Patents

Literature

60results about How to "Short production line" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

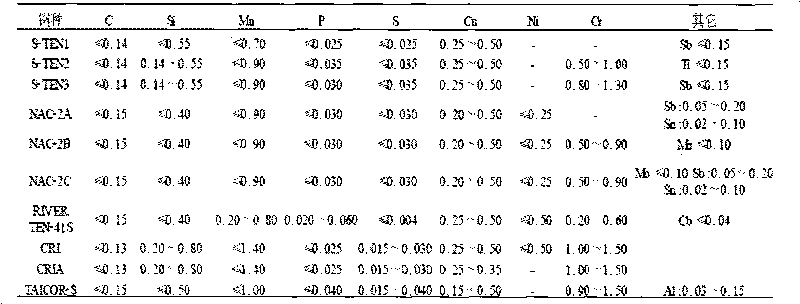

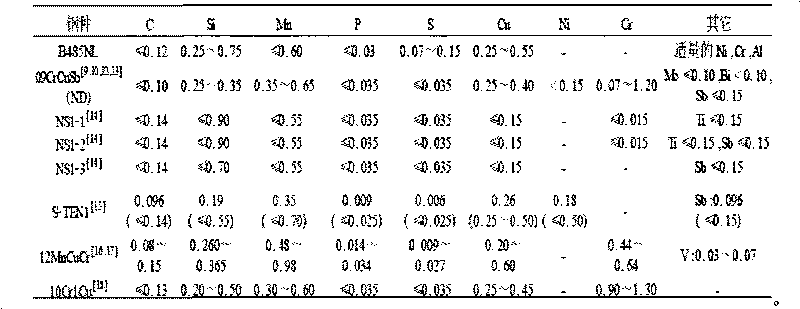

Sulphuric acid dew point corrosion resisting steel and method for producing same

InactiveCN101736202AShort Cooling IntensityStable temperatureProcess efficiency improvementElectric furnaceChemical compositionMolten steel

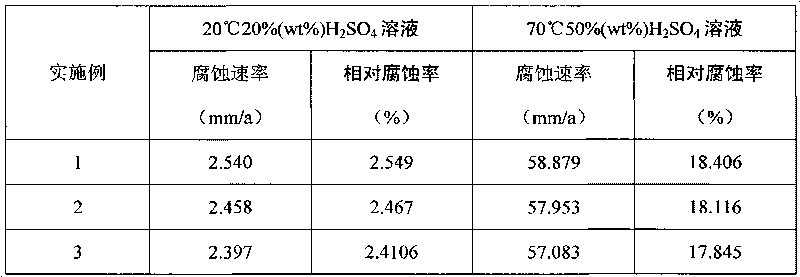

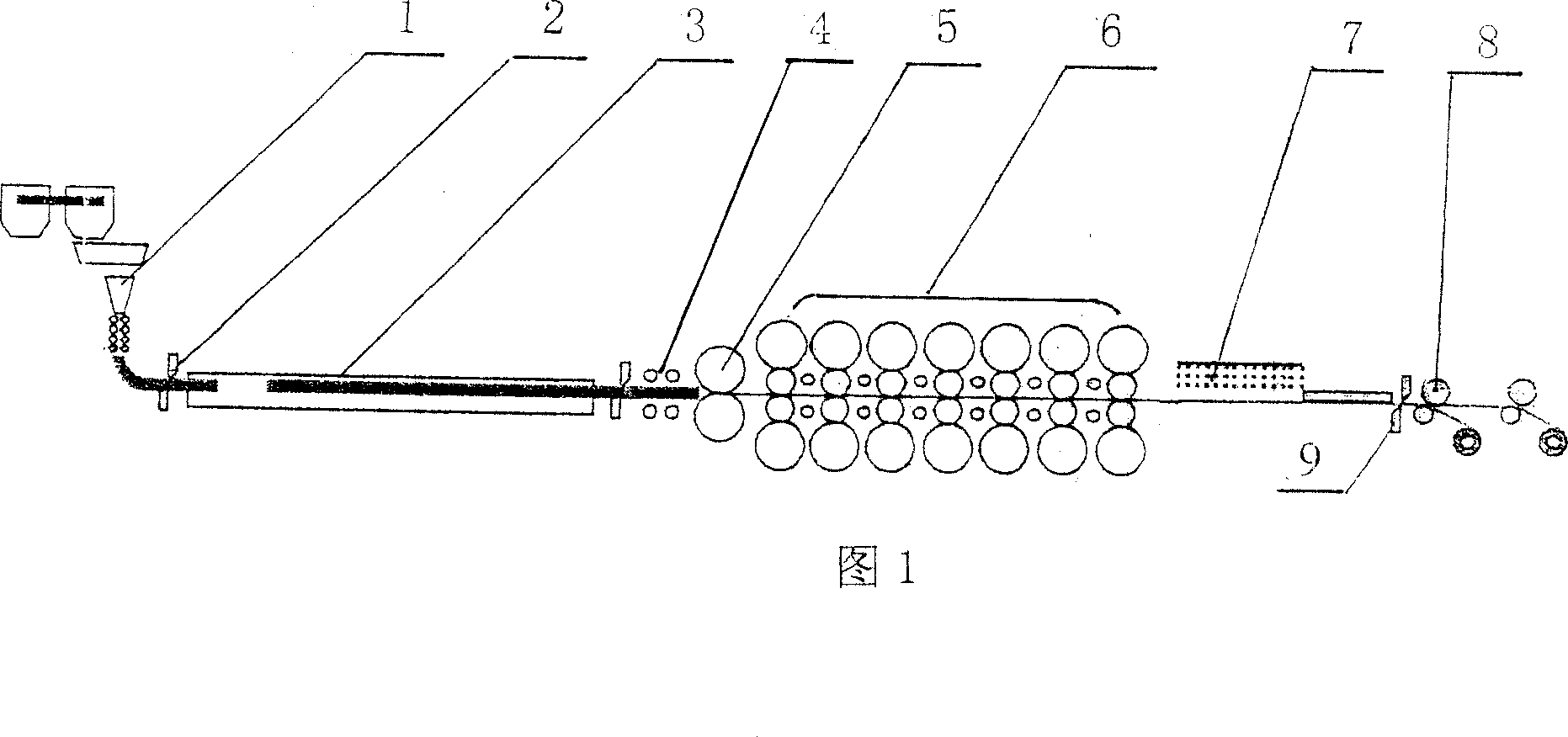

The invention discloses sulphuric acid dew point corrosion resisting steel and a method for producing the same by continuously casting and rolling a thin steel billet with an electric furnace. The molten steel comprises the following chemical components by weight percent: 0.03-0.08 percent of C, 0.10-0.45 percent of Si, 0.40-1.0 percent of Mn, 0.025 percent of P or less, 0.035 percent of S or less, 0.15-0.50 percent of Cu, 0.40-1.0 percent of Cr, 0.02-0.15 percent of Sb, 0.04-0.30 percent of Ni and 0.01-0.05 percent of Ti and also comprises 100ppm of N or less. The thin steel billet is continuously cast at the speed of 3.5-5.5m / min, and the cast thin steel billet is placed in the electric furnace of 900-1050 DEG C, soaked at 1100-1200 DEG C, rolled at 1040-1120 DEG C, finally rolled at 850-920 DEG C and winded at 550-650 DEG C. The Cu-Cr-Sb composite micro-alloyed sulphuric acid dew point corrosion resisting steel having good mechanical performance, welding performance and corrosion resisting performance can be produced by continuously casting and rolling the thin steel billet with the electric furnace.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

