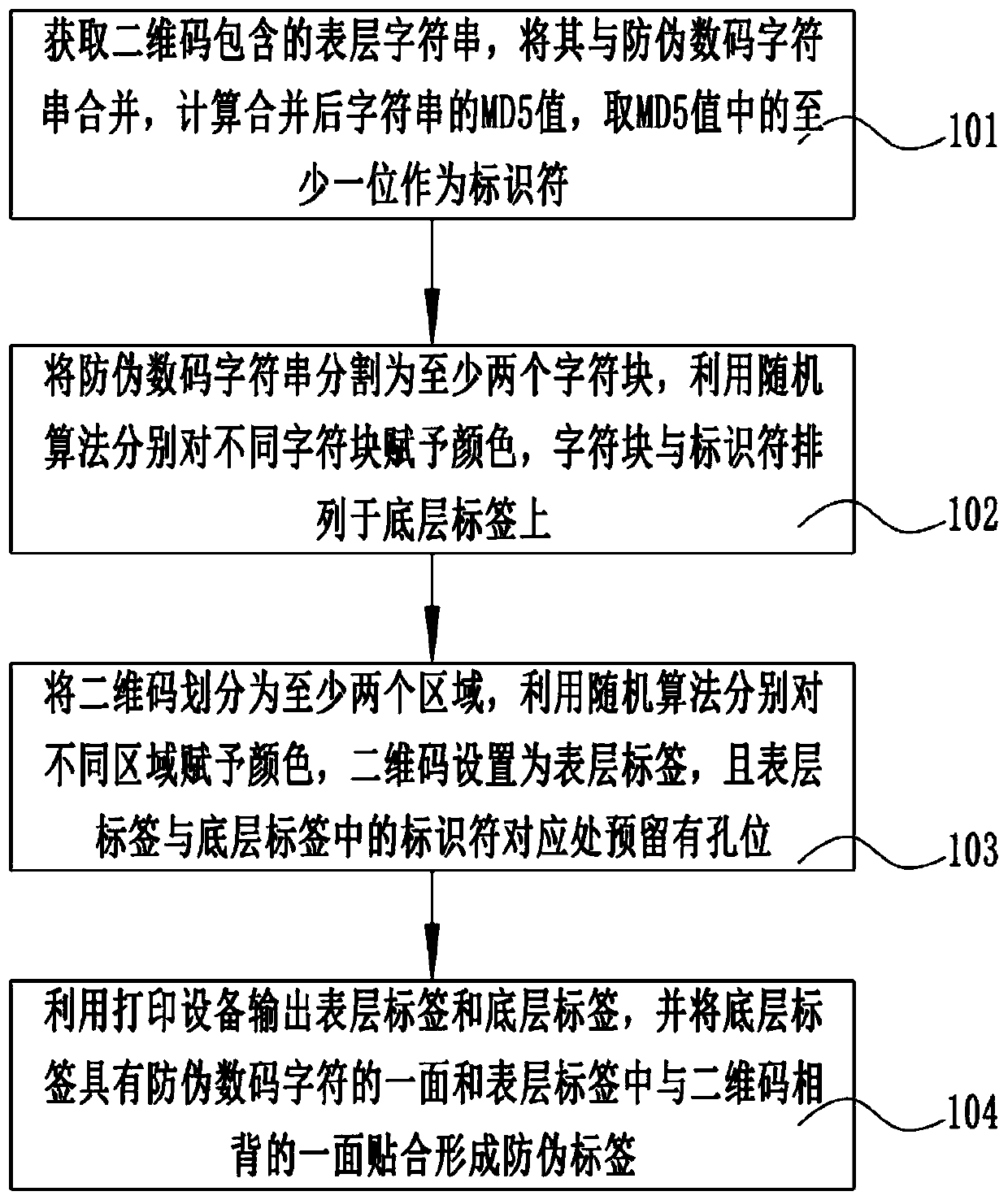

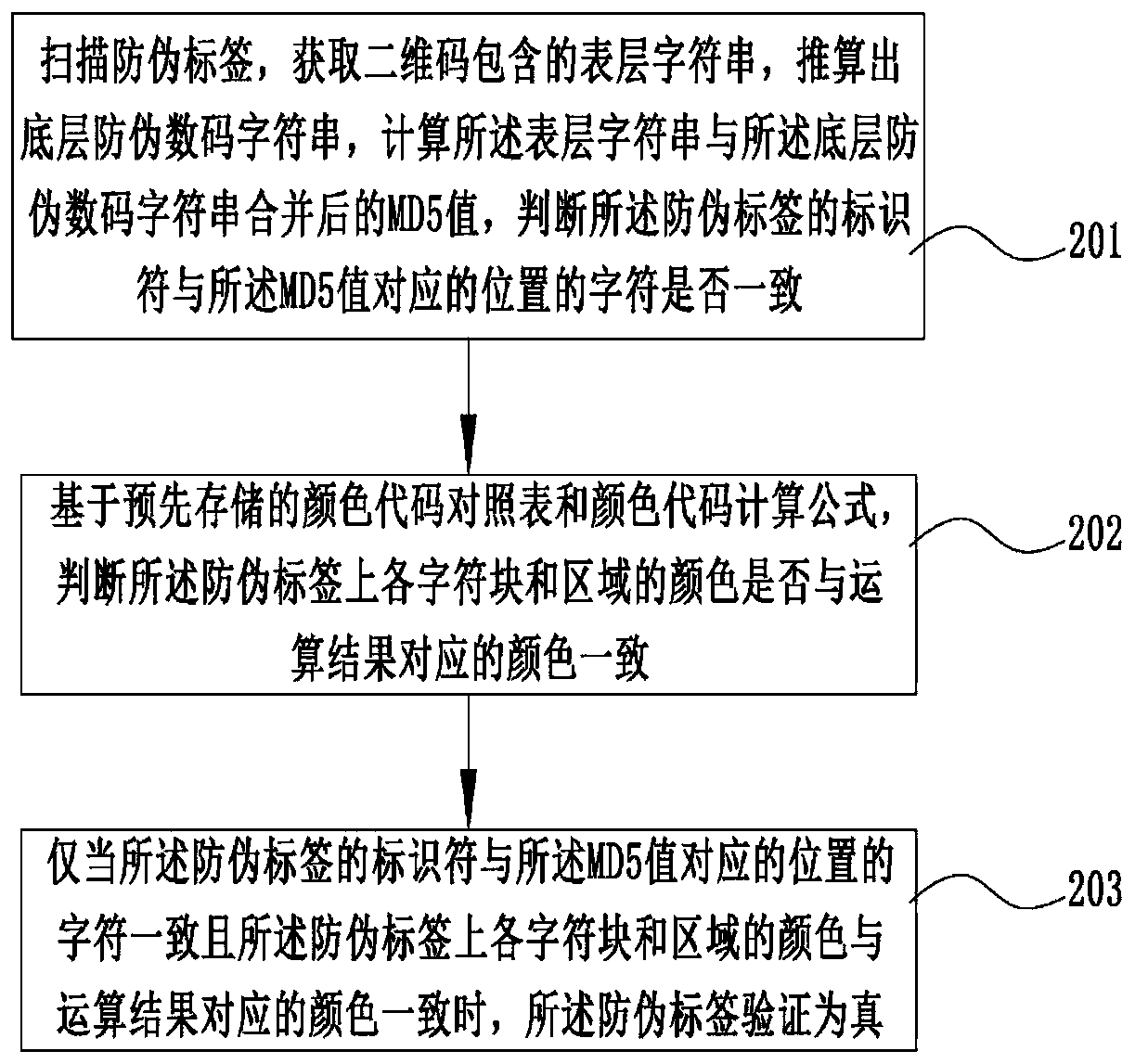

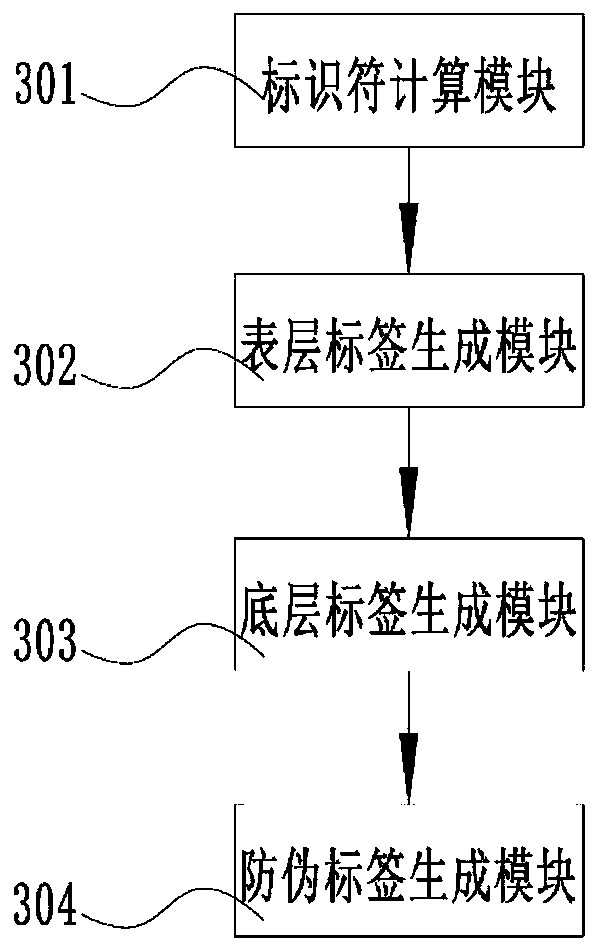

Generation method, verification method and system of anti-counterfeit label and anti-counterfeit label

ActiveCN110796221AEasy to forgeRecord carriers used with machinesAlgorithmTheoretical computer science

The invention provides an anti-counterfeit label generation method, an anti-counterfeit label verification method, an anti-counterfeit label verification system and an anti-counterfeit label. The anti-counterfeit label generation method comprises the following steps: acquiring a surface character string contained in a two-dimensional code, combining the surface character string with an anti-counterfeit digital character string, calculating an MD5 value of the combined character string, and taking at least one bit of the MD5 value as an identifier; dividing the anti-counterfeiting digital character string into at least two character blocks, respectively endowing different character blocks with colors by utilizing a random algorithm, and arranging the character blocks and identifiers on a bottom layer label; dividing the two-dimensional code into at least two regions, respectively endowing different regions with colors by using a random algorithm, setting the two-dimensional code as a surface layer label, and reserving hole sites at positions, corresponding to identifiers in a bottom layer label, of the surface layer label; and outputting the surface layer label and the bottom layerlabel by using printing equipment, and attaching the surface, with the anti-counterfeiting digital characters, of the bottom layer label to the surface, opposite to the two-dimensional code, of the surface layer label to form the anti-counterfeiting label. According to the anti-counterfeit label, various encryption measures are combined with colors, so that the safety is greatly enhanced.

Owner:周晓明

10Cr9Mo1VNb steel forge piece manufacturing process

ActiveCN103990758AReduced tendency to crackAvoid crackingEngine componentsInternal stressRefined grains

The invention provides a 10Cr9Mo1VNb steel forge piece manufacturing process which can well reduce internal stress of a forge piece and effectively avoid forge piece cracking and scrapping, can well refined grains, accordingly ensures the final product quality, reduces the annealing time and improves the production efficiency. The 10Cr9Mo1VNb steel forge piece manufacturing process is characterized by comprising the following steps of 1 heating the 10Cr9Mo1VNb steel forge piece, wherein the heating temperature is 850-1250 DEG C; 2 forging the heated 10Cr9Mo1VNb steel forge piece; 3 performing primary normalizing and tempering on the forged 10Cr9Mo1VNb steel forge piece; 4 performing secondary normalizing and tempering on the primarily normalized and tempered 10Cr9Mo1VNb steel forge piece.

Owner:WUXI HONGDA HEAVY IND

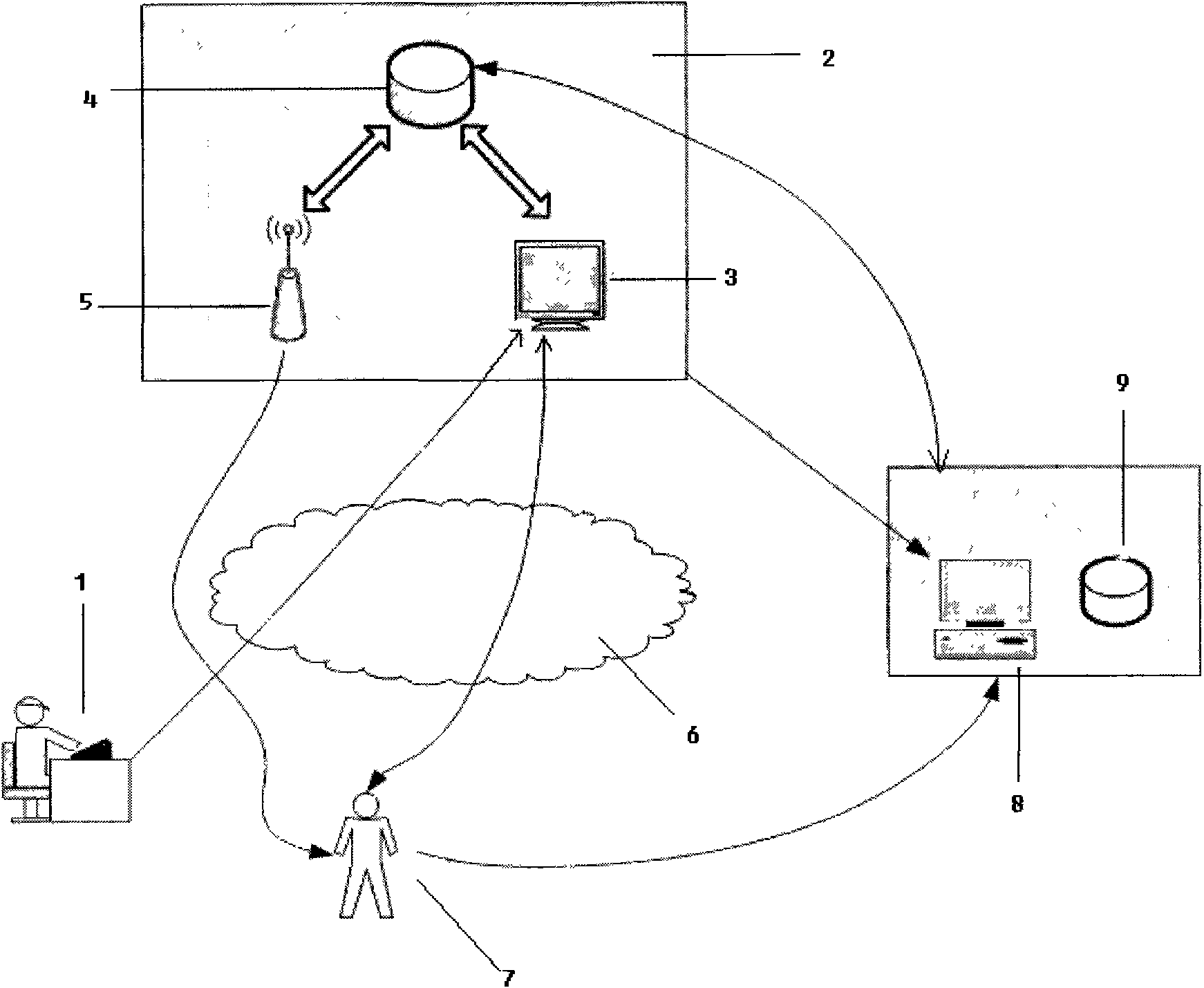

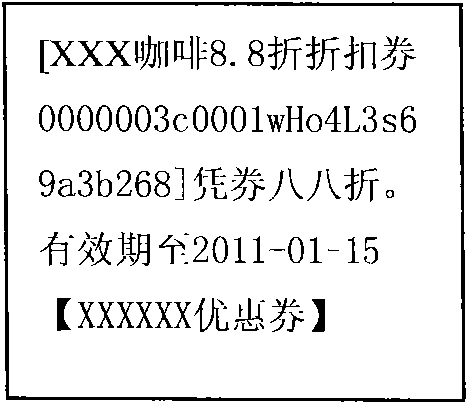

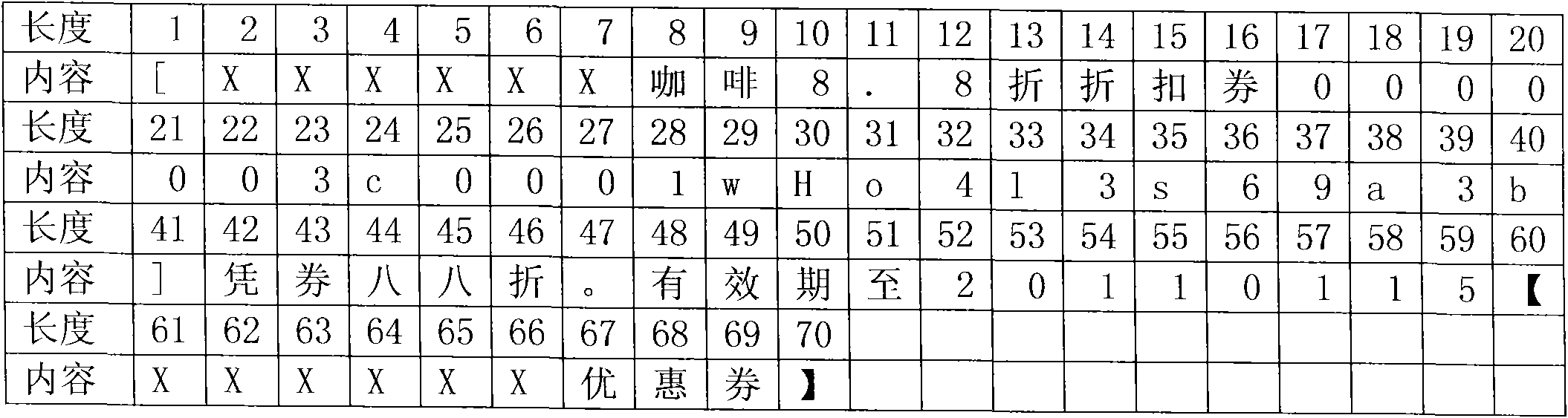

Short message coupon and application method thereof

InactiveCN101807281AEasy to useEasy to carryMessaging/mailboxes/announcementsMarketingChinese charactersE-commerce

