Beta-gamma TiAl alloy and preparation method thereof

A technology of alloy and metal casting, which is applied in the field of TiAl alloy and its preparation, and can solve the problems of poor deformation ability of TiAl alloy at high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

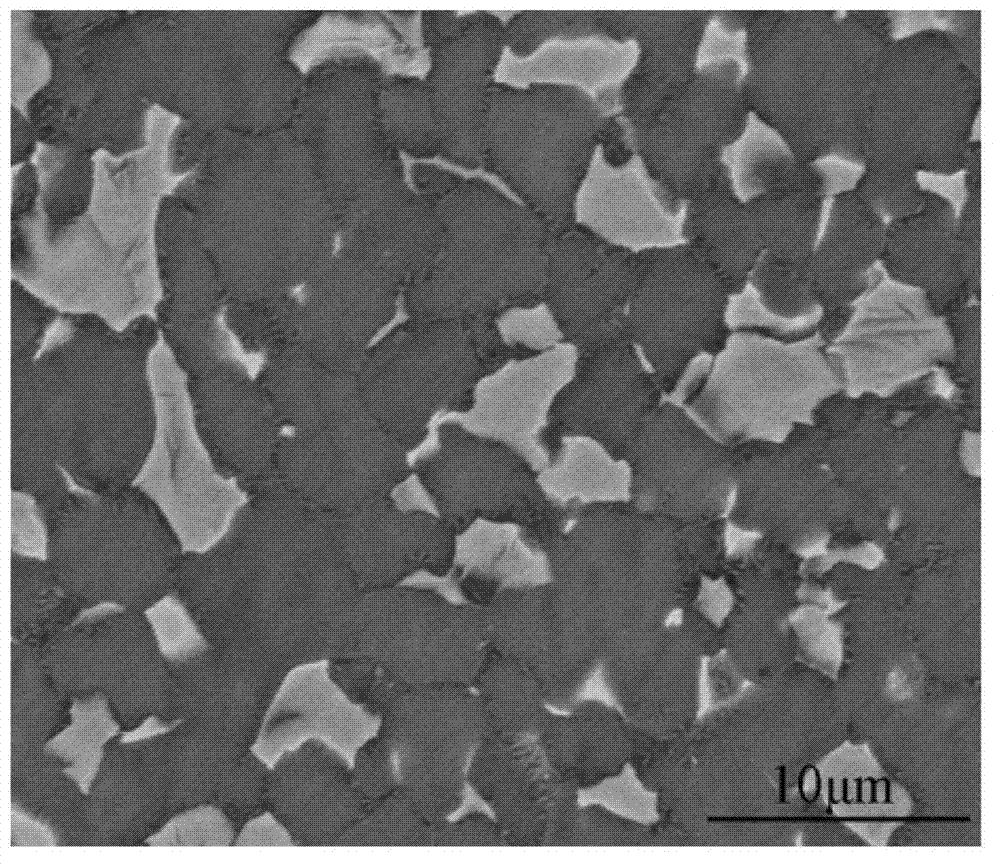

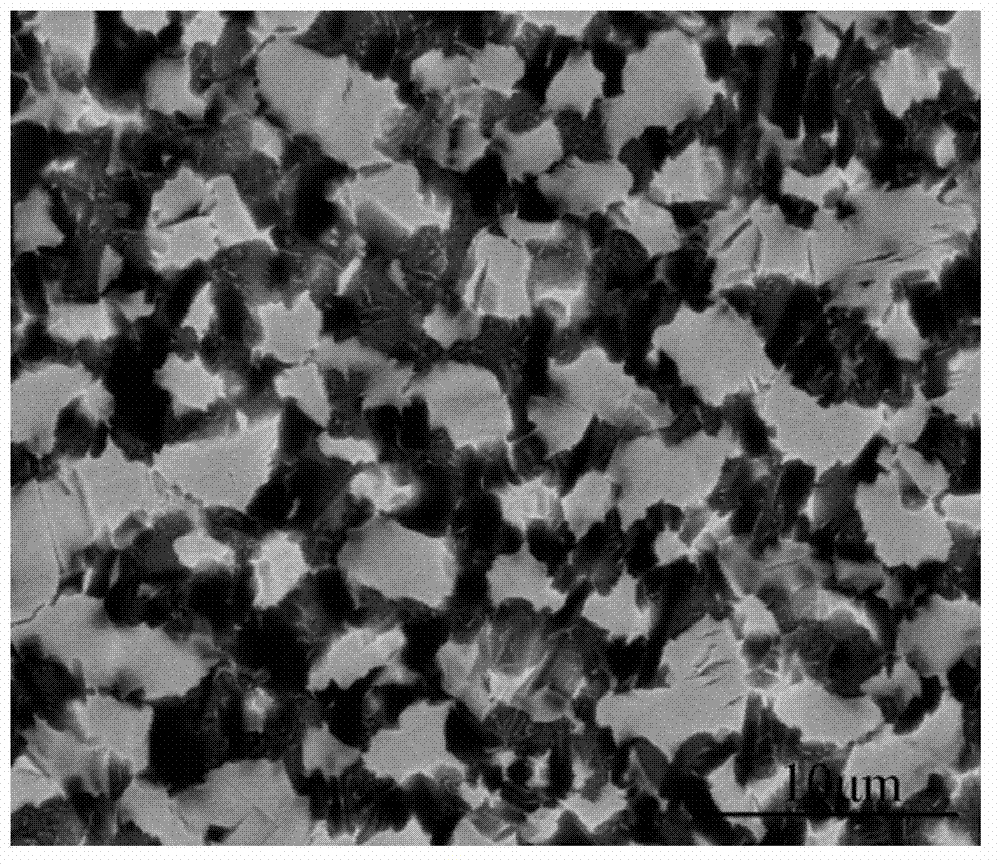

[0015] Specific Embodiment 1: In this embodiment, the beta-gamma TiAl alloy is made of 38% to 43% Al, 2% to 8% X, 0% to 2% A and the rest Ti, wherein X Is Mo or Mn element, A is B or Y (yttrium) element.

specific Embodiment approach 2

[0016] Specific Embodiment 2: In this embodiment, the beta-gamma TiAl alloy is made of 38.6% to 40% of Al, 2.5% to 4% of X, 0% to 2% of A and the rest of Ti, wherein X Is Mo or Mn element, A is B or Y (yttrium) element.

specific Embodiment approach 3

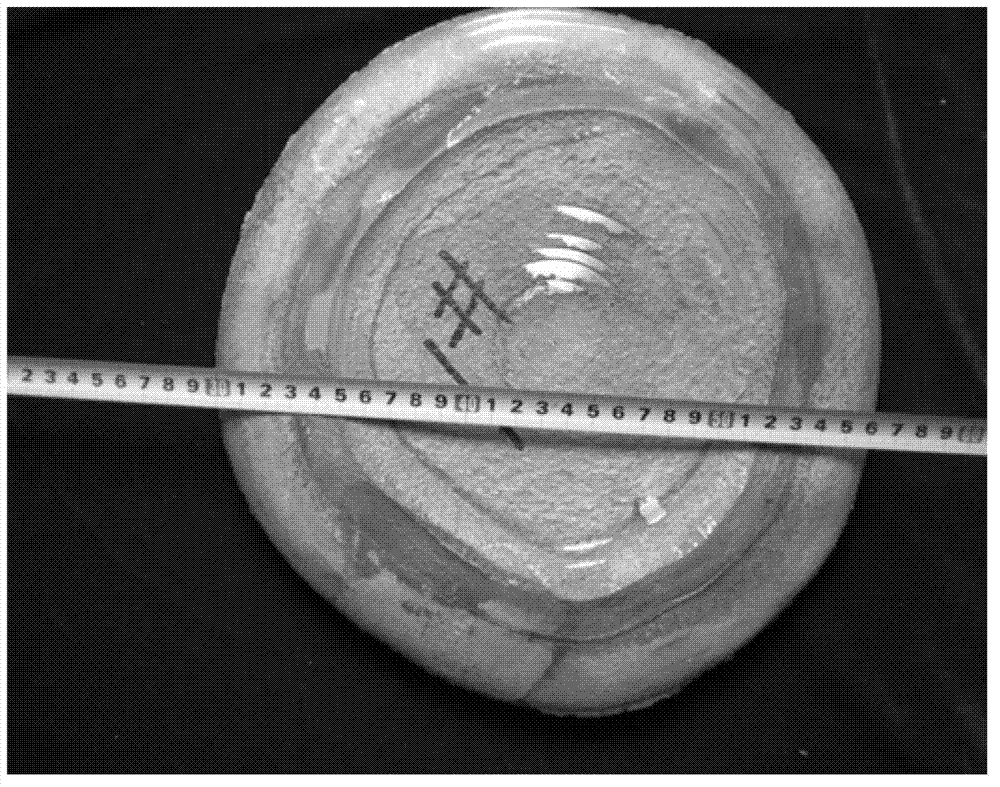

[0017] Specific embodiment three: the preparation method of the present embodiment beta-gamma TiAl alloy is implemented according to the following steps:

[0018] 1. According to the atomic percentage of 38%~43%Al, 2%~8%X, 0%~2%A and the rest of Ti, weigh the sponge titanium, high-purity aluminum, AlX master alloy and high-purity A; 2. Pour the raw materials weighed in step 1 into a water-cooled copper crucible vacuum induction melting furnace, and control the vacuum degree of the melting chamber to be less than 10 -2 mbar, adjust the power of the smelting furnace to increase to 350-400KW within 20 minutes, then stop increasing the power, and keep warm for 8-20 minutes to obtain the alloy melt; 3. Preheat the metal casting mold to 200-500°C to obtain the preheated metal casting mold, and then pour the alloy melt into the preheated metal casting mold, and cool it to room temperature in a vacuum induction furnace to obtain a beta-gamma TiAl alloy;

[0019] Wherein the X describ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com