Method for producing dissymmetrical die forging

A production method and die forging technology, which is applied in the production field of asymmetric die forgings, can solve the problems of reduced die life, asymmetric die forging structure, and low production efficiency, so as to improve production efficiency, reduce machining allowance, and improve use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The production method of the asymmetric die forging of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

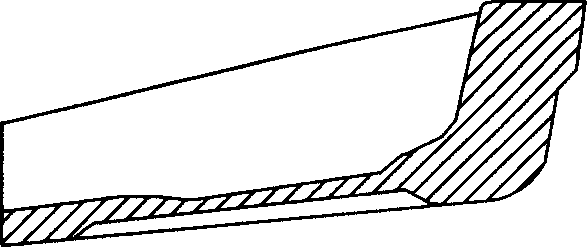

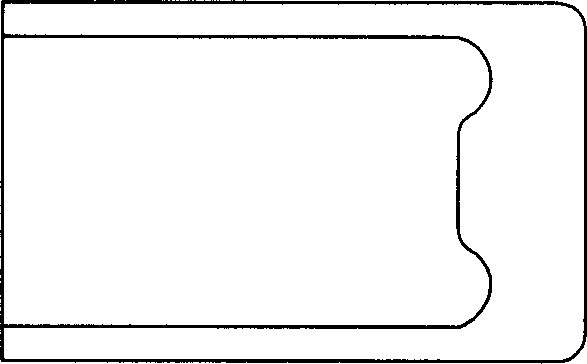

[0017] by figure 1 The production of asymmetric die forgings with the structure shown is taken as an example, and the process is as follows:

[0018] (1) Heating the ingot and mold;

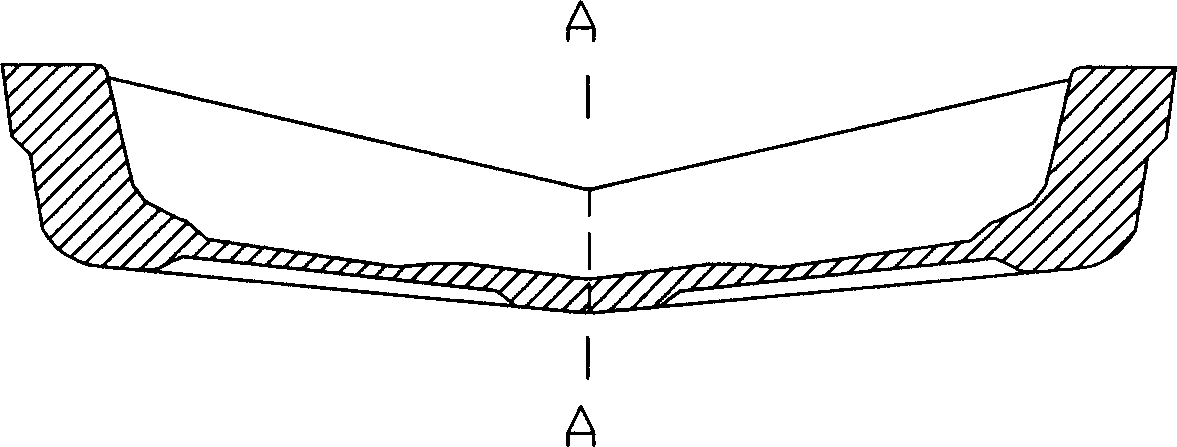

[0019] (2) First forge on the hydraulic press to produce image 3 , Figure 4 Elongated blanks for the products shown;

[0020] (3) then heating the strip-shaped blank;

[0021] (4) Installation on the hydraulic press can produce image 3 and Figure 4 The mold of the die forging shown is that the long forging blank is put into the mold and pressed to obtain image 3 and Figure 4 Die forgings of the structure shown;

[0022] (5) Then trimming, milling, and flame inspection were carried out;

[0023] (6) Then heat treatment and flaw detection, 100% hardening;

[0024] (7) Last edge image 3 and F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com