The invention relates to the filed of electronic commerce, in particular relating to a short message coupon and an application method thereof. The short message coupon comprises two half pieces of short message coupons, namely a merchant check coupon containing contrast check information and another half piece of coupon to be checked containing profit information, the information forms short messages in the form of format coding, and the profit information is recorded, transmitted and checked in the form of short message. The invention has the benefits that in the invention, profit information with large information content is realized in the form of short message under the restriction of 70 Chinese characters through a well-designed coding rule, thus electronizing the coupon, and pertinently generating, sending down and using check and management, thereby successfully solving the problems in the prior art.

Owner:杭州一渡网络技术有限公司

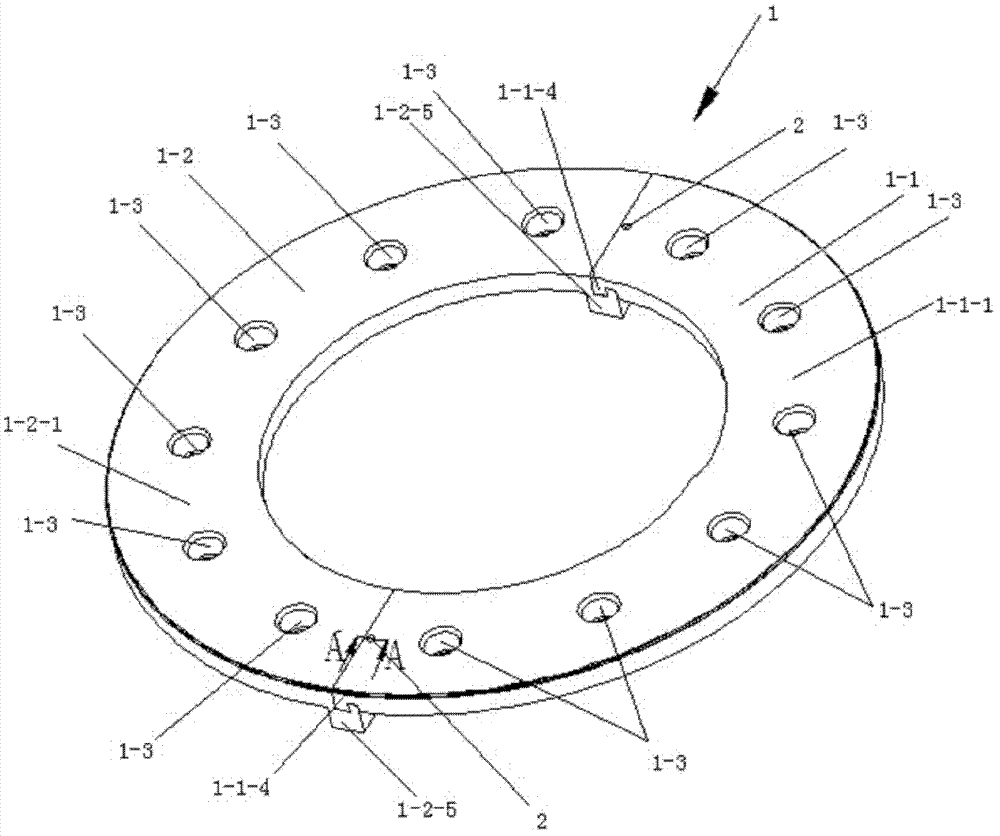

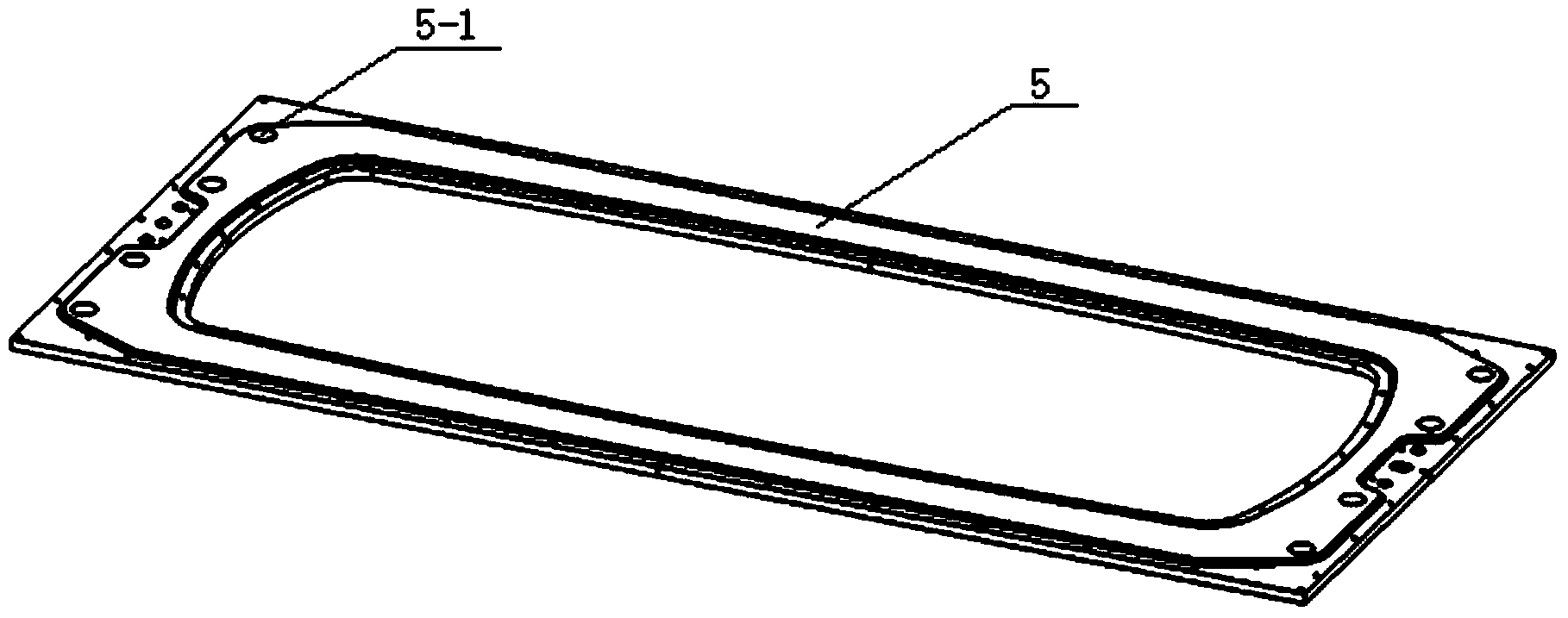

Split-type train brake disc

ActiveCN102900794ASimple connection structurePlay a positioning roleBraking discsEngineeringMechanical engineering

The invention discloses a split-type train brake disc which comprises a circular-ring-type disc body formed by assembling a first disc block and a second disc block; when the first disc block and the second disc block are assembled and connected, a first radial protrusion is positioned in a second radial groove; a second radial protrusion is positioned in a first radial groove; the first radial protrusion and the second radial groove are provided with communicated pin holes and / or the second radial protrusion and the first radial groove have communicated pin holes, and correspondingly, pin shafts pass through the corresponding pin holes on the first radial protrusion and the second radial groove and / or pin shafts pass through the corresponding pin holes on the second radial protrusion and the first radial groove. The split-type train brake disc provided by the invention is simple in connecting structure, and is convenient to position.

Owner:CRRC CHANGZHOU TECH MARK IND CO LTD +1

Production process of aluminium alloy casting rod specially used for Ford automobile rotary-swaged hub decorative rings

A production process of an aluminium alloy casting rod specially used for Ford automobile rotary-swaged hub decorative rings. The aluminium alloy casting rod comprises the following components by weight: 95.95-97.30% of Al, 0.95-1.05% of Mg, 0.72-0.8% of Si, 0.21-0.24% of Cu, 0.20-0.24% of Fe, 0.16-0.20% of Cr, 0.06-0.10% of Mn, 0-0.05% of Zn, and 0-0.05% of Ti. The process comprises the following steps: melting the components of Al, Mg, Si, Cu, Fe, Cr, Mn, Zn, and Ti in a melting furnace according to the weight ratios, uniformly stirring the melt, removing slag to obtain aluminium alloy melt; introducing the aluminium alloy melt into a standing furnace, refining with argon, nitrogen and No.2 flux powder; allowing the refined aluminium alloy melt to stand in a standing furnace at a temperature of 735 DEG C-745 DEG C for 30 min; performing casting molding by a hot-top casting machine, performing oil-gas mixing treatment on a casting machine by using oil-gas mixing lubrication graphite ring technology to obtain the aluminium alloy casting rod; cutting the aluminium alloy casting rod, and performing uniformization treatment and cooling treatment to obtain the aluminium alloy casting rod specially used for Ford automobile hubs.

Owner:秦皇岛开发区美铝合金有限公司

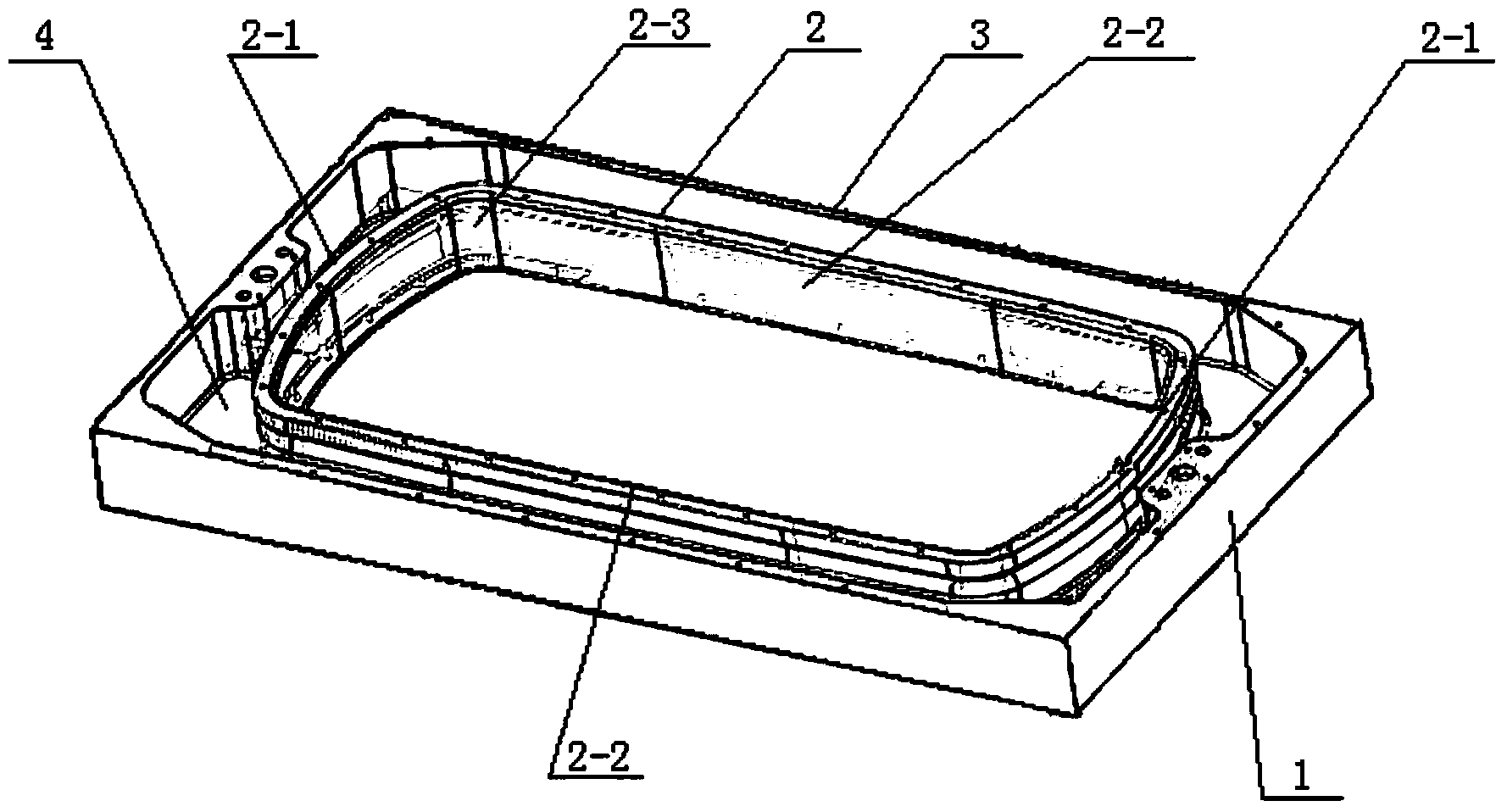

Crystallizer for preparing superhard aluminum alloy flat cast ingot and use method of crystallizer

The invention discloses a crystallizer for preparing a superhard aluminum alloy flat cast ingot and a use method of the crystallizer and relates to a tool for preparing the superhard aluminum alloy flat cast ingot and a use method of the tool.The crystallizer aims at solving the problem that superhard aluminum alloys produced by the existing casting tool have high possibility of crack rejects. The crystallizer for preparing the superhard aluminum alloy flat cast ingot comprises a crystallizer water chamber, a water chamber gland, a secondary water distribution plate and an oil gland, wherein the crystallizer water chamber comprises a water chamber internal wall, a water chamber external wall and a water chamber base; a plane is arranged at a junction between the internal surface and the upper surface of the water chamber internal wall; water outlet holes are formed in the plane; water inlet holes are formed at the two ends of the water chamber gland in a length direction; and a lubricating oil channel is arranged on the water chamber base and located close to the water chamber internal wall on the plane on the outer side of a cavity.The use method comprises the step of arranging a water baffle in a down direction of the cast ingot below the crystallizer when in use.The method reduces crack tendency.

