Split-type train brake disc

A split-type, brake disc technology, applied in the direction of brake discs, brake types, brake components, etc., can solve the problems of unreasonable matching of alloy forged steel components, easy dispersion and unevenness, and reduced plasticity and toughness of materials. Achieve the effect of excellent comprehensive mechanical properties, simple connection structure and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention is described in further detail below in conjunction with the embodiment that accompanying drawing provides.

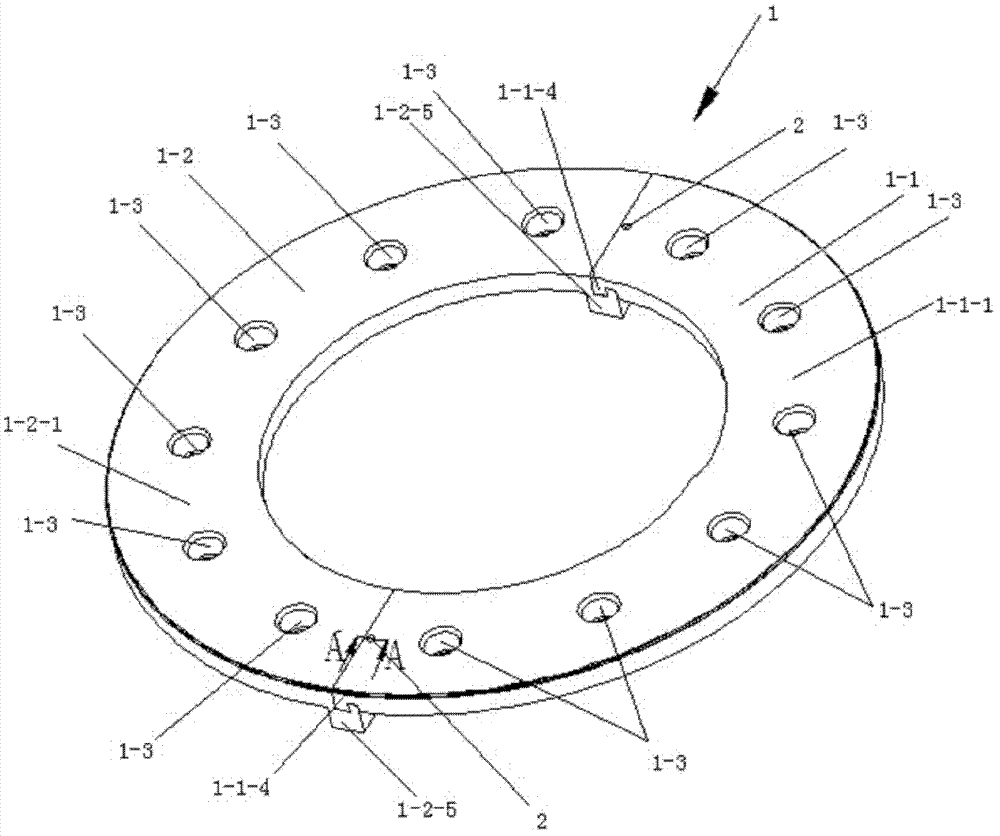

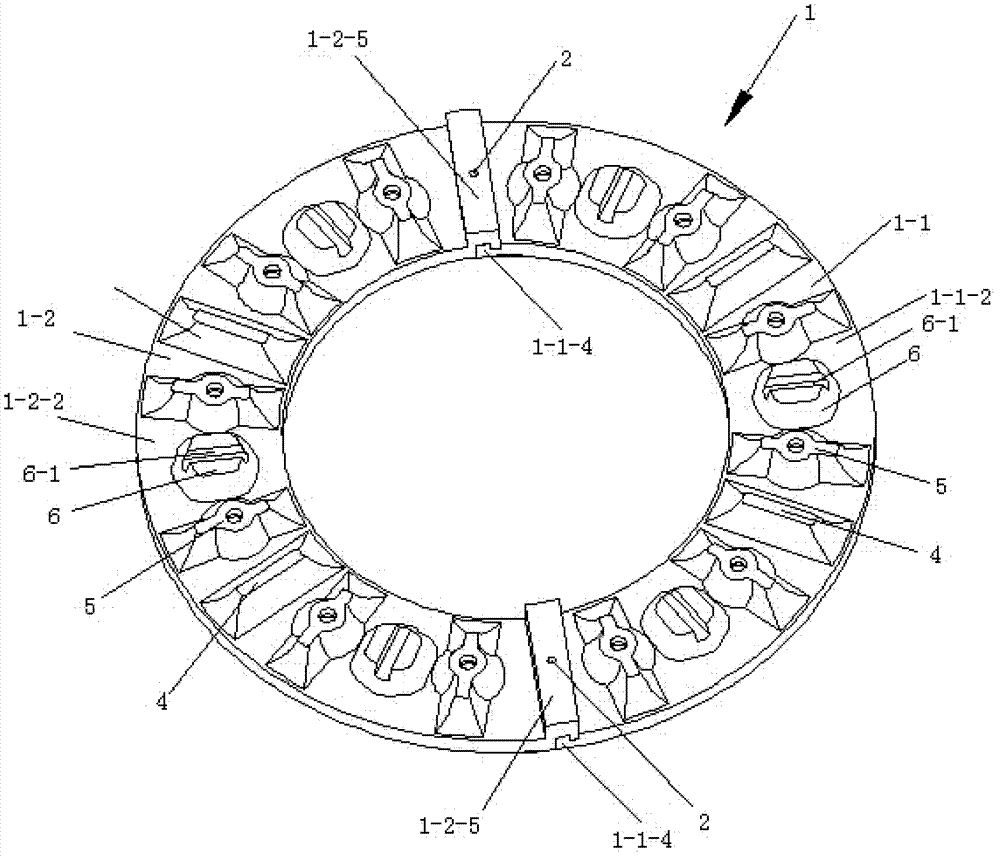

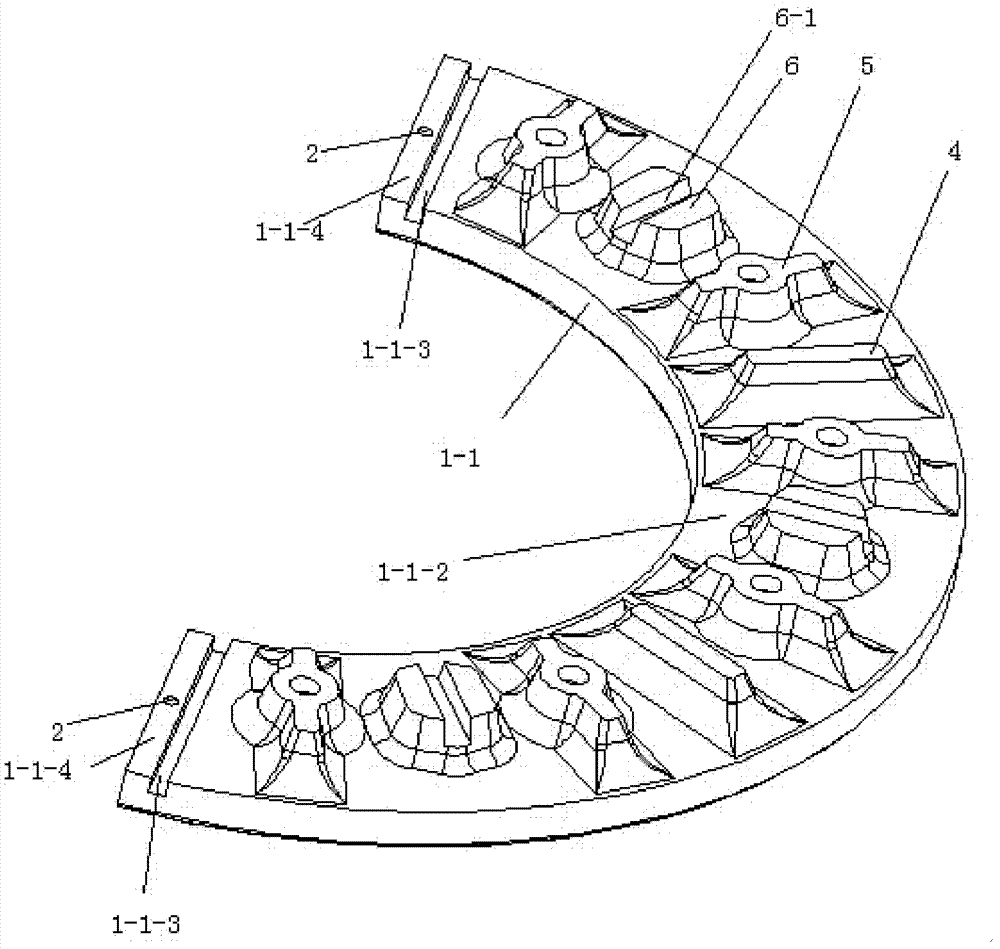

[0068] see Figure 1~6 As shown, a split train brake disc includes a circular disc body 1 formed by connecting the first disc block 1-1 and the second disc block 1-2, and the disc body 1 is evenly distributed along the circumferential direction. Several installation holes 1-3 are distributed, the first disk block 1-1 has a first friction surface 1-1-1 and a first inner surface 1-1-2 behind the first friction surface 1-1-1, The second disk block 1-2 has a second friction surface 1-2-1 and a second inner surface 1-2-2 behind the second friction surface 1-2-1, the first disk block 1-1 Both ends have a first radial groove 1-1-3 opening toward the direction of the first inner surface 1-1-2 and a first radial protrusion 1 facing the direction of the first inner surface 1-1-2 -1-4, both ends of the second disc block 1-2 have second radial groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com