Seasoning oyster juice powder and preparation method thereof

The invention relates to seasoning and provides seasoning oyster juice powder which has the characteristic of intense oyster fragrance and wide application range and is convenient to transport and preserve, and a preparation method thereof. The seasoning oyster juice powder comprises the following raw materials in mass ratio: concentrated oyster juice 100, maltodextrin 12-14, white granulated sugar 5.5-7.5, common salt 3-7, monosodium glutamate 3-5, glucose 2.5-3.5, starch 2.5-3.5, yeast extracts 0.3-0.5 and disodium 5'-ribonucleotides 0.2-0.4. The preparation method comprises the following steps of: firstly preparing the oyster juice; filtering the oyster juice to obtain oyster juice filtrate; concentrating the oyster juice filtrate to obtain concentrated oyster juice liquid; adding the sugar and the common salt and heating for reaction; adding the monosodium glutamate and the disodium 5'-ribonucleotides into reaction feed liquid, heating, melting and flavoring; then, adding the predissolved maltodextrin and the starch and curing; regulating the concentration of the feed liquid with water to obtain flavoring oyster juice feed liquid; sterilizing and homogenizing the flavoring oyster juice feed liquid to obtain spray feed liquid; drying the feed liquid; collecting materials in a clean room to obtain the oyster juice powder; and sieving, packing and inspecting the oyster juice powder.

Owner:XIAMEN DOINGCOM BIOTECH

High-strength ship hull structural steel and production method of plate roll

ActiveCN101082102AReduce smelting costSmelting operation is simpleRoll mill control devicesFurnace typesProduction lineHull structure

The present invention relates to low alloy steel and is especially steel for hull structure and its production process. The steel for hull structure consists of C 0.03-0.075 wt%, Si 0.01-0.35 wt%, Mn 1.40-1.60 wt%, Als 0.015-0.100 wt%, V 0.020-0.080 wt% and Fe and impurity elements for the rest. It is produced in a CSP production line with special temperature system, reduction schedule and cooling system, and through casting blank, hydraulically shearing, heating and descaling, rolling into strip steel, stream cooling and finally winding. It has the advantages of less alloy elements, simple production process, high production efficiency, low power consumption, high product performance, etc.

Owner:MAANSHAN IRON & STEEL CO LTD

Polyester film and producing process thereof

The polyester film is made with 0.62 over viscosity lustrous polyester slice, 0.58 over viscosity regenerated grain and 0.62 over viscosity monox polyester slice. The making process of the polyester film includes mixing lustrous polyester slice, regenerated grain, monox polyester slice, lustrous IPA polyester slice and calcium acetate polyester slice in certain proportion, drying, extrusion, filtering, metering, casting film, longitudinal stretching, transverse stretching, thermally setting and cutting. The polyester film has the advantages of low production cost, high product performance, high dielectric strength, high heat stability, short production process and no environmental pollution in production process.