Owner:NORTHEAST LIGHT ALLOY CO LTD

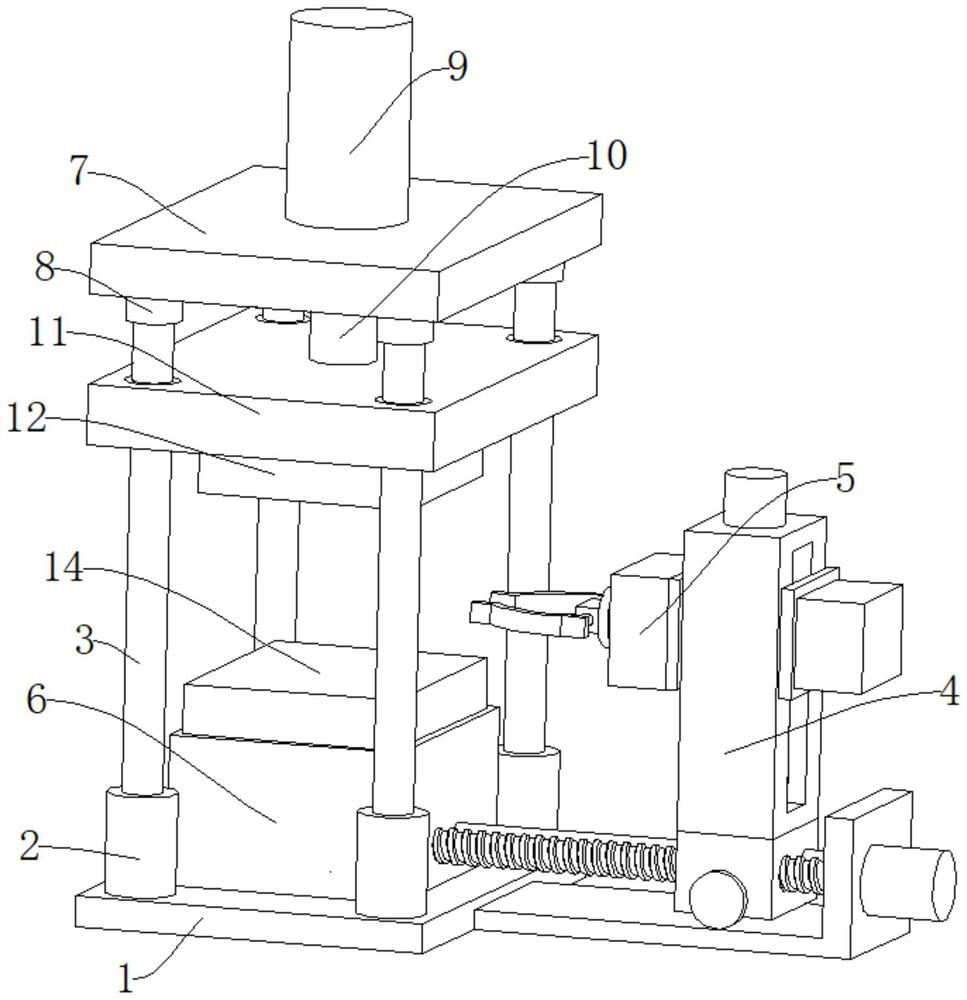

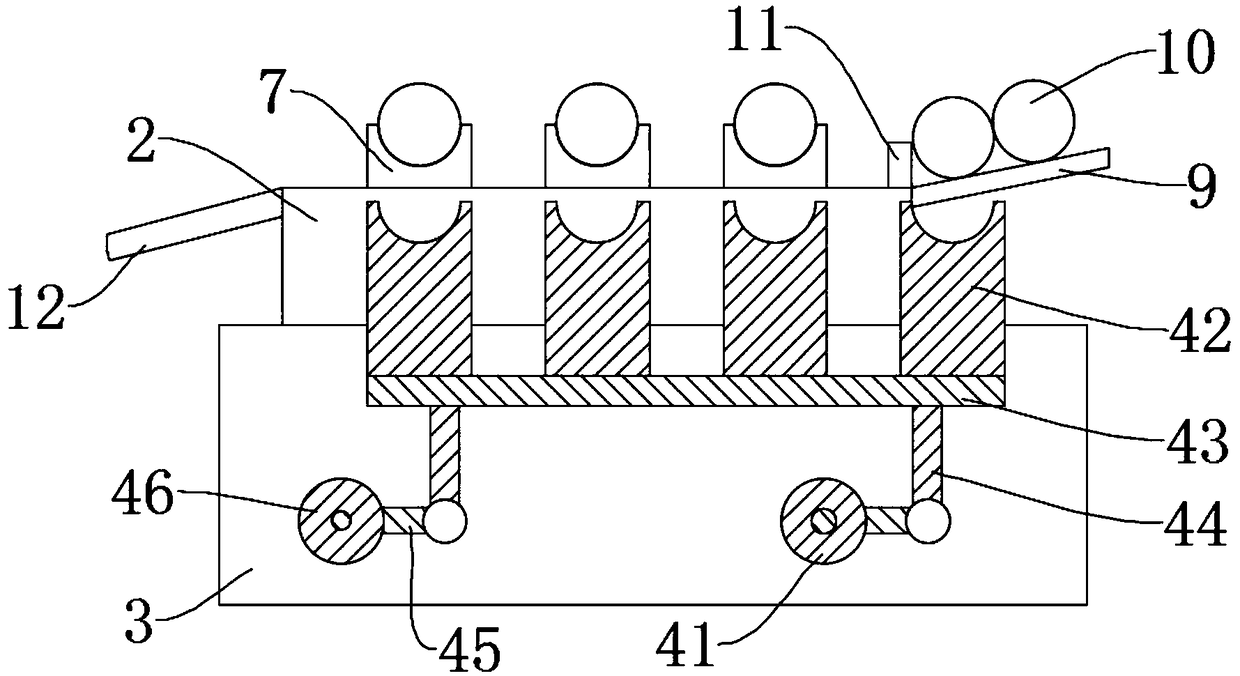

Forging forming device for coal mine scraper production

InactiveCN112157204AAvoid burnsImprove securityForging/hammering/pressing machinesForging press detailsHydraulic cylinderStructural engineering

The invention discloses a forging forming device for coal mine scraper production. The forging forming device comprises a bottom plate, sleeves and guide columns, the four sleeves are arranged at thetop of the bottom plate, a base is arranged inside the sleeves and at the top of the bottom plate, a workbench is arranged at the tops of the bases, the guide columns are arranged at the tops of the sleeves, fixing sleeves are arranged at the tops of the guide columns, a top plate is arranged at the tops of the fixing sleeves, and a one-way hydraulic cylinder is arranged on the top of the top plate. Due to the arrangement of moving mechanism and a clamping mechanism, workers can be prevented from being scalded by high-temperature chippings splashed during forging, and therefore the machining safety coefficient is increased; due to the arrangement of a fixing mechanism, scraper forging pieces of different sizes can be clamped, and the practicability of the device is improved; due to the arrangement of a rotating assembly, the scraper forging pieces can be adjusted in different directions, and therefore machining is facilitated; and due to the arrangement of the moving assembly and a height adjusting assembly, the clamping positions of the scraper forging pieces are adjusted, and machine forging is facilitated.

Owner:余秀朵

Composite metal article

InactiveUS20080299409A1Improve processing speedEasy for forgingFencingTablesHigh pressureCarbon steel

A composite metal article provided in the present invention includes a carbon steel core and a dissimilar composite metal out-layer, said out-layer combined with the carbon steel core by high pressure forging. As the high pressure forging belongs to the precise forging type, which molded by the method of inpour the metal liquid into the cavity on high pressure, thus it can form a thin composite out-layer out of the carbon steel core; it can combined a composite out-layer with the complex structure carbon steel core thus form a complex structure railing and metal table / chair etc.; it can combined complex structure composite out-layer with the simplex structure carbon steel core thus form a complex structure railings and metal table / chair etc.; as there are no air holes on the composite out-layer surface, it has a precise and nice-looking surface and can manufacture products by a simple post-processing.

Owner:HU JIAHUI

High-strength high-toughness corrosion-resistant zirconium-titanium-vanadium alloy and preparation method thereof

InactiveCN112226647ADoes not affect corrosion resistanceImprove mechanical propertiesTitaniumUltimate tensile strength

The invention relates to a high-strength high-toughness corrosion-resistant zirconium-titanium-vanadium alloy and a preparation method thereof. The alloy is a zirconium-titanium-vanadium alloy, and the atomic ratios of the three elements are as follows: 45-49 at% of Zr, 45-49 at% of Ti, 2-10 at% of V and the balance of inevitable impurities. The zirconium-titanium-vanadium ternary alloy with the vanadium element content being 6-10 at% shows good plasticity and yield strength, the zirconium-titanium-vanadium ternary alloy with the vanadium element content being 2-4 at% has high microhardness and yield strength, and besides, the zirconium-titanium-vanadium ternary alloy further has the characteristics of being simple in production process, good in corrosion resistance and the like.

Owner:HEBEI UNIV OF TECH

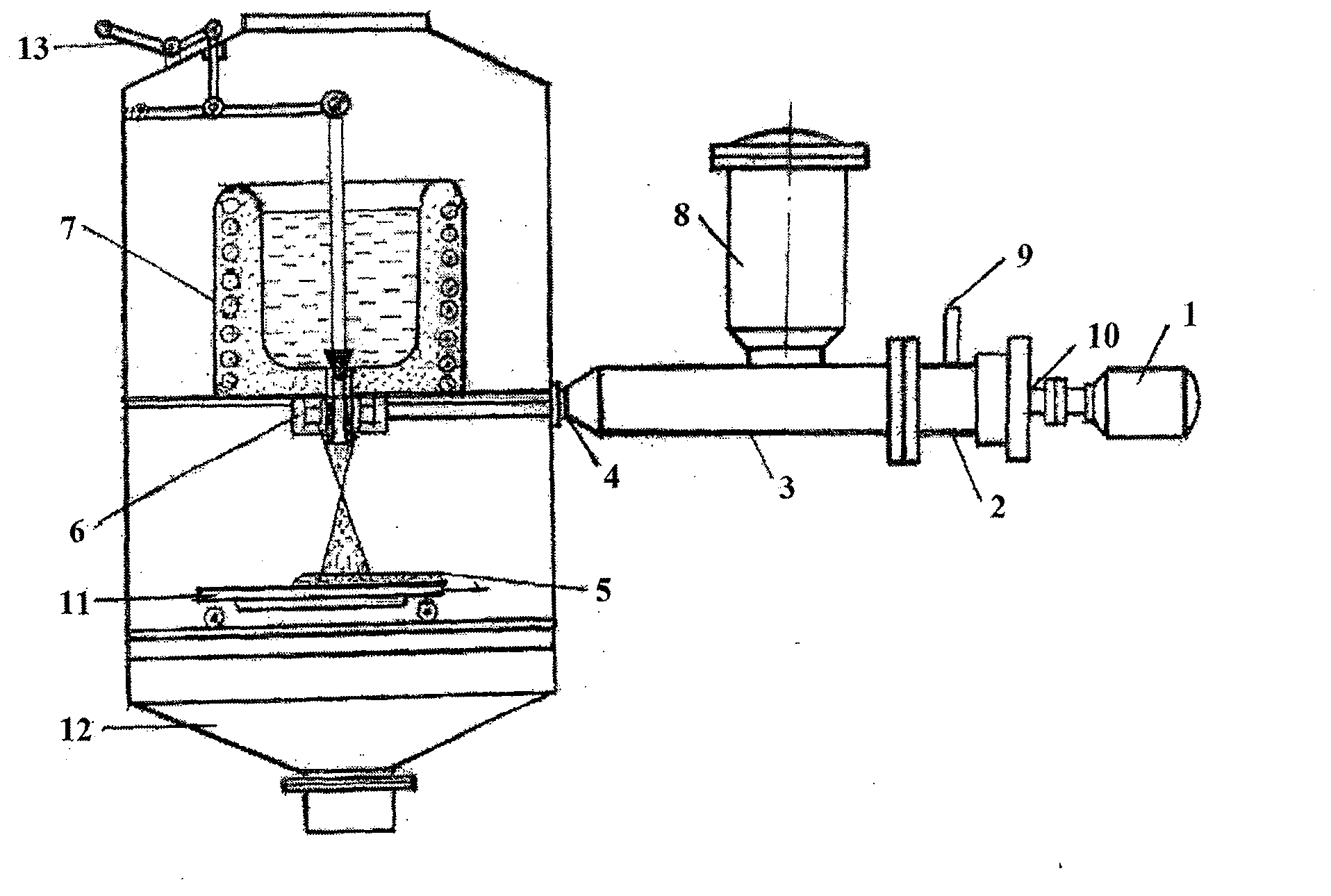

Preparation method for (WC/high-speed steel) steel-bonded cemented carbide and lamination material

InactiveCN103882361ASpeed up coolingEasy to forgeMolten spray coatingEmbossing decorationsHigh energyWear resistant

The invention belongs to the technical field of injection deposition of(WC / high-speed steel) steel-bonded cemented carbide and preparation of lamination materials, and provides a new method for preparing (WC / high-speed steel) steel-bonded cemented carbide by employing high-speed solid-phase particles such as WC, TiC or VC to performing injection deposition on a high-speed molten steel flow, and a new steel type for superhard cutter steel and hot work die steel. The invention provides a new technology for preparing armoring and special composite wear-resistant parts formed by compounding two layers or multiple layers of WC superhard high-speed steel and plain carbon steel or stainless steel. The invention provides a technical means for performing high-energy rapid quenching on molten steel, and under all kinds of technological states, the prepared (WC / high-speed steel) steel-bonded cemented carbide possesses the mechanical properties comprehensively better than those of conventional high-speed steel. A new special research means is provided for researching and developing new materials and revealing new phenomenon in material science. The technical scheme enables our country injection deposition technology to be improved to a world leading level, and have wide popularization meaning and application value.

Owner:吴庆华 +2

Authenticity indicator

ActiveUS7940436B2Easy to forgeConvenient and accurateOther printing matterPaper-money testing devicesSelective reflectionOptoelectronics

An authenticity indicator is difficult to be forged and has an authenticity that can be confirmed easily and accurately. The authenticity of the authenticity indicator can be checked by making light enter the authenticity indicator from front side and observing the light emerging from the front side or rear side. The authenticity indicator includes a polarized-light selectively reflecting layer that reflects a specified polarized component of incident light, and a transmission volume hologram layer disposed on the front side of the polarized-light selectively reflecting layer. According to this authenticity indicator, its authenticity can be checked accurately by making use of its first authenticity recognition function attributed to the diffracting action of the transmission volume hologram layer and its second authenticity recognition function attributed to the polarized-light selectivity of the polarized-light selectively reflecting layer.

