Patents

Literature

52results about How to "Easy for forging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

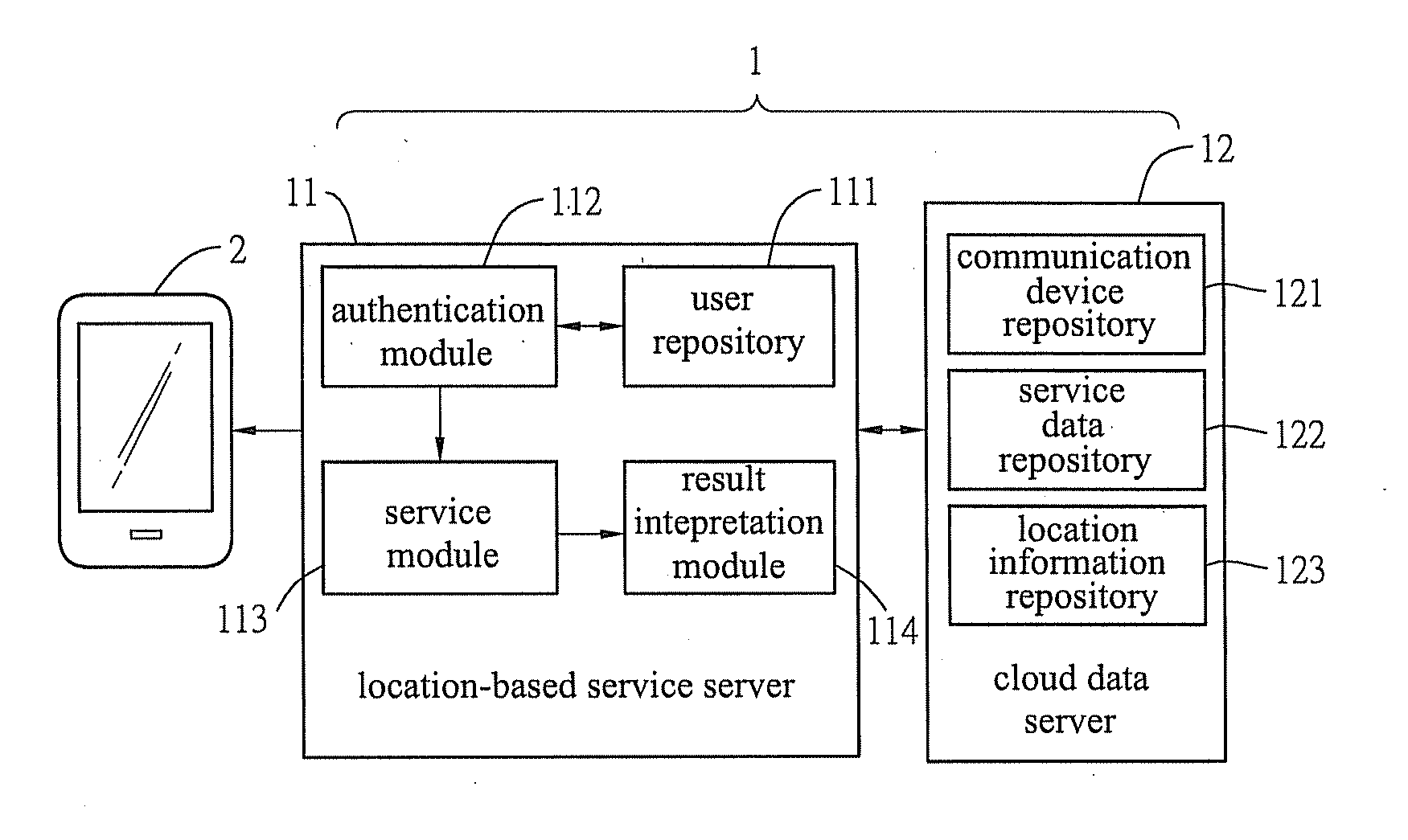

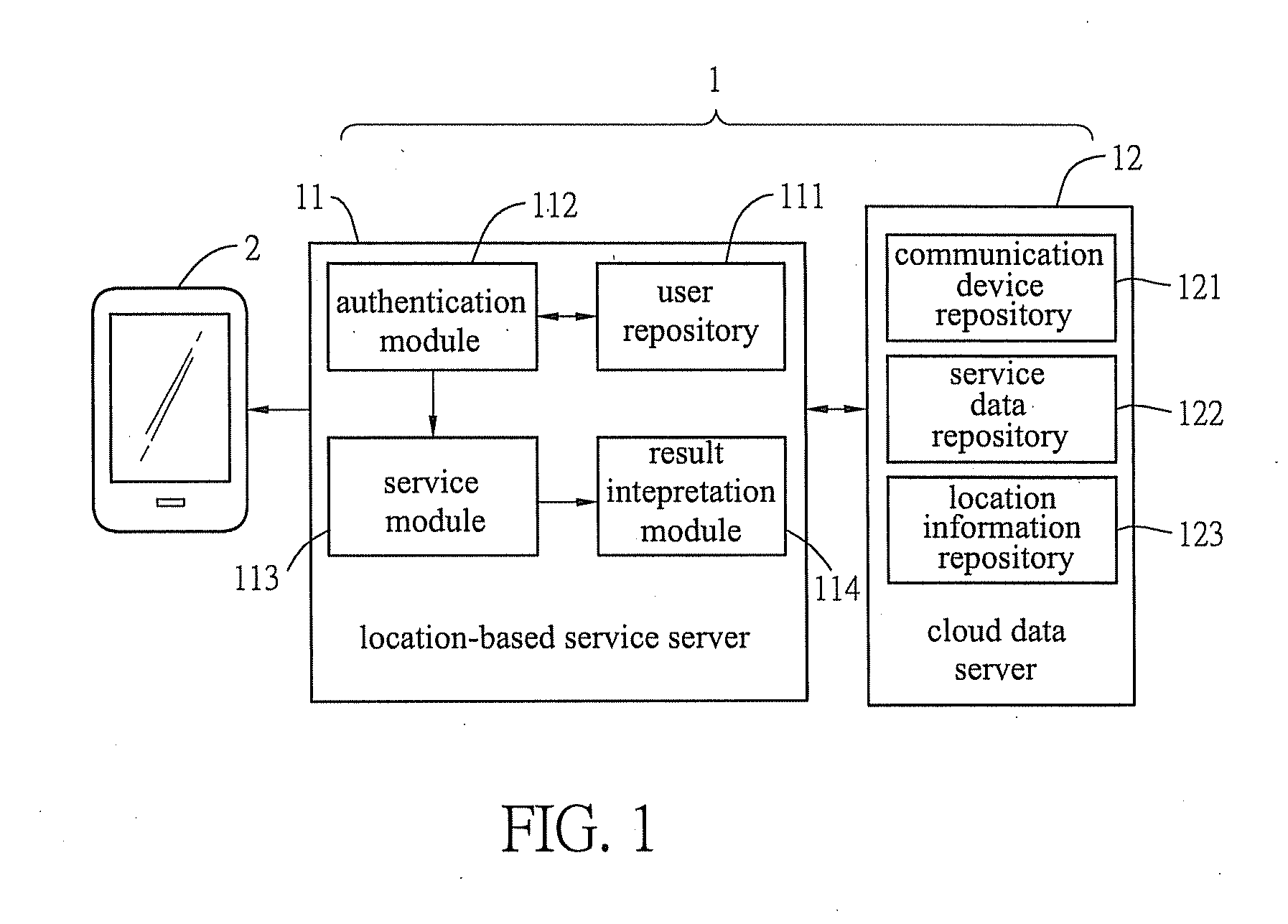

Location-based service system and serving method

ActiveUS20130122863A1Easy for forgingEasy to modifyUnauthorised/fraudulent call preventionEavesdropping prevention circuitsCloud dataService mode

A location-based service system and method, which allows a location-based service server connected with a communication device and a cloud data server to perform registration authorization procedures and service authorization procedures using an international mobile subscriber identity of the communication device that cannot be easily modified or forged in the registration and service modes, so that a user may obtain a specific location-based service result via the communication device, and this distributed authentication technique reduces the risk of data theft while increasing the flexibility and convenience in obtaining services.

Owner:NAT CHIAO TUNG UNIV

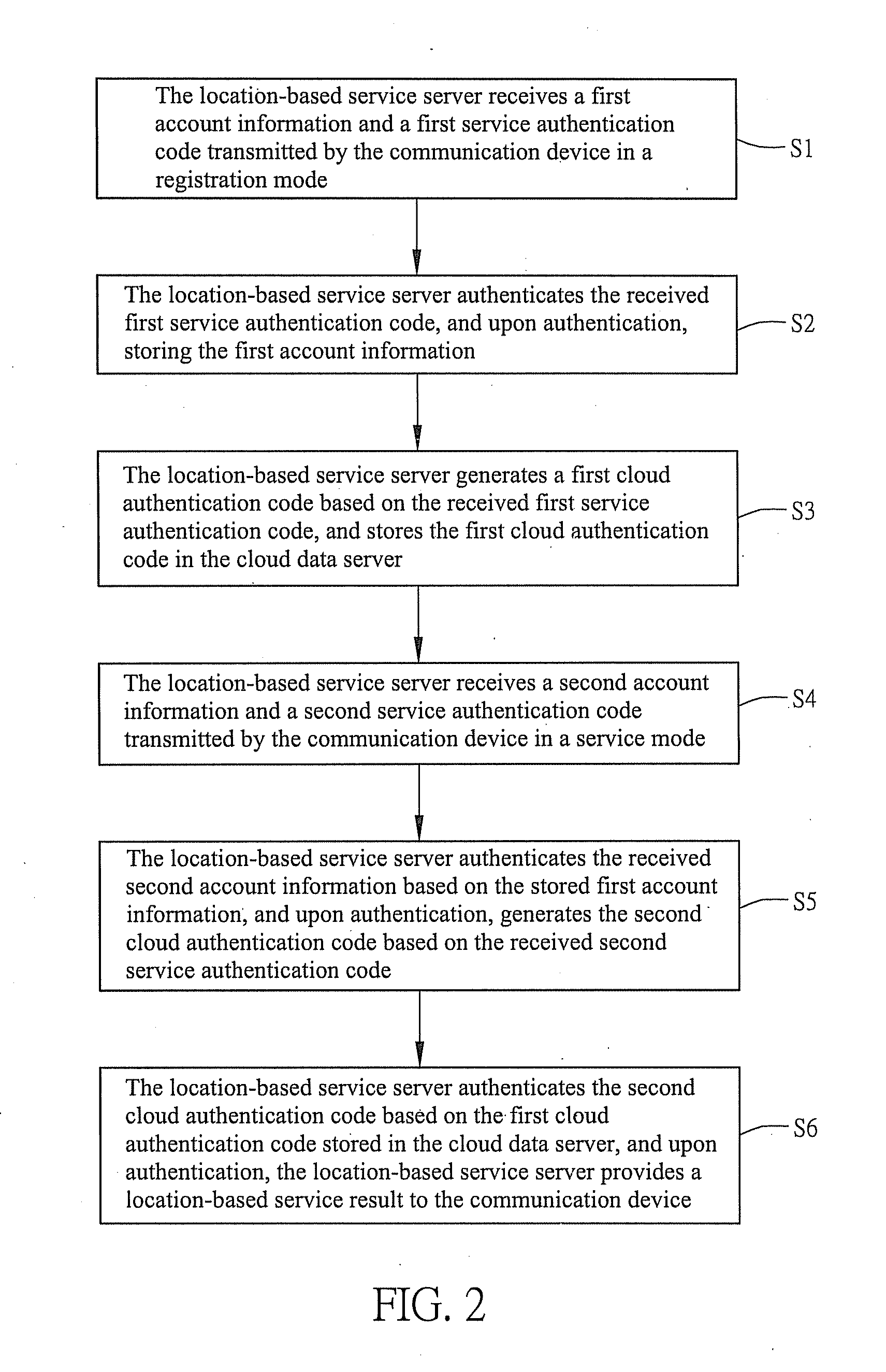

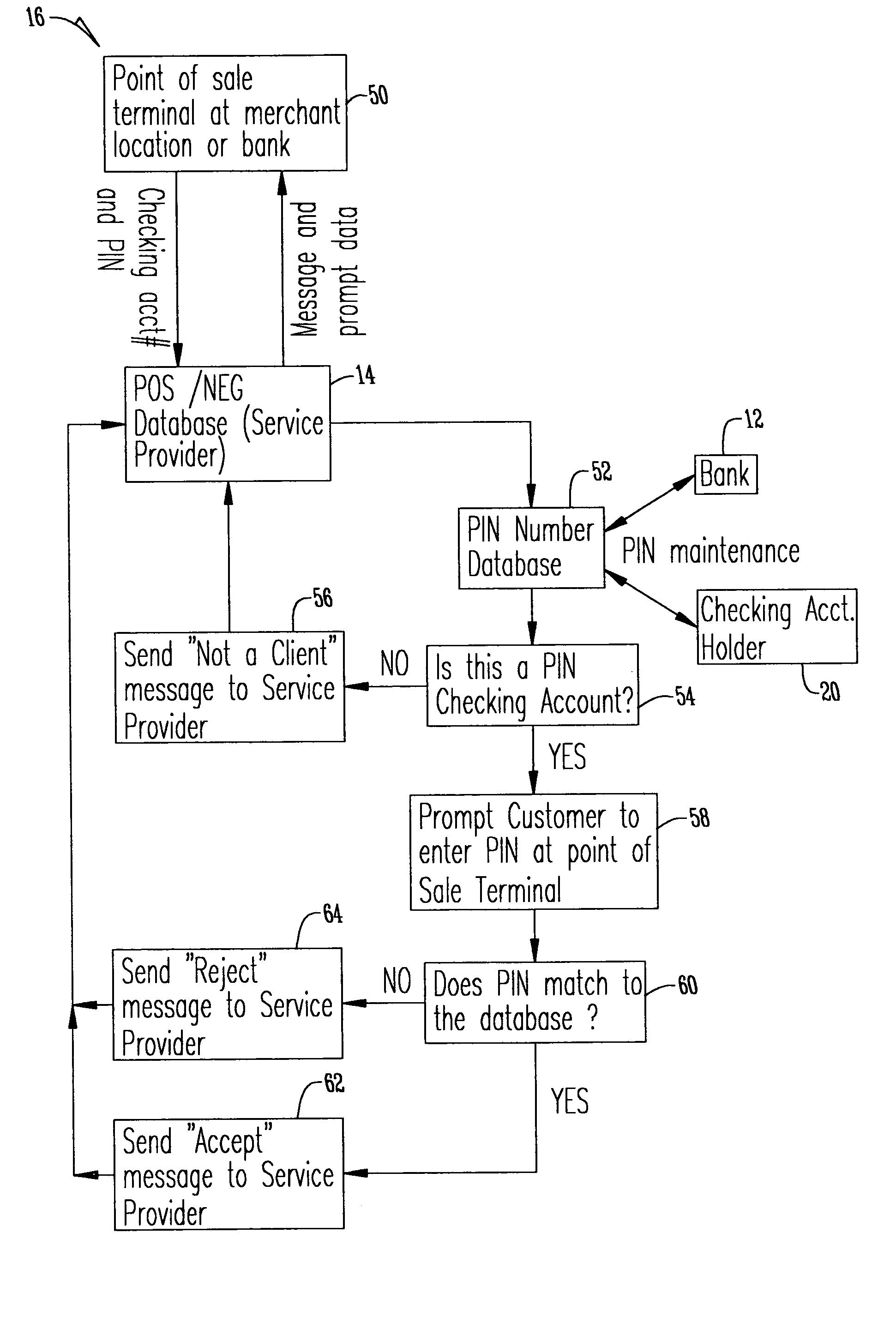

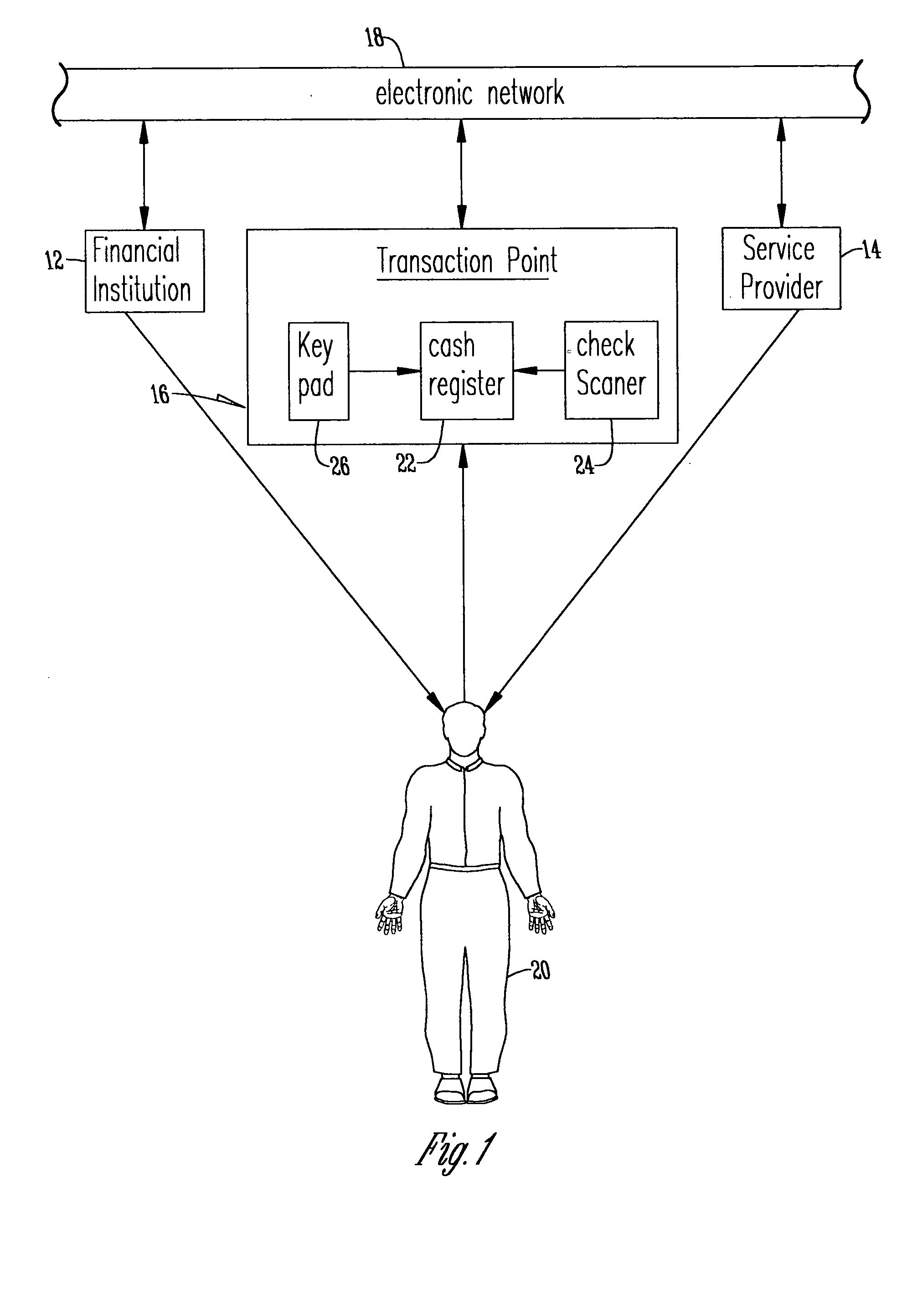

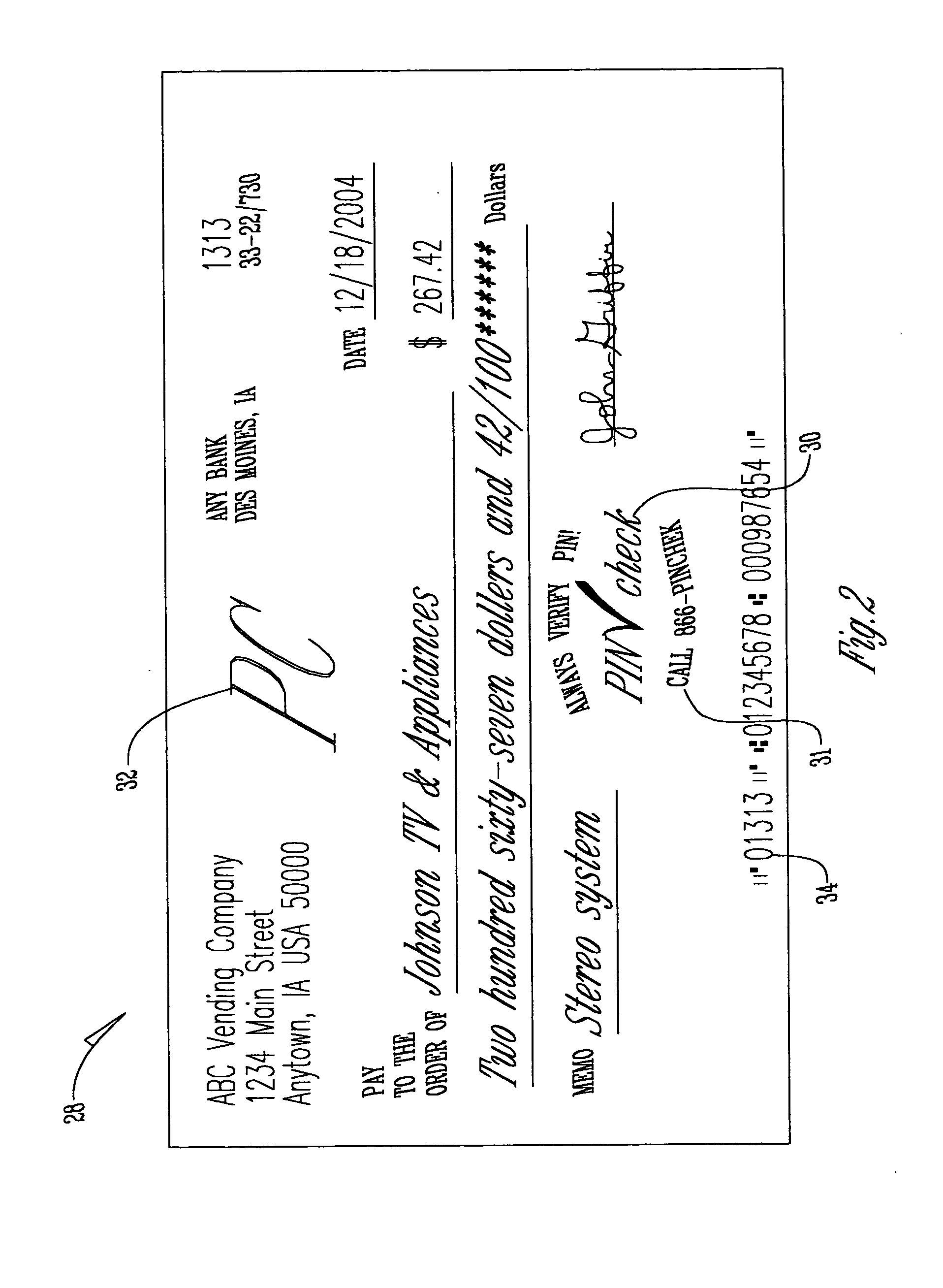

Checking account personal identification method

InactiveUS20050049969A1Impossible to forgeImpossible to stealFinancePayment circuitsChequeArtificial intelligence

This invention is a method of establishing and associating personal identification information to a checking account so that the personal identification information must be entered by the customer, the personal identification information and checking account information transmitted to a remote location for verification, and then a verification message sent from the remote location to the merchant at the point of presentment before the check is accepted by the merchant.