Owner:YIHUA GROUP CORP

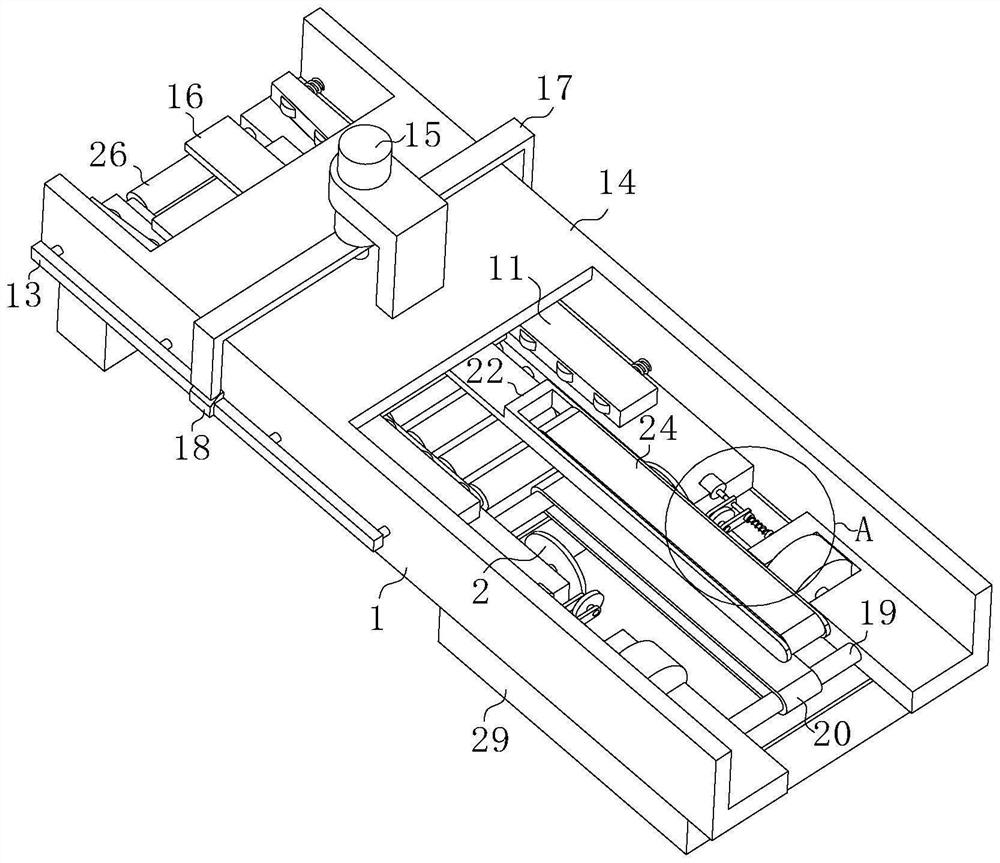

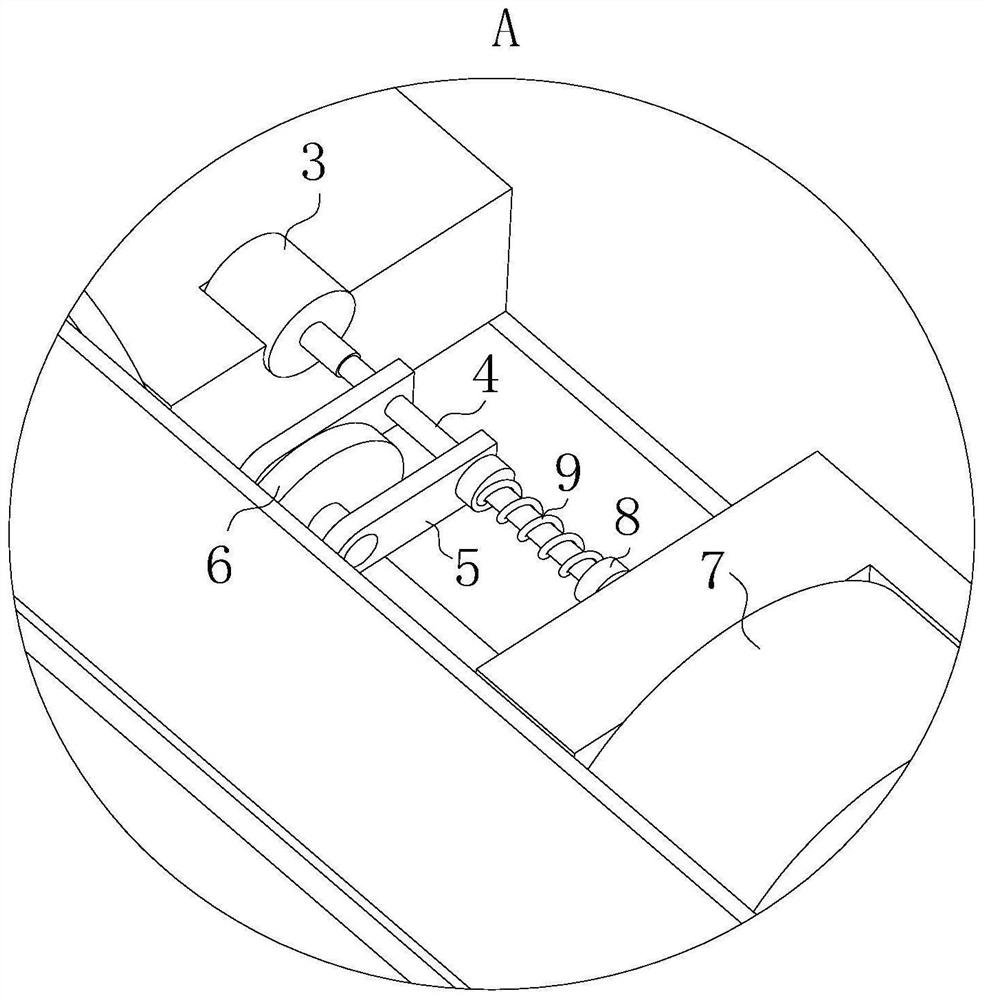

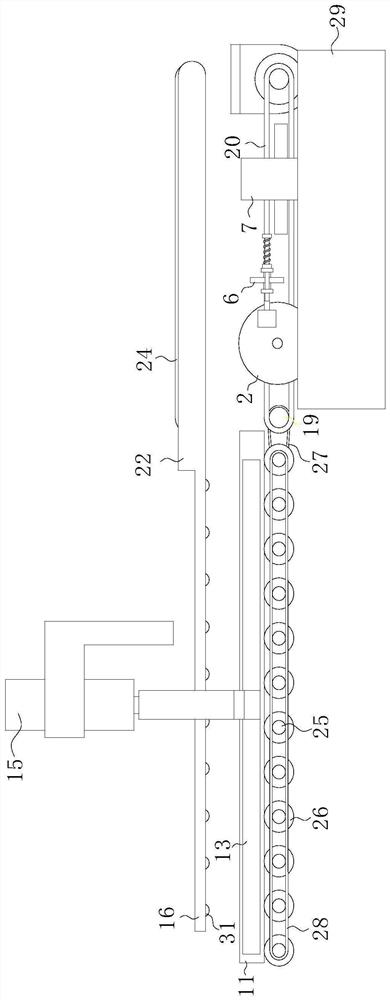

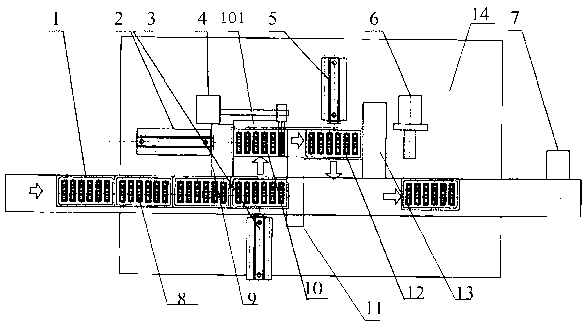

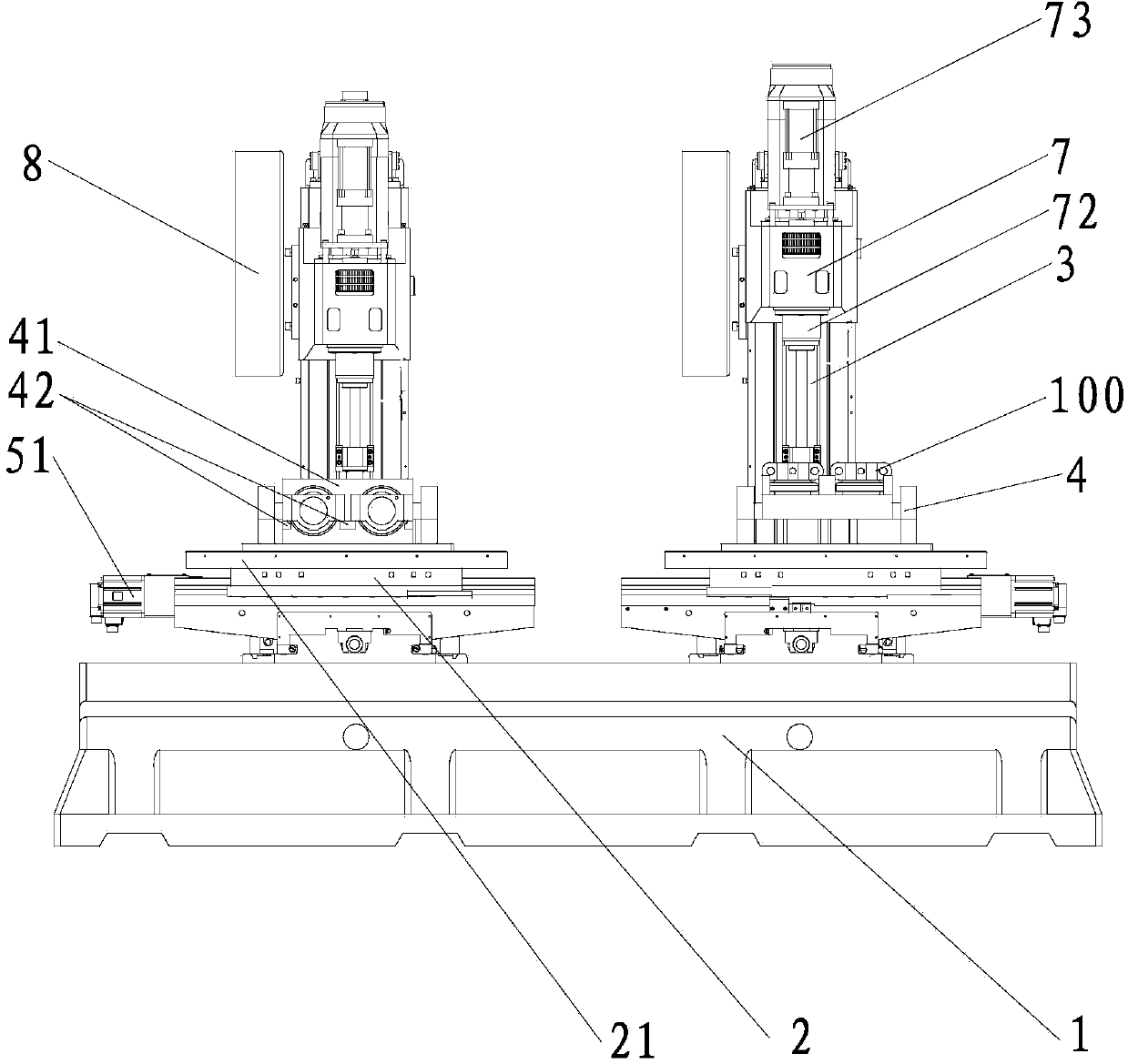

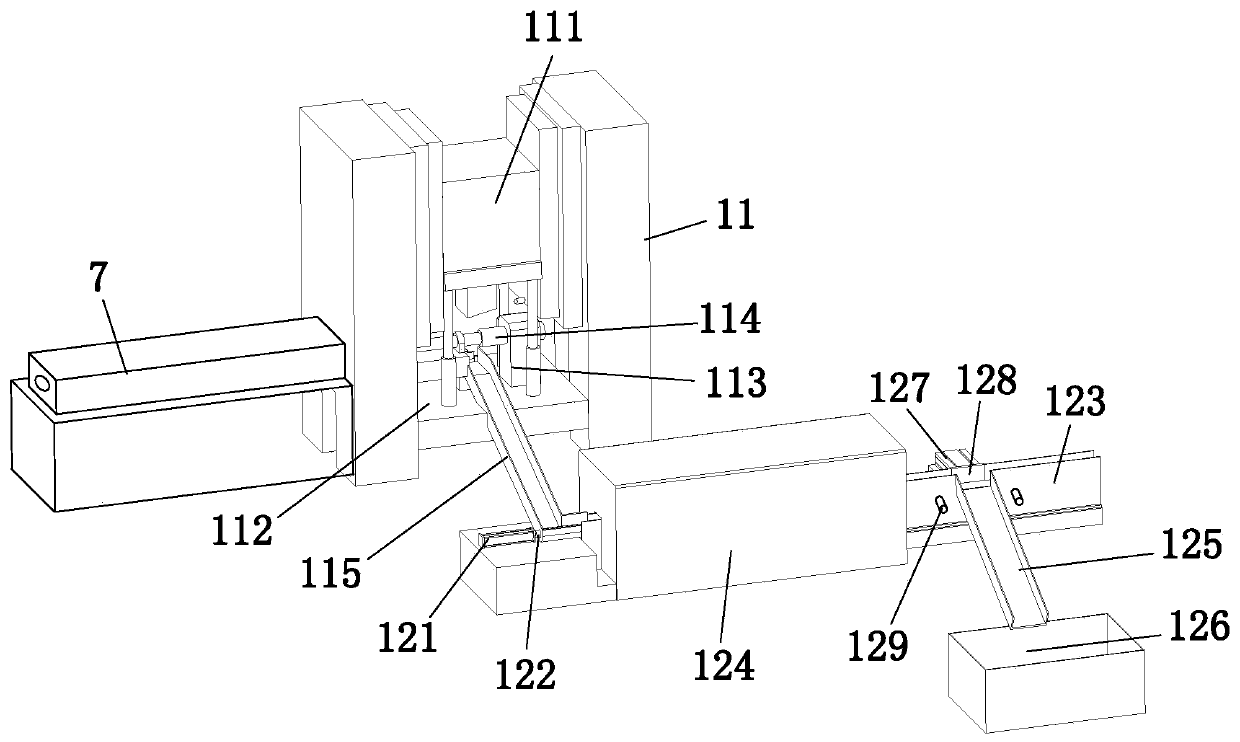

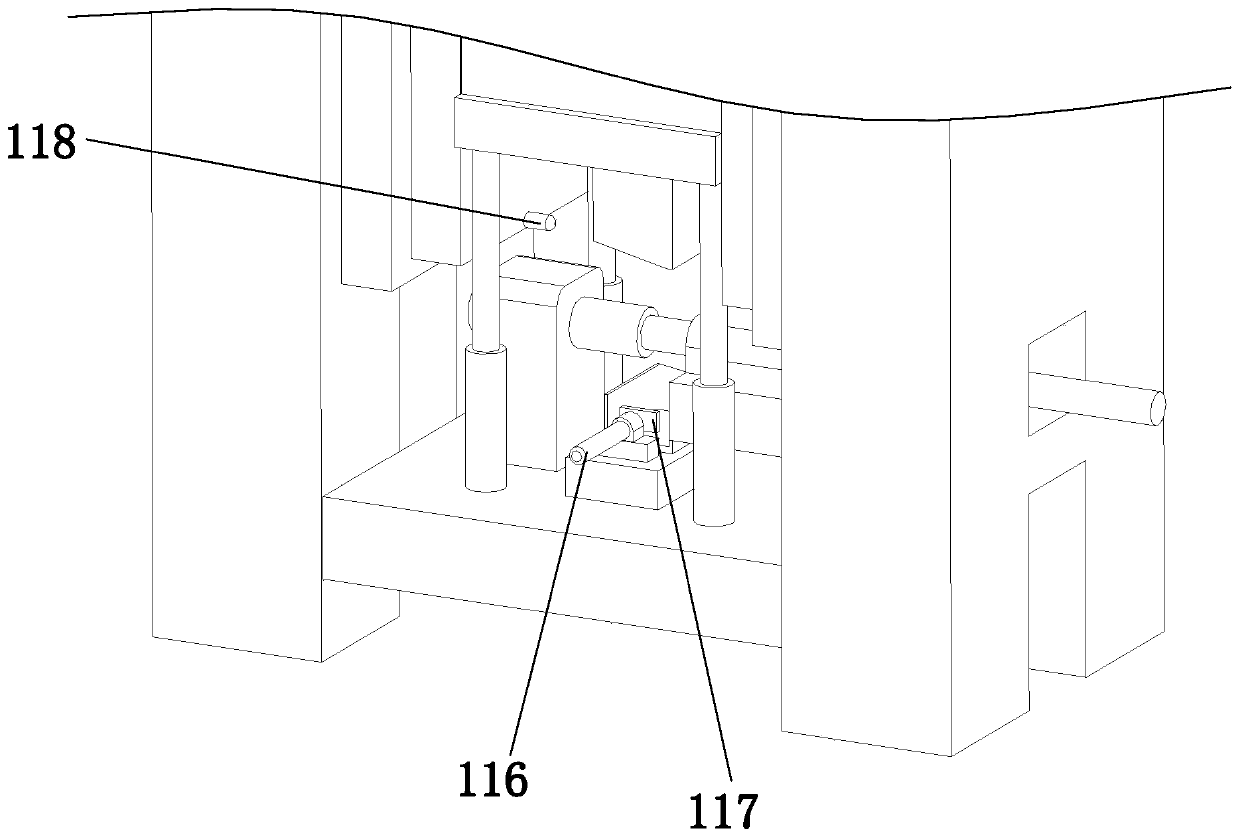

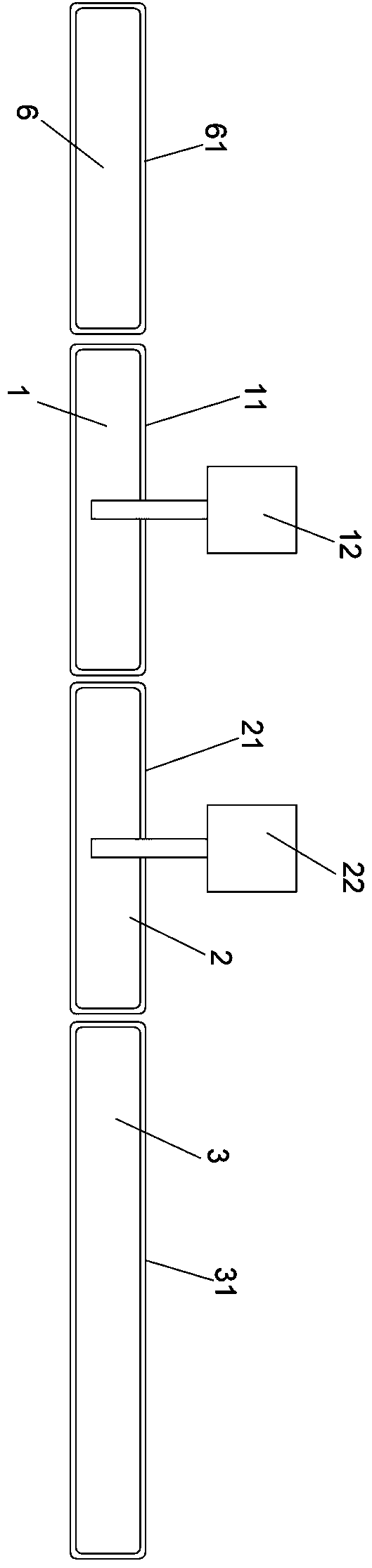

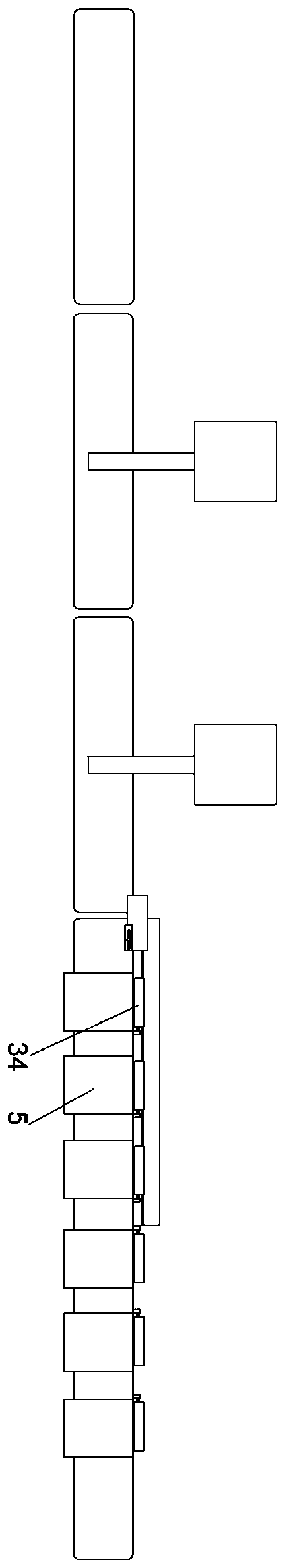

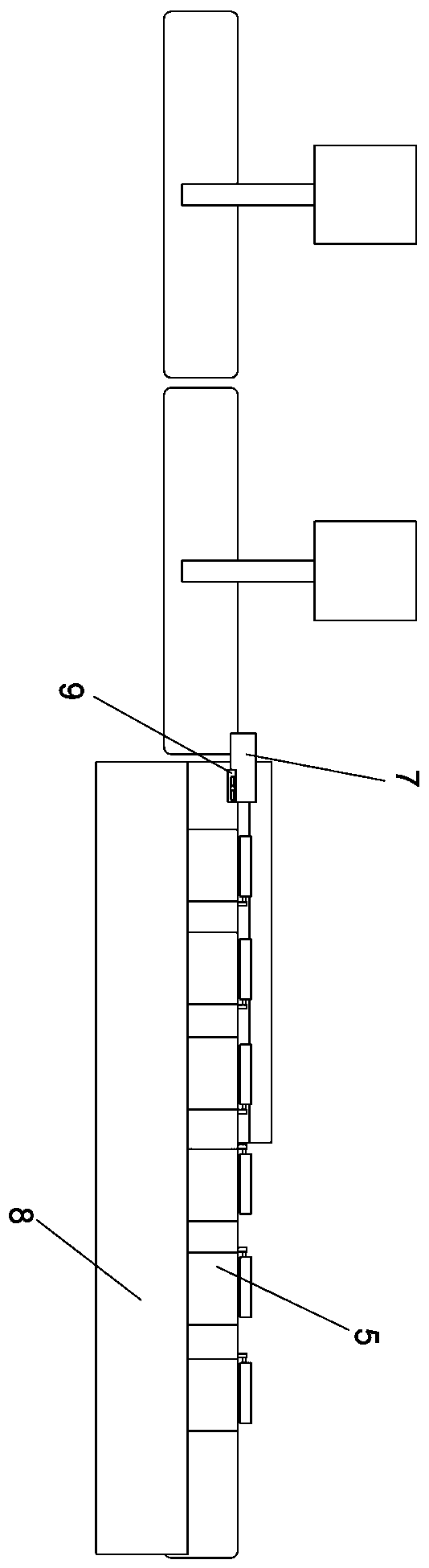

Automatic machining equipment for supporting wheel side covers