Owner:DAI NIPPON PRINTING CO LTD

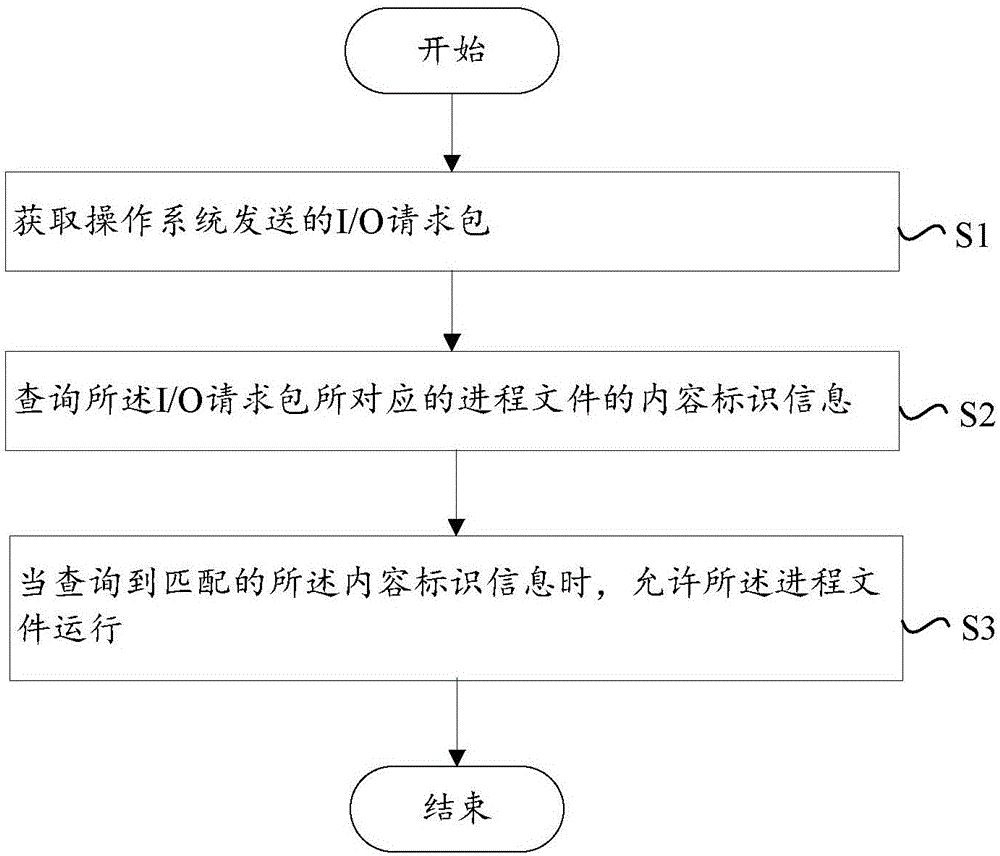

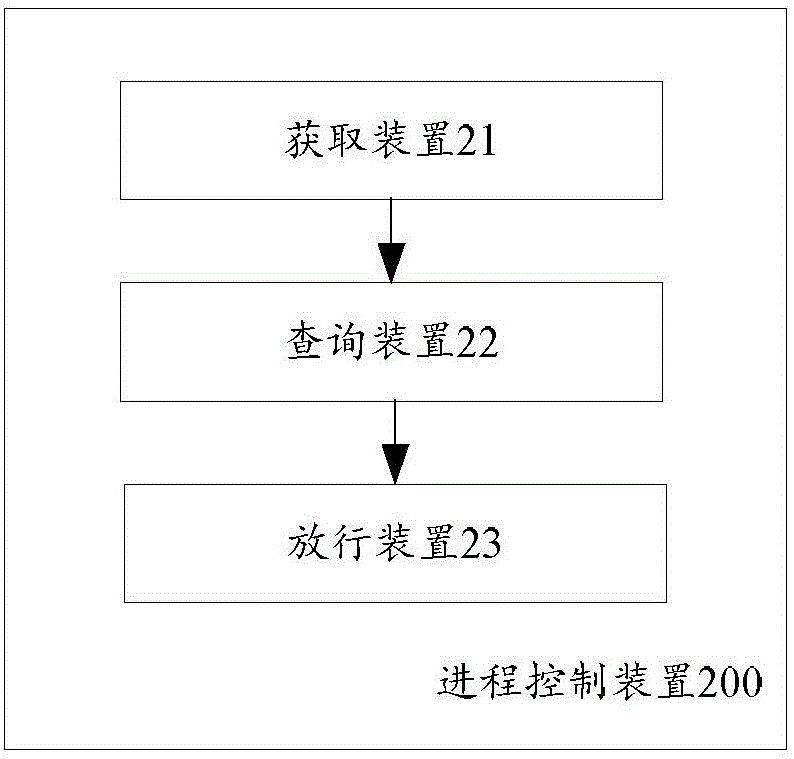

Process control method, apparatus and system

InactiveCN106548048AEasy to forgePrecise screeningProgram/content distribution protectionContent IdentifierOperational system

The invention aims to provide a process control method, apparatus and system. The method comprises the steps of obtaining an I / O request package sent by an operation system through the process control apparatus, wherein the I / O request package is generated by an I / O manager when an application is started; querying content identifier information of a process file corresponding to the I / O request package, wherein the content identifier information is generated based on contents of the process file; and when the matched content identifier information is queried, allowing the process file to run. A white list in the prior art generally stores names of process files, and as long as the names are same, processes are trusted processes, so that the processes are very easily counterfeited. Compared with the prior art, the process control method, apparatus and system has the advantages that the content identifier information of the process file needs to be checked before process running, and if the content identifier information is not in the white list, the process file is not allowed to run, so that hackers cannot counterfeit the trusted processes and whether the processes are the trusted processes or not can be accurately identified.

Owner:BEIJING UXSINO SOFTWARE

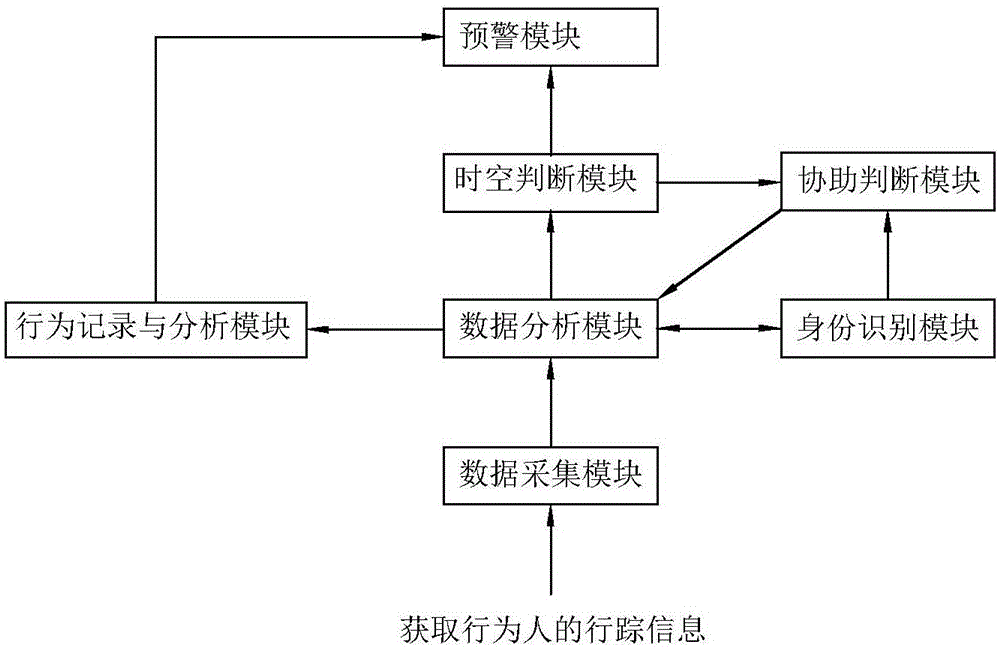

Identity authentication method and system for performing space-time uniqueness and continuity judgment

The invention relates to an identity authentication method and system for performing space-time uniqueness and continuity judgment. On the basis of big data rule analysis, unreasonable situations can be deduced according to existing rule calculation instead of exhaustion of all unreasonable situations in advance. Just like the game of go, on the basis of a chess manual, regular and reasonable judgment conclusions can be deduced automatically according to chess playing conditions. By means of the automatic deduction method, any counterfeiting and sneaking behaviors needing to be forewarned can be found in an almost non-dead-corner and non-loophole mode. The space-time uniqueness and continuity concept is adopted, in other words, the real identity of a doer is unique, the real doer should be in the unique location at a certain time, locations should be connective in the continuous time progress, and habit rules also exist on the basis that behaviors are executed at the certain time possibly or can be roughly deduced according to other information.

Owner:耀灵天华人工智能公共服务平台(山东省)有限公司

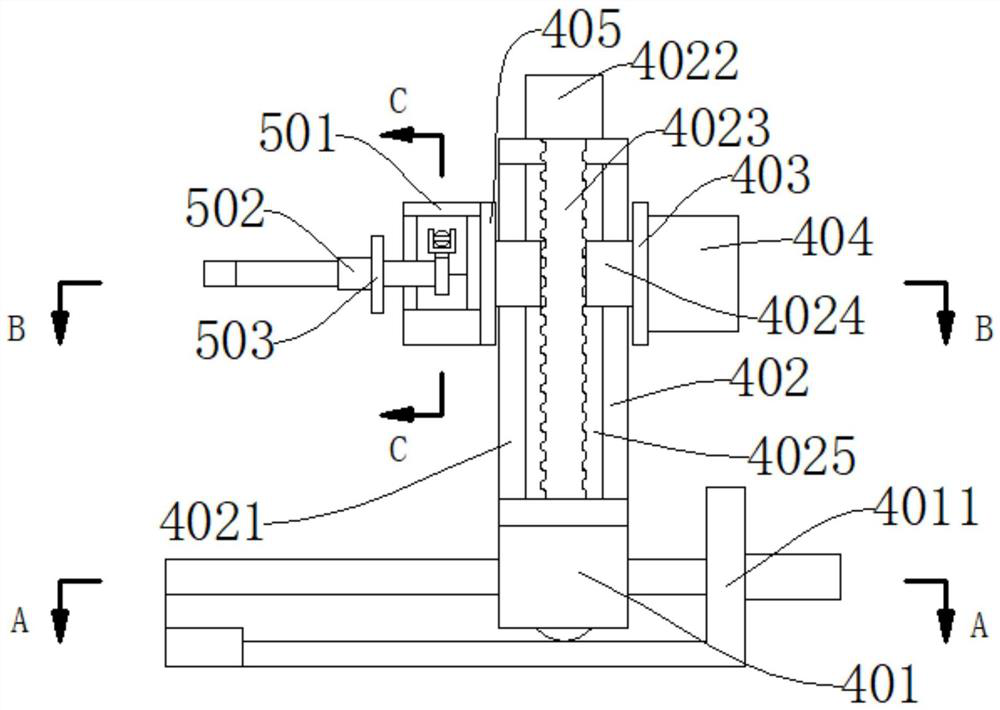

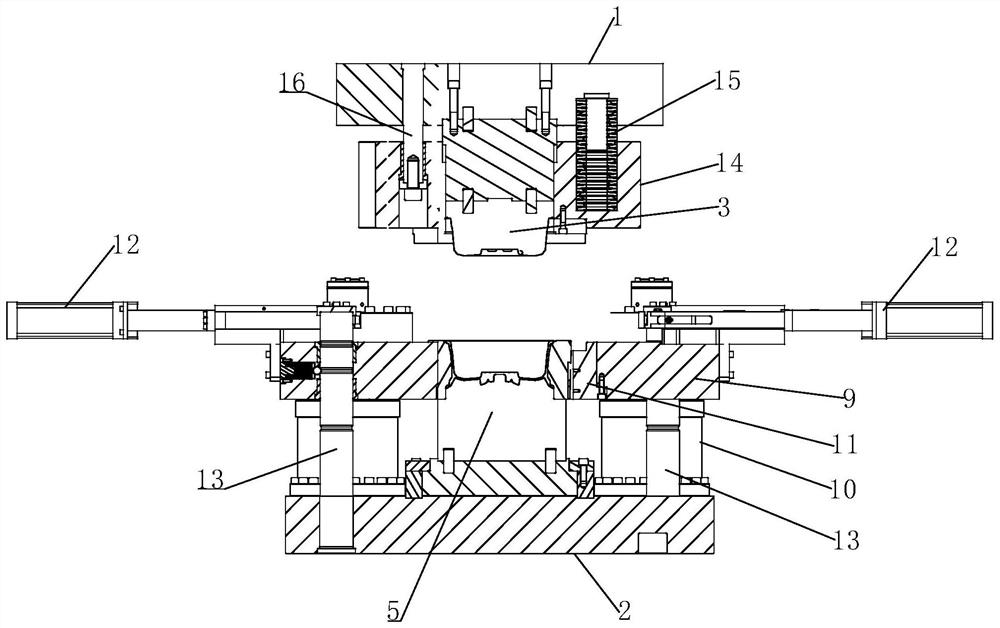

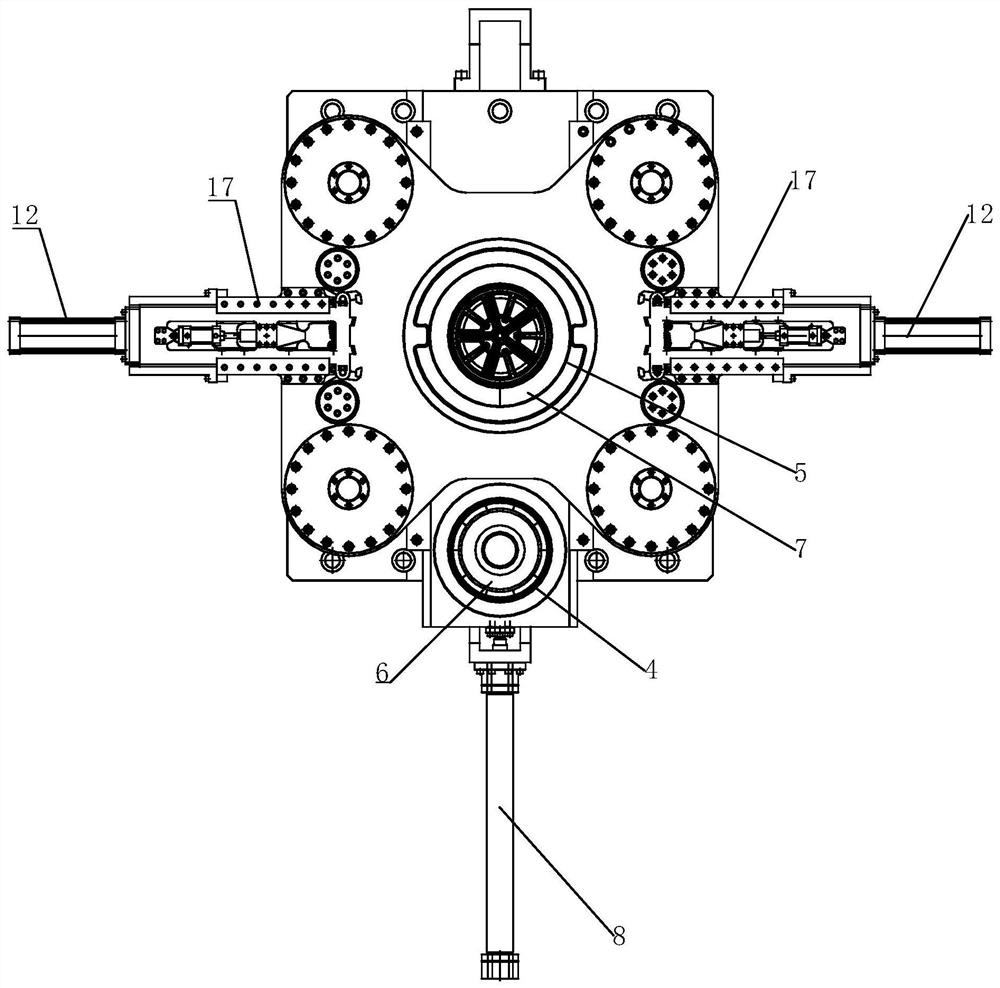

Forging forming device for automobile hub and using method thereof

PendingCN112496248AEasy to forgeIncrease productivityForging/hammering/pressing machinesWheelsHydraulic cylinderEngineering

The invention relates to a forging forming device for an automobile hub and a using method of the forging forming device. When the automobile hub is manufactured, a hub blank is heated and then placedin a pre-forging cavity of a pre-forging lower die; a second hydraulic cylinder drives a floating die holder to move upwards to the position above the lower die holder; a first hydraulic cylinder drives the lower die holder to move so that the pre-forging cavity can right face an upper die core. the second hydraulic cylinder drives the floating die holder to move downwards, so that two separabledie rings surround the edge of the pre-forging lower die and are combined with the pre-forging cavity; a press drives the upper die core to forge and press downwards, so that the hub blank is preformed; then, the second hydraulic cylinder drives the floating die holder to drive the preformed hub to move upwards to the position above the lower die holder; the first hydraulic cylinder drives the lower die holder to move so that a finish forging cavity can right face the upper die core; the second hydraulic cylinder drives the floating die holder to move downwards so that the preformed hub can beplaced in a middle section die cavity; and the press drives the upper die core to forge downwards, so that the hub blank is finally formed.

