A corrosion-resistant 6082 aluminum alloy material and its melting and casting process

An aluminum alloy material, corrosion-resistant technology, applied in the field of deformed aluminum alloy material preparation, to achieve the effects of excellent casting performance, excellent extrudability, and low extrusion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

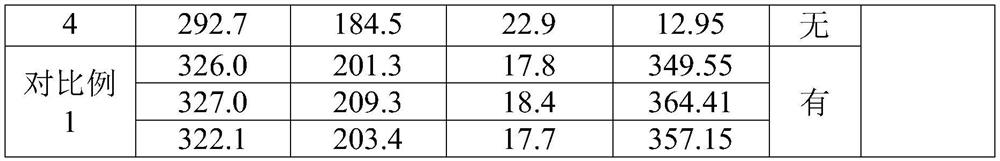

Examples

Embodiment 1

[0025] A corrosion-resistant 6082 aluminum alloy material, in terms of mass fraction, comprising the following components: silicon 0.876%; iron 0.147%; copper 0.0048%; magnesium 0.846%; manganese 0.591%; chromium 0.157%; titanium 0.0491%, the balance For aluminum and inevitable impurities.

Embodiment 2

[0027] A corrosion-resistant 6082 aluminum alloy material, in terms of mass fraction, comprising the following components: silicon 0.834%; iron 0.115%; copper 0.0025%; magnesium 0.801%; manganese 0.557%; chromium 0.135%; titanium 0.0353%; balance For aluminum and inevitable impurities.

Embodiment 3

[0029] A corrosion-resistant 6082 aluminum alloy material, in terms of mass fraction, comprising the following components: silicon 0.841%; iron 0.123%; copper 0.0021%; magnesium 0.794%; manganese 0.560%; chromium 0.129%; titanium 0.0339%; balance For aluminum and inevitable impurities.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com