Bearing ring forging machining process and machining system

A bearing ring and processing technology, which is applied in the field of bearing ring forging and processing, can solve the problems of thickening of the decarburized layer of the bearing ring, increase of the cutting allowance, rough surface of the bearing ring, etc., so as to reduce the cutting Effect of machining allowance, improved accuracy, low surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

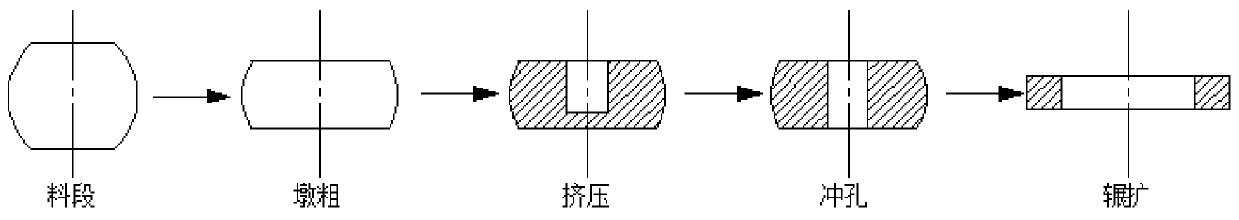

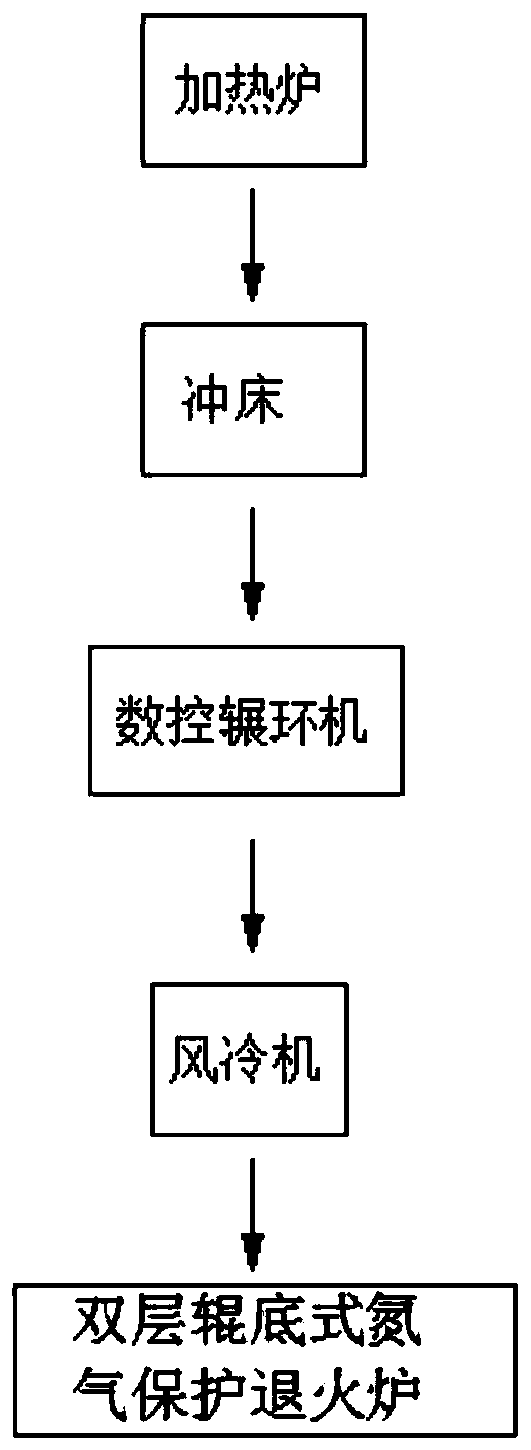

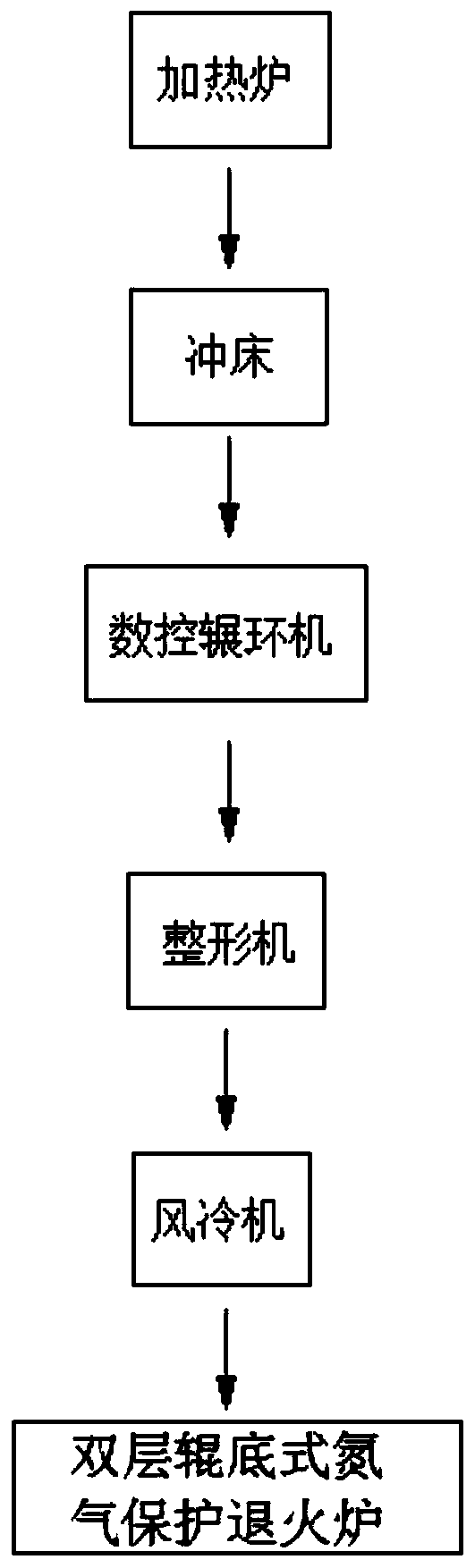

[0035] A bearing ring forging process and its processing system, such as figure 1 and figure 2 as shown,

[0036](1) Heating material section: first preheat the heating mold to 250°C-350°C in order to speed up the heating efficiency of the regenerative through heating furnace for the material section; then put the material section made of high-carbon chromium bearing steel into the already Put it into the preheated heating mold, and then put it into the regenerative through heating furnace to heat to 1130°C-1180°C. When the material section made of high-carbon chromium bearing steel is heated to 1130°C-1180°C, the metallographic structure of the material section It transforms into an austenite structure with good plasticity, which is convenient for subsequent forging, extrusion and punching of the heated material section, which is obtained by cutting off the bar.

[0037] Further, in the process of heating the material section, when detecting the temperature of the heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com