Owner:SHANGHAI YUNLIANG FORGING PRESS

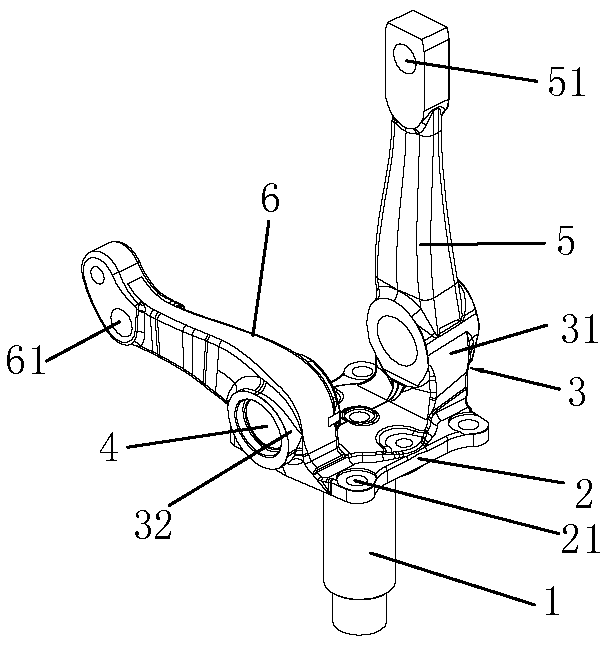

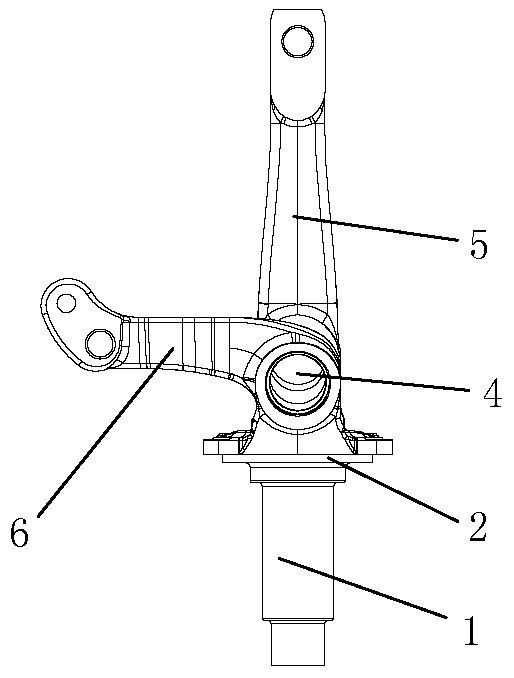

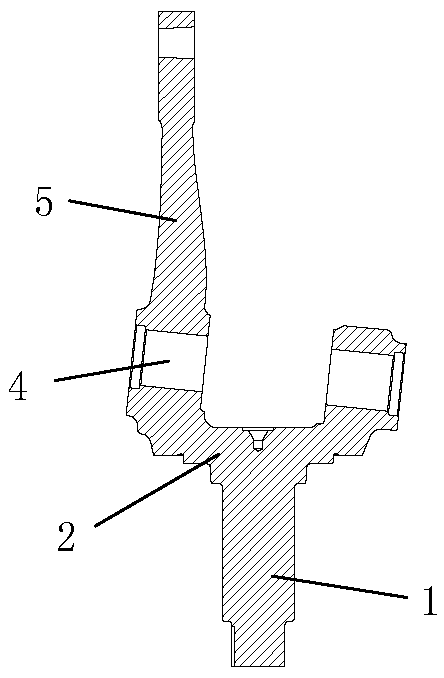

Automobile steering knuckle integrally formed with steering arm and machining technology of such automobile steering knuckle

ActiveCN107628107AStructural scienceSimple structureSteering linkagesRailway componentsMachiningWeight light

The invention relates to the technical field of steering knuckles, in particular to an automobile steering knuckle integrally formed with a steering arm and a machining technology of such automobile steering knuckle. The automobile steering knuckle is integrally formed by forging and comprises a rod portion, a disk portion and a lug portion, the lug portion comprises a long lug and a short lug, each of the long lug and the short lug is provided with a main pin hole, and the front end of the short lug extends out of the side face on the plane perpendicular to the main pin hole to form the steering arm connected with a steering tie rod. The automobile steering knuckle has the advantages that the automobile steering knuckle is scientific in structure and can be connected with other parts by extension of the steering arm, so that an automobile steering system is structurally simplified, and the novel lightweight steering knuckle is obtained; during machining, the lug portion is simple in structure without other connecting arms and convenient to forge and is machined into two long straight arms firstly, and then one long straight arm is bent into the steering arm, so that forging difficulty is reduced.

