Wheel convenient to replace and provided with self-lubricating rims

A wheel and rim technology, applied in the field of hoisting machinery, can solve problems such as contradicting green development, and achieve the effects of reducing maintenance workload, improving lubrication conditions, and eliminating heat treatment manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

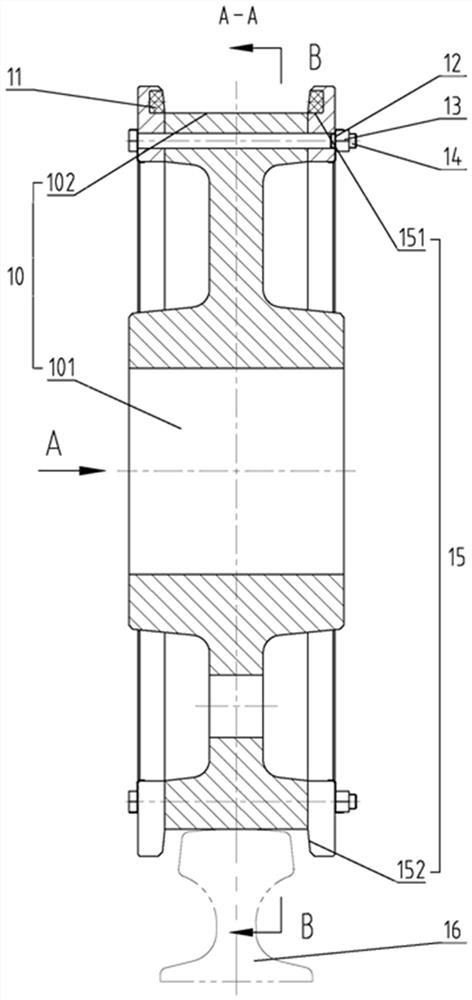

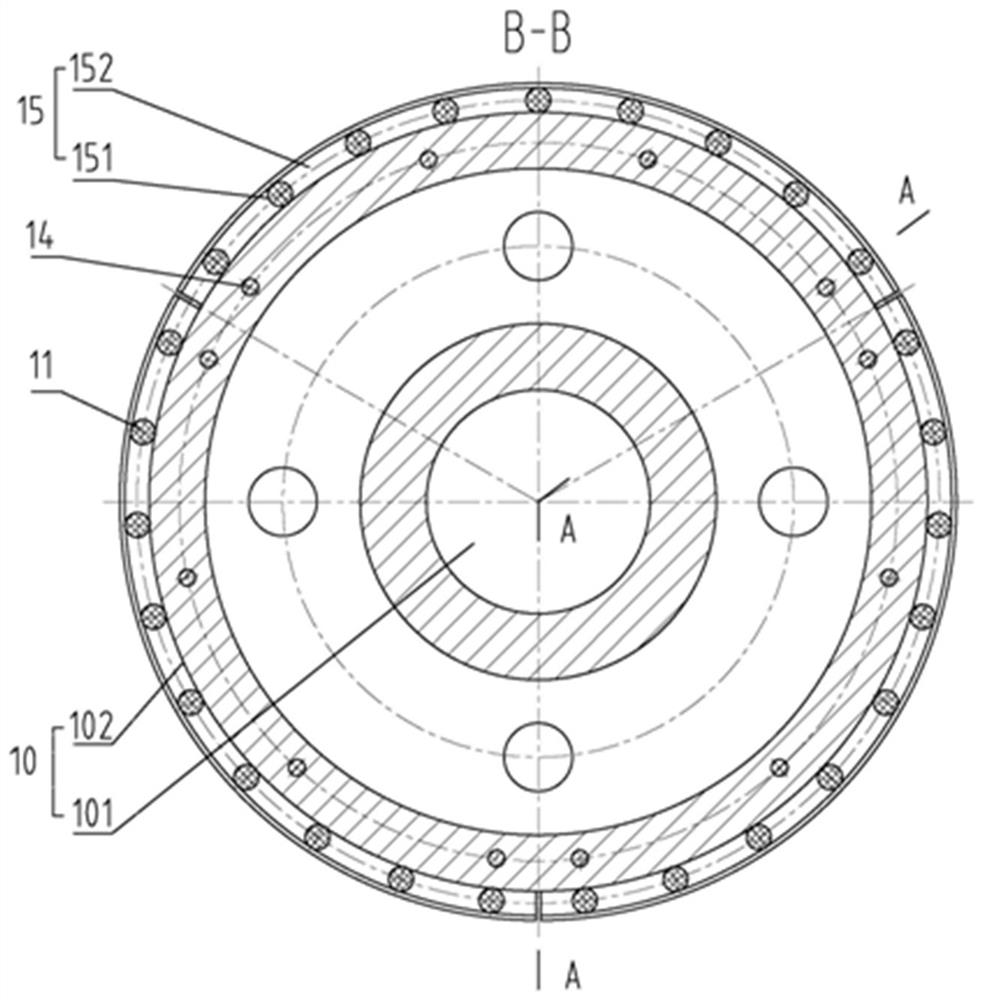

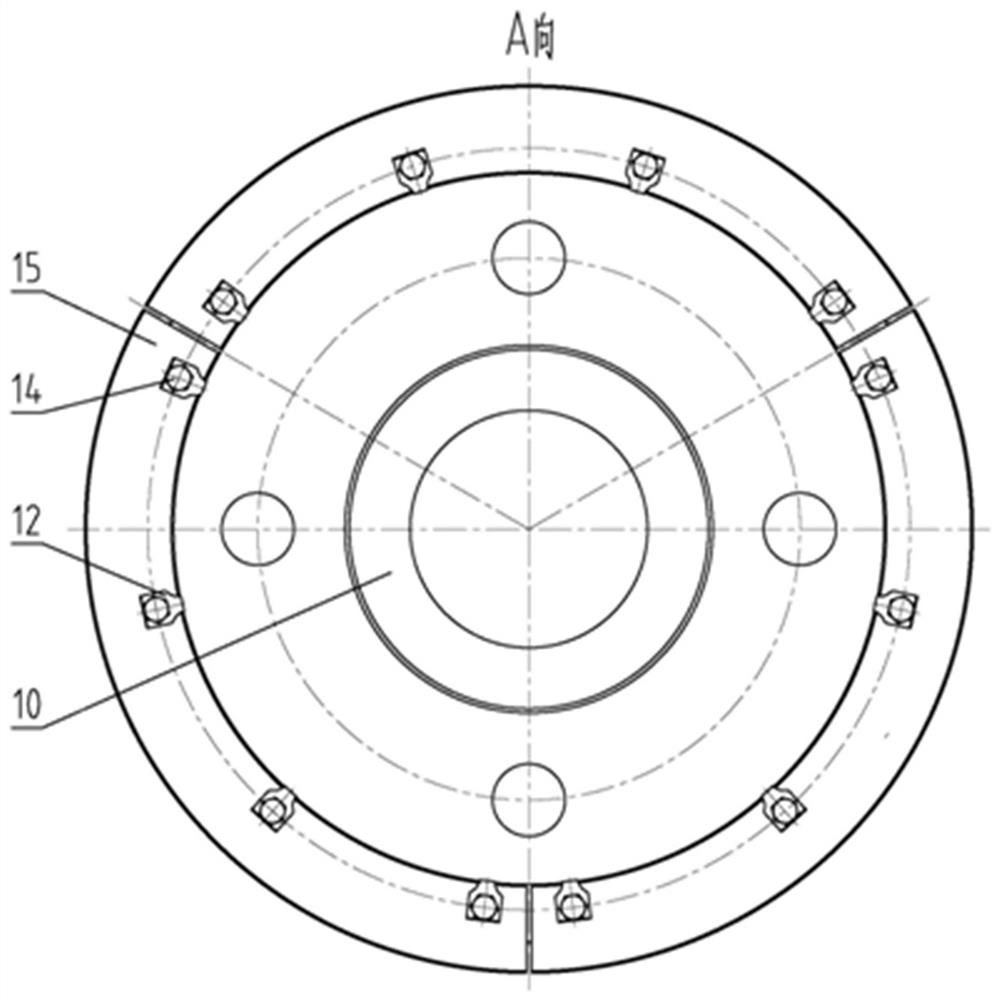

[0030] like figure 1 As shown, a wheel that is easy to replace and has a self-lubricating rim is composed of a wheel body 10, a solid lubricant 11, a single-ear stop washer 12, a nut 13, a hexagon head bolt 14 for reaming holes, and a rim 15. ; This figure shows a double rim structure, and a single rim means that only one side has a rim.

[0031] like figure 1 As shown, the wheel rim 15 is fixed on both sides of the wheel body 10 with bolts 14, nuts 13 and single-ear stop washers 12 by the hexagonal head reaming hole, and the wheel rim can be replaced without disassembling the wheel group after the wheel rim 15 is worn, which reduces the Maintenance workload.

[0032] like figure 2 , image 3 and Figure 4 As shown, the rim 15 is composed of three arcs, and the rim 15 is made of wear-resistant material, and the wear-resistant material is a high-strength wear-resistant plate for construction machinery that meets the national standard GB / T24186, and the grade is NM300 or N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com