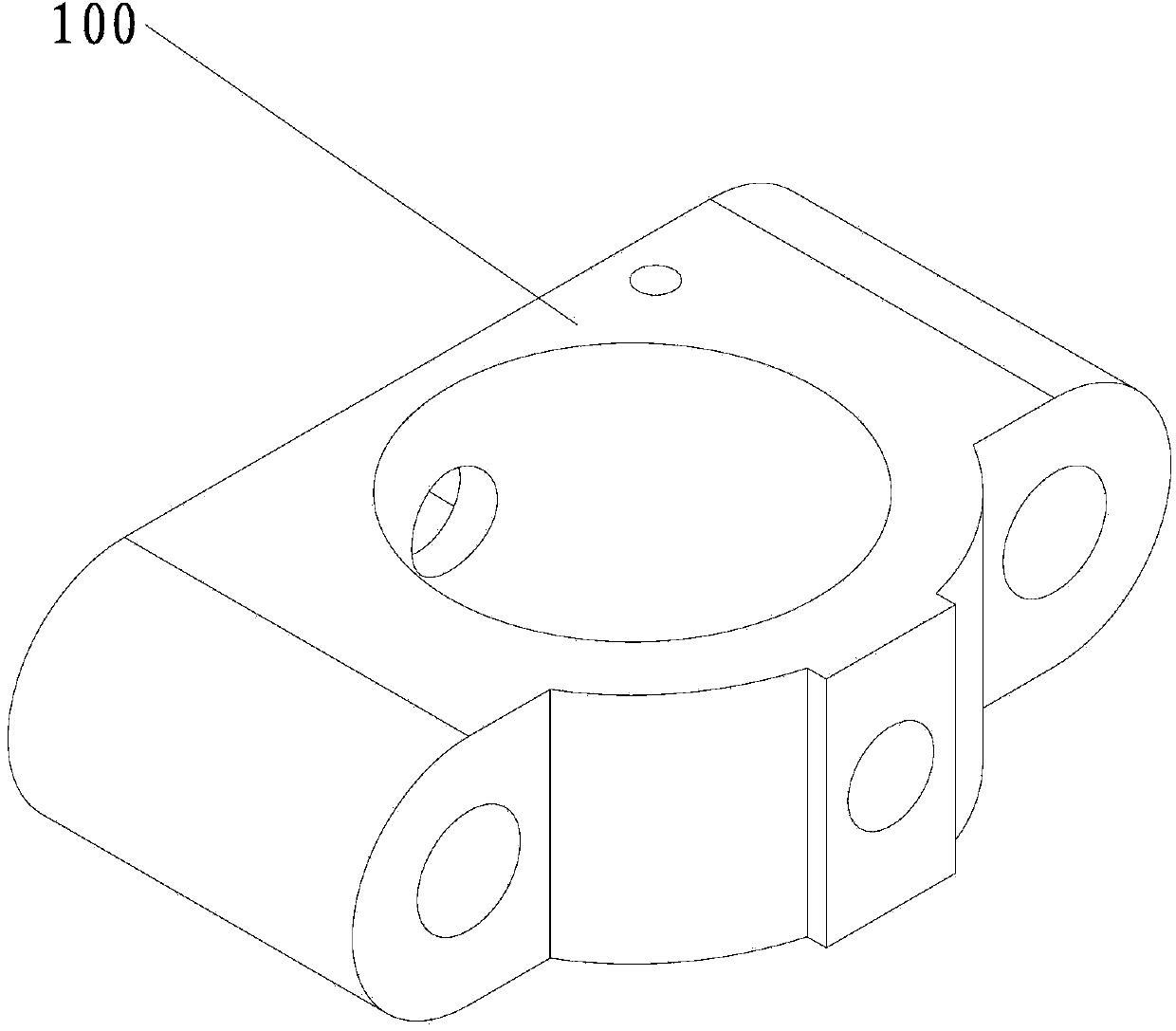

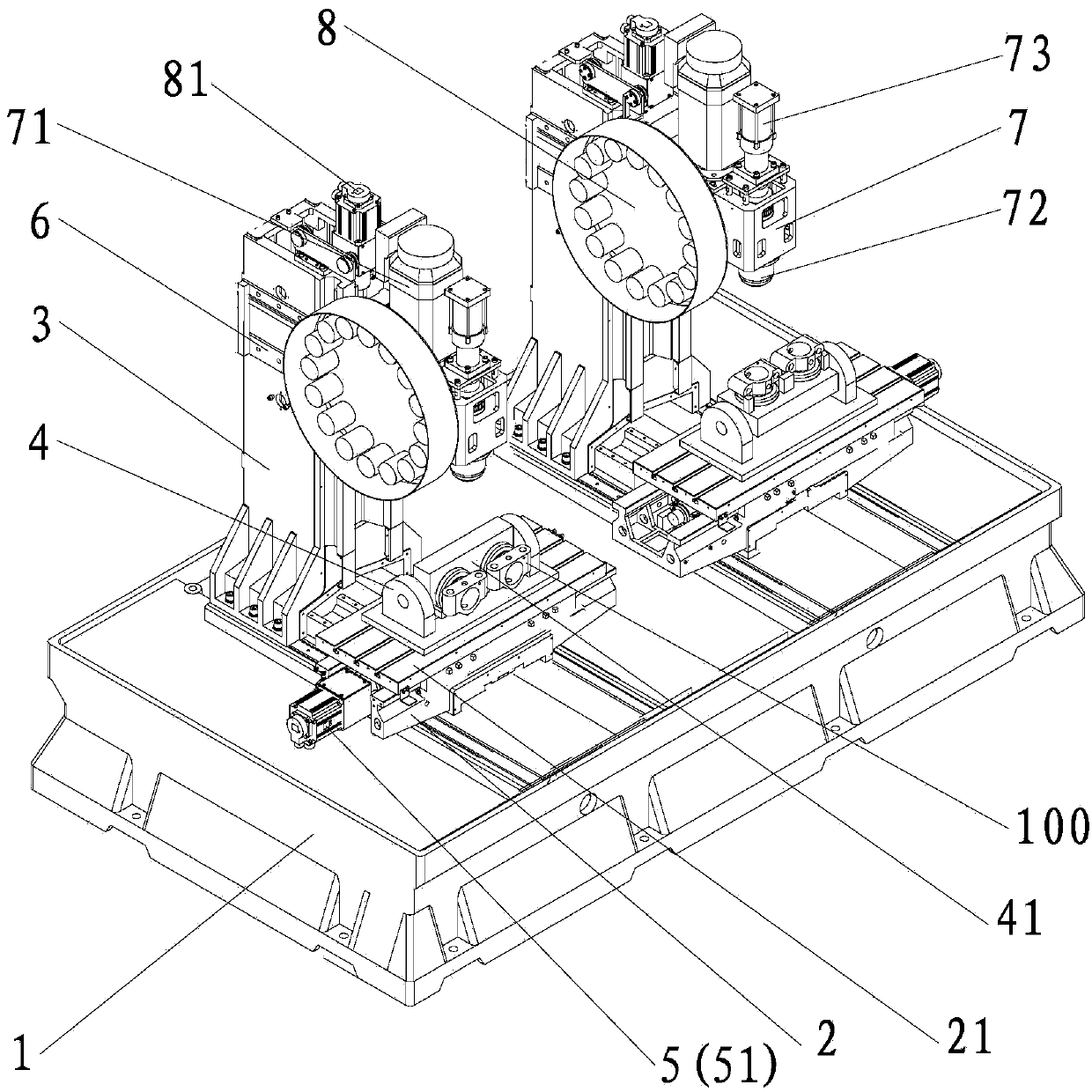

InactiveCN104209754AImprove machining accuracyShort production lineFeeding apparatusOther manufacturing equipments/toolsProduction lineWork in process

The invention provides automatic machining equipment for supporting wheel side covers. The automatic machining equipment for supporting wheel side covers comprises a control device, a base, saddles and stand columns, wherein a clamping mechanism, a clamping driving mechanism and a saddle driving mechanism are installed on each saddle, an installation rack is arranged on each stand column, one end of each installation rack is fixedly connected onto the corresponding stand column, a spindle box is installed at the other end of each installation rack, a servo motor, a cutter installation part and a cutter driving mechanism are respectively installed on each spindle box, and the control device controls the operation time sequence of the clamping driving mechanism, the saddle driving mechanisms, the servo motors and the cutter driving mechanisms. Therefore, the machining of a plurality of installation holes and a plurality of planes can be finished in one clamping step only, and the machining accuracy is higher; since all machining processes are finished on the same equipment, the production line is short, the risk that semi-finished products are damaged or oxidized during transfer is avoided during machining, the reject rate of products is lower and the production efficiency is effectively improved.