Owner:HUBEI TRI RING FORGING

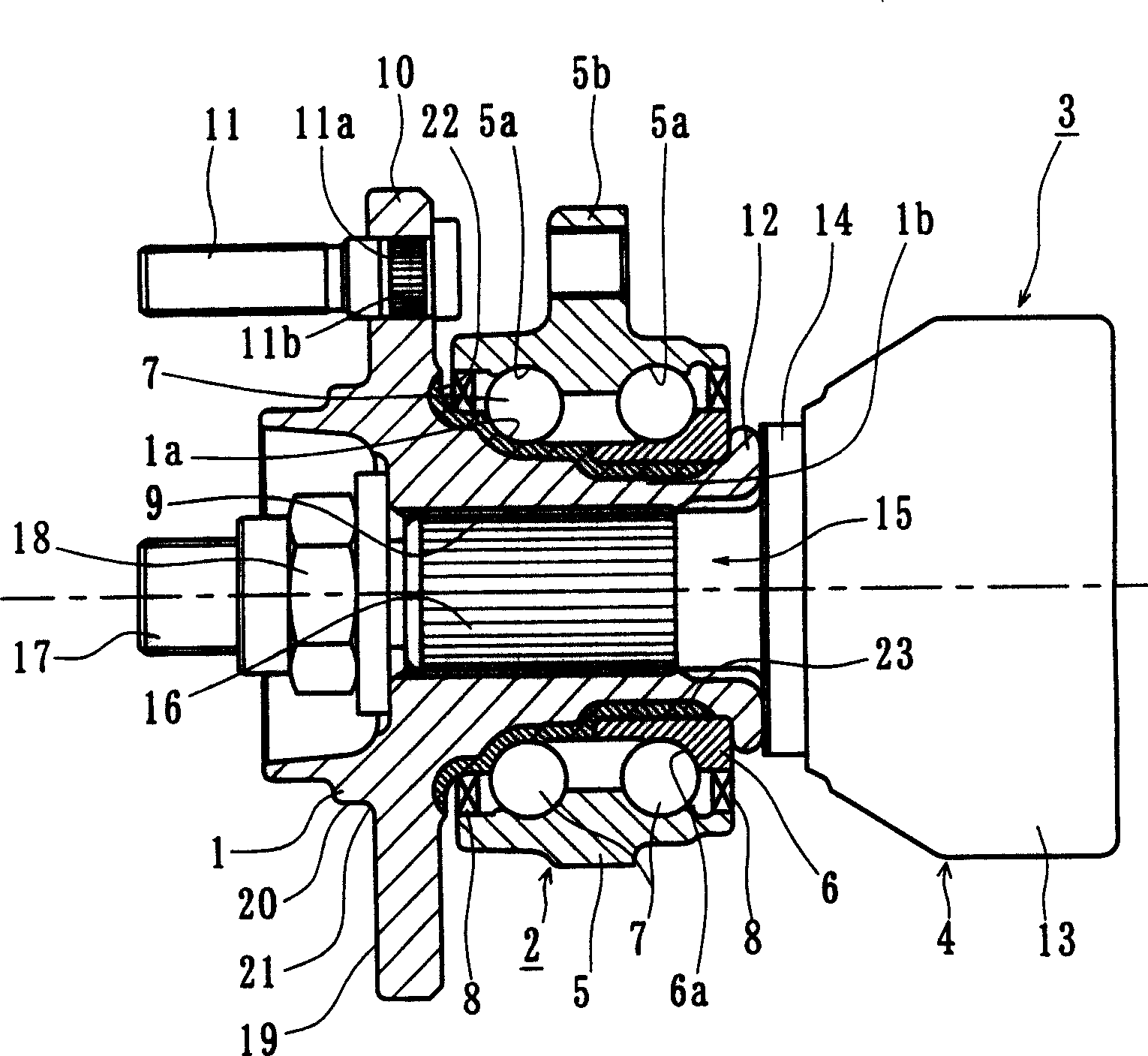

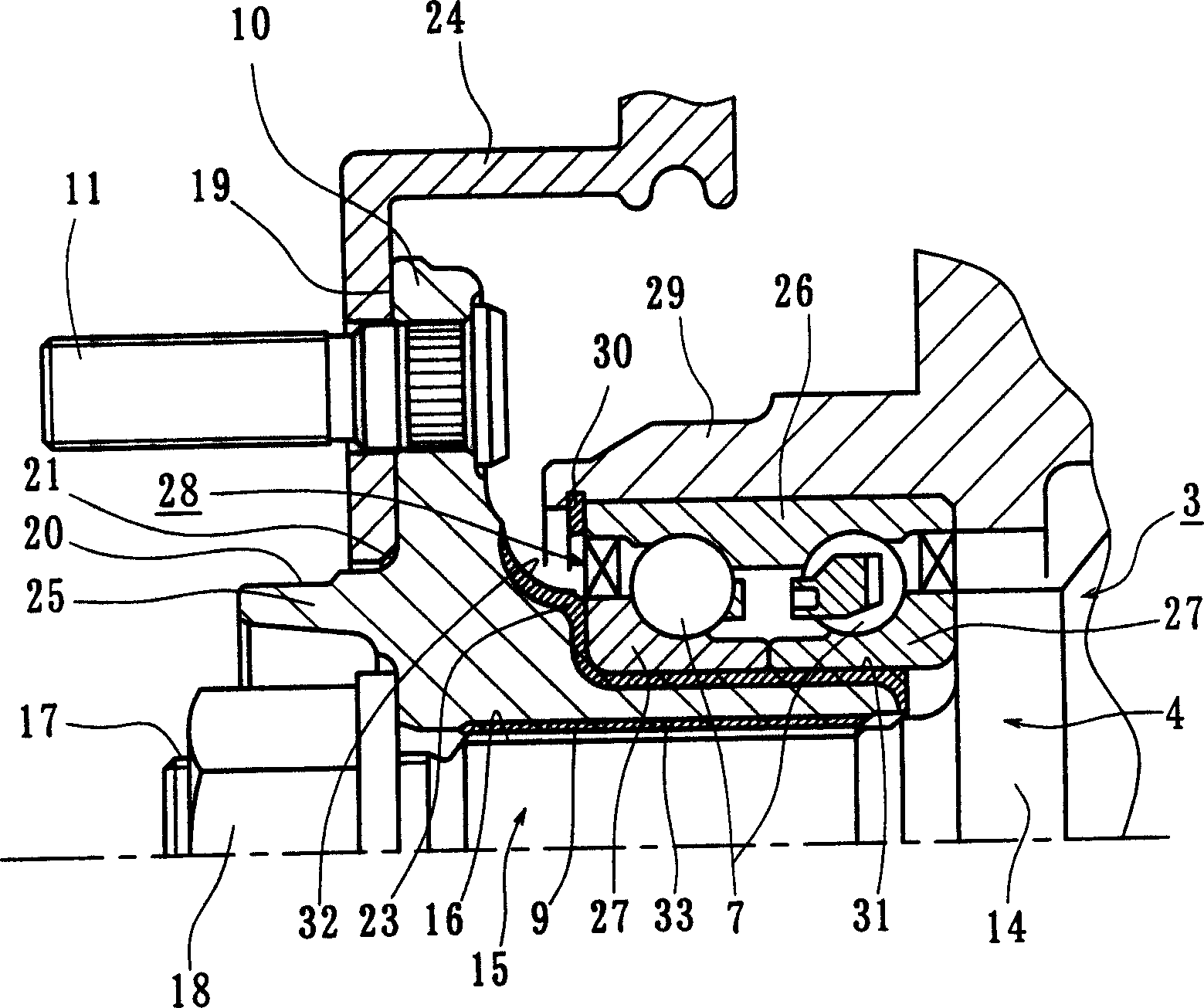

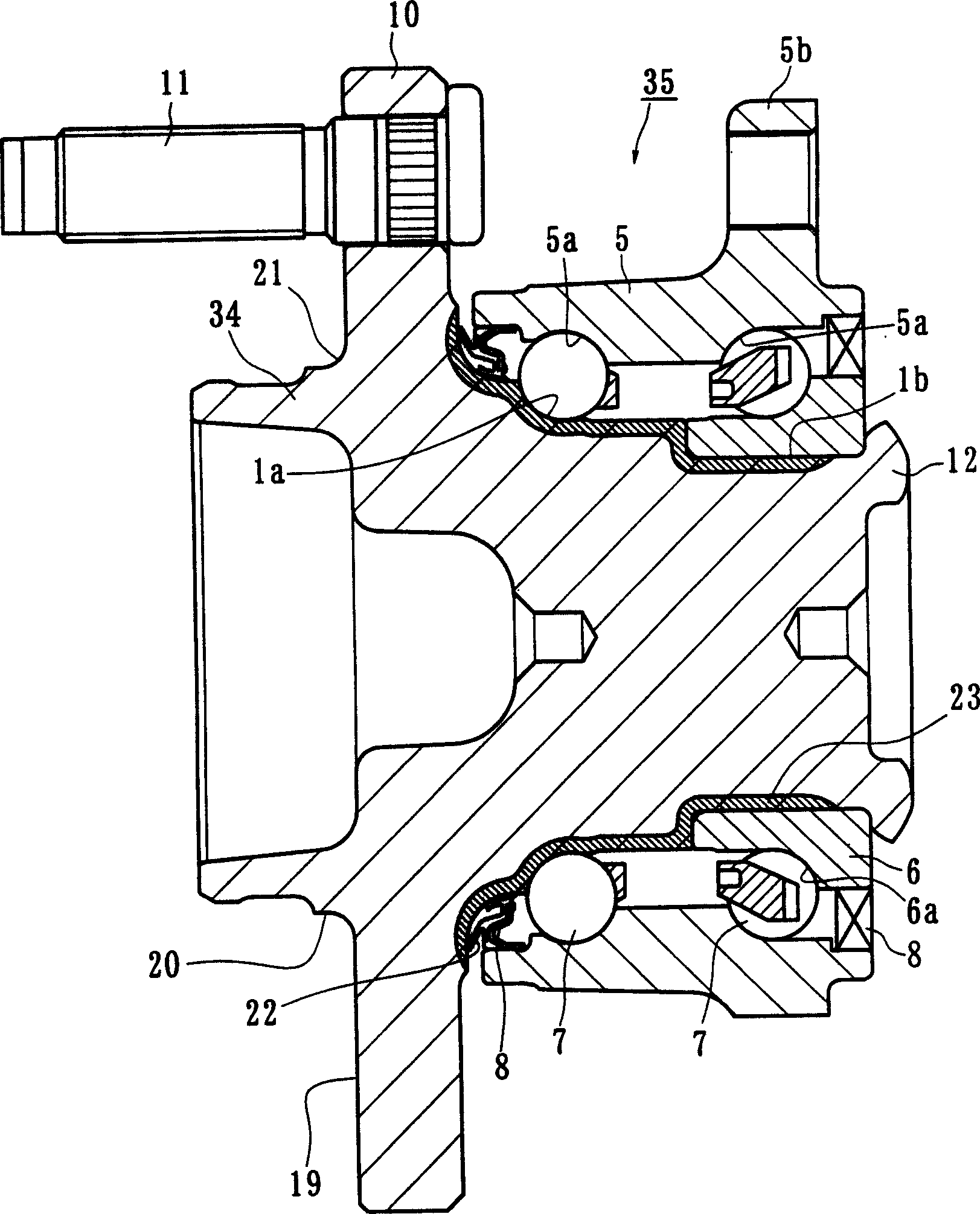

Bearing apparatus for a wheel of vehicle

Owner:NTN CORP

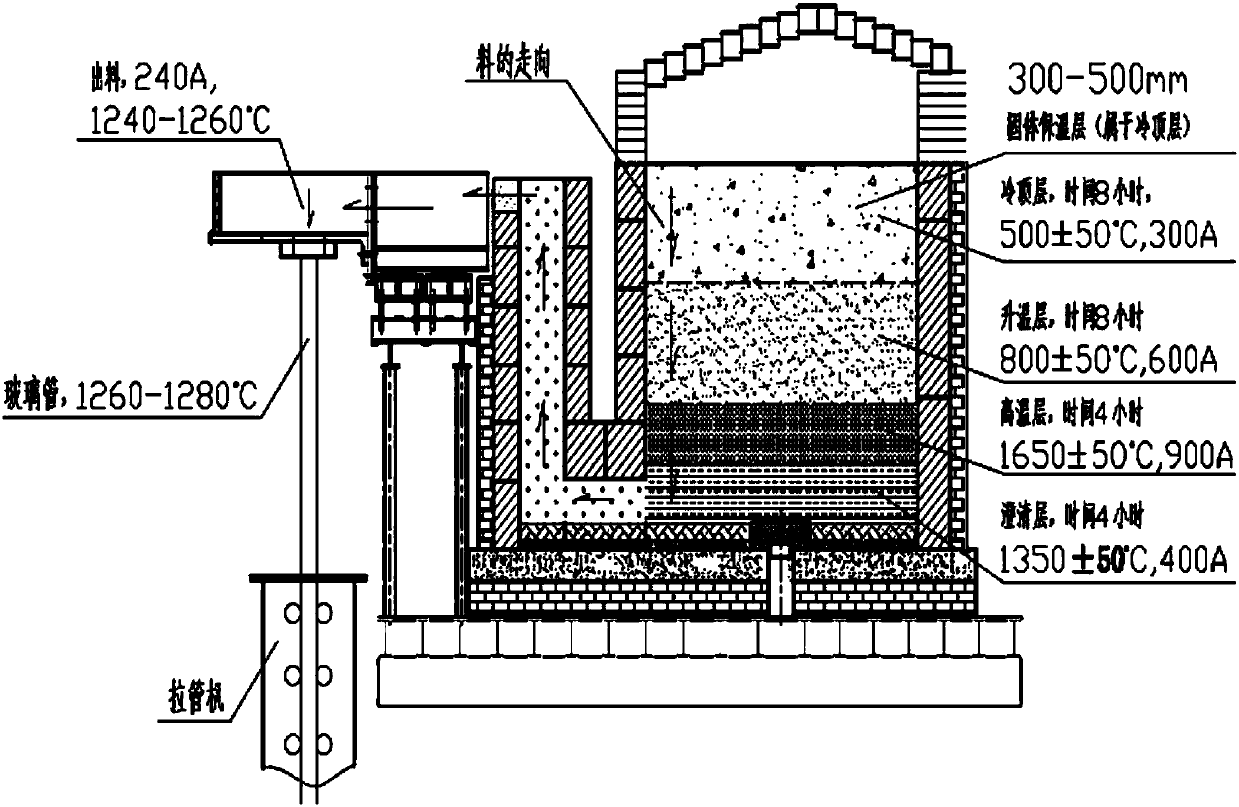

White jade color high borosilicate glass and preparation method thereof

ActiveCN107601873AModerate transparencyStable colorGlass furnace apparatusGlass productionTransmittanceChemistry

The invention discloses white jade color high borosilicate glass and a preparation method thereof. On the basis of maintaining original properties of high borosilicate 3.3 glass, the glass is internally colored, and by selecting a coloring agent in a formula of the high borosilicate 3.3 glass, selecting the ratio of the coloring agent to other materials, and strictly controlling the melting temperature and the melting time, so that the effect that a coloring agent is not volatilized is achieved, the prepared glass is of a white jade color, is uniformly distributed and is free of bubble or water wave, and is excellent in refractive index or light transmittance.

Owner:HUAILAI TIANYUAN SPECIAL TYPE GLASS

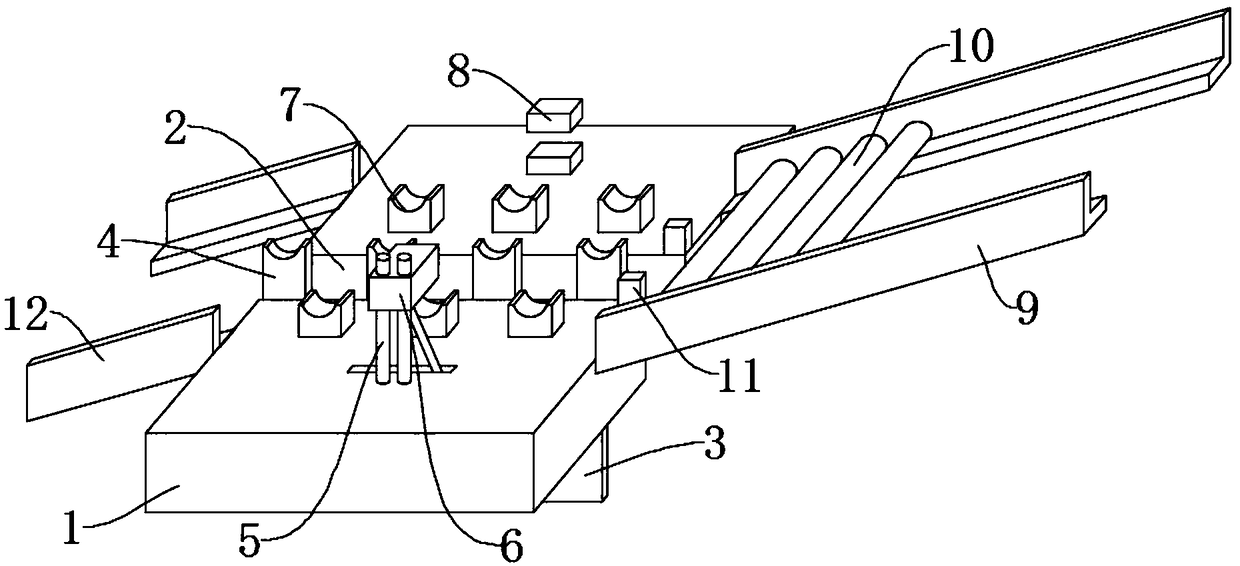

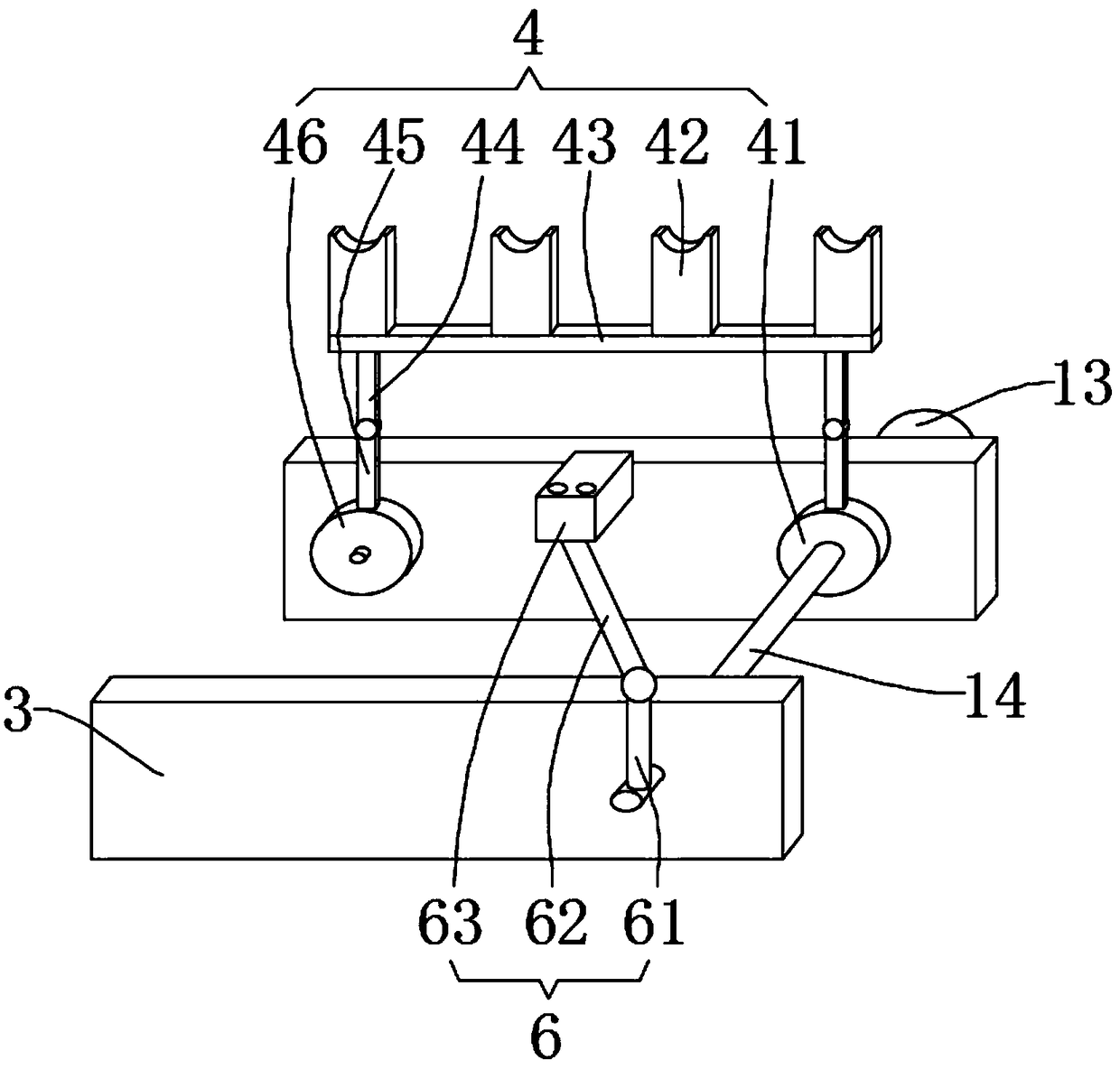

High-performance continuous forging and pressing device for alloy steel rods

ActiveCN109261883AEasy to forgeEasy to transport awayEngine componentsHandling devicesMotor driveMaterials science

The invention discloses a high-performance continuous forging and pressing device for alloy steel rods. The device includes a worktable, a sliding groove is formed in the worktable, a feeding groove is connected with one end of the sliding groove and contains the steel rods, the other end of the sliding groove is connected with a discharge groove, and a bearing platform is installed on the top ofthe sliding groove; fixing plates are installed on both sides of the bottom of the sliding groove, and a rotating shaft is rotatably sleeved with the fixing plates; a motor is installed on the fixingplate on one side of the sliding groove, an output shaft of the motor is connected with the rotating shaft, one end of the rotating shaft is provided with a conveying mechanism, the conveying mechanism is clamped into the sliding groove, a guide rail is installed on one side of the worktable, a clamping mechanism is installed between the guide rail and the other end of the rotating shaft, and a forging and pressing mechanism is installed on the other side of the worktable. The steel rods slide down along the feeding groove, the motor drives the rotating shaft to rotate, the conveying mechanismlifts the steel rods onto the bearing platform one by one, the rotating shaft drives the clamping mechanism to move at the same time, the clamping mechanism presses the steel rods on the bearing platform, and the forging and pressing mechanism conducts forging and pressing on the end face of each steel rod; after forging and pressing are finished, the clamping mechanism loosens the steel rods, and the conveying mechanism lifts the steel rods to the discharge groove.

Owner:安徽震祥精工科技有限公司

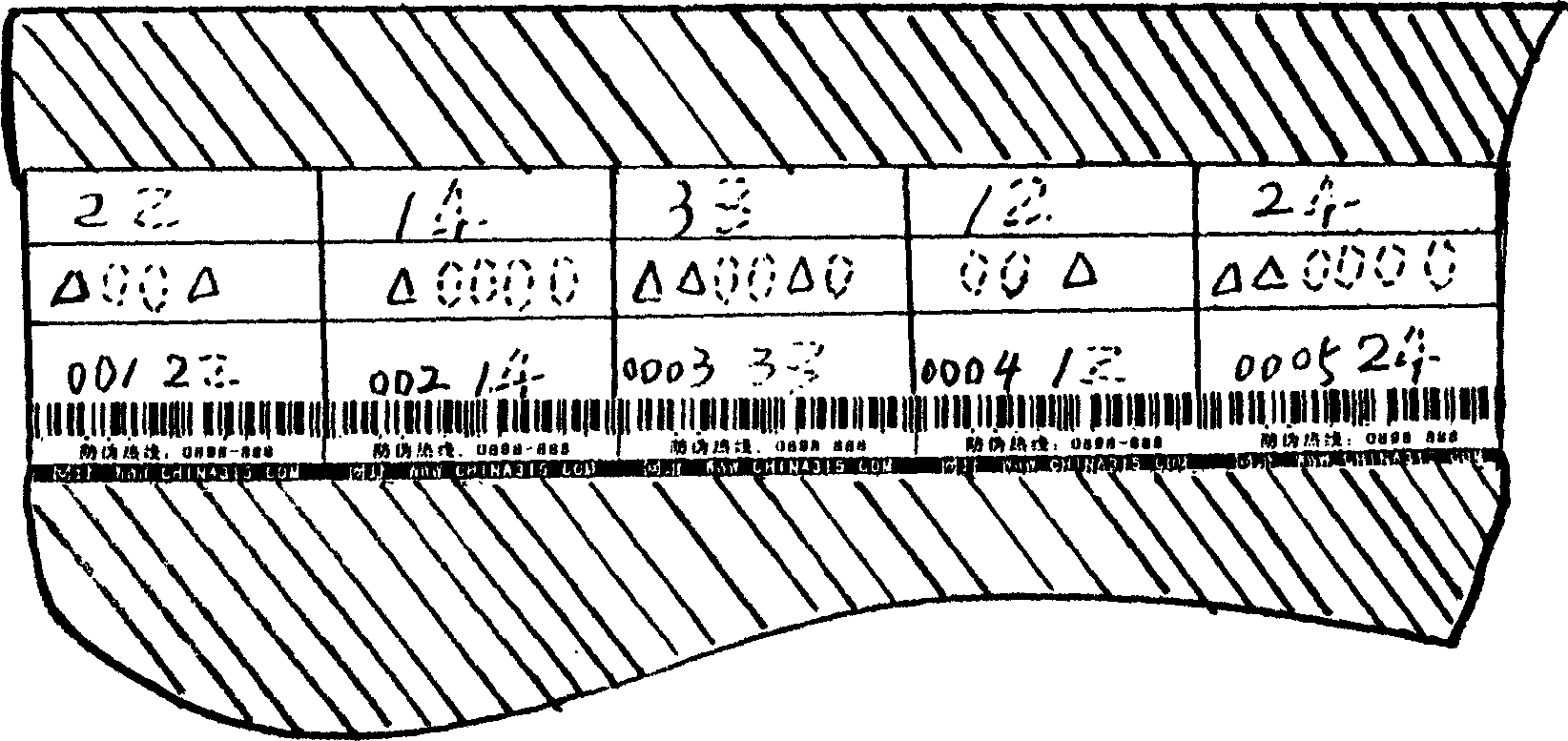

Self nucleus structure anti-fake peper method

InactiveCN1782228AImprove recognition rateImprove query rateNon-fibrous pulp additionRecord carriers used with machinesProgramming languageBarcode

The present invention relates to a kind of self-checking structure anti-fake paper method. The random anti-fake characteristic information on the safety line embedded inside paper is selected and converted into self-checking code and bar code corresponding to the number characteristic of the random anti-fake characteristic information and printed on the safety line. The self-checking code and the sequence code are stored in the computer database, and the consumer may one by one check based on the structure characteristic and its conversion code in different frames on the safety line. Or, by means of communication facility and inputting the conversion code and sequence code, the truth of the paper product may be checked via inquiring the stored code in the database. The bar code in the safety line may be also used in management.

