Preparation method for (WC/high-speed steel) steel-bonded cemented carbide and lamination material

A technology of steel-bonded hard alloy and high-speed steel, which is applied in the direction of metal material coating technology, coating, decorative art, etc., can solve the problems of backward equipment, uneven distribution of WC particles, etc., and achieve easy machining and promotion Use, efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

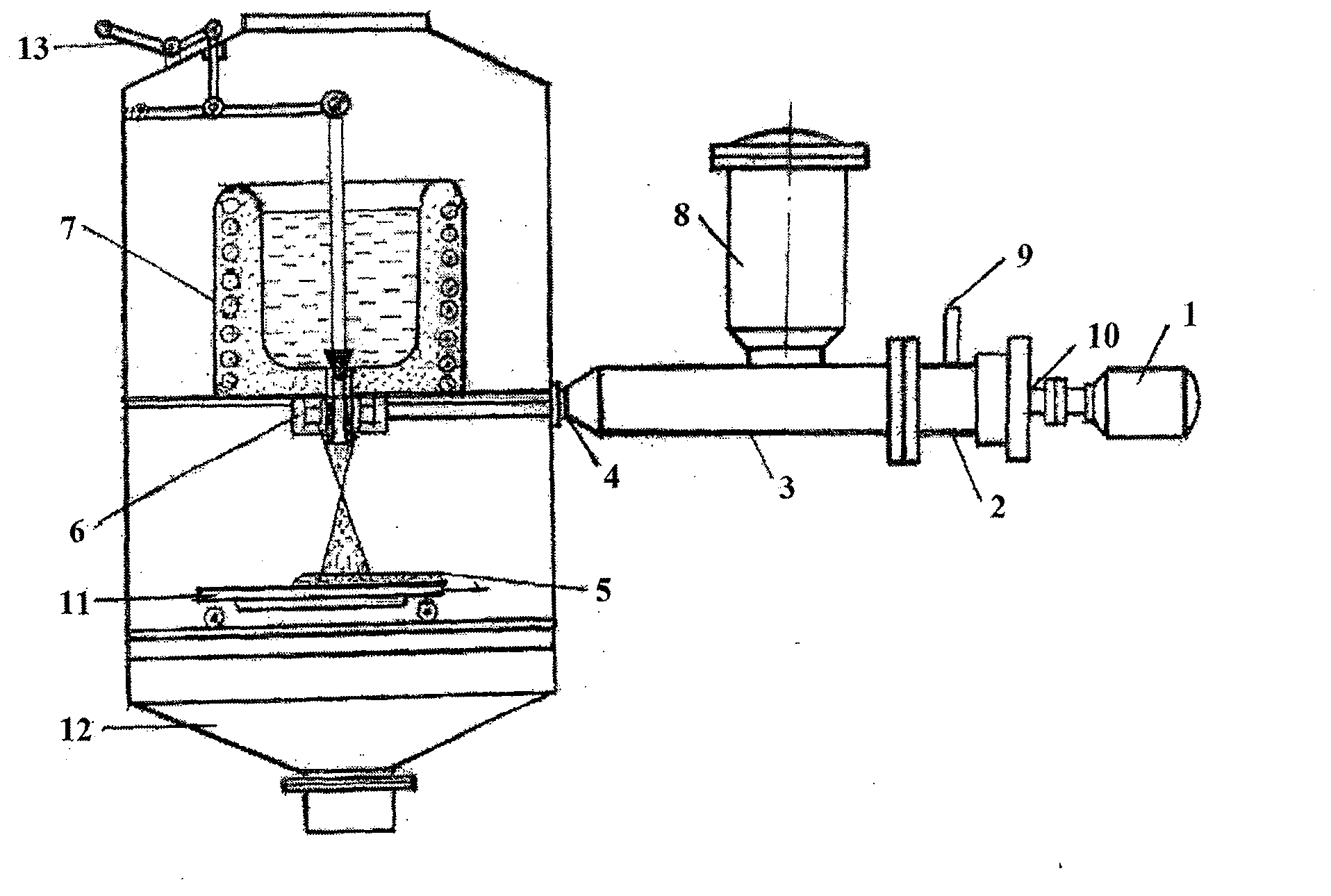

[0027] Prepare a piece of 20kg, WC20% (mass) / M 2 High-speed steel 80% (mass) high-speed solid-phase particle spray-deposited steel-bonded carbide. The M 2 The high-speed steel alloy liquid has a total injection time of 10 minutes, a melting point of 1480°C, solid phase particles of 4 kg of WC powder, and an average particle size of 1.5 μm. Using 1MPa pressure, high-purity N 2 Gas is a particle accelerating gas, and its preparation method and steps are as follows:

[0028] 1.1 Selection of raw materials

[0029] m 2 16kg of high-speed steel ingot (broken material), 4kg of pure WC powder (purity > 99.9% by mass), high-purity N 2 Gas 4 bottles.

[0030] 1.2 Modulation of high-speed solid-phase particle flow

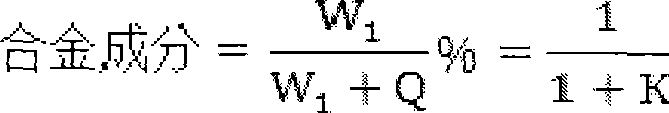

[0031]According to the deposition rate (1.6kg / min) and alloy composition WC20% (mass) + steel (balance), it can be known that the supply rate of high-speed solid phase particle WC powder is 400g / min. A low-speed and infinitely variable speed motor is used. See attac...

Embodiment 2

[0045] Prepare a piece of 450X450mm 2 Double-layer composite armor plate, the composition of superhard composite layer alloy on the surface is WC30% (mass); M 2 High speed steel 70% (mass); thickness 5mm; density 9.63g / cm 3 , the substrate is 45 ordinary carbon steel plate (450X450X10)mm 3. , see attached figure 1 Middle 11. Its preparation method and steps are as follows:

[0046] 2.1 Selection of raw materials

[0047] Super hard layer volume V 1 =(45X45X0.5)cm 3 =1012cm 3

[0048] Super hard layer weight W 0 =1012cm 3 X9.63g / cm 3 =9764.3g

[0049] WC powder weight W 1 =9746.3X30%=2923.9g;

[0050] m 2 High speed steel weight W 2 =9746.3X70%=6822.4g

[0051] The average particle size of WC powder is 1.5μm; the purity is 99.9%

[0052] 2.1.2 Molten steel injection speed and process parameters

[0053] The melting amount of molten steel is 6.83kg, and the actual melting is 7kg. The spraying deposition rate of molten steel is controlled at 0.7kg / min, the spr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com