Owner:泉州市华盛机械设备有限公司

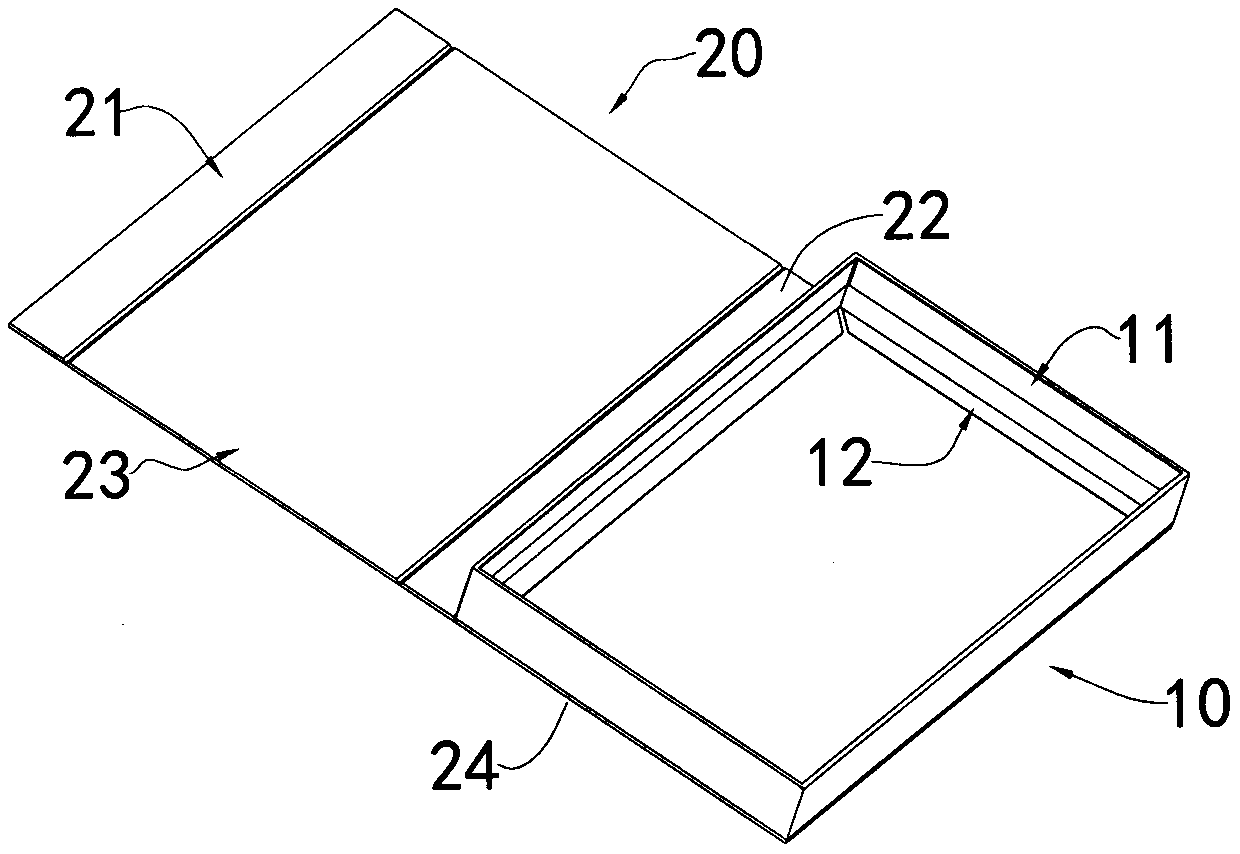

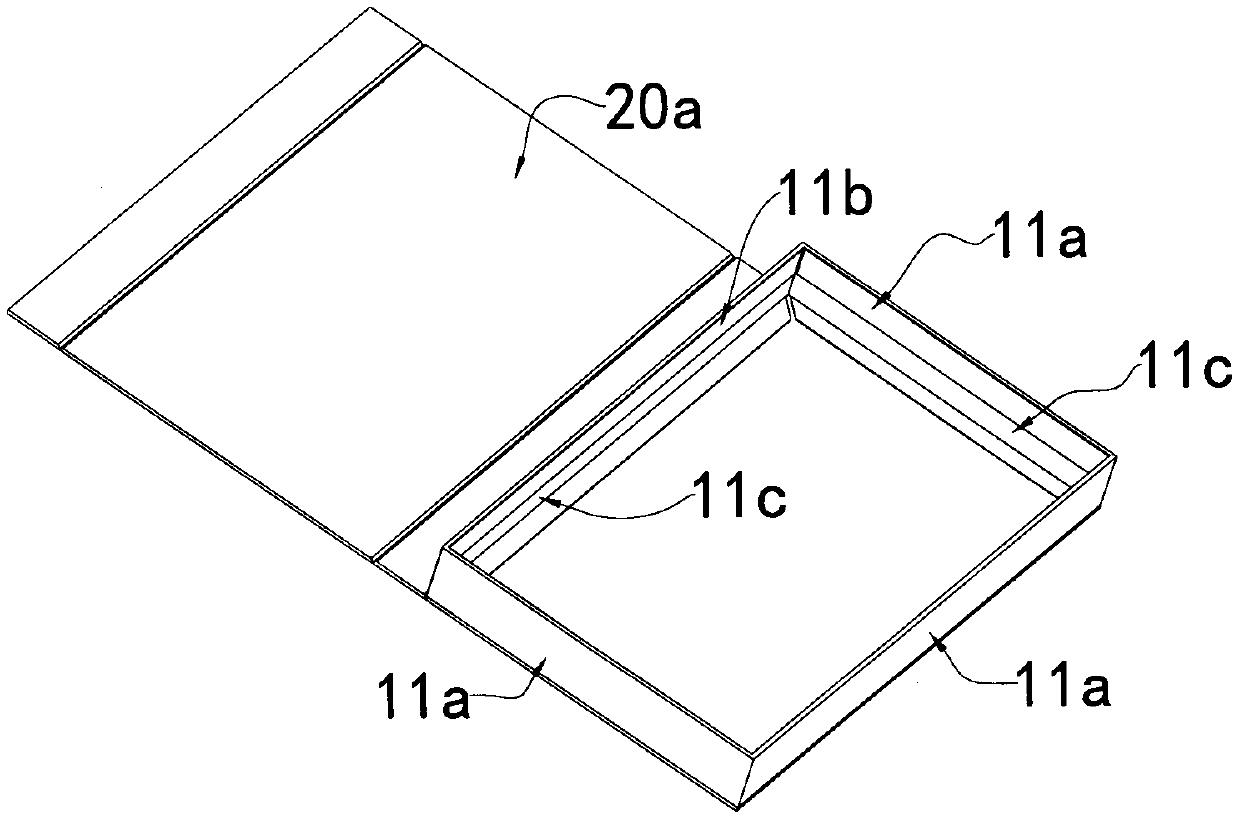

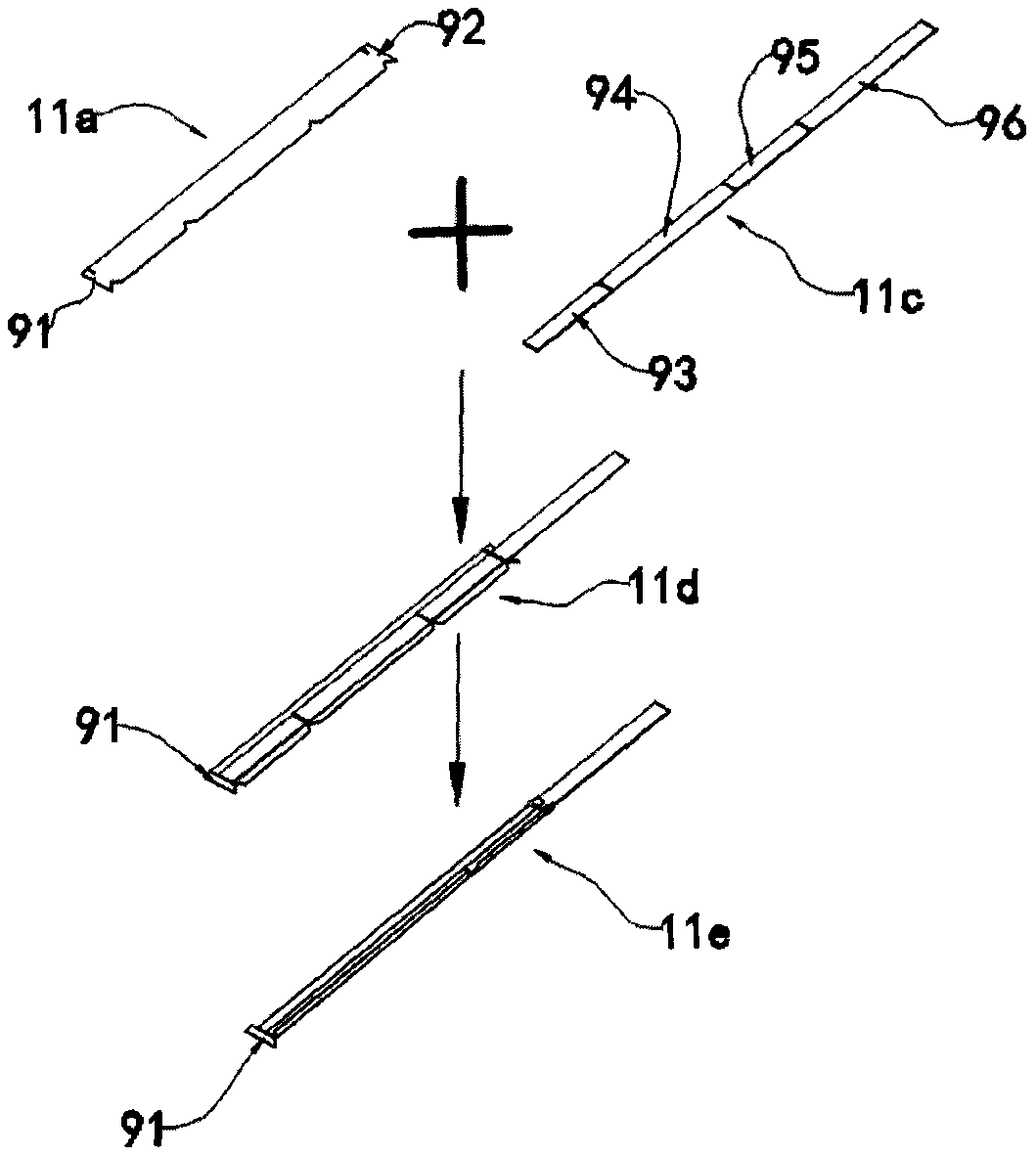

Manufacturing method and production process of leather shell surrounding frame box type

ActiveCN110978618ANeat appearance and qualitySharp edgeBox making operationsPaper-makingEngineeringStructural engineering

The invention relates to the technical field of packaging box processing, and discloses a manufacturing method and a production process of a leather shell surrounding frame box type. Surface paper isdivided into long surface paper and short surface paper, a grey board is divided into four sections, a leather shell is divided into four sections, and a first lug part and a second lug part are arranged at the two ends of the long surface paper respectively; the grey board is downwards attached to the long surface paper, and the first lug part is exposed to form a first surrounding strip; on thefirst surrounding strip, one side edge of the long surface paper is turned over and attached to the first surrounding strip