Method for forging combined forged steel coupler yoke for railway vehicles

A railway vehicle and hook tail frame technology is applied in the forging field of combined forged steel hook tail frame, which can solve the problems of difficult process, low material utilization rate, short service life and other problems of the integral forged steel hook tail frame, and achieves a reduction in machine tools. The effect of adding allowance, high material utilization rate and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

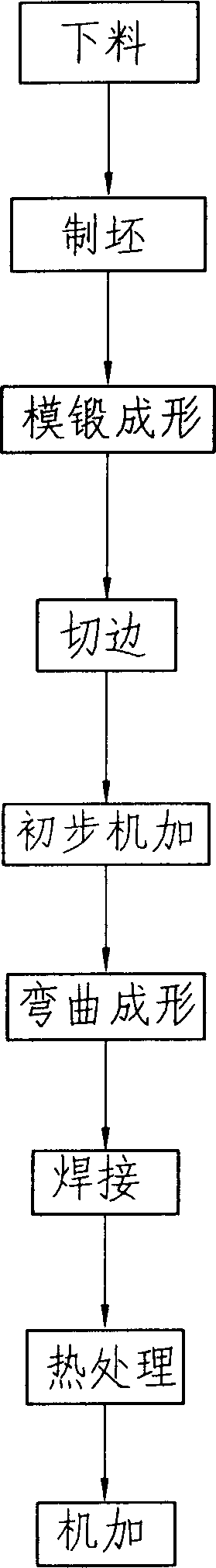

[0023] The process steps of the method of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

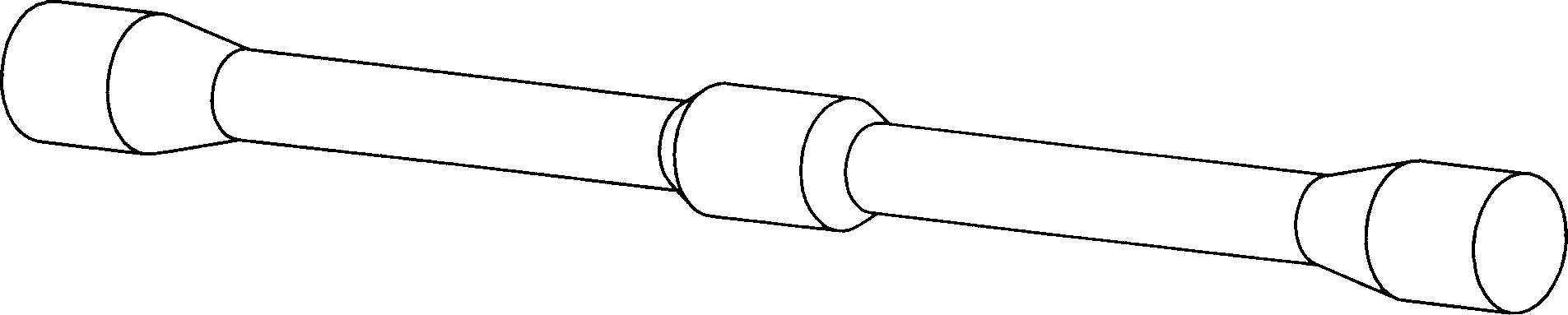

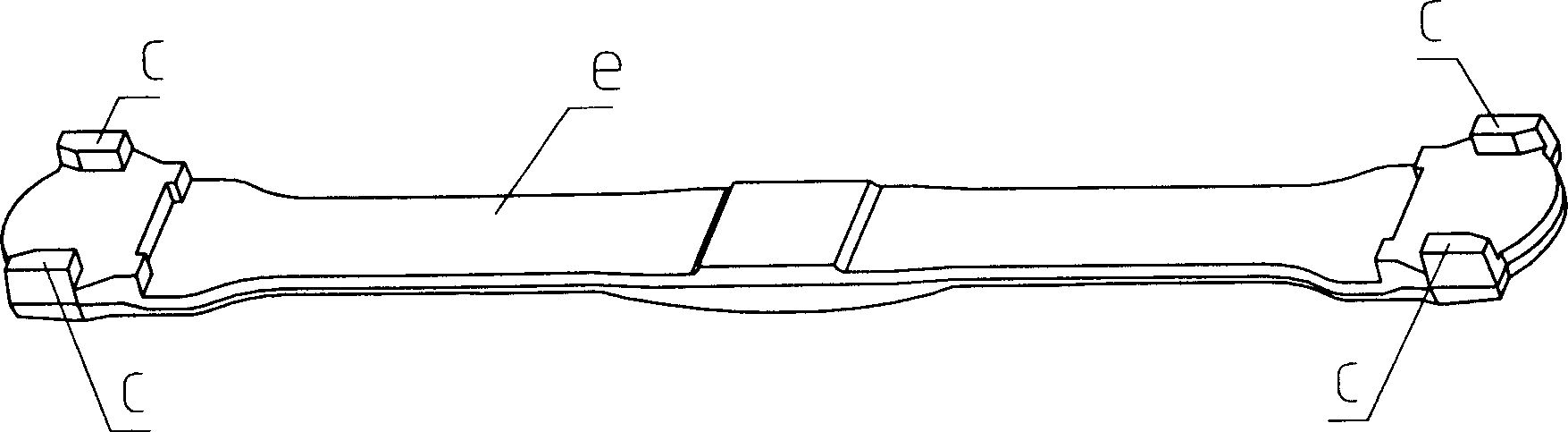

[0024] Such as Figure 1 to Figure 5 As shown, take the production of railway coupler yoke frame No. 17 as an example. The yoke frame is a frame-type thin-walled structure with a minimum wall thickness of 28mm and a minimum height of 140mm. The square hole at the head cannot be forged, and the draft angle needs to be machined. , the amount of machining is large, the utilization rate of materials is low, the weight of the coupler frame is 97.5Kg, and it must be forged on a 16t hammer or other large die forging equipment. The manufacturing steps are:

[0025] (1) Blanking to obtain a blank of a certain length.

[0026] (2) Blank making, the blank obtained by blanking is heated and drawn on the free forging anvil to make blank, or other process methods are used to make blank, so that the blank is initially def...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com