Owner:李峰

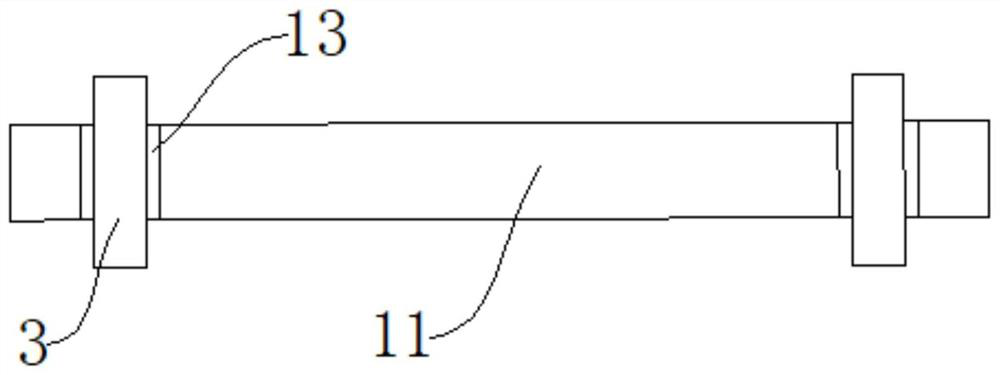

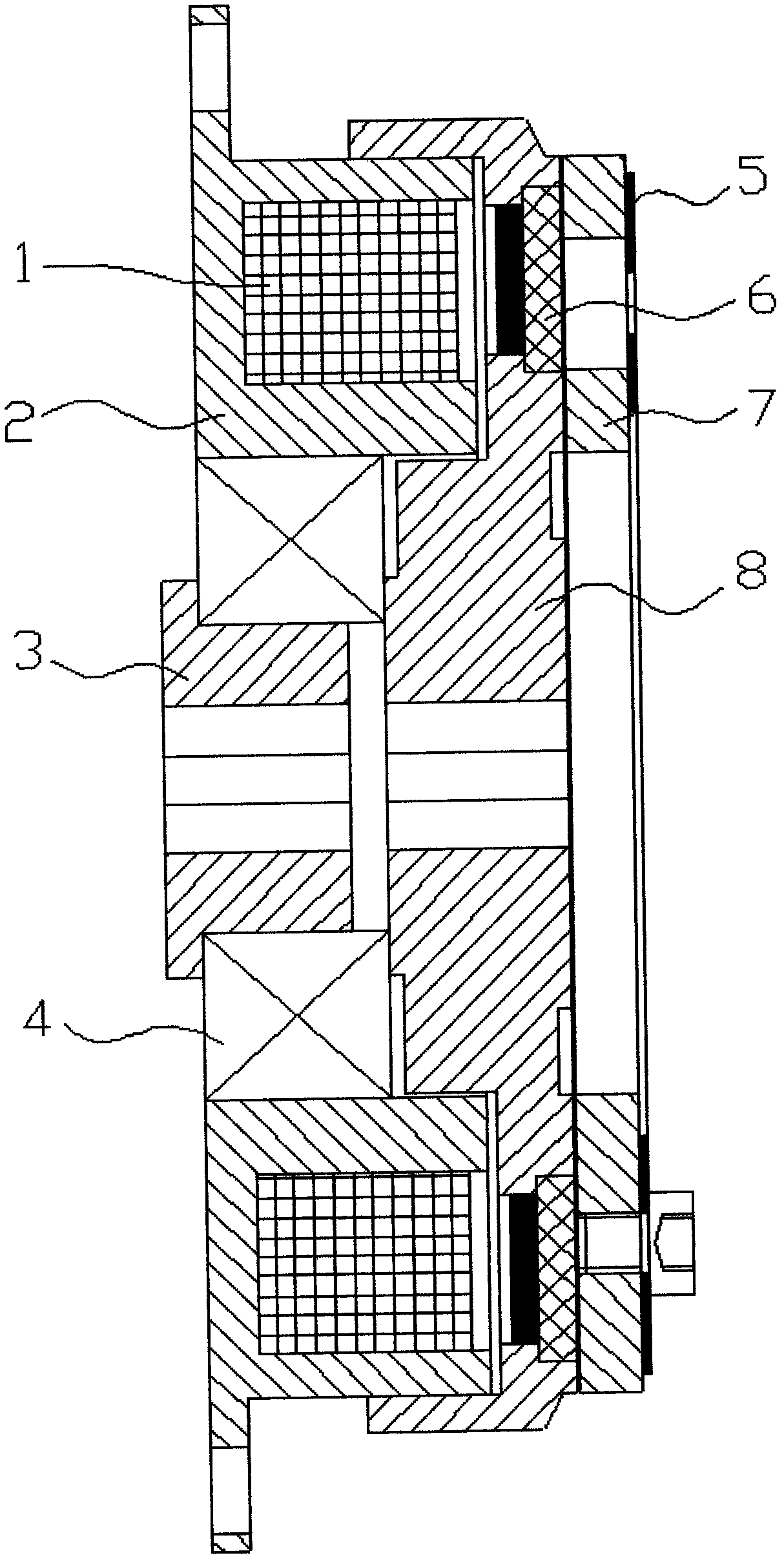

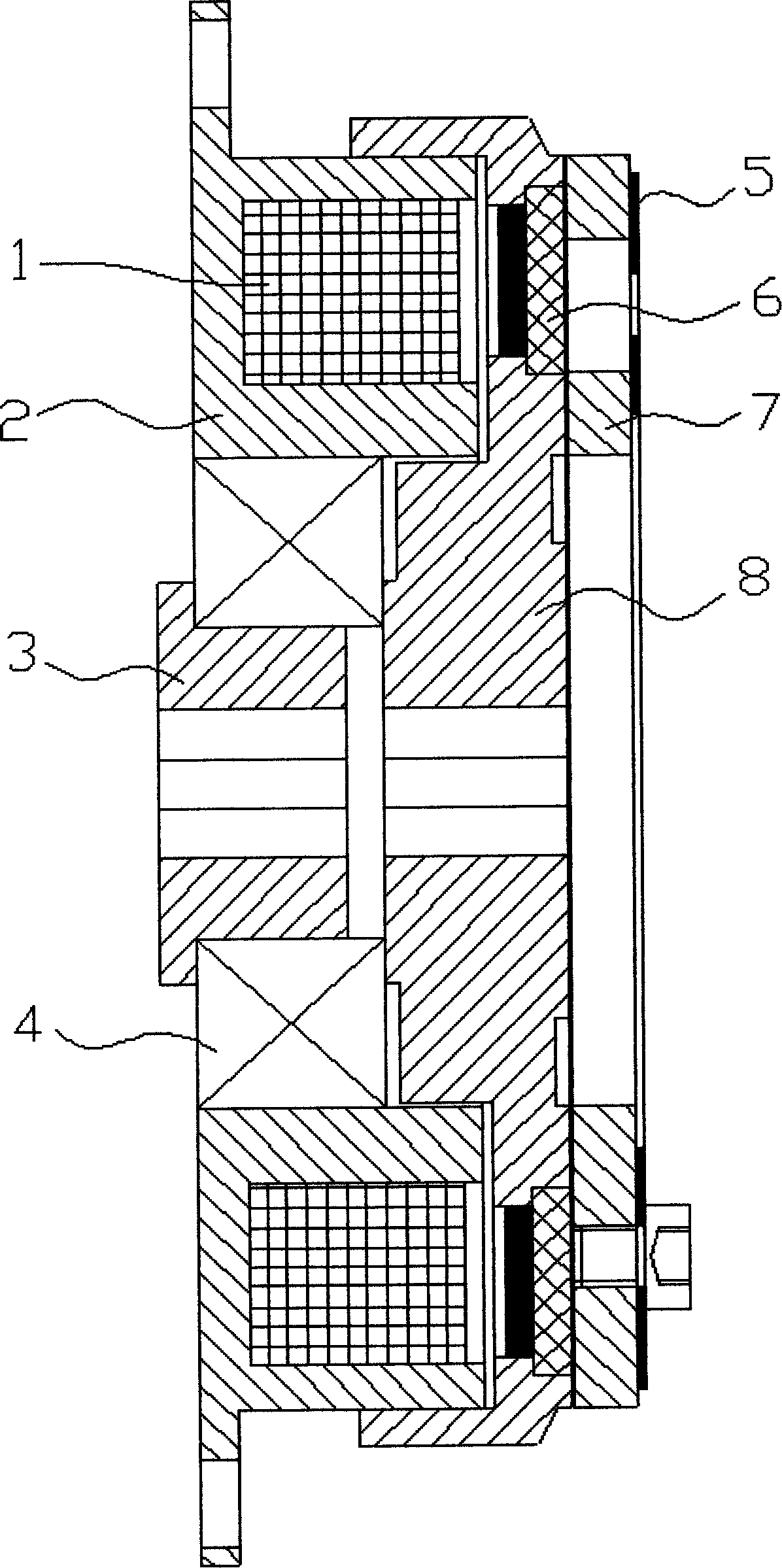

Split clutch

InactiveCN102562855AReasonable structural designEasy to forgeMagnetically actuated clutchesEngineeringActuator

A split clutch relates to the technical field of electrical automatic actuators and comprises a magnetic yoke. A coil is arranged in the magnetic yoke, a baffle plate is arranged on the right of the coil, a friction plate is arranged on the right of the baffle plate, an armature is arranged on the right of the friction plate, and a spring sheet is arranged at the right end of the armature. The split clutch is characterized in that a shaft sleeve is arranged on the left of the baffle plate and coaxially split from the baffle plate. The split clutch is reasonable in structural design, a baffle plate of a traditional structure is changed into the baffle plate and the shaft sleeve of the novel structure, forging is facilitated, materials are saved, cutting is simple and convenient, the size of the split clutch is easy to control, and stability of the quality of the split clutch is improved.

Owner:广德力达电气有限公司

Automobile gear shaft and forging method thereof

The invention discloses an automobile gear shaft and a forging method thereof. The gear shaft comprises, by weight, 0.16-0.2% of carbon, 0.15-0.3% of silicon, 0.75-0.90% of manganese, 0-0.015% of phosphorus, 0-0.025% of sulfur, 0.5-1.1% of chromium, 0.01-0.03% of aluminum, 0-0.025% of copper, 0.12-0.28% of nickel, 2.98-3.58% of molybdenum and the balance iron. A raw material blank is subjected tocirculating heating and cooling many times, then subjected to surface treatment, cooled to 1100-1300 DEG C and kept warm; then, upsetting and drawing are carried out to reach the specification required by forge pieces, and the forging temperature is 850-1300 DEG C; the blank is drawn into an octagonal shape and distributed, small head drawing, rolling and finishing are carried out, and then the blank is subjected to thermal treatment and carburizing treatment. The hardness, fatigue resistance and overload resistance of the gear shaft are improved while the application stability of the gear shaft is ensured.