to be fixed, the other side edge of the long surface paper is folded and formed, and a second surrounding strip is formed; the second surrounding strip is folded and formed, the first lug part is folded and attached to the exposed surface of the second surrounding strip, anda first surrounding frame is formed; the short surface paper is adhered to the exposed surface of the first surrounding frame to form a second surrounding frame; the upper side edge and the lower sideedge of the short surface paper on the second surrounding frame are folded and formed, then the upper side edge is folded into the inner wall of the second surrounding frame to be fixed, and a thirdsurrounding frame is formed; and the third surrounding frame is adhered to the leather shell. The method and the process can be effectively expanded to complex box types, and the quality and the productivity are convenient to control.

Owner:SINOTECHO WUHAN INTELLIGENT TECH CO LTD

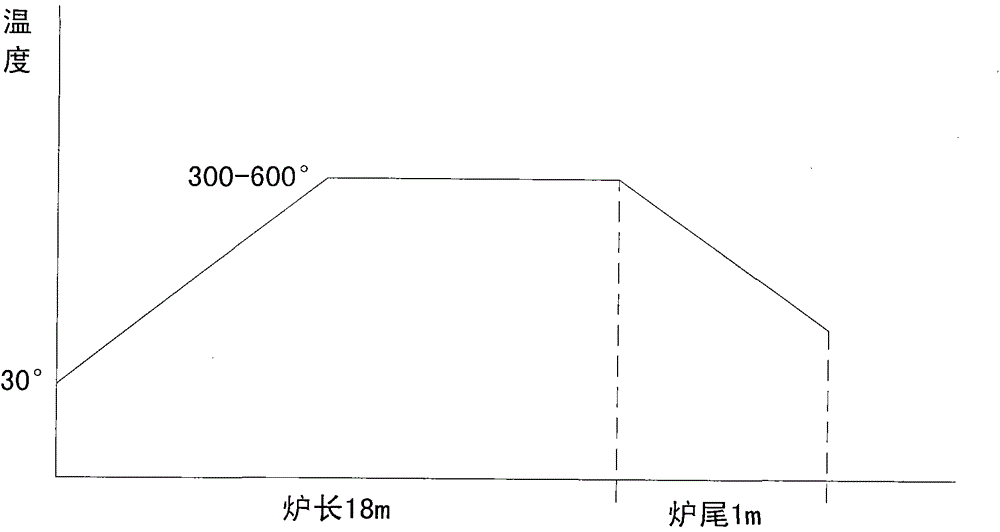

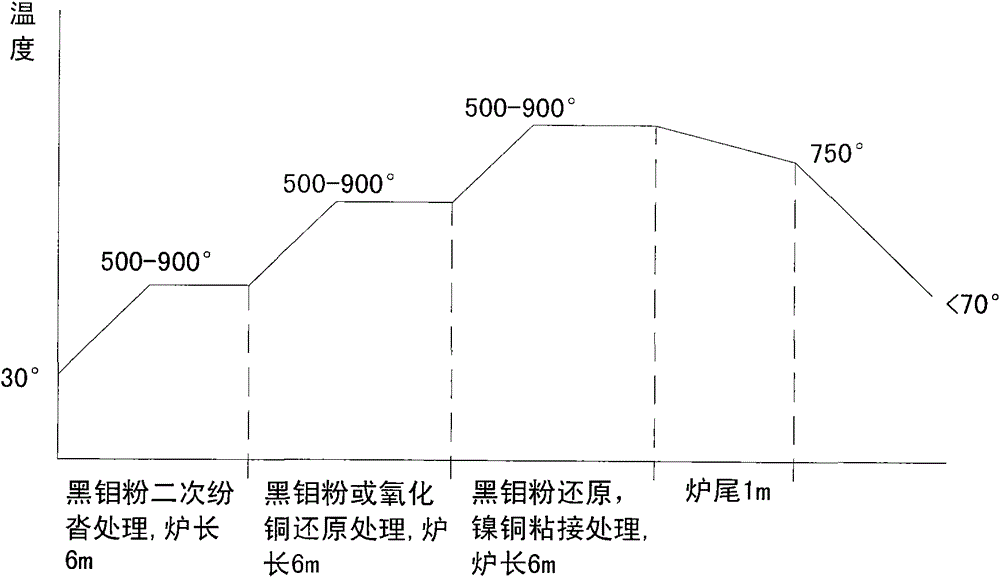

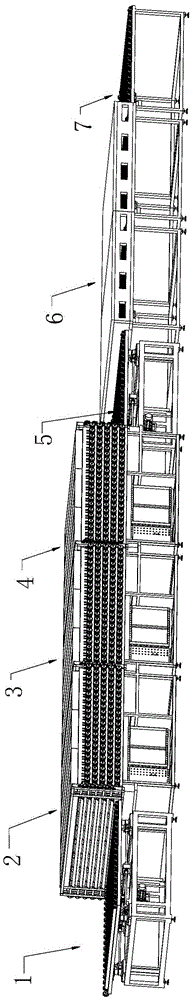