Owner:KANE LARRY J

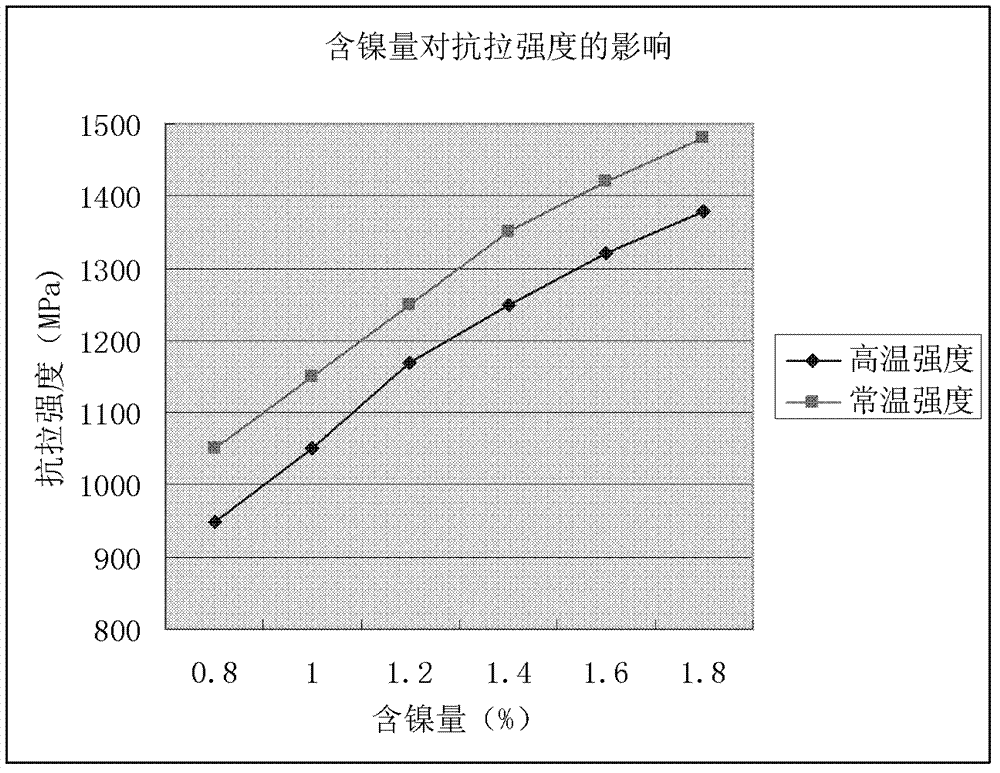

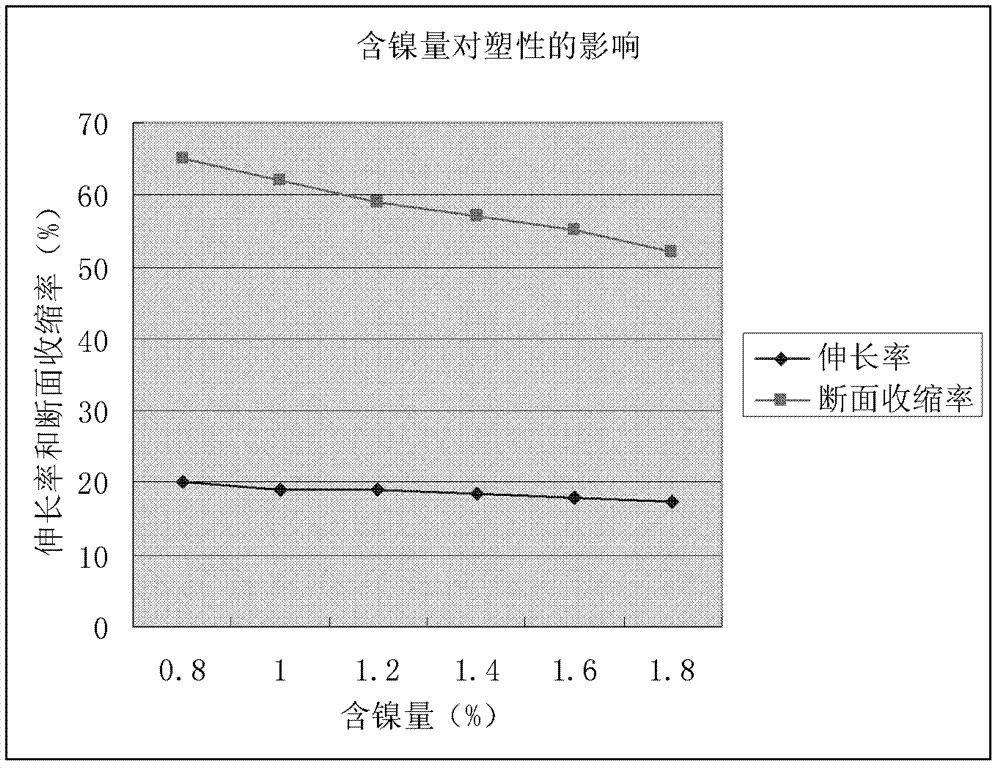

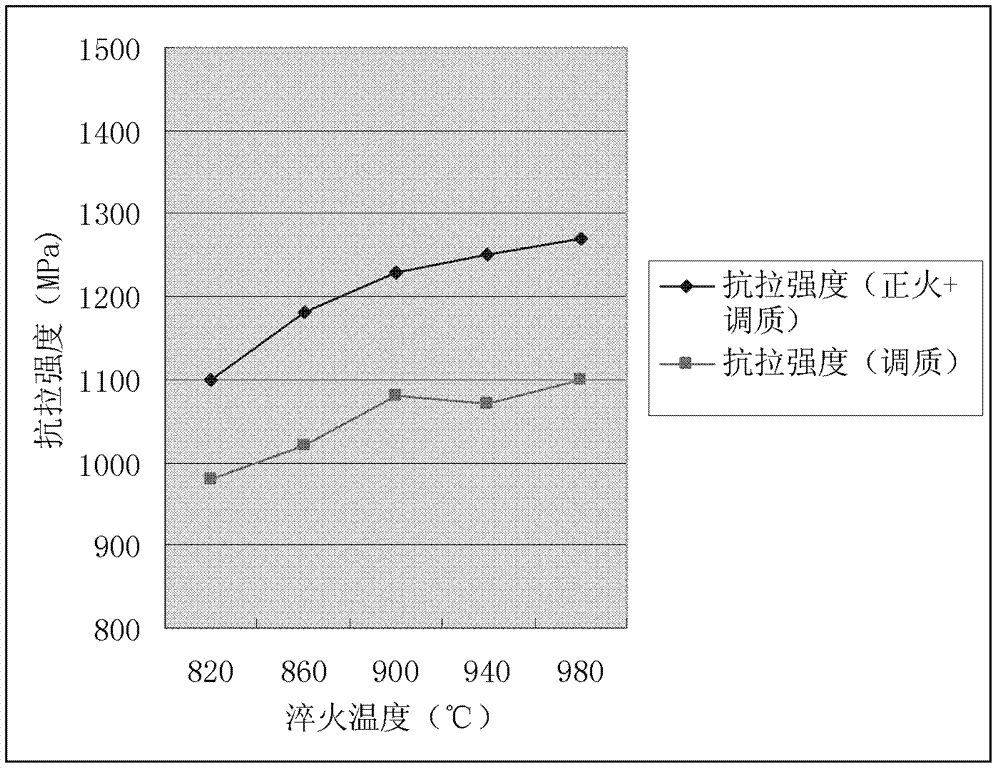

Alloy forged steel and its heat treatment method and use

ActiveCN102953008AGood comprehensive mechanical propertiesImprove hardenability and heat strength propertiesBraking membersAlloy elementCompound (substance)

The invention provides an alloy forged steel and its heat treatment method and use. The alloy forged steel comprises: by mass, 0.26 to 0.35% of C, 0.15 to 0.39% of Si, 0.85 to 1.50% of Mn, less than or equal to 0.02% of P, less than or equal to 0.01% of S, 0.80 to 2.00% of Cr, 0.70 to 2.00% of Ni, 0.35 to 1.00% of Mo, and the balance Fe and other elements. Through reasonable proportioning of alloy elements such as Mn, Ni, Cr and Mo, and main chemical components such as C and Si in forged steel materials, through appropriate heat treatment processes, grains are refined; hardenability and heat intensity properties of the alloy forged steel are improved; normal temperature strength and high temperature strength of the alloy forged steel are greatly improved; and excellent comprehensive mechanical properties of the alloy forged steel are obtained.

Owner:CRRC QISHUYAN INSTITUTE CO LTD +1

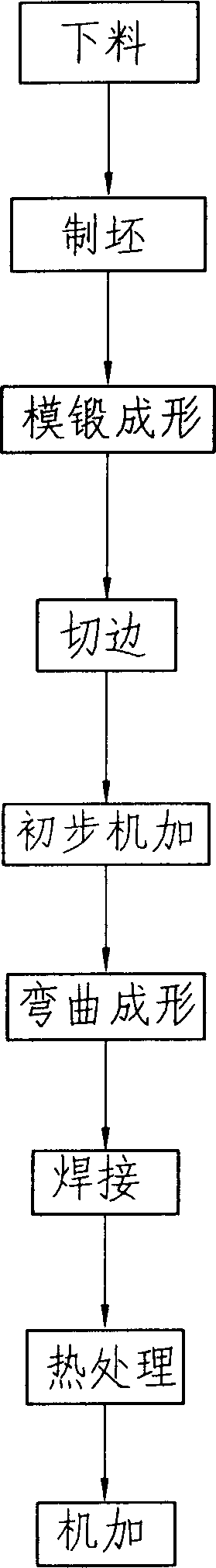

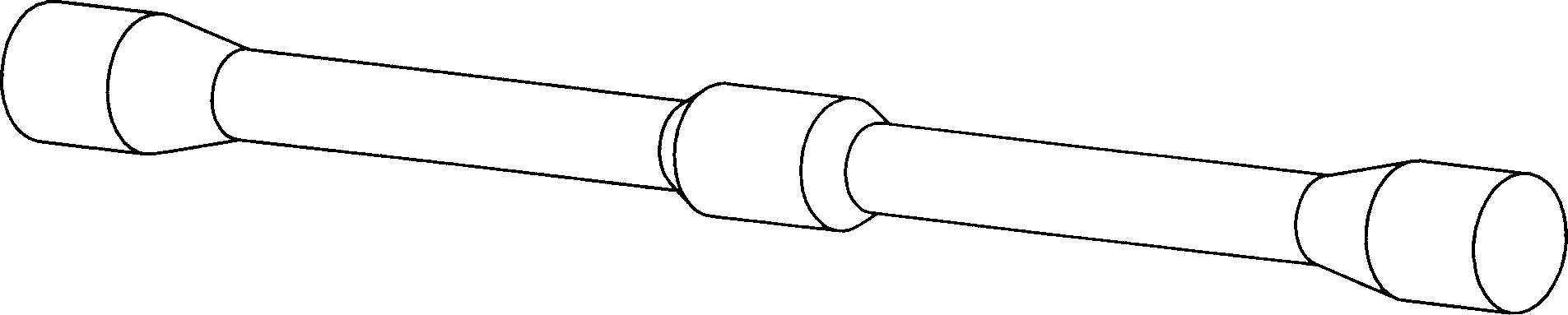

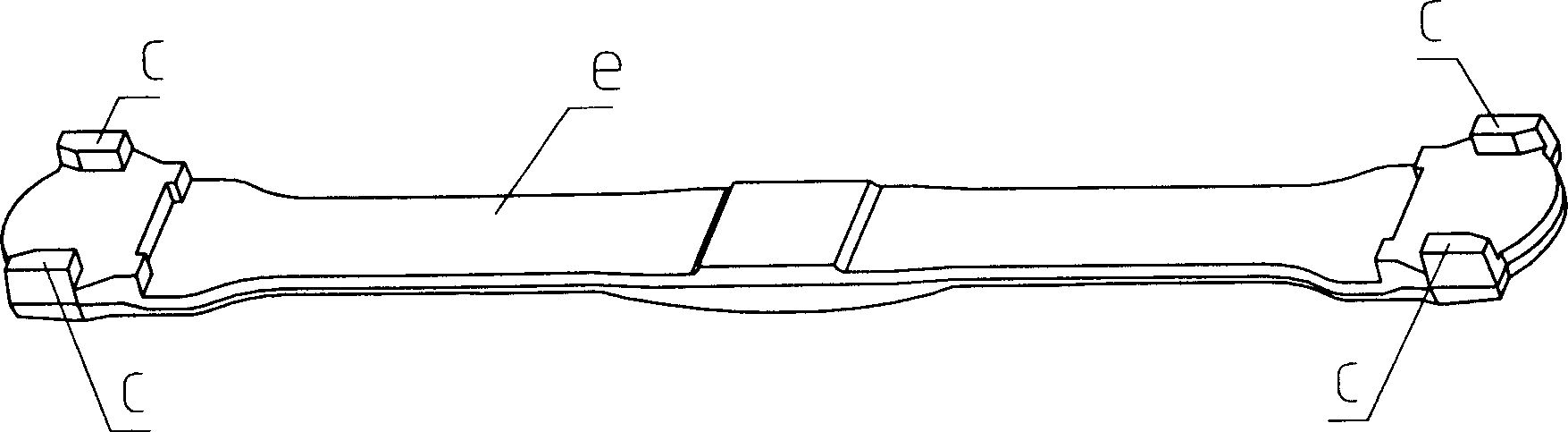

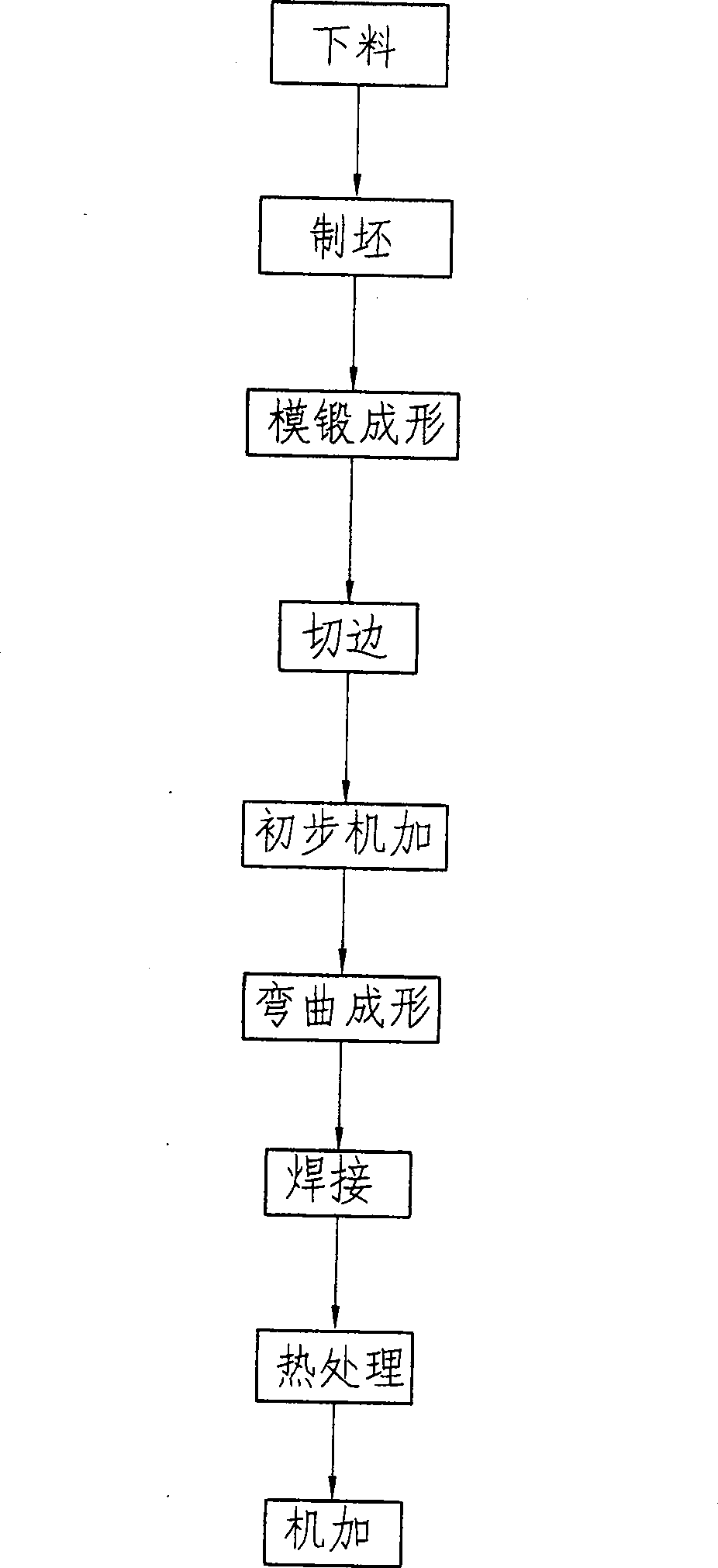

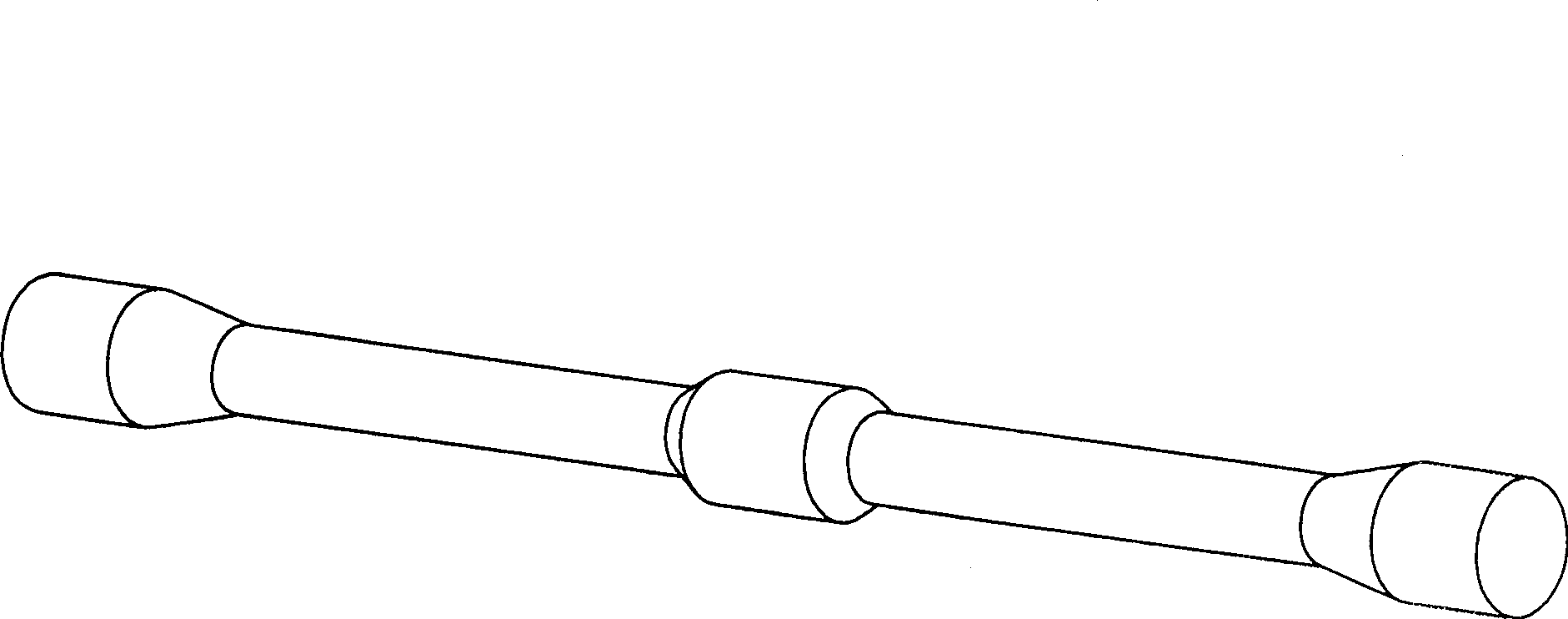

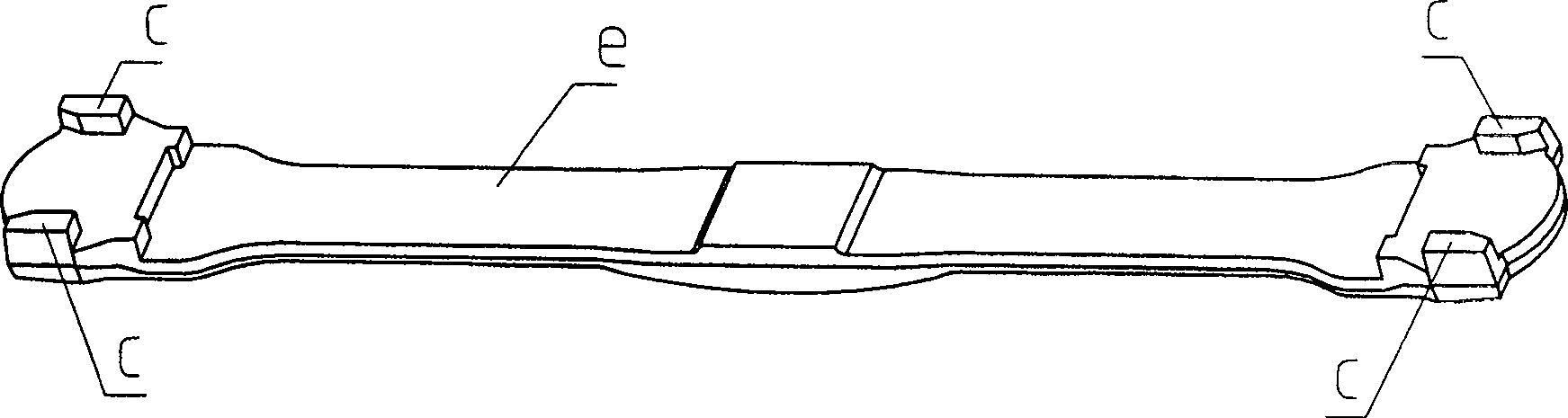

Method for forging combined forged steel coupler yoke for railway vehicles

ActiveCN1807009AIncrease profitReduce forging difficultyMetal-working apparatusOther manufacturing equipments/toolsHigh volume manufacturingMetal fibers

The invention relates the forging method of composite steel-forged coupler yoke frame, comprising blanking, making flan, die forging forming, cutting edge, preprocessing, bending forming, welding, heat treatment and machining. Making flan is that the blank is forged to get the explosion blank whose shape and size are close to coupler yoke frame; die forging forming is that the blank is putted in final forging mold cavity to get the explosion rough; bending forming is that the explosion rough is bended to U-shaped; welding is combination welding to form butt plate of coupler yoke frame. The invention possesses the following characters: metal fiber current direction is good, forging forming is easy, the die lifetime is long, forging and machining difficulty are reduced, material utilization is high, and the cost is low.

Owner:CHONGQING CHANGZHENG HEAVY IND

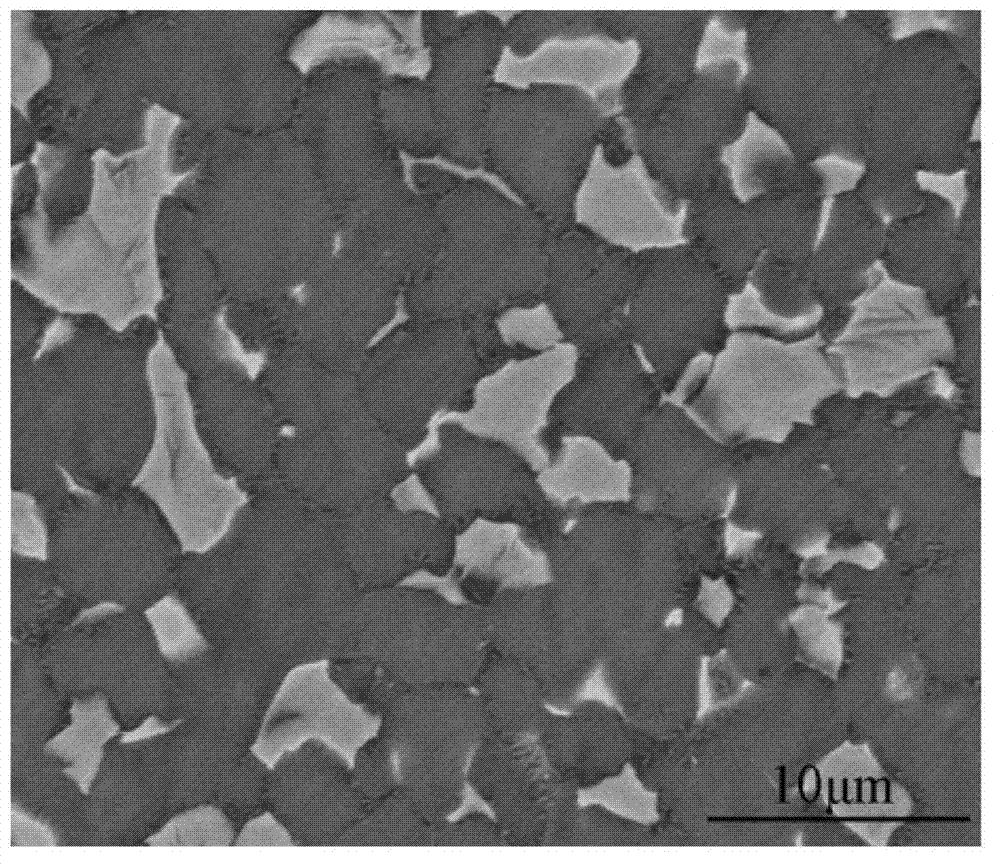

Technique method for improving density of injection molding high-speed steel columnar deposition blank

The invention relates to a technique method used for raising the density of a steel-column shaped sediment blank of a spray-forming high-speed tool and belongs to the technical field of material processing. The invention thoroughly combines the theory idea and the technical advantage of spray-forming and heat-control concretion. In an early phase of the spray sediment process, the advantages of the spray-forming that an equiaxed grain (less than 20Mum) having no segregation but a uniform and thin structure can be manufactured in a short process can be performed, and then the manufactured high-speed steel sediment blank has high strength, better plasticity and easy-forging capability. In a later phase of the sediment process, i.e. after the spray-forming is finished, the structure of a main body of equipment (such as a tundish and an atomizing sprayer, etc.) is adopted to control output and radiation of the heat. The invention enhances solidification of easy-loosening part of the high-speed steel sediment blank, so as to manufacture high quality and high density sediment blank. The technique not only can solve the segregation of the high-speed steel but also further enhance the density of the sediment blank to guarantee a following smooth process of fine-forging, etc.

Owner:BEIJING AVIATION MATERIAL INST NO 1 GRP CORP CHINA AVIATION IND

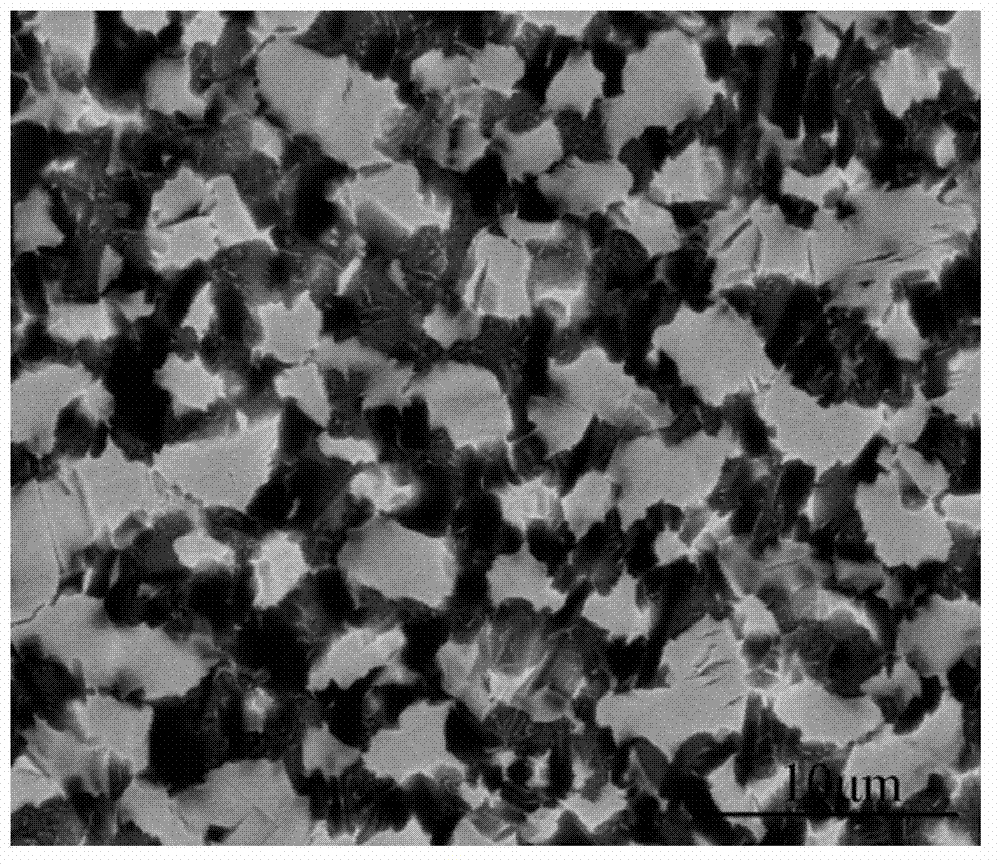

Beta-gamma TiAl alloy and preparation method thereof

InactiveCN102828067AGood deformabilitySmall high temperature deformation resistanceVacuum induction meltingAerospace

The invention provides a beta-gamma TiAl alloy and a preparation method thereof, relating to a TiAl alloy and a preparation method thereof. The invention mainly solves the problem that the existing TiAl alloy has poor high temperature deformability. The beta-gamma TiAl alloy is prepared from Al, X, A and balance of Ti, wherein X is element Mo or Mn, and A is element B or Y. The preparation method comprises the following steps of: firstly, weighing raw materials in percent by atom; secondly, pouring the raw materials into a vacuum induction melting furnace to be subjected to vacuum melting; and thirdly, pouring an alloy melt into a preheated metal casting mould, thus the beta-gamma TiAl alloy is obtained. The beta-gamma TiAl alloy prepared by adopting the invention improves high temperature deformability of a titanium-aluminium alloy, deformation adopting nearly isothermal sheath forging can reach up to 80%, surface of a prepared forging stock is smooth, internal tissue is thin and uniform, and the prepared forging stock is mainly applied to aviation and automobile industrial materials.

Owner:HARBIN INST OF TECH +1

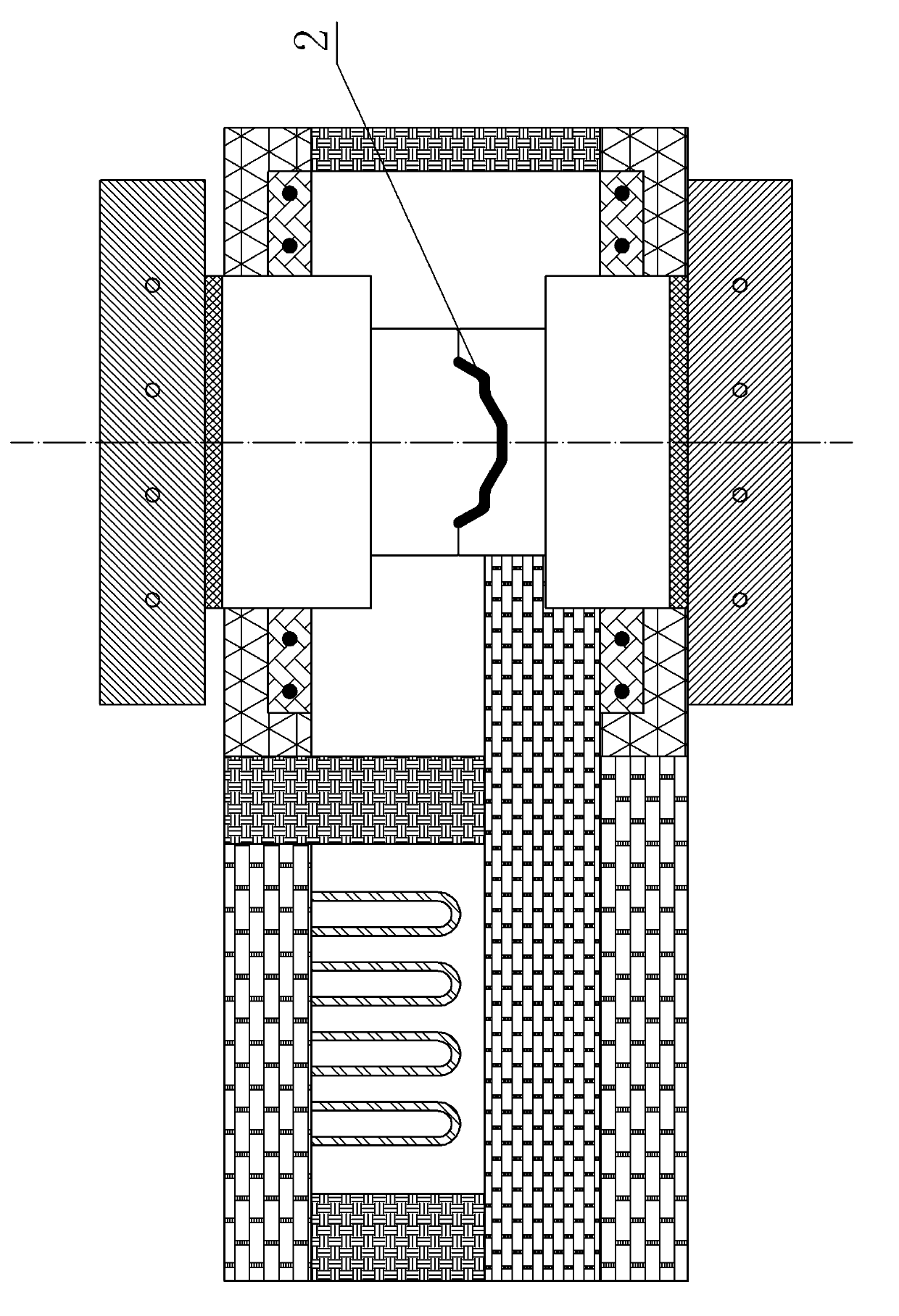

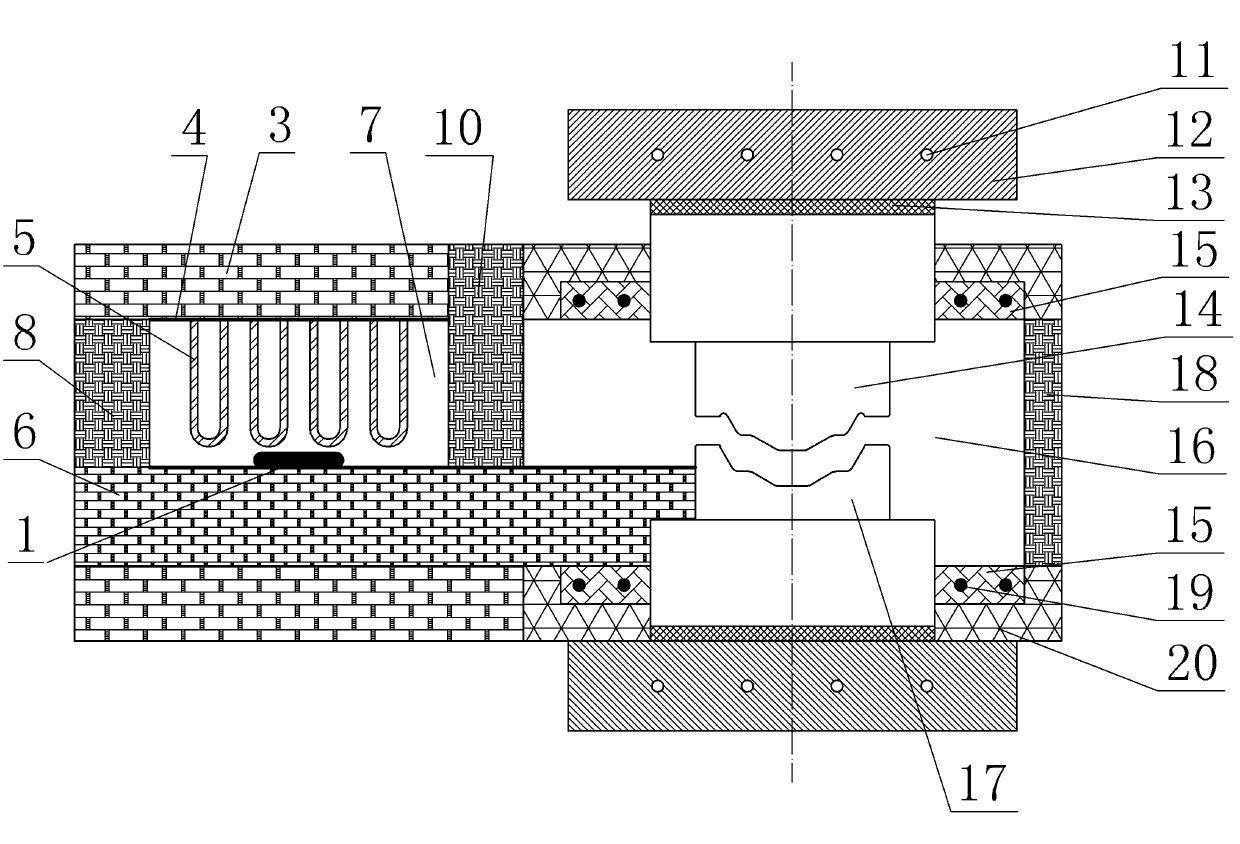

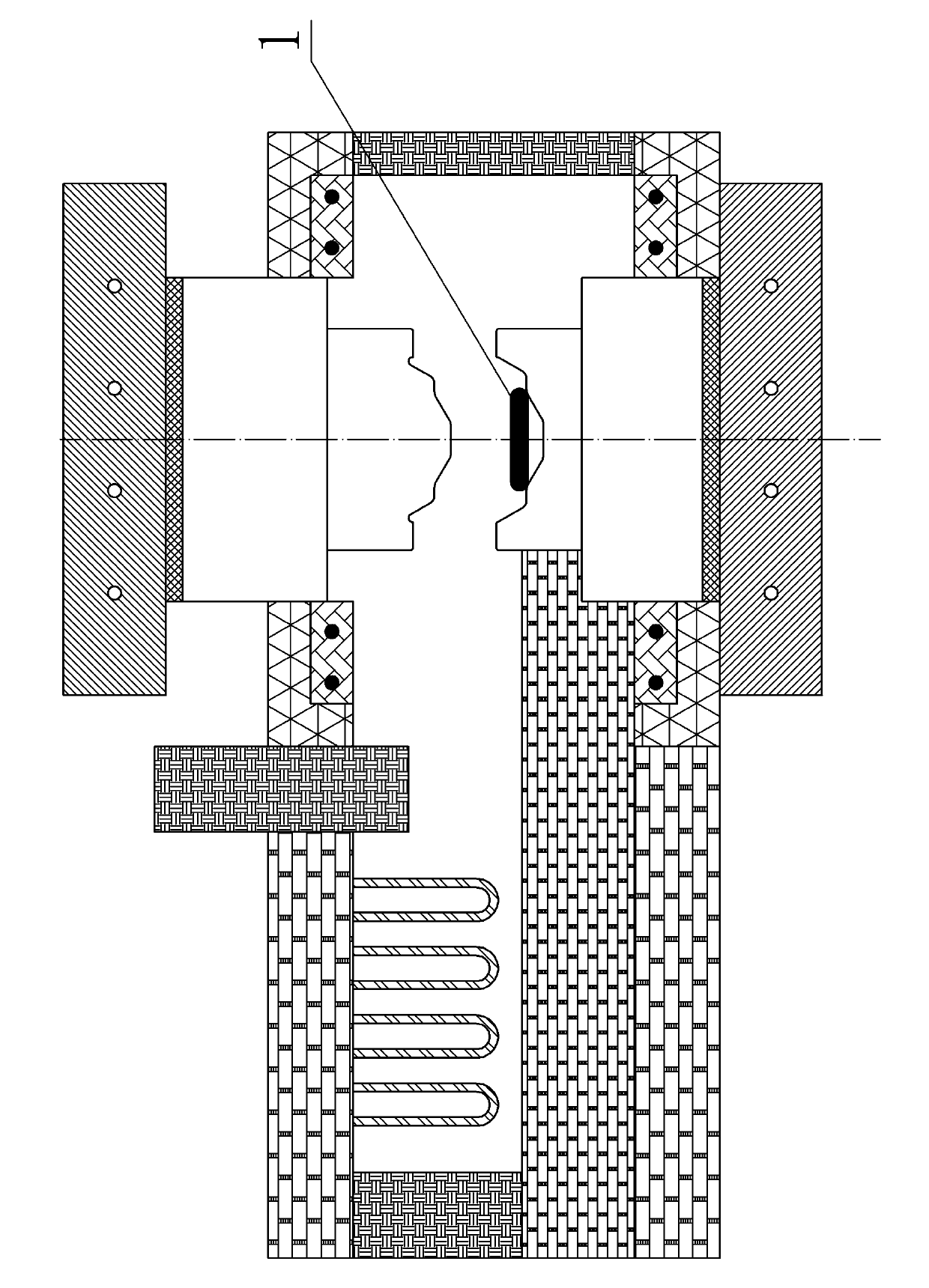

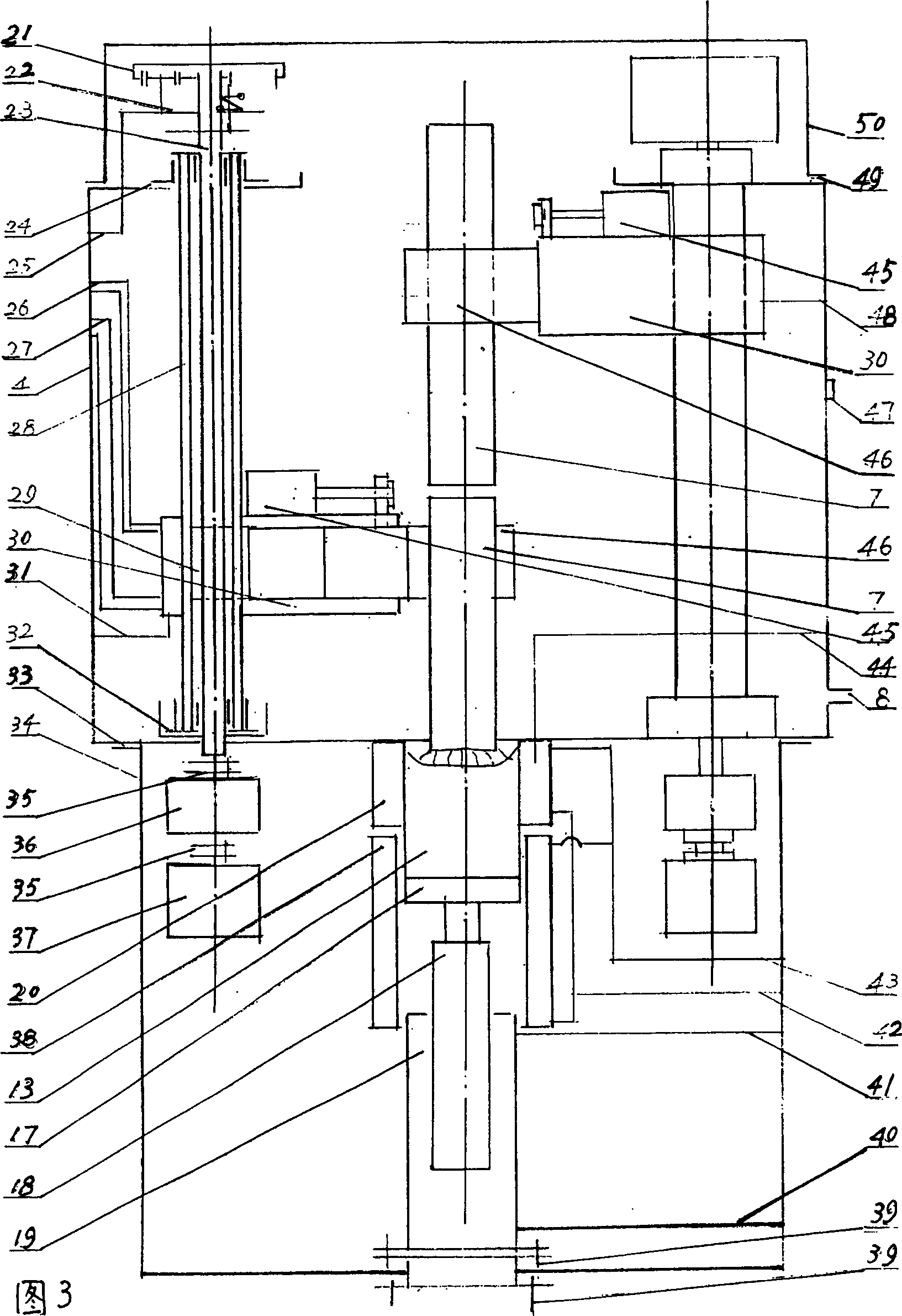

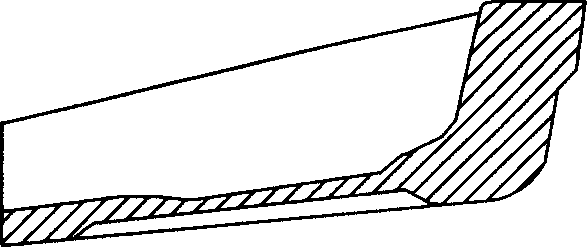

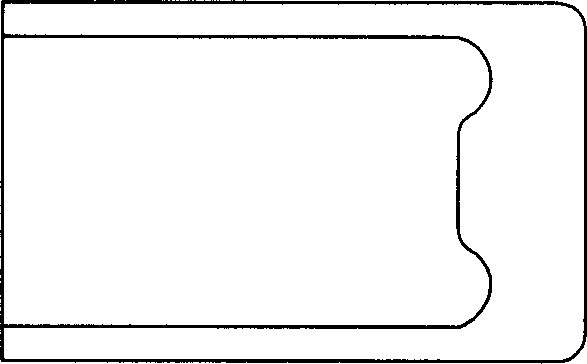

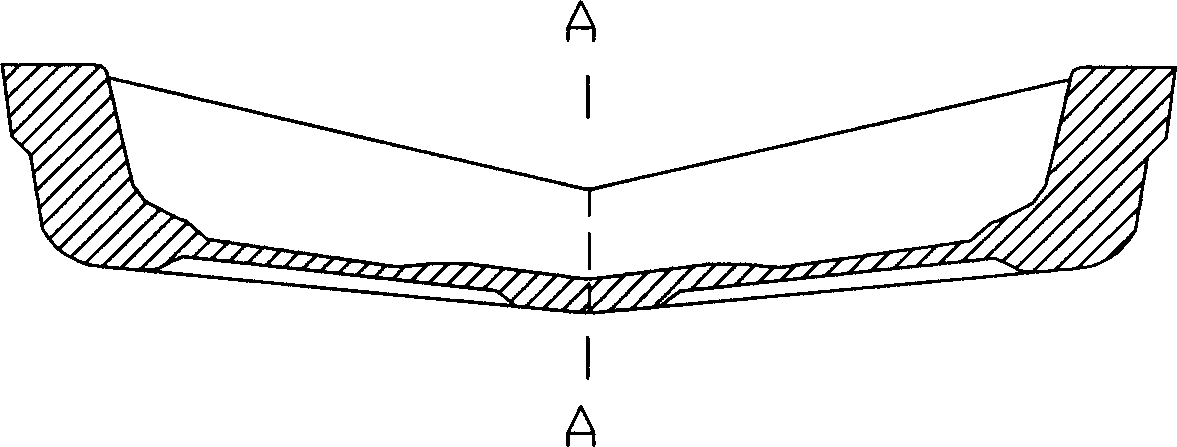

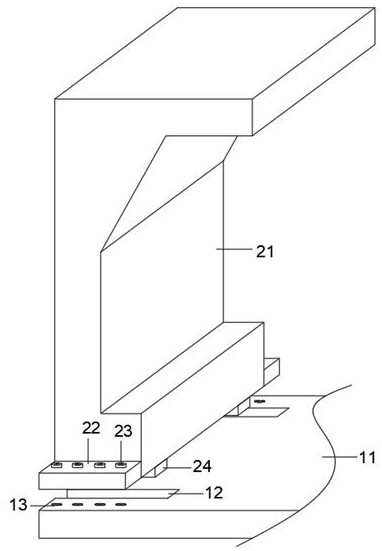

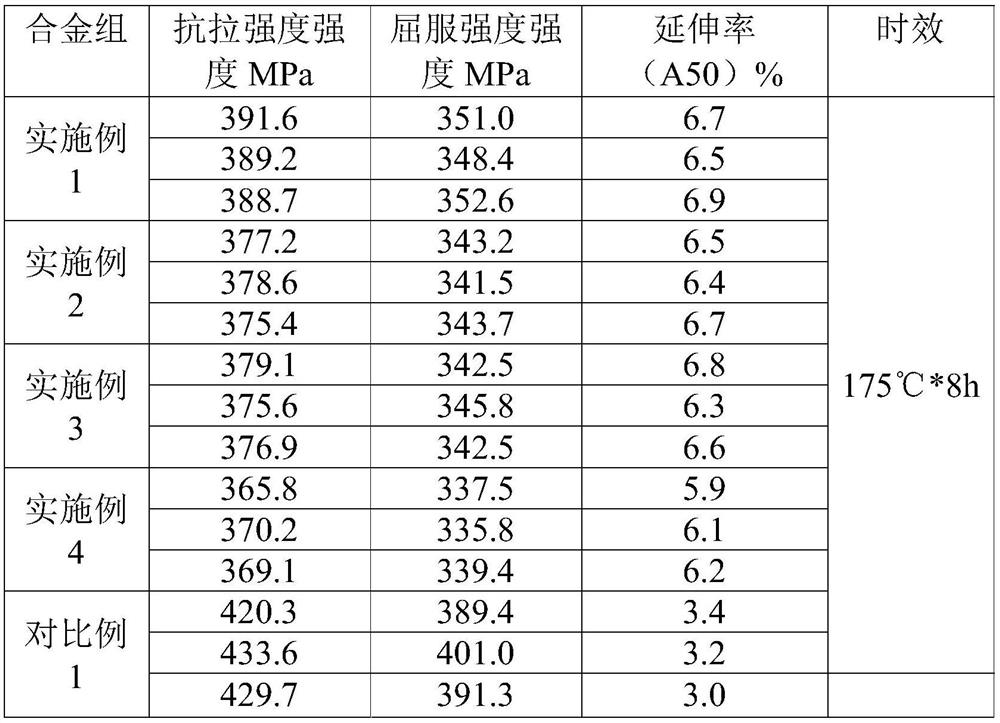

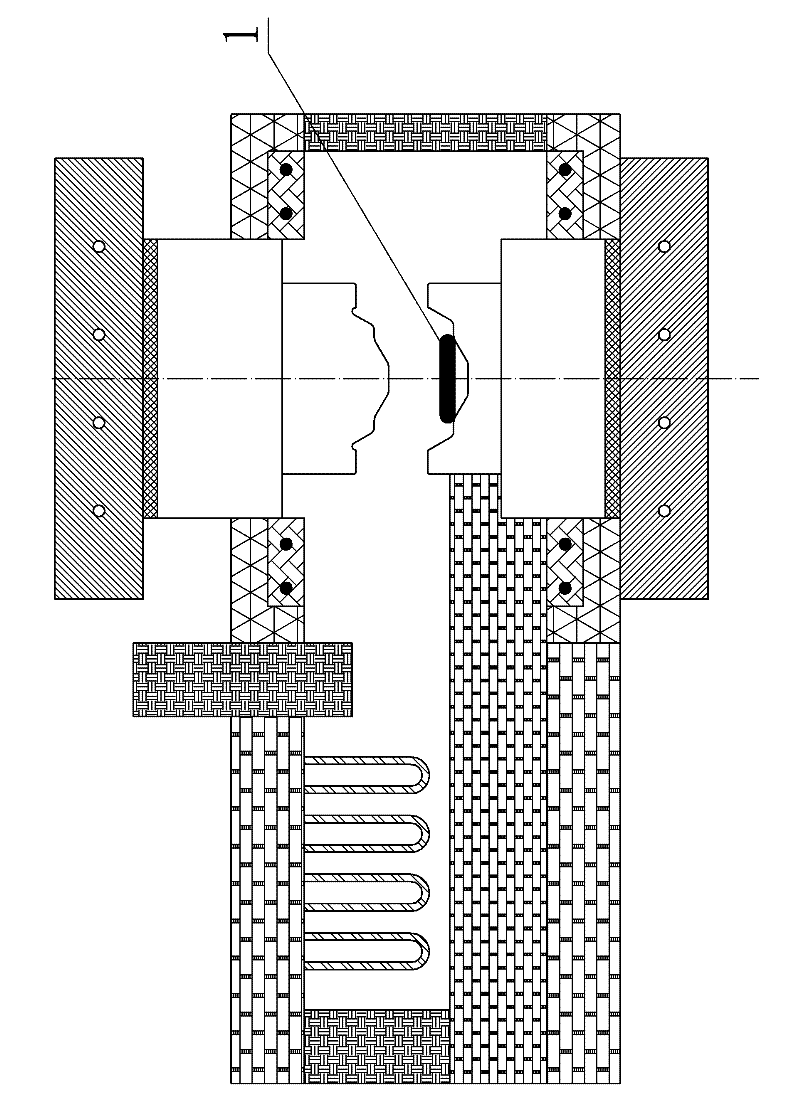

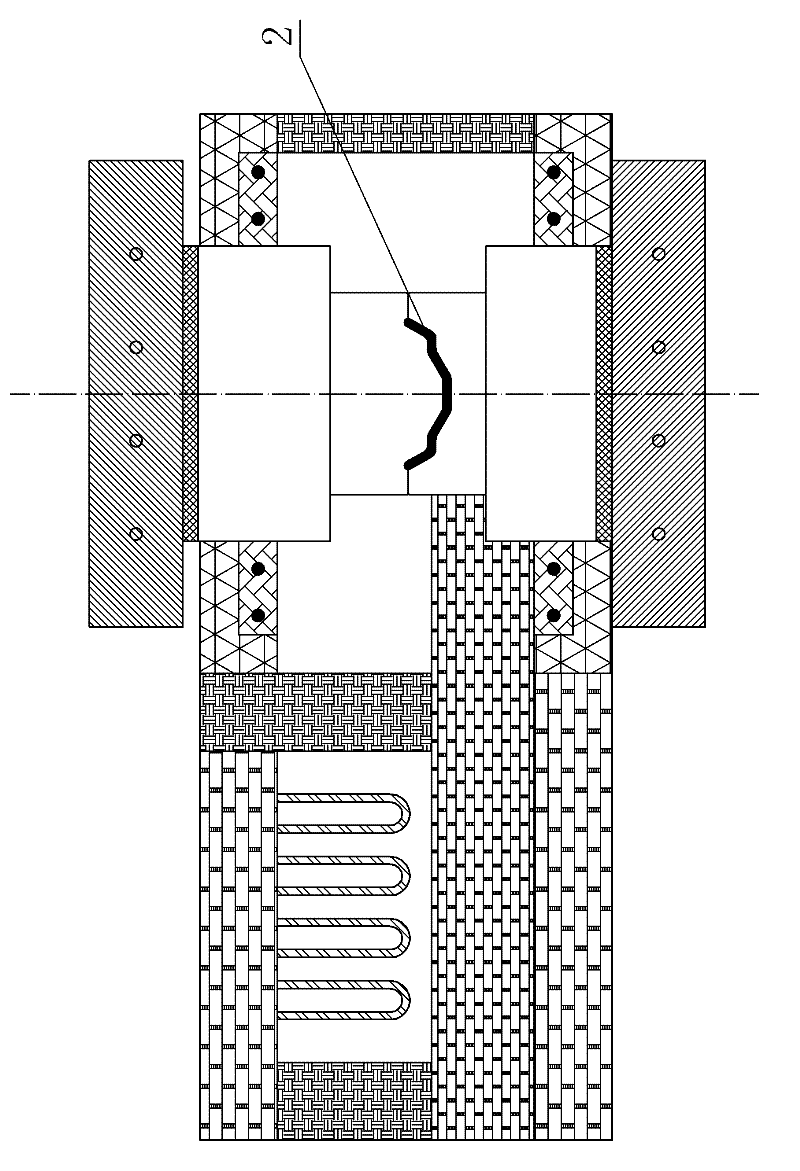

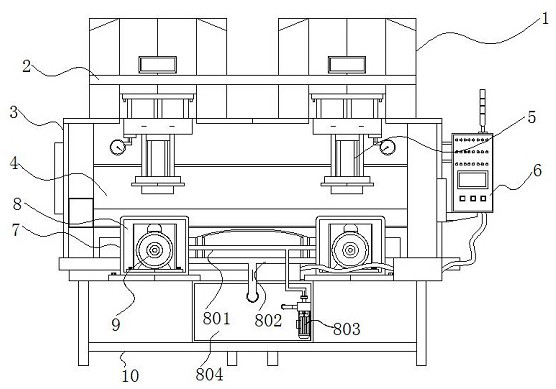

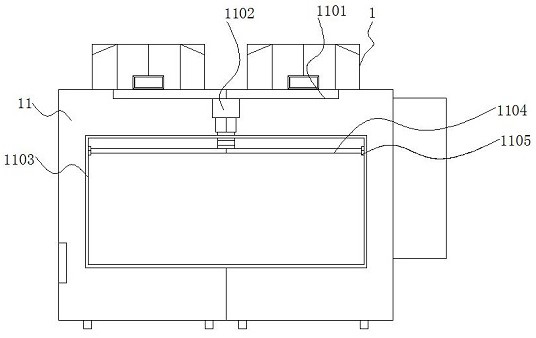

Double-chamber high-temperature forging and forming device of TiAl intermetallic compound forge piece and method thereof

ActiveCN101947617AAlleviate the problem of high deformation resistanceEasy forgingHeating/cooling devicesHeat lossesHearth

The invention relates to a double-chamber high-temperature forging and forming device of a TiAl intermetallic compound forge piece and a method thereof, belonging to forming methods and devices of TiAl intermetallic compound forge pieces. The invention solves the problems of large heat loss, large deformation resistance, small forging deformation, difficult forging and the like generated when the traditional forging technology is used for forging the TiAl intermetallic compound forge piece. A blank heating chamber and a mould heating chamber are adjacently arranged and a movable baffle plate is arranged between the blank heating chamber and the mould heating chamber, and a hearth of the blank heating chamber and a hearth of the mould heating chamber are mutually penetrated and mutually independent by pulling the movable baffle plate up and down. TiAl blanks and a mould are heated to 1230-1300 DEG C and 800-1000 DEG C respectively in different heating chambers; the movable baffle plate is opened to push the TiAl blanks into the mould heating chamber along a carrying platform and put the TiAl blands into a mould cavity; and the mould is closed for forging. The invention is used for high-temperature forging and forming of TiAl intermetallic compound materials.

Owner:HARBIN INST OF TECH

Method for preparing double-scanning and spray forming high-speed steel under purification

Owner:BEIJING AVIATION MATERIAL INST NO 1 GRP CORP CHINA AVIATION IND

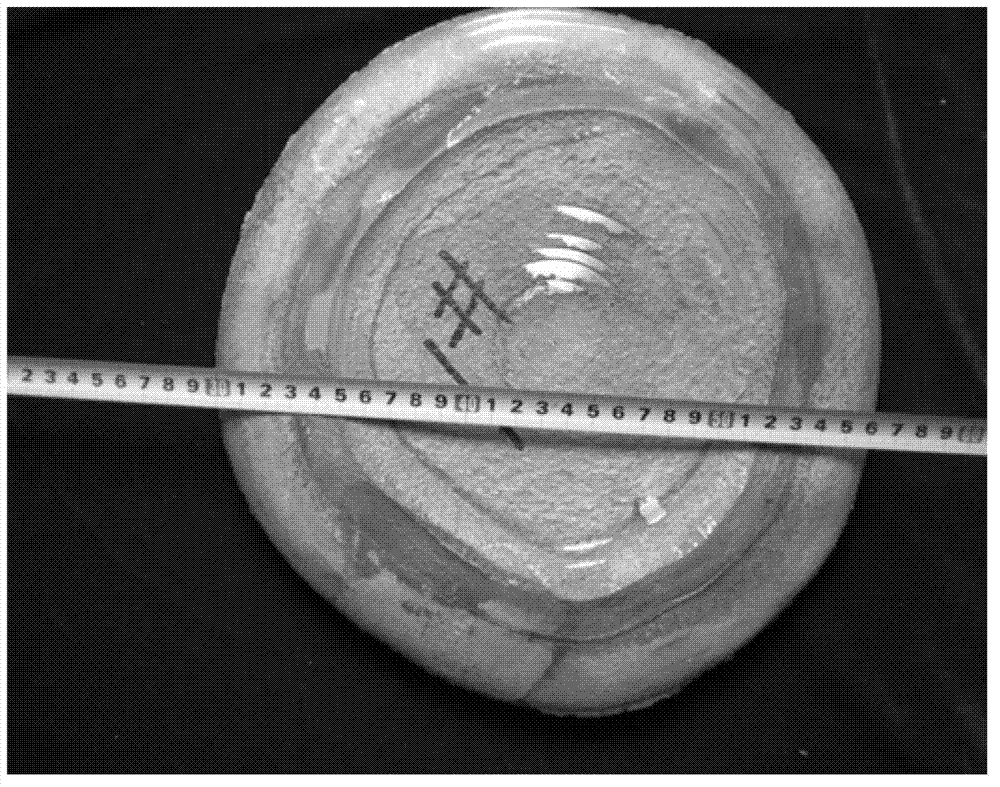

Forging method for equal-atomic-ratio titanium-nickel alloy large cast ingot

The invention discloses a forging method for an equal-atomic-ratio titanium-nickel alloy large cast ingot. The titanium-nickel alloy large cast ingot is subjected to homogenization treatment, the technological parameter is 930-980 DEG C, and heat preservation time is 10-12 h, and air cooling is conducted; the air-cooled titanium-nickel alloy large cast ingot is subjected to the first heating number of forging, the heating temperature is 900-920 DEG C, heat preservation is conducted for 4-5 h, deformation is phi460-phi320, the strain rate is (0.05-0.10) s<1>, and a forging blank is obtained after the first heating number in a breaking mode; the forging blank is subjected to the second heating number of forging, the heating temperature is 880-900 DEG C, heat preservation is conducted for 3-3.5 h, deformation is phi320-phi200, the strain rate is (0.10-0.25) s<1>, and the forging blank is obtained after the second heating number in a breaking mode; and the forging blank is subjected to the third heating number of forging, the heating temperature is 850-880 DEG C, heat preservation is conducted for 2-2.5 h, deformation is phi200-phi110, the strain rate is (0.05-0.20) s<1>, and a titanium-nickel alloy square billet is obtained in a breaking mode. The method of the low strain rates, the multiple heating numbers and increasing deformation is adopted, forging of the titanium-nickel alloy large cast ingot is achieved, the cracking phenomenon in forging is eliminated, and the good structure and performance of materials are achieved.

Owner:西安赛特思迈钛业有限公司

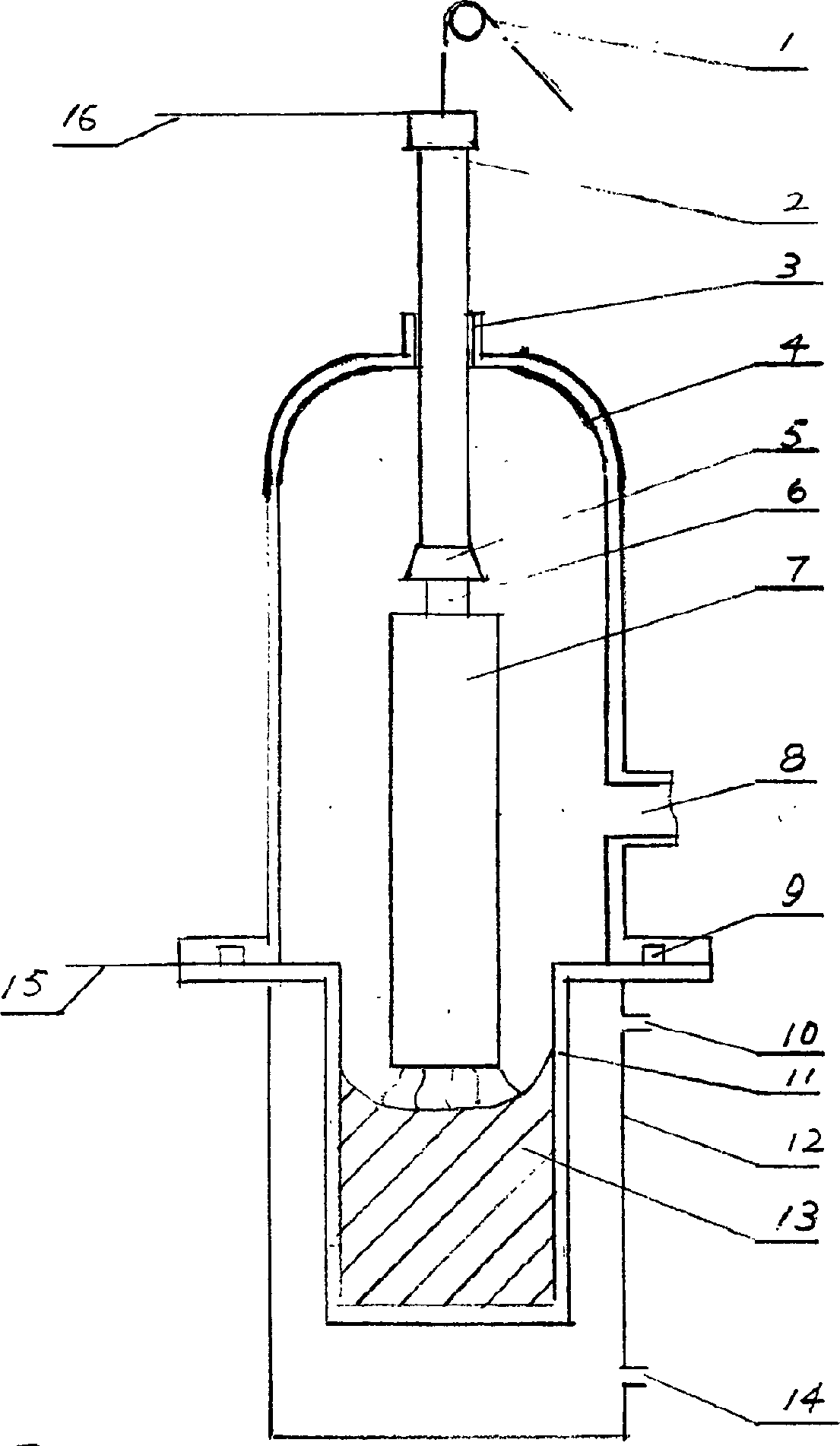

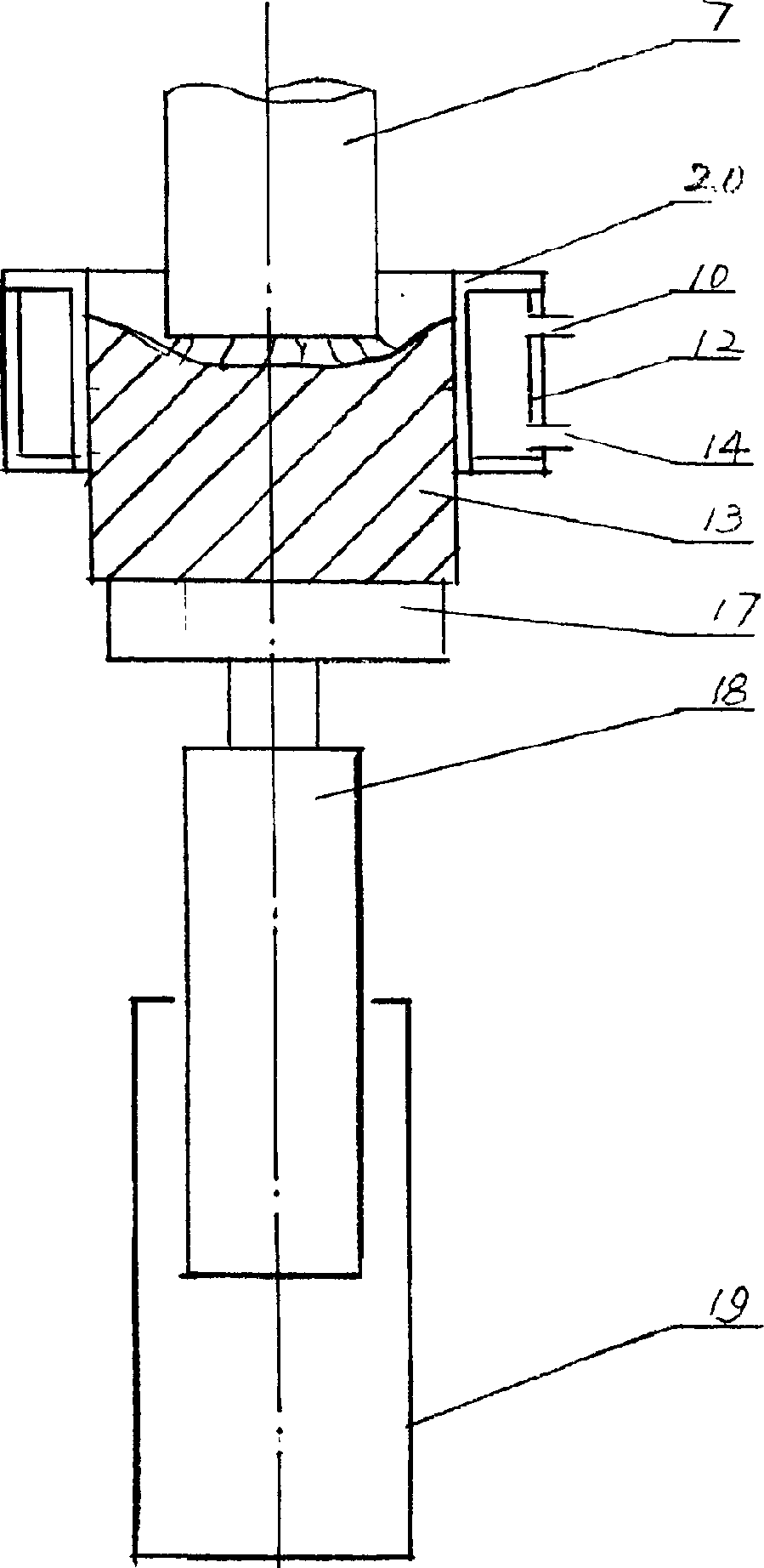

Vacuum consumable furnace with automatic welding electrode in furnace

InactiveCN1827807AIncrease vacuumLower the altitudeLighting and heating apparatusReduction driveElectromagnetic clutch

The invention relates the internal furnace electrode automatic welding vacuum consumable furnace, comprising furnace body, double-sleeve upright column, and mechanical arm device, cooler crystallizer at the middle of bottom furnace, wall-cooling surface, dummy head, dummy bar, and dummy actuating device at the bottom of dummy bar. The characters are following: at one end of upright column there is servomotor and harmonic decelerator, which are connected with elevating screw in upright column and lifting screw through coupler, and at the other end of upright column there is planetary deceleration mechanism which is connected with upright column through clutch; the mechanical arm comprises arm, telescopic arm and clamping hand, and the lifting screw drives the arm; the return circuit of melting electrical source comprises dummy head mechanical arm, the welding power source superposes between two mechanical arms; the vacuum system, hydraulic system, voltage control system, cooling system, smelting electrical source, welding power source are installed on out of furnace; the clutch is electromagnetic clutch, when the clutch switches on, the elevating screw drives upright column and drives mechanical arm.

Owner:王晓邦 +2

Method for producing dissymmetrical die forging

InactiveCN1827255AAvoid uneven forceExtended service lifeMetal-working apparatusMetallurgyMaterials science

The invention discloses a method for producing asymmetry dies forging, which according to the structure of single asymmetry dies forging product to produce one symmetry die forging formed by two symmetry connected asymmetry die forging elements, then along the symmetry axle of said symmetry die forging to be divided into two needed asymmetry die forging elements. The inventive method can simplify the process and improve the producing efficiency.

Owner:SOUTHWEST ALUMINUM GRP

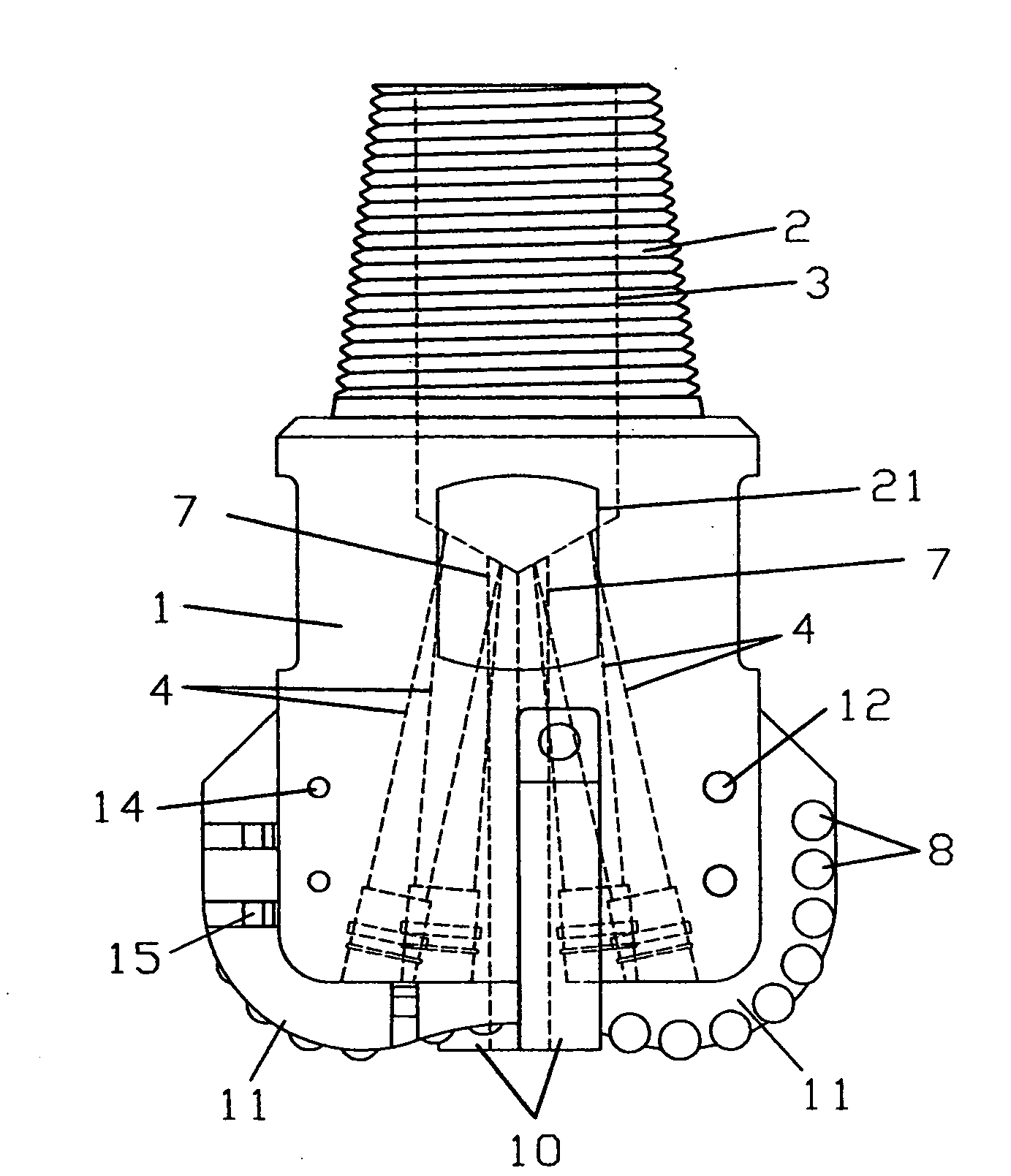

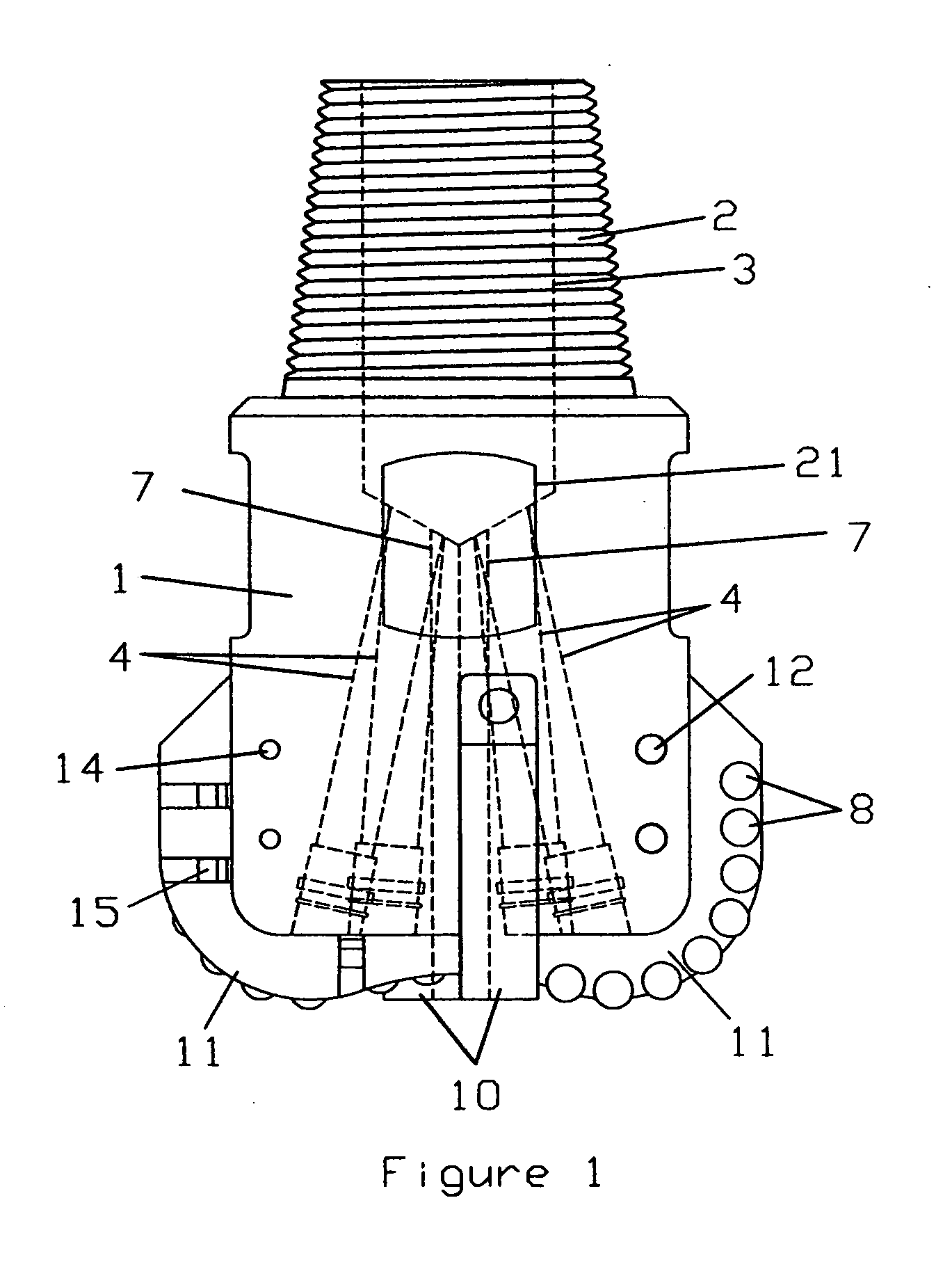

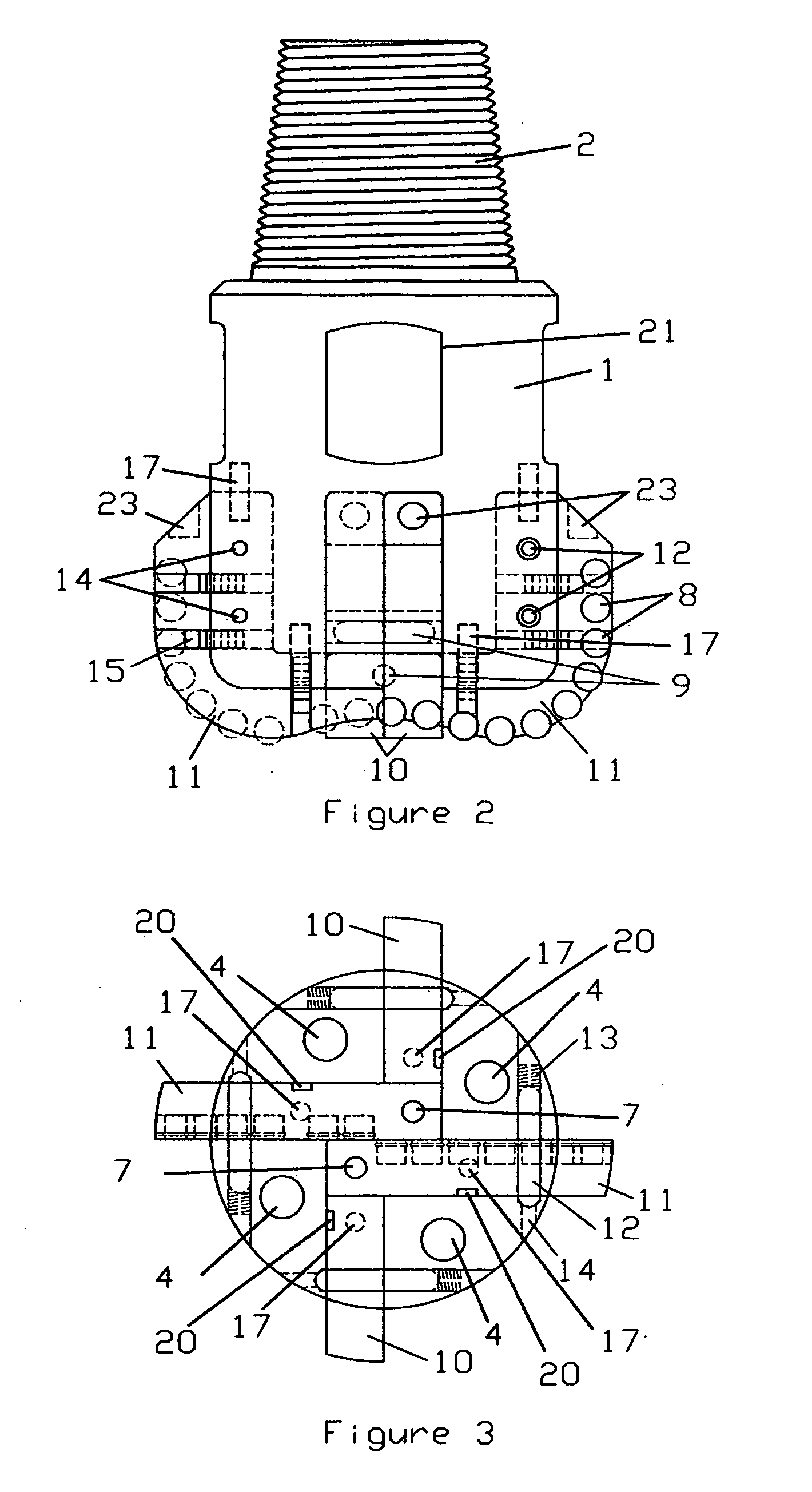

Drill bit with replaceable blade members

InactiveUS20090308664A1Cutting structure coverageHigh strengthDrill bitsConstructionsEngineeringKnife blades

A drill bit for rotary drilling a well bore of a subterranean formation which has replaceable blades which overlap and interlock with each other and have retention means on more than one axis. The replaceable blades may have cutters with enhanced retention by brazing ring grooves and the body may be flared at its bottom to better retain the blades and cutters.

Owner:NACKERUD ALAN L

Double-scanning spray forming preparation method of high-carbon wear resisting tool and mold steel

InactiveCN105478770AImprove performanceHigh yieldMetal-working apparatusHigh carbonMaterials processing

The invention belongs to the field of processing and manufacturing of advanced materials, and relates to a double-scanning spray forming preparation method of high-carbon wear resisting tool and mold steel. The method fully uses advantages of a double-scanning spray forming process, and proposes a double-scanning spray forming preparation process of high-carbon wear resisting tool and mold steel. Compared with a single-nozzle spray forming process, the double-scanning spray forming has the following advantages: (1) the material structure is more uniform; the performance is higher; and the mass and heat distribution of alloy atomization molten drips of double-nozzle spray is more uniform; (2) a deposition blank is more regular in shape; and in two scanning nozzles, one nozzle is used for forming a cylindrical blank, and the other nozzle is mainly used for filling and feeding the middle mass of the blank; and (3) the cost is lower; and as the material yield of double-scanning spray forming is higher, the double-scanning spray forming is lower in cost compared with single-nozzle spray forming.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

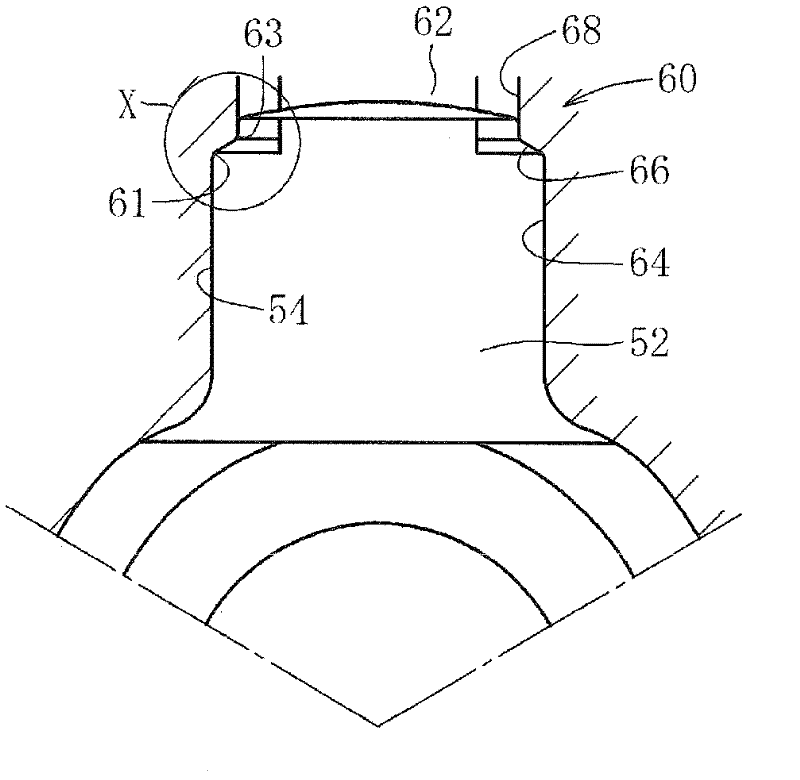

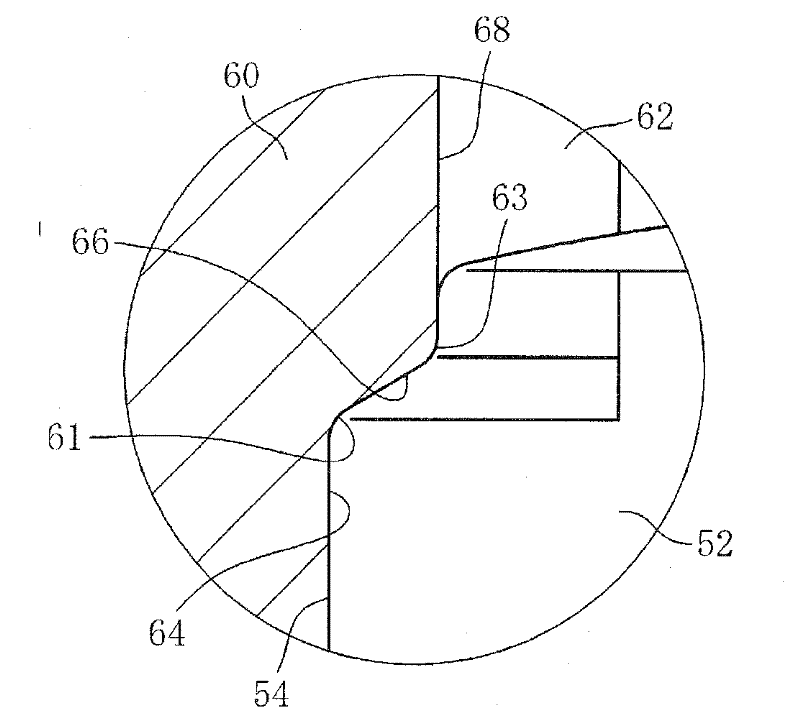

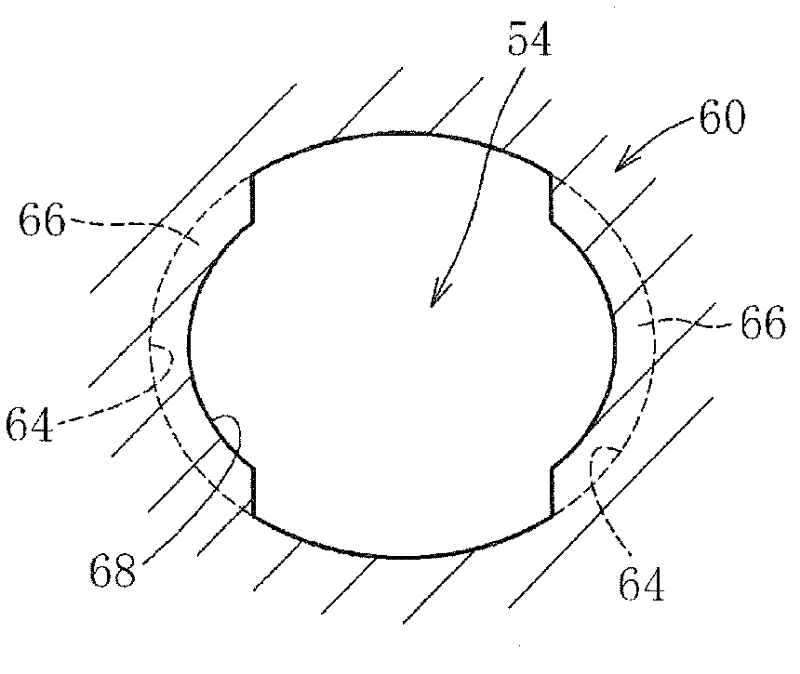

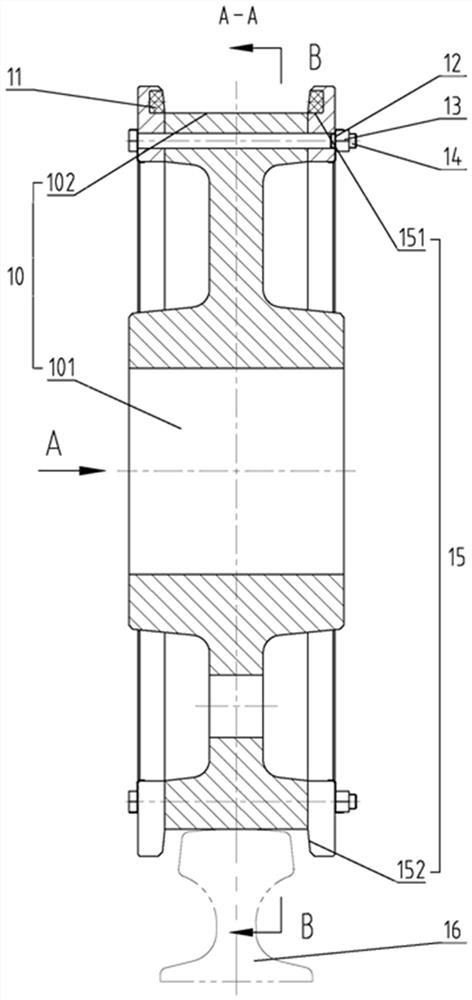

Tripod constant-velocity universal joint and method for producing the same

ActiveCN102405357ARealize Manufacturing HoursAchieve lifeYielding couplingEngine componentsConstant velocityUniversal joint

Disclosed is a method for producing a tripod constant-velocity universal joint comprised of an outer ring which has an inner peripheral surface in which three axially extending track grooves are formed, and has roller guiding surfaces axially extending in both sides of each track groove; a tripod member having three leg shafts which are radially projected; and roller units which are rotatably supported by the leg shafts of the tripod member, and are rotatably inserted to the track grooves of the outer ring, wherein, when the material of the leg shaft is forged into a shape of the leg shaft by a molding surface of a molding die, a relief portion is provided on the material front end-side of the molding die, and the outer peripheral surface of the material is molded into a convex round shape by a tapered surface formed in the molding surface to be in contact with the outer peripheral surface of the material and a concave round surface formed between the molding surface and the tapered surface.

