Forging machine

A technology for a forging machine and a motor frame, applied in the field of forging machines, can solve the problems of less processing volume, poor practicability, and single forging method, and achieve the effects of convenient forging processing, good applicability, and convenient manual forging.

Inactive Publication Date: 2018-10-23

WUHU KAIDE MACHINERY MFG

View PDF12 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Forging is a processing method that uses forging machinery to exert pressure on metal blanks to cause plastic deformation to obtain forgings with certain mechanical properties, certain shapes and sizes. Although with the advancement of science and technology, forging processing of most parts has adopted It is completed in an automated and intelligent way, but for some parts with a small amount of processing and specific shapes, it is still more convenient to forge manually. However, most of the forging equipment used for forging is relatively single and has poor practicality.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach

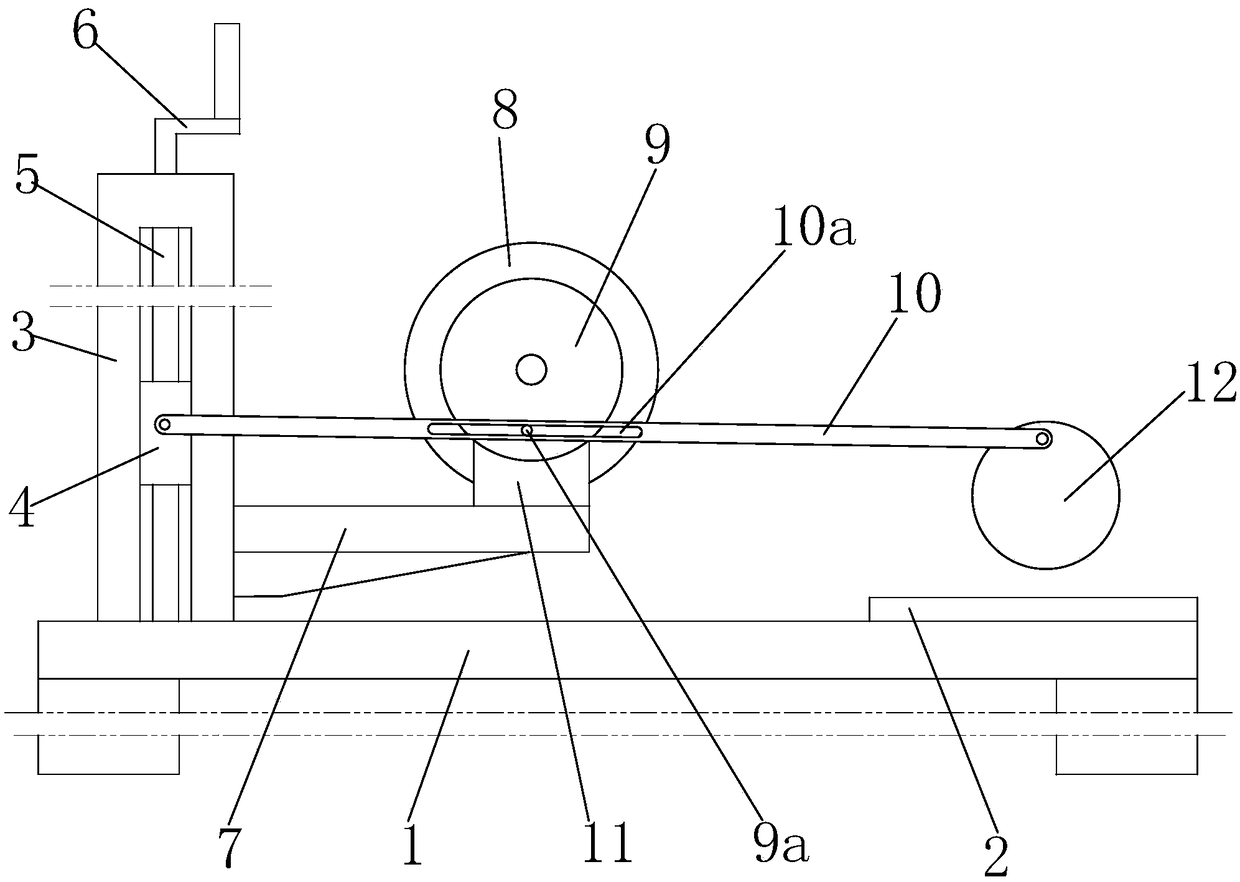

[0020] As the second embodiment of the present invention, it is possible to directly shake the lead screw 5 forward and reverse by manually holding the crank handle 6, so that the main slider 4 can be raised and lowered in the vertical direction, so that the right side of the long rod 10 and the forging hammer 12 It can swing around the bump 9a to realize manual forging of parts.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a forging machine. The forging machine comprises a forging table and a base plate fixedly mounted on the forging table. A rail support is fixedly mounted on the left side of the base plate. A main slide block is mounted vertically on the rail support in a sliding mode and is in threaded connection with a lead screw which is mounted on the rail support through a bearing. Amotor support is fixedly mounted on the right side of the rail support. A motor is mounted on the motor support and connected with a wheel disc. A lug is arranged on the front end surface of the wheeldisc in an eccentric mode. A long rod is hinged to the main slide block. A matching groove which is in sliding fit with the lug is formed in the middle of the long rod. A forging hammer is mounted atthe right end of the long rod in a hinged mode. The forging machine is convenient to use, components can be automatically forged, in addition, manual forging by labor can also be performed conveniently, the adjustability and the choosability are quite good, various components can be forged conveniently, and the applicability is quite good.

Description

technical field [0001] The invention relates to a mechanical processing equipment, specifically a forging machine. Background technique [0002] Forging is a processing method that uses forging machinery to exert pressure on metal blanks to cause plastic deformation to obtain forgings with certain mechanical properties, certain shapes and sizes. Although with the advancement of science and technology, forging processing of most parts has adopted It is completed in an automated and intelligent way, but for some parts with a small amount of processing and specific shapes, it is still more convenient to manually forge, but most of the forging equipment currently used for forging is relatively single, and the practicability is poor. Contents of the invention [0003] Now in order to overcome the defects of the above-mentioned traditional forging equipment, the present invention proposes a forging machine. [0004] The technical problem to be solved by the present invention ad...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B21J7/32

CPCB21J7/32

Inventor 邢超陈邦军吴空涛

Owner WUHU KAIDE MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com