Owner:浙江恒利五金科技有限公司

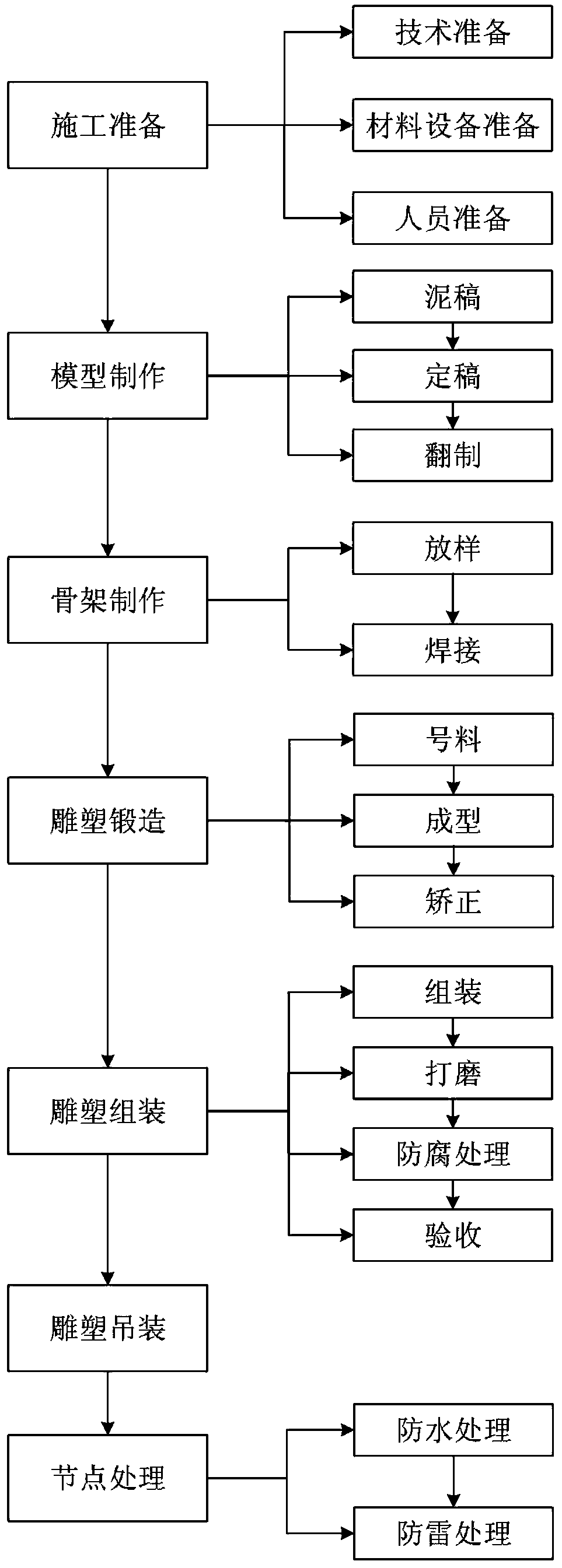

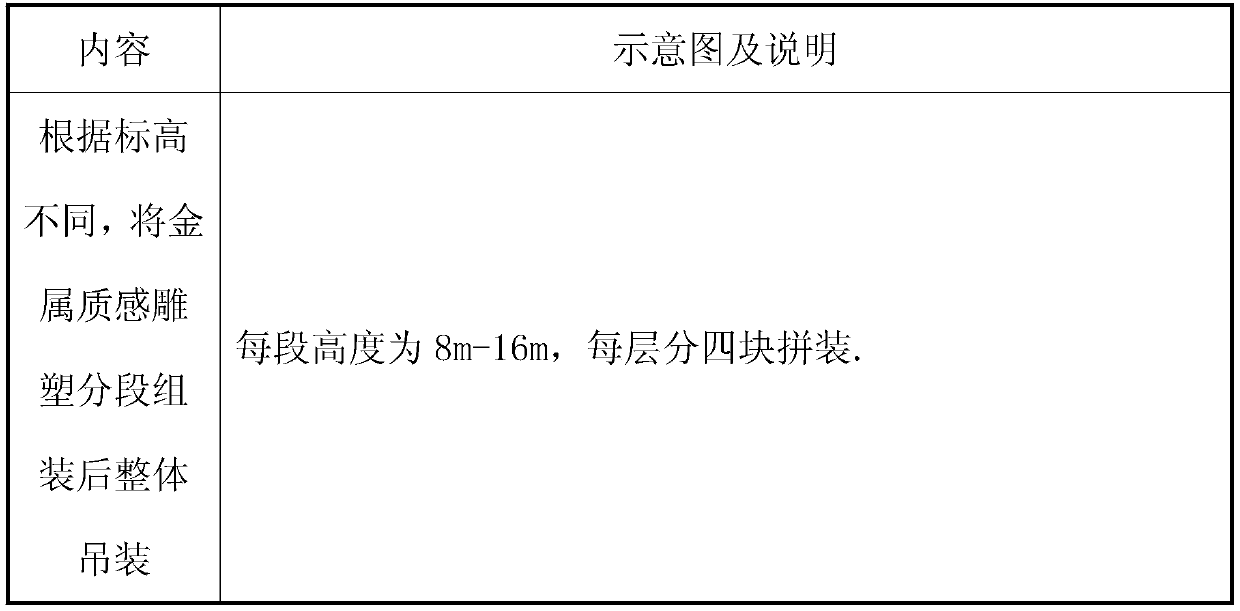

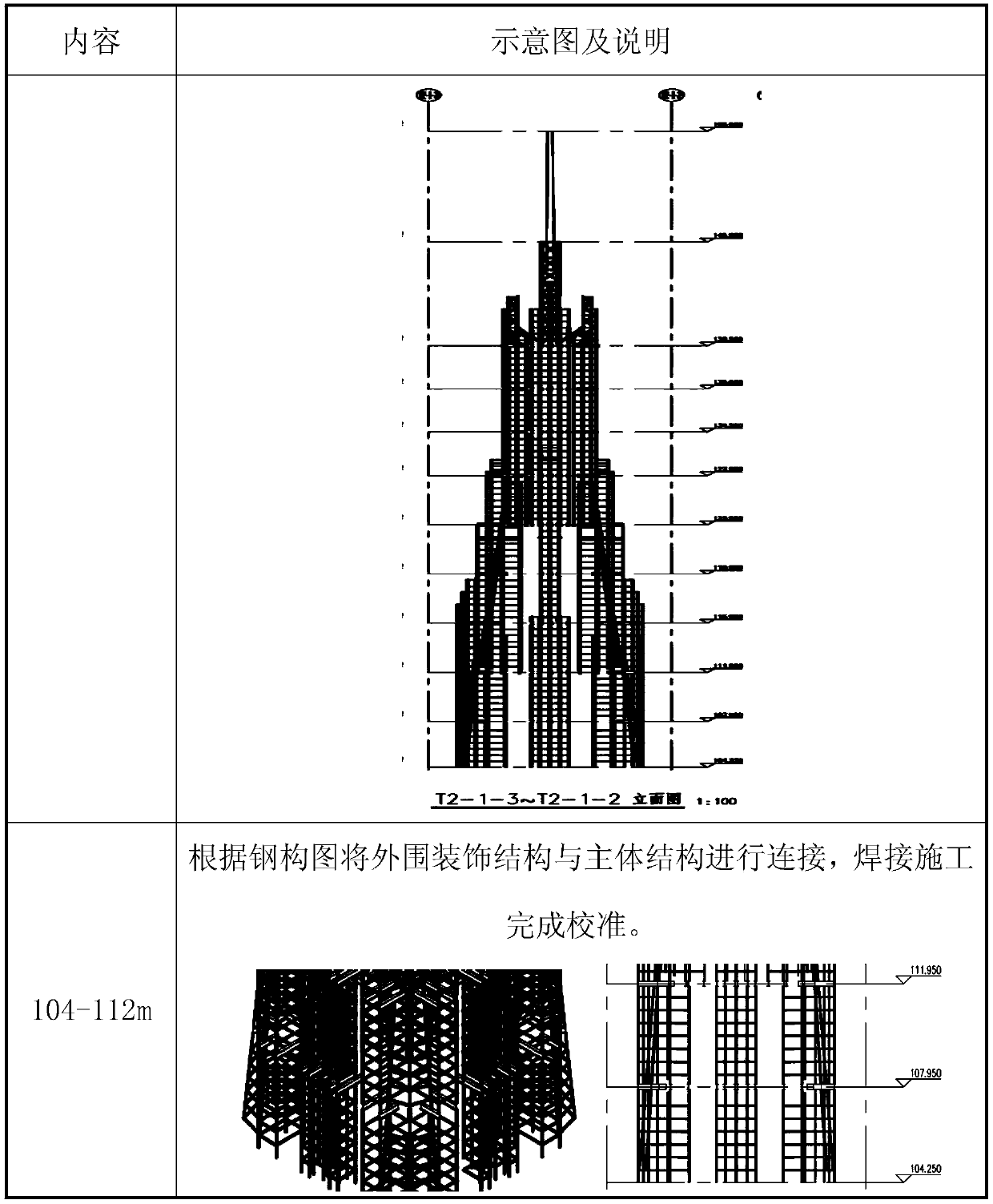

Ultra-high metal texture sculpture construction method

The invention relates to an ultra-high metal texture sculpture construction method. The ultra-high metal texture sculpture construction method comprises the following steps of S1, construction preparation, specifically technical preparation, material equipment preparation and personnel preparation; S2, making a model, specifically preparing a mud draft, setting a draft and turning; and S3, manufacturing a framework. According to the ultra-high metal texture sculpture construction method, a sculpture model and a sculpture are processed in the field, an industrial production process is adopted,the progress is controllable, the quality is controllable, a BIM technology is utilized to simulate the hoisting process, the process for installation, outer wall construction and roof operation of tower top sculpture is reasonably determined, the influence caused by unreasonable working procedures can be reasonably determined, the overall construction period is indirectly shortened, the potentialsafety hazard of high-altitude operation is reduced, the construction difficulty is reduced, and the construction period is easy to guarantee.

Owner:中铁建设集团南方工程有限公司

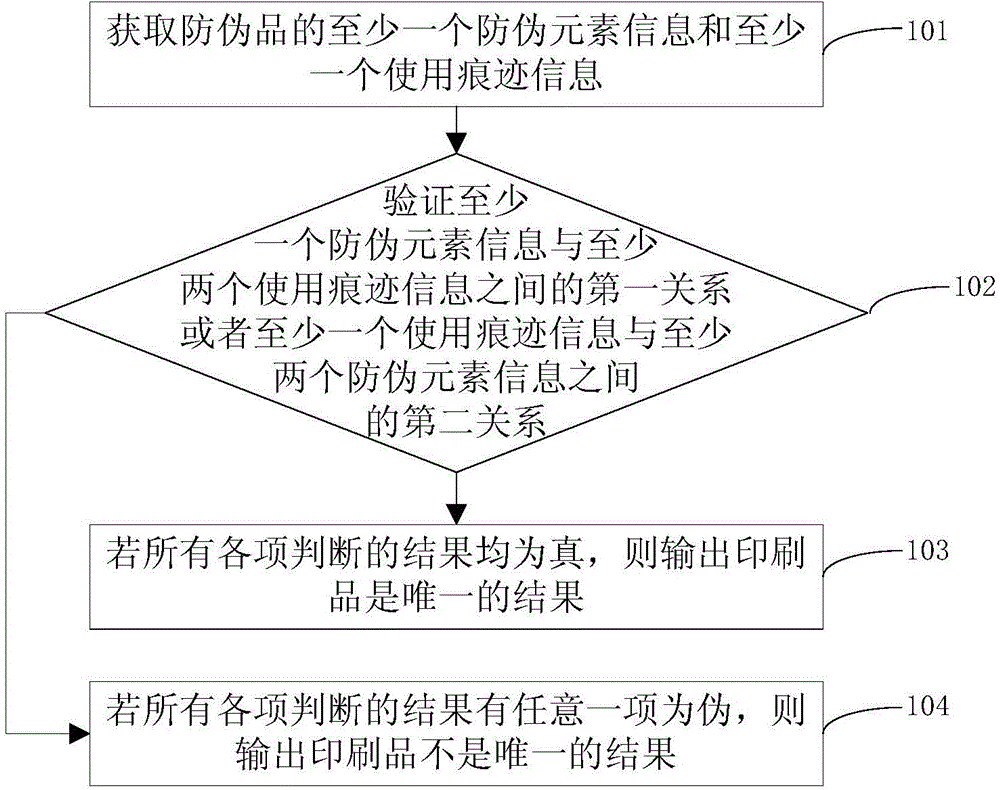

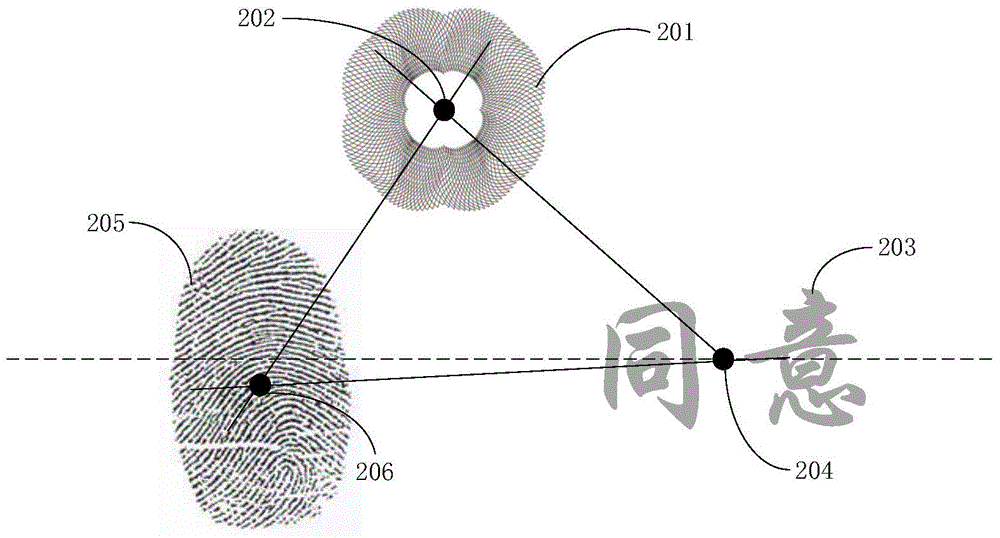

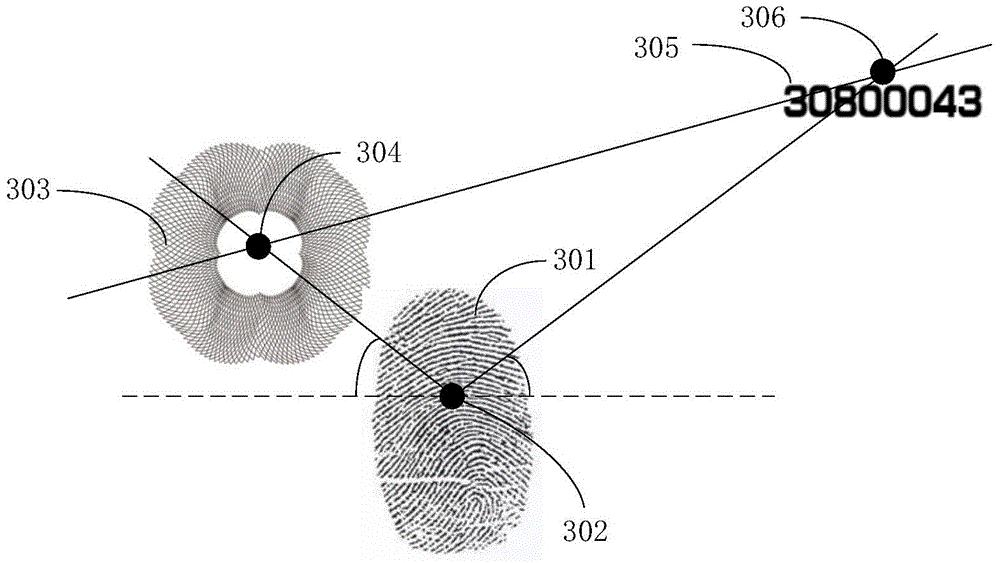

Verification method and verification device for anti-fake product

ActiveCN104376635AEasy to fakePosition judgment is accuratePaper-money testing devicesCharacter and pattern recognitionValidation methodsComputer science

The invention discloses a verification method and verification device for an anti-fake product. The verification method comprises the steps that at least one piece of anti-fake element information and at least one piece of use trace information of the anti-fake product are obtained; the first relation between the at least one piece of anti-fake element information and at least two pieces of use trace information or the second relation between the least one piece of use trace information and at least two pieces of anti-fake element information is verified; if all the judgment results of all the relations are real, the result that the anti-fake product is real and unique is output. In this way, the uniqueness of the anti-fake product can be determined by verifying the relation between one anti-fake element and a plurality of use traces and the relation between one use trace and a plurality of anti-fake elements, and the verification result of the anti-fake product can be more precise and safer.

Owner:深圳聚融科技股份有限公司

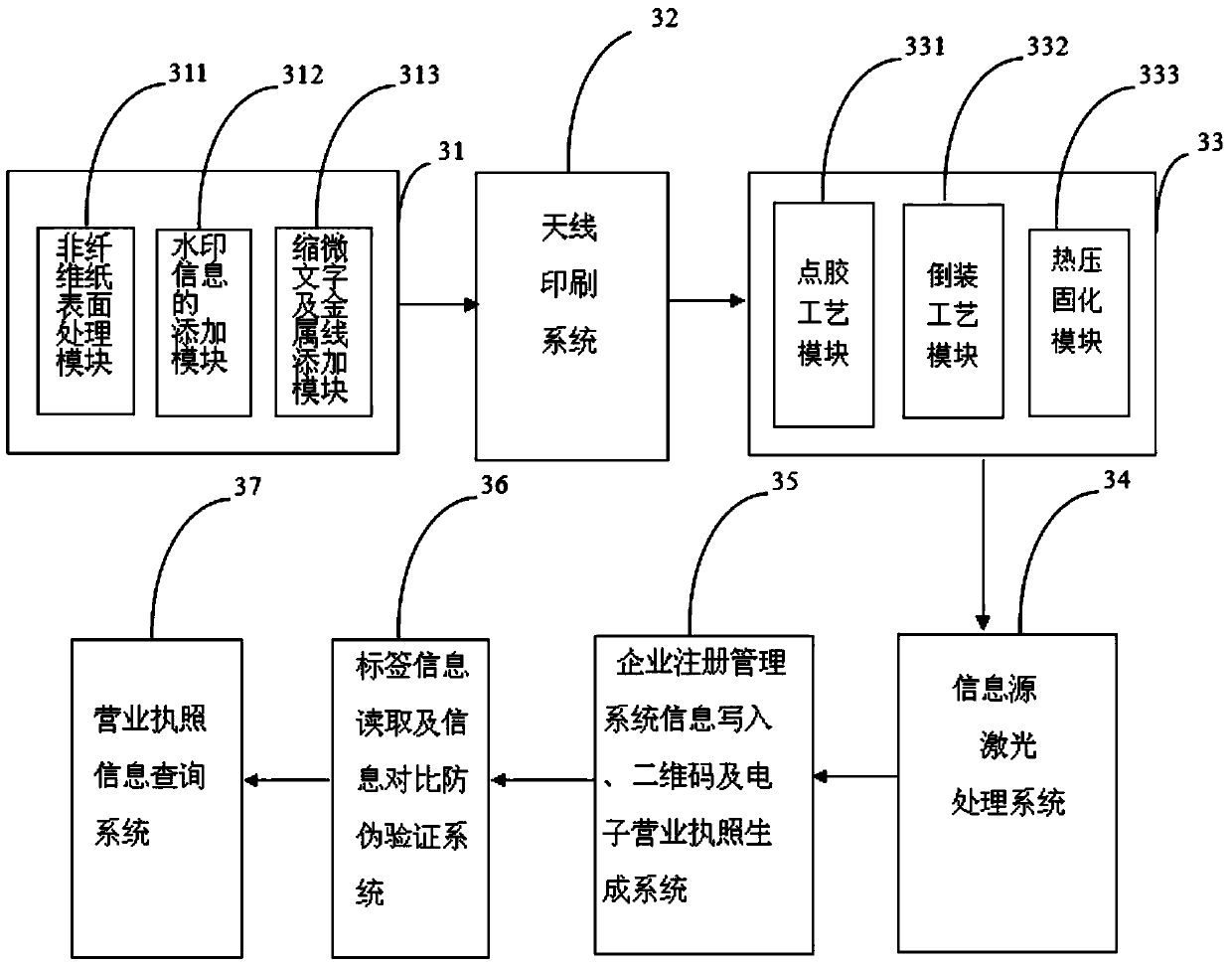

Production system of novel non-fiber material-based certificate with intelligent anti-counterfeiting function and application of production system

PendingCN105787547AEasy to forgeEasy to identifyCommerceRecord carriers used with machinesRadio frequencyMaterials processing

The invention relates to a production system of a novel non-fiber material-based certificate with an intelligent anti-counterfeiting function. The production system comprises a base material processing system, an antenna printing system and a chip packaging system, wherein the above three systems are sequentially connected. The production system can be applied to certificate production. By means of the above production system, the surface of a piece of non-fiber paper is machined and processed, and the embedding of watermark information and metal anti-counterfeiting lines into the paper is conducted at the same time, and therefore, the piece of non-fiber paper is turned into a piece of anti-counterfeiting non-fiber paper special for certificate printing; an antenna is directly printed on the piece of non-fiber paper by using a silk-screen printing method, instead of being manufactured as a tag and then attached onto the surface of the printed material; and a high-safety intelligent chip is embedded in the certificate printed with the antenna, so that the certificate itself has the function of a smart card, and therefore, wireless radio-frequency identification can be carried out on the certificate; and the functions of multi-level encryption and dual cryptography-based chip data protection are realized.

Owner:TIANJIN ZHONGTIAN LICENSE PRINTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com