Method for working a metal slug, sleeve for implementing the method and sleeve and lid assembly for implementing the method

A blank and sleeve technology, used in metal processing equipment, forging/pressing/hammer devices, manufacturing tools, etc., can solve problems such as blank cracks and defects, and achieve the effect of no material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

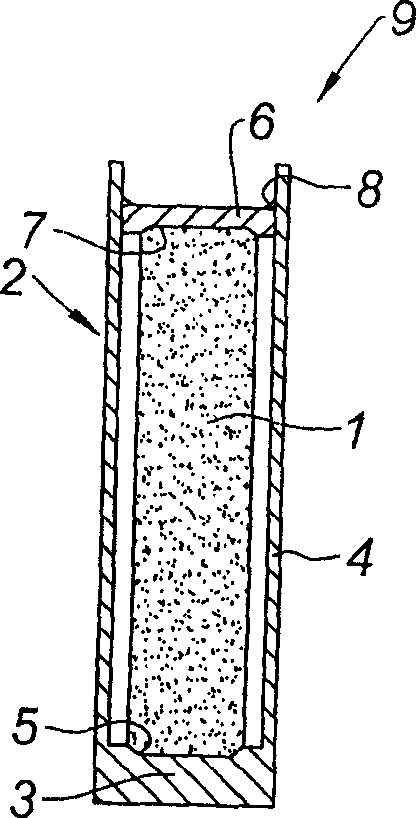

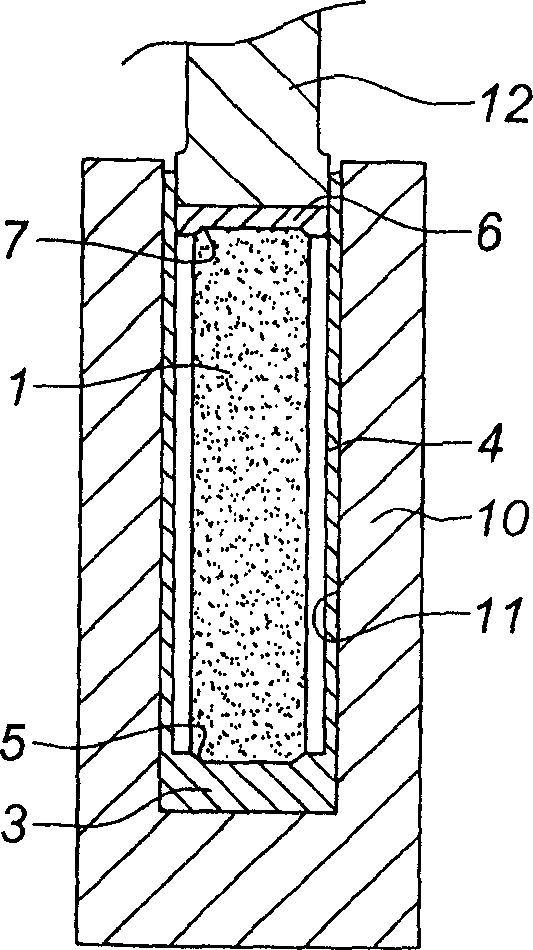

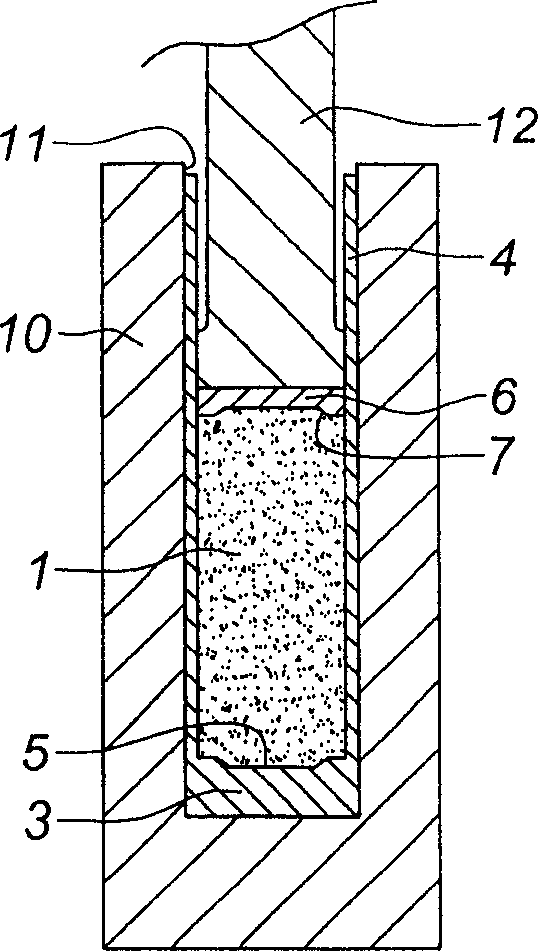

[0025] The object of the method of the invention is to upset a metal blank 1 , which in this example is made of a nickel- or cobalt-based alloy produced by powder metallurgy. The blank 1 is cylindrical. It has a given cross-section and a given length. Its slenderness ratio, the ratio of its length to the diameter of its cross section, exceeds 2.8, possibly 10 or more. The blank 1 is covered with a layer of glaze by vitrification.

[0026] The blank 1 is housed in a cylindrical sleeve 2 . The sleeve 2 comprises an end wall 3 from which rises a cylindrical side wall 4 which is relatively thin compared to the diameter of the cover sleeve. The cross-section of the cylinder formed by the inner surface of the side wall 4 is larger than the cross-section of the blank 1 . In this case, in the case of a blank 1 having a cross-sectional diameter of approximately 235 mm, the inner cross-sectional diameter of the sleeve 2 is approximately 300 mm, while its side walls have a thickness ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com