Owner:NTN CORP

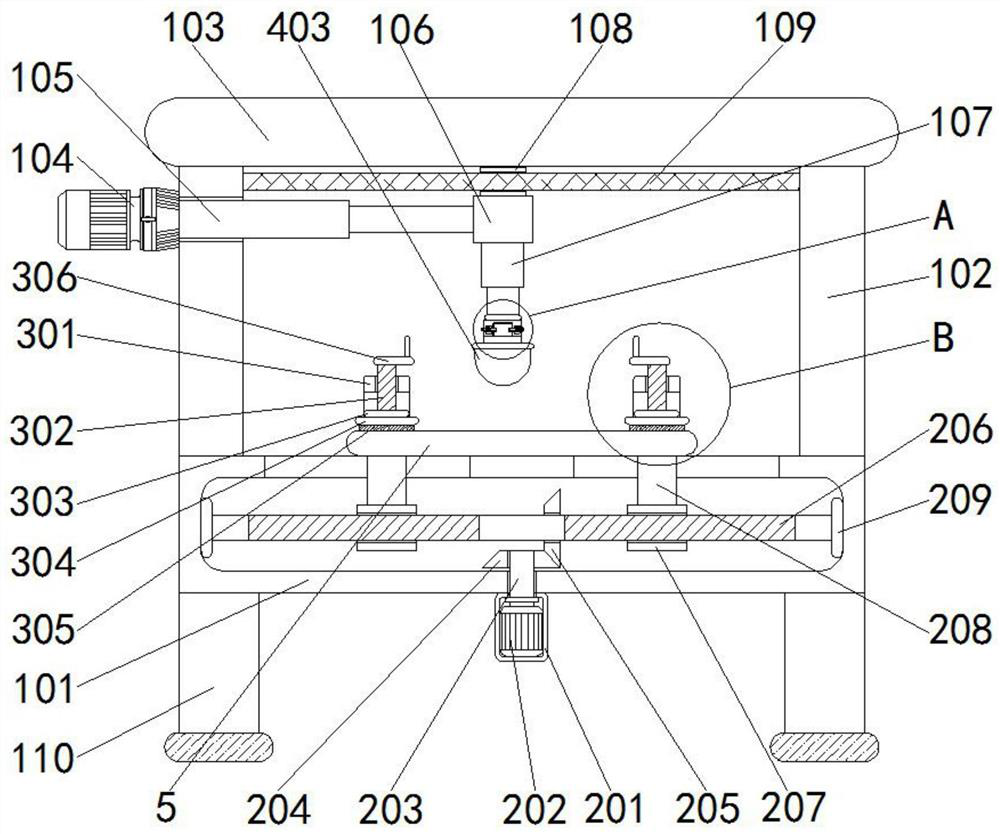

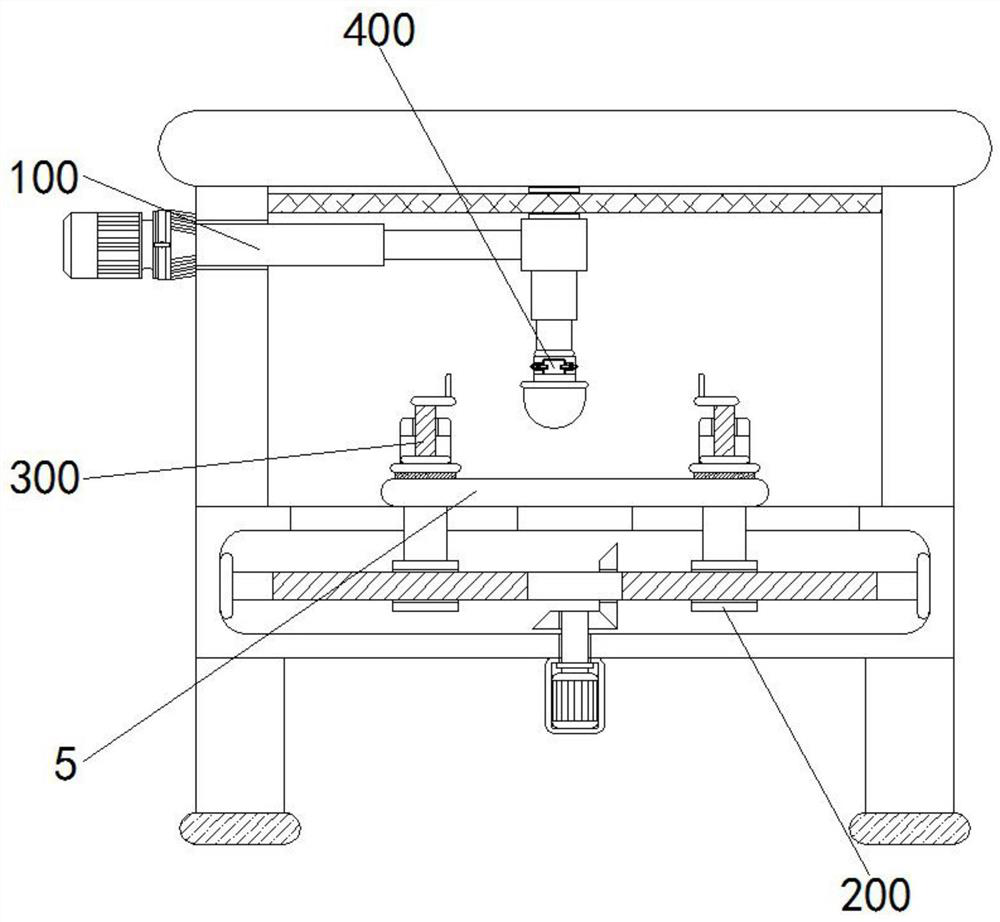

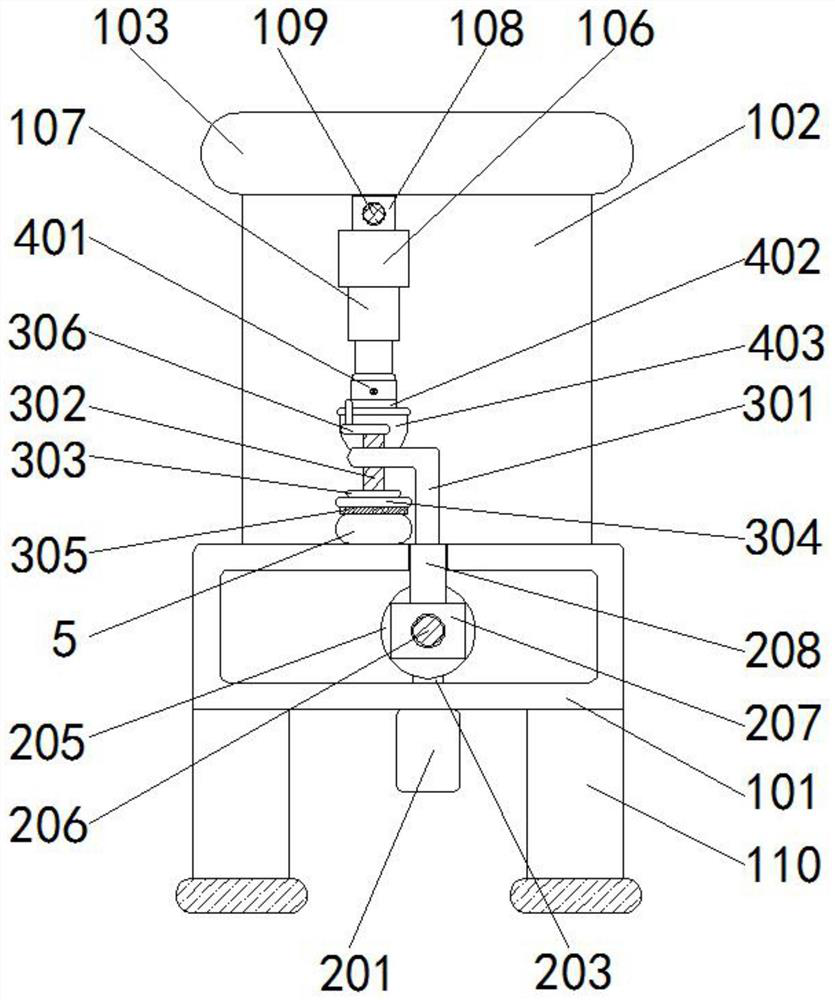

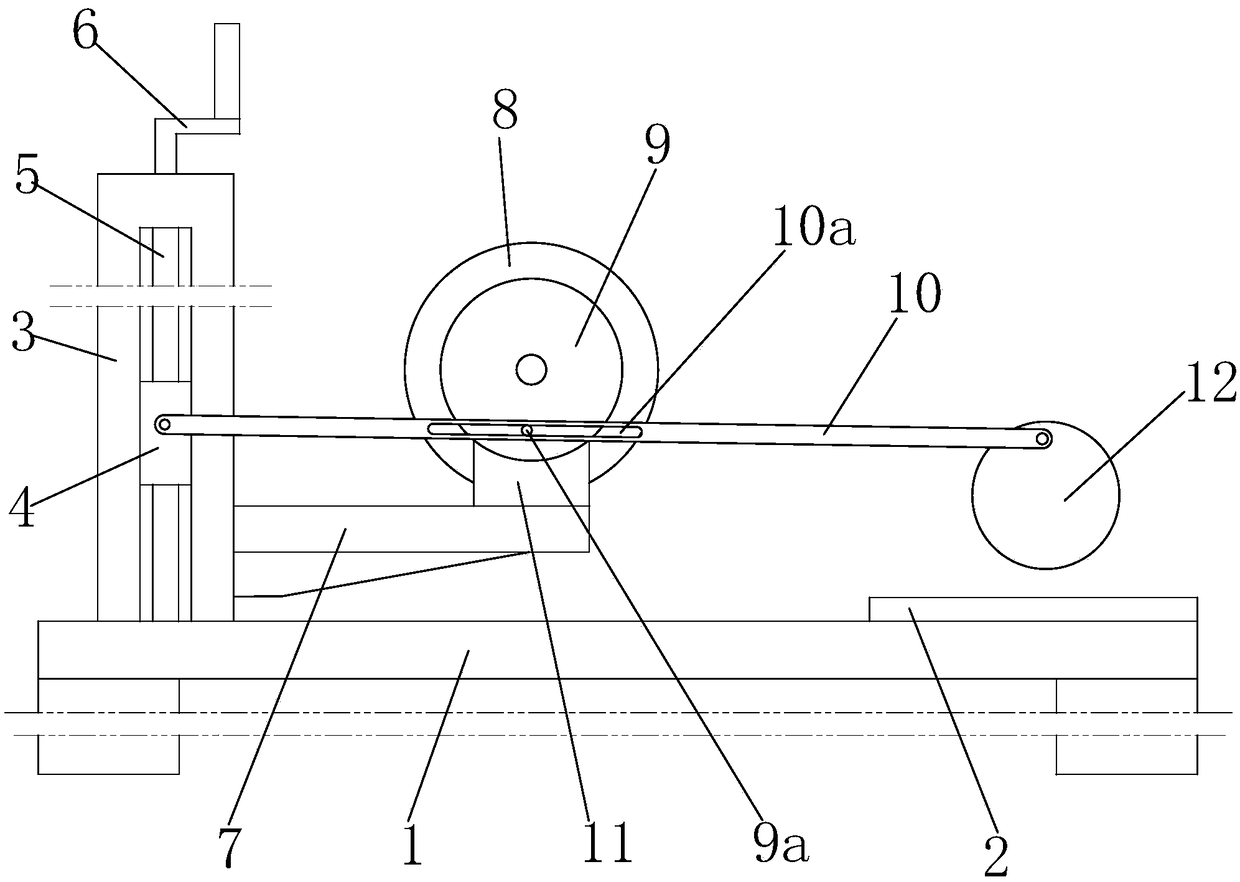

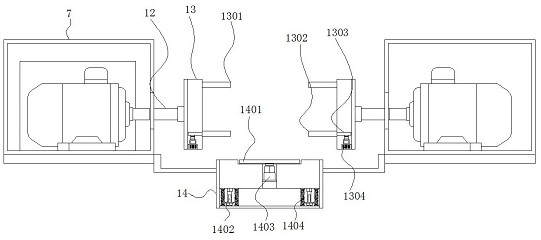

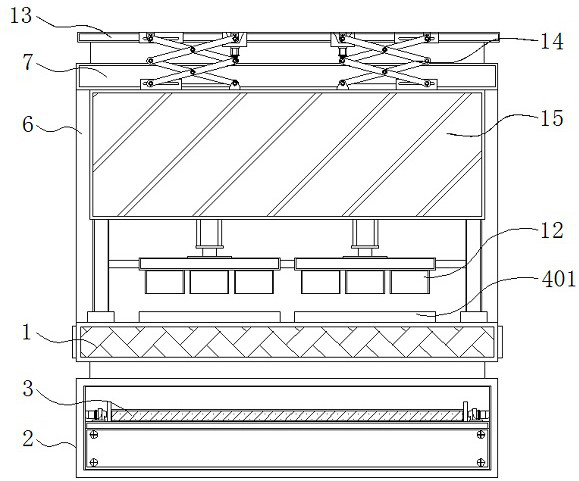

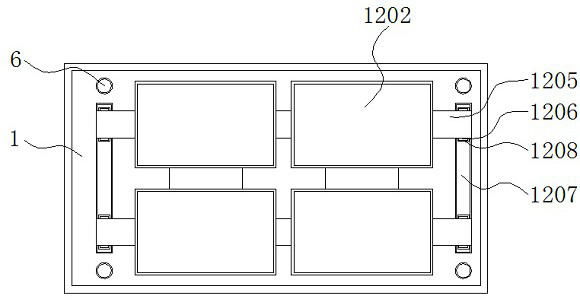

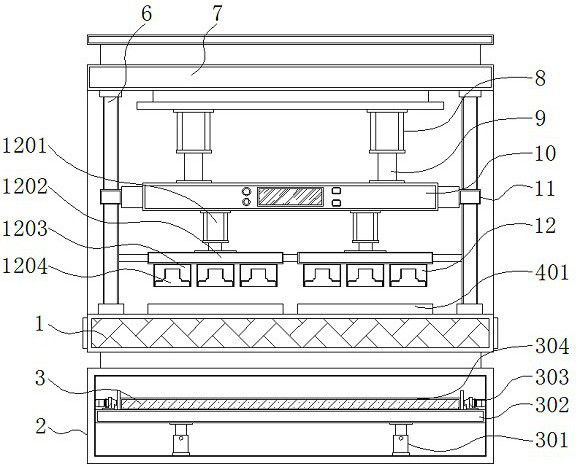

Forging and pressing production line for anchor chain manufacturing

PendingCN113263127AEasy for forgingTo achieve the purpose of multi-range forgingUpsetting pressesSwagging pressesProduction lineDrive shaft

The invention relates to a forging and pressing production line for anchor chain manufacturing. The production line comprises an adjusting mechanism, a driving mechanism, a clamping mechanism, a dismounting and mounting mechanism and an anchor chain body; the clamping mechanism is located above the driving mechanism, the anchor chain body is located below the clamping mechanism, the driving mechanism comprises a motor box, the inner bottom wall of the motor box is fixedly connected with a motor, an output shaft of the motor is fixedly connected with a driving shaft, the top end of the driving shaft is fixedly connected with a first bevel gear, the right side of the first bevel gear meshes with a second bevel gear, the inner side of the second bevel gear is fixedly connected with a threaded rod, the outer side of the threaded rod is in threaded connection with a threaded block, the top of the threaded block is fixedly connected with a limiting block, and the left end and the right end of the threaded rod are both fixedly connected with rolling bearings. The forging and pressing production line for anchor chain manufacturing is simple in overall structure and convenient to use, the purpose of adjusting a forging press is achieved, and the forging press can conduct multi-range forging and pressing on an anchor chain.

Owner:安徽亚太锚链制造有限公司

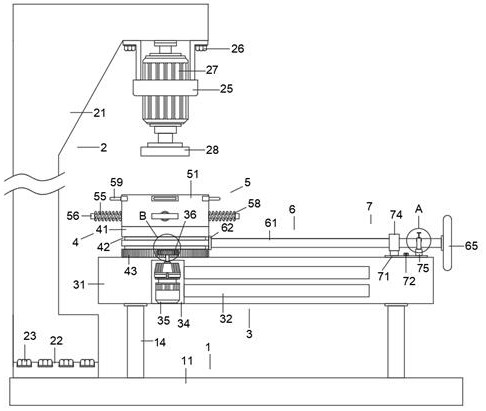

Forging equipment for steel manufacturing

InactiveCN112024803AEasy for forgingProblems causing bodily damagePower hammersForging/hammering/pressing machinesMachiningManufacturing engineering

The invention discloses forging equipment for steel manufacturing. The equipment comprises a base mechanism, the base mechanism comprises a fixed base, first sliding grooves, first screw grooves and supporting columns, the supporting columns are fixed to the four corners of one side of the top of the fixed base correspondingly, and the two first sliding grooves are dug at the side, away from the four supporting columns, of the top of the fixed base. The plurality of first screw grooves are dug at the sides, where the two first sliding grooves are away from each other, of the top of the fixed base. Through the arrangement of a forging mechanism, steel and iron manufacturing parts can be conveniently forged, and during machining, through cooperation use of a limiting sliding mechanism, a rotating mechanism, a machining mechanism, a dragging mechanism and a limiting mechanism, movable operation work of manual clamping, limiting and angle adjusting of the manufacturing parts can be replaced, and the problem that the body of a worker is damaged due to the fact that the physical strength of the worker is greatly consumed is solved.

Owner:徐子敏

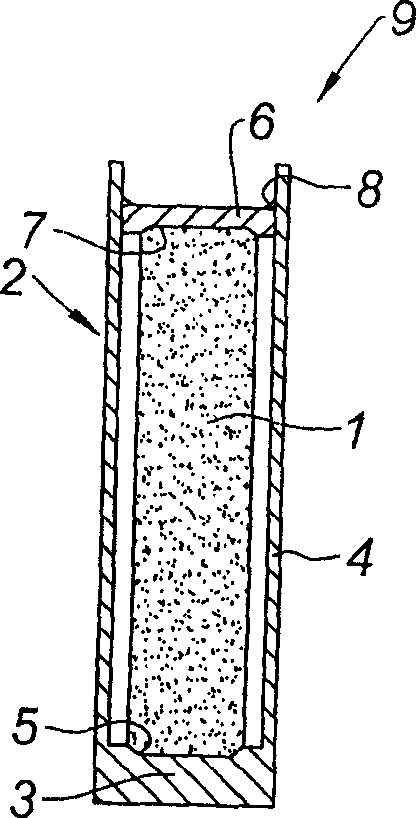

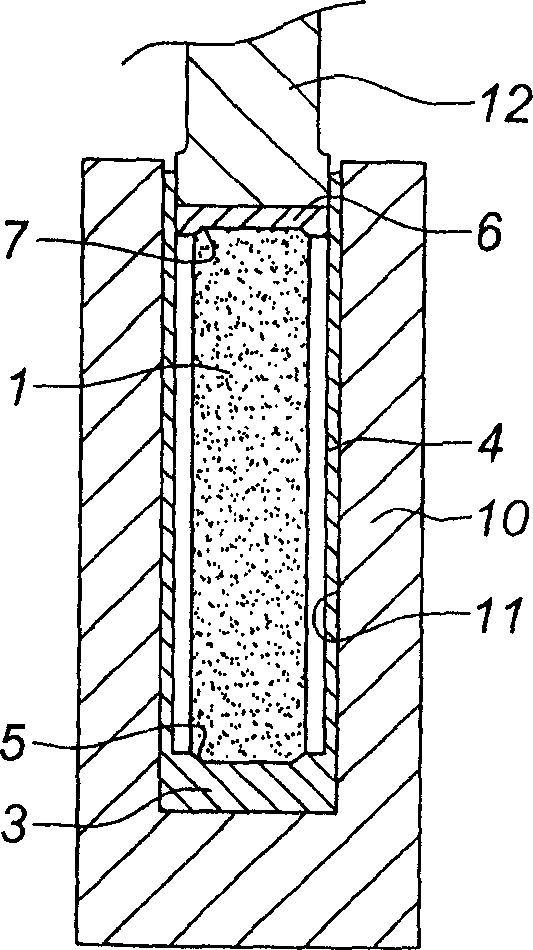

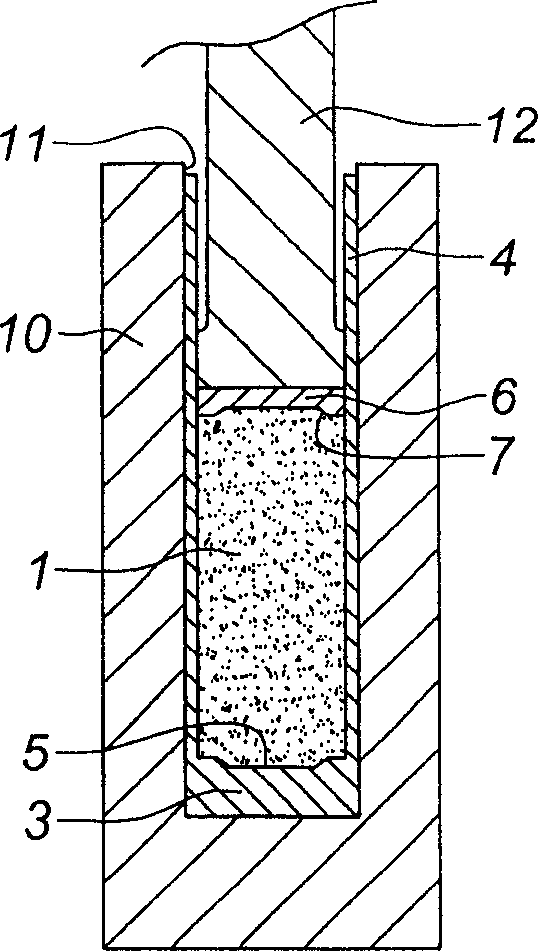

Method for working a metal slug, sleeve for implementing the method and sleeve and lid assembly for implementing the method

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

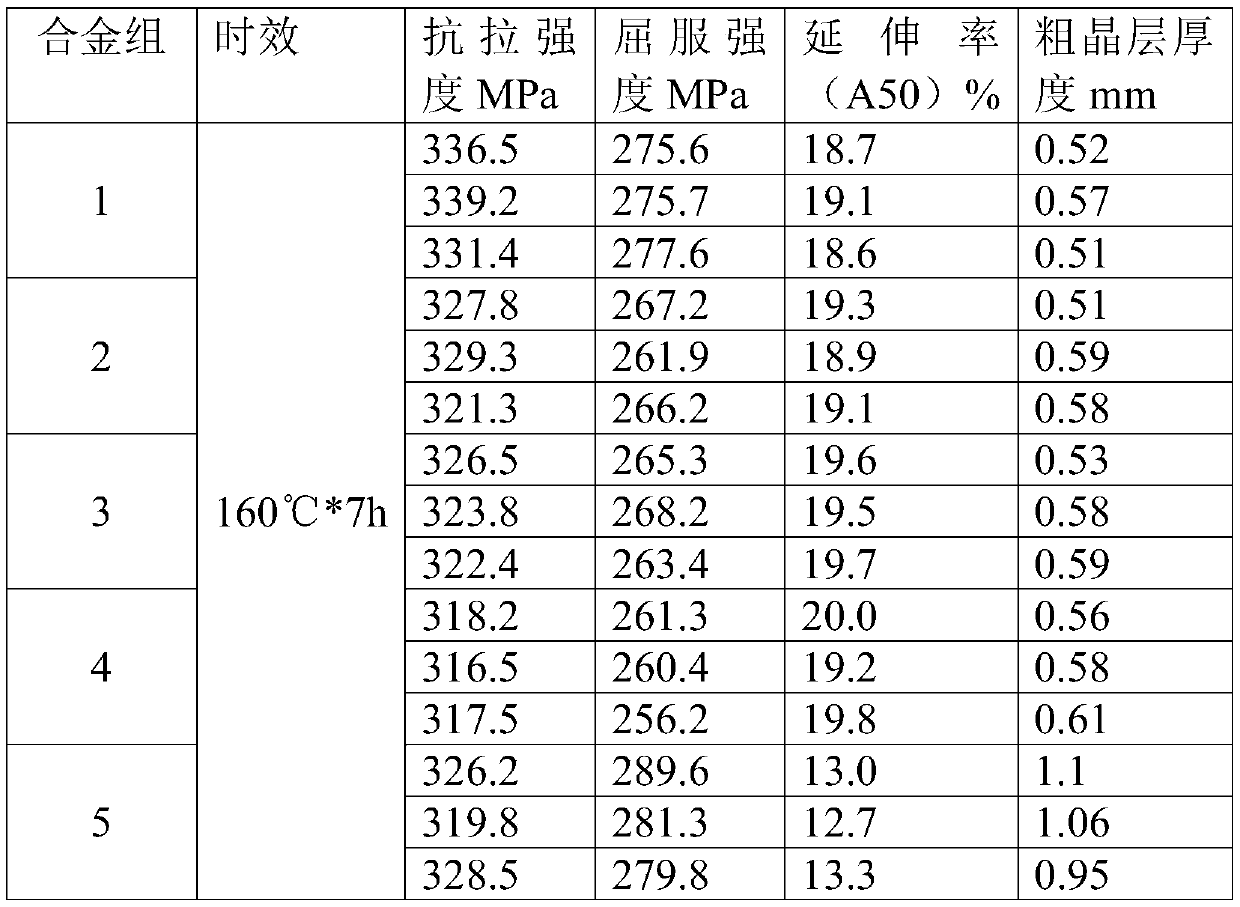

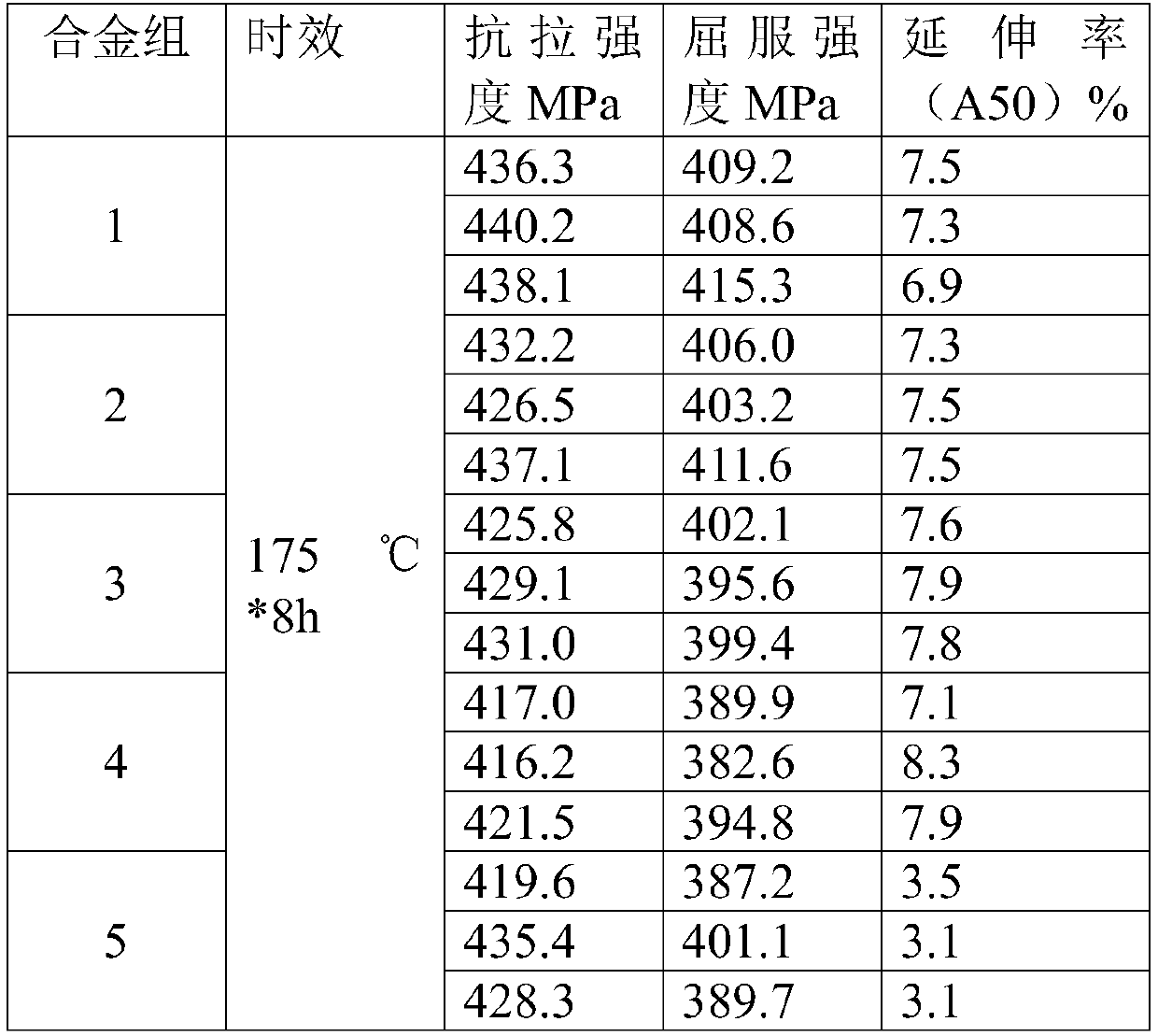

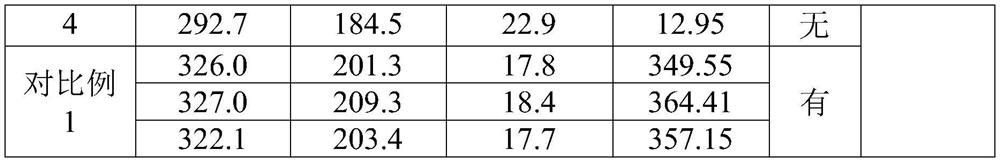

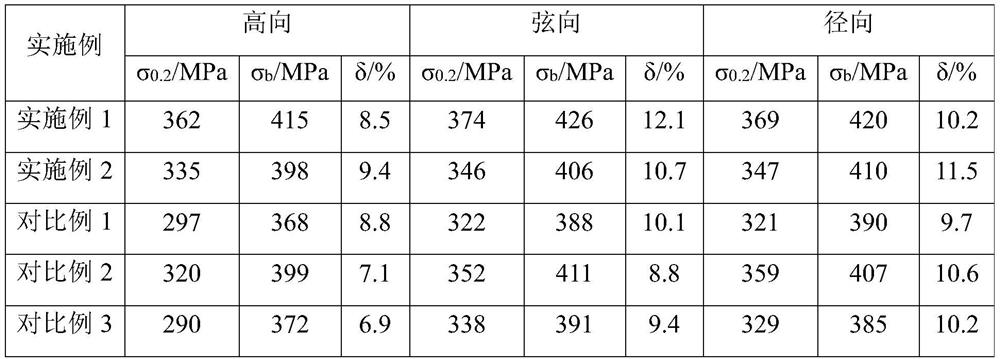

Al-Mg-Si alloy for forging and preparation method of Al-Mg-Si alloy

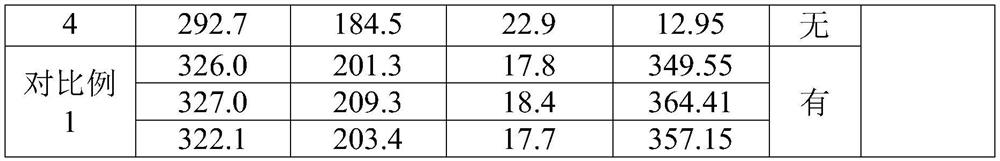

The invention belongs to the field of wrought aluminum alloy material preparation, and particularly relates to an Al-Mg-Si alloy for forging and a preparation method of the Al-Mg-Si alloy. The component of the Al-Mg-Si alloy contains the following elements of, in percentage by mass, 0.75-0.85 of silicon, less than or equal to 0.25 of iron, 0.06-0.1 of copper, 0.75-0.85 of magnesium, 0.6-0.64 of manganese, 0.01-0.03 of chromium, less than or equal to 0.05 of zinc, 0.01-0.03 of titanium, and the balance aluminum. According to the Al-Mg-Si alloy for forging and the preparation method of the Al-Mg-Si alloy, the extrusion performance is excellent, the extrusion resistance is small, and the service life of the mold is long; after extrusion, the T61 performance are as follows, the tensile strength is larger than or equal to 310 Mpa, the yield is larger than or equal to 250-300 Mpa, the elongation is larger than or equal to 17%, and the coarse grain layer is less than or equal to 1 mm, so thatsubsequent forging machining is facilitated; after forging, the T6 performance requirements are as follows, the tensile strength is larger than or equal to 390 Mpa, the yield is larger than or equalto 360 Mpa, and the elongation is larger than or equal to 6%; and the casting performance is excellent, the universality is high, and the process can be consistent with an existing 6082 smelting process.

Owner:江苏亚太航空科技有限公司

Method for forging combined forged steel coupler yoke for railway vehicles

ActiveCN100486760CSmall machining allowanceReduce workloadMetal-working apparatusOther manufacturing equipments/toolsHigh volume manufacturingMetal fibers

The invention relates the forging method of composite steel-forged coupler yoke frame, comprising blanking, making flan, die forging forming, cutting edge, preprocessing, bending forming, welding, heat treatment and machining. Making flan is that the blank is forged to get the explosion blank whose shape and size are close to coupler yoke frame; die forging forming is that the blank is putted in final forging mold cavity to get the explosion rough; bending forming is that the explosion rough is bended to U-shaped; welding is combination welding to form butt plate of coupler yoke frame. The invention possesses the following characters: metal fiber current direction is good, forging forming is easy, the die lifetime is long, forging and machining difficulty are reduced, material utilization is high, and the cost is low.

Owner:CHONGQING CHANGZHENG HEAVY IND

Mould material for high-strength forging and preparation method thereof

The invention discloses a mould material for high-strength forging and a preparation method thereof and belongs to the field of mould steel. The material for high-strength forging is composed of the following elements by weight percent: 0.36-0.38% of C, 0.30-0.50% of Si, less than or equal to 0.035% of P, less than or equal to 0.010% of S, 6.8-7.6% of Cr, 4.7-5.4% of Mo, 1.8-2.6% of V and the balance of Fe. The preparation method of the mould material comprises the following steps: (1) smelting an electroslag steel ingot according to the formula and forging a forging blank; (2) machining; (3) heating a workpiece to the temperature of 1030-1080 DEG C, and quenching; and (4) heating the workpiece to the temperature of 400-550 DEG C. By utilizing the second phase intensifying and dispersion strengthening, the cracking tendency is reduced, the forging process is benefited, furthermore the anti-fatigue performance is increased and the service life of the workpiece is prolonged.

Owner:MAANSHAN ZHIYUAN FORGING CO LTD

Forging machine

The invention relates to a forging machine. The forging machine comprises a forging table and a base plate fixedly mounted on the forging table. A rail support is fixedly mounted on the left side of the base plate. A main slide block is mounted vertically on the rail support in a sliding mode and is in threaded connection with a lead screw which is mounted on the rail support through a bearing. Amotor support is fixedly mounted on the right side of the rail support. A motor is mounted on the motor support and connected with a wheel disc. A lug is arranged on the front end surface of the wheeldisc in an eccentric mode. A long rod is hinged to the main slide block. A matching groove which is in sliding fit with the lug is formed in the middle of the long rod. A forging hammer is mounted atthe right end of the long rod in a hinged mode. The forging machine is convenient to use, components can be automatically forged, in addition, manual forging by labor can also be performed conveniently, the adjustability and the choosability are quite good, various components can be forged conveniently, and the applicability is quite good.

Owner:WUHU KAIDE MACHINERY MFG

Technique method for improving density of injection molding high-speed steel columnar deposition blank

The invention relates to a technique method used for raising the density of a steel-column shaped sediment blank of a spray-forming high-speed tool and belongs to the technical field of material processing. The invention thoroughly combines the theory idea and the technical advantage of spray-forming and heat-control concretion. In an early phase of the spray sediment process, the advantages of the spray-forming that an equiaxed grain (less than 20Mum) having no segregation but a uniform and thin structure can be manufactured in a short process can be performed, and then the manufactured high-speed steel sediment blank has high strength, better plasticity and easy-forging capability. In a later phase of the sediment process, i.e. after the spray-forming is finished, the structure of a main body of equipment (such as a tundish and an atomizing sprayer, etc.) is adopted to control output and radiation of the heat. The invention enhances solidification of easy-loosening part of the high-speed steel sediment blank, so as to manufacture high quality and high density sediment blank. The technique not only can solve the segregation of the high-speed steel but also further enhance the density of the sediment blank to guarantee a following smooth process of fine-forging, etc.

Owner:BEIJING AVIATION MATERIAL INST NO 1 GRP CORP CHINA AVIATION IND

Corrosion-resistant 6082 aluminum alloy material and casting process thereof

ActiveCN113564433AGood castabilityImprove general performanceProcess efficiency improvementFerrosiliconManganese

The invention belongs to the technical field of wrought aluminum alloy material preparation, and particularly relates to a corrosion-resistant 6082 aluminum alloy material and a casting process thereof. The corrosion-resistant 6082 aluminum alloy material disclosed by the invention comprises the following components in percentage by mass: 0.78 to 0.88 percent of silicon, less than or equal to 0.15 percent of iron, less than or equal to 0.005 percent of copper, 0.75 to 0.85 percent of magnesium, 0.5 to 0.6 percent of manganese, 0.1 to 0.16 percent of chromium, 0.02 to 0.05percent of titanium, and the balance of aluminum and inevitable impurities. The 6082 aluminum alloy material provided by the invention is excellent in casting performance and high in universality and can be consistent with an existing 6082 smelting and casting process, the prepared 6082 aluminum alloy material is excellent in extrusion performance and small in extrusion resistance, and the service life of a mold is long. After the aluminum alloy material is extruded and subjected to T4 stabilization treatment, the tensile strength is larger than or equal to 270 MPa, the yield strength is larger than or equal to 175 MPa, the ductility is larger than or equal to 17 percent, the intergranular corrosion depth is smaller than or equal to 50 microns, and laminar corrosion is avoided, so that follow-up forging machining is facilitated; and the forged T6 performance requirements are as follows: the tensile strength is greater than or equal to 355MPa, the yield strength is greater than or equal to 325MPa, and the ductility is greater than or equal to 5 percent, so that the requirements of customers can be met.

Owner:江苏亚太航空科技有限公司

Double-chamber high-temperature forging and forming device of TiAl intermetallic compound forge piece and method thereof

The invention relates to a double-chamber high-temperature forging and forming device of a TiAl intermetallic compound forge piece and a method thereof, belonging to forming methods and devices of TiAl intermetallic compound forge pieces. The invention solves the problems of large heat loss, large deformation resistance, small forging deformation, difficult forging and the like generated when thetraditional forging technology is used for forging the TiAl intermetallic compound forge piece. A blank heating chamber and a mould heating chamber are adjacently arranged and a movable baffle plate is arranged between the blank heating chamber and the mould heating chamber, and a hearth of the blank heating chamber and a hearth of the mould heating chamber are mutually penetrated and mutually independent by pulling the movable baffle plate up and down. TiAl blanks and a mould are heated to 1230-1300 DEG C and 800-1000 DEG C respectively in different heating chambers; the movable baffle plateis opened to push the TiAl blanks into the mould heating chamber along a carrying platform and put the TiAl blands into a mould cavity; and the mould is closed for forging. The invention is used for high-temperature forging and forming of TiAl intermetallic compound materials.

Owner:HARBIN INST OF TECH

Treatment method of die material for high-strength forging

Owner:MAANSHAN ZHIYUAN FORGING CO LTD

Preparation method of ultra-large aluminum alloy ring forge piece

The invention relates to a preparation method of an ultra-large aluminum alloy ring forge piece. The method comprises the following steps: controlling the aluminum alloy to be molten at a certain temperature, refining, degassing in vacuum, filtering, semi-continuous casting, milling, homogenizing before forging, pre-deforming before forging, recrystallizing before forging, forging, quickly die-cutting, ring rolling forming, heat treatment and the like. The aluminum alloy is subjected to component optimization, and forging forming comprises the steps that a cast ingot is directly upset to be in a cake shape; rapidly punching holes in the round cake by adopting a die; remelting for the second time for heat preservation homogenization treatment for eliminating internal stress; and forging into an annular forge piece on a numerical control ring rolling machine. The aluminum alloy is subjected to treatment such as recrystallization after pre-deformation before component optimization and forging, so that impurity phases such as Fe and Si are converted from grain boundary aggregation to intragranular distribution through recrystallization, and meanwhile, the forging structure is refined. The ultra-large aluminum alloy ring forging prepared by the method has the advantages of uniform and symmetrical stress distribution, small anisotropy of three-direction mechanical properties of the ring forging and the like.

Owner:SHANGHAI JIAO TONG UNIV

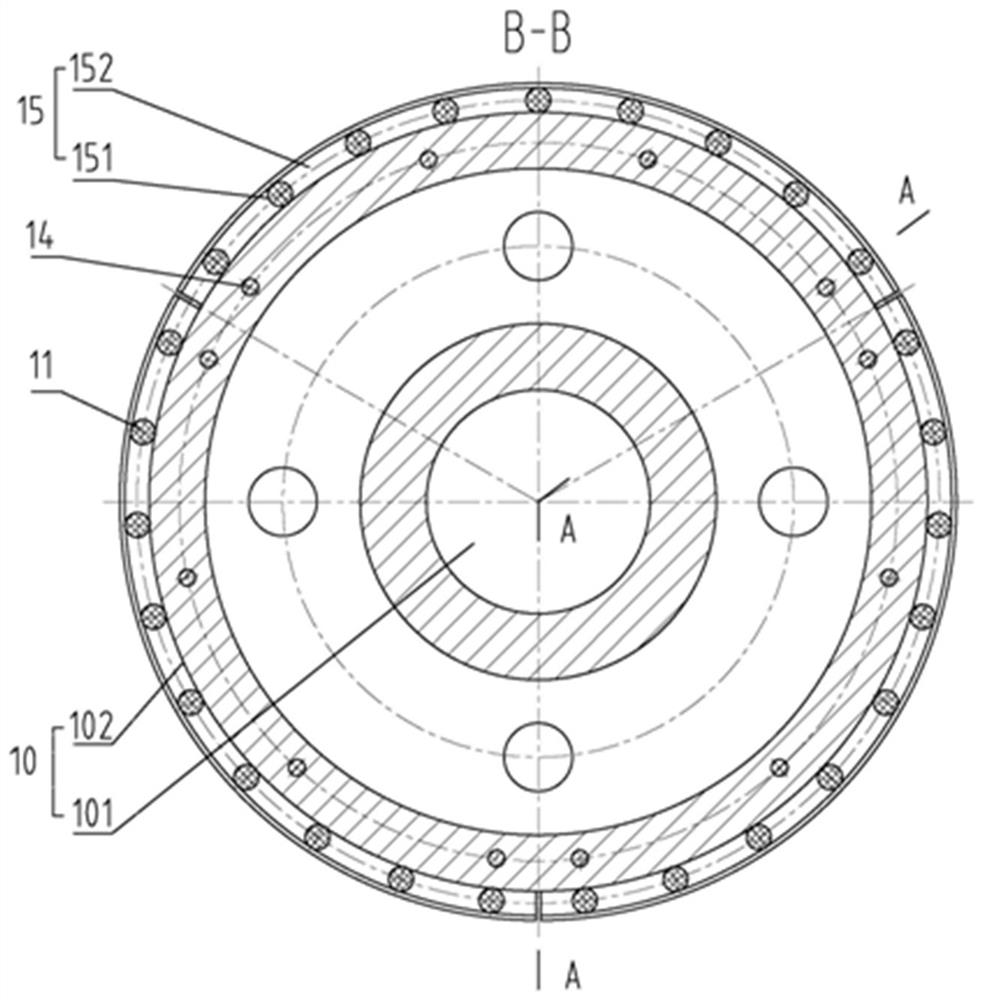

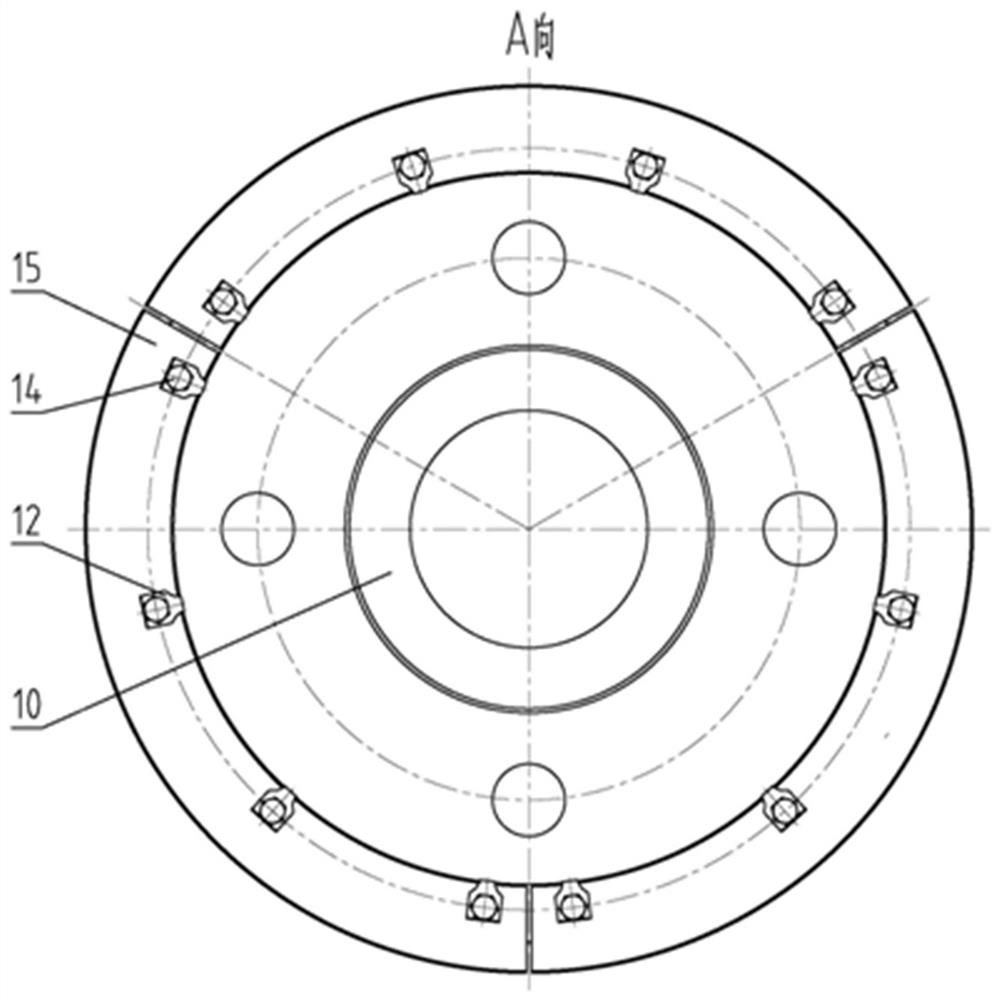

Wheel convenient to replace and provided with self-lubricating rims

PendingCN112249894AImprove lubrication conditionsExtended service lifeTravelling gearEngine lubricationTreadLubricant

The invention discloses a wheel convenient to replace and provided with self-lubricating rims, and relates to hoisting machinery. Due to factors such as wheel deflection, a crane gnaws a rail to operate, especially when an operating mechanism is high in working level, the service life of a rim is far shorter than that of a wheel tread, and therefore a wheel is scrapped too early due to rim abrasion. A structural form that the rims are replaceable is adopted, no matter a single-rim wheel or a double-rim wheel, the rim on each side is divided into a plurality of sections of arcs, the rims are fixed on a wheel body by bolts, and a certain proportion of solid lubricant is embedded in the rim friction surfaces, so that the lubricating condition of a friction pair formed by the rims and the sidesurface of a steel rail is improved. The service life of the rims and the steel rail is prolonged, the friction resistance of crane operation is reduced, when the rim abrasion reaches the scrap degree, the rims can be replaced under the condition that a wheel set is not disassembled, the rims are made of high-strength wear-resisting plates, a heat treatment manufacturing procedure is omitted, therims and the wheel body are manufactured separately, and die forging of the wheel body becomes possible.

Owner:NINGXIA TIANDI BENNIU YINQI EQUIP

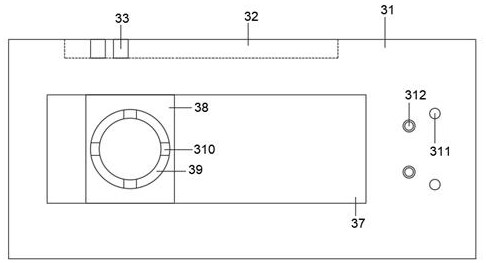

Forging and pressing device for slide insert of die

InactiveCN112077249AEasy for forgingFlexible controlVibration dampersNon-rotating vibration suppressionDevice formEngineering

The invention discloses a forging and pressing device for a slide insert of a die and relates to the technical field of forging and pressing. The forging and pressing device comprises a joining frameand a substrate. A slideway is arranged outside the front end of the joining frame, a cleaning device is mounted in the slideway, a main body is arranged at the bottom of the joining frame, forging and pressing air cylinders are arranged at two ends in the main body, and adsorption devices are arranged outside the back ends of the forging and pressing air cylinders. Four fixing devices are arranged and every two fixing devices form a group, so that two slide inserts of dies placed on the two fixing devices can be fixed by arranging second hydraulic gas rods, positioning plates, movable platesand adapter plates in the fixing devices, so that articles are prevented from swinging when the articles are forged and pressed. It is convenient to forge and press a position needed to be forged andpressed precisely. The fixing devices are matched with auxiliary devices to process some irregular slide inserts of dies, so that it is convenient to adjust a needed shape by means of the placing height of a top plate.

Owner:东莞市龙飞数控科技有限公司

Machining and collection facilitating forging device with linkage structure

The invention discloses a machining and collection facilitating forging device with a linkage structure, and relates to the technical field of forging devices. A workbench, a die set mechanism and a forging mechanism are included, a bottom frame is fixed to the lower portion of the workbench, a collecting and feeding mechanism is installed in the bottom frame, and the die set mechanism is installed in the workbench. A forging part is arranged in the die set mechanism, stand columns are fixed to the two sides of the upper portion of the workbench, a top plate is fixed to the upper portions of the stand columns, air cylinders are installed on the two sides of the lower portion of the top plate, piston rods are arranged on the lower sides of the air cylinders, a lifting frame is fixed to the lower portions of the piston rods, and movable limiting rings are fixed to the two ends of the lifting frame and arranged on the outer sides of the stand columns. The machining and collection facilitating forging device has the beneficial effects that the device is provided with the die set mechanism, the die set mechanism comprises four forging and pressing bases, and three combined dies are arranged in each forging and pressing base so that a plurality of machining stations can be conveniently formed.

Owner:重庆新禹智能科技有限公司

A corrosion-resistant 6082 aluminum alloy material and its melting and casting process

ActiveCN113564433BGood castabilityImprove general performanceProcess efficiency improvementManganeseFerrosilicon

The invention belongs to the technical field of preparation of deformed aluminum alloy materials, and in particular relates to a corrosion-resistant 6082 aluminum alloy material and a melting and casting process thereof. The corrosion-resistant 6082 aluminum alloy material of the present invention comprises the following components by mass fraction: 0.78-0.88% of silicon; 0.15% of iron; 0.005% of copper; 0.75-0.85% of magnesium; 0.5-0.6% of manganese; ‑0.16%; titanium: 0.02‑0.05%, the balance being aluminum and unavoidable impurities. The 6082 aluminum alloy material of the invention has excellent casting performance and strong versatility, and can be consistent with the existing 6082 smelting and casting process. The 6082 aluminum alloy material prepared by the invention has excellent extrudability, small extrusion resistance and long mold life. The performance of the aluminum alloy material after extrusion T4 stabilization treatment of the present invention reaches: tensile strength ≥ 270 MPa, yield strength ≥ 175 MPa, elongation ≥ 17%, intergranular corrosion depth ≤ 50 μm, and no lamellar corrosion, To facilitate subsequent forging processing; T6 performance requirements after forging: tensile strength ≥ 355MPa, yield strength ≥ 325MPa, elongation ≥ 5%, which can meet customer needs.

Owner:江苏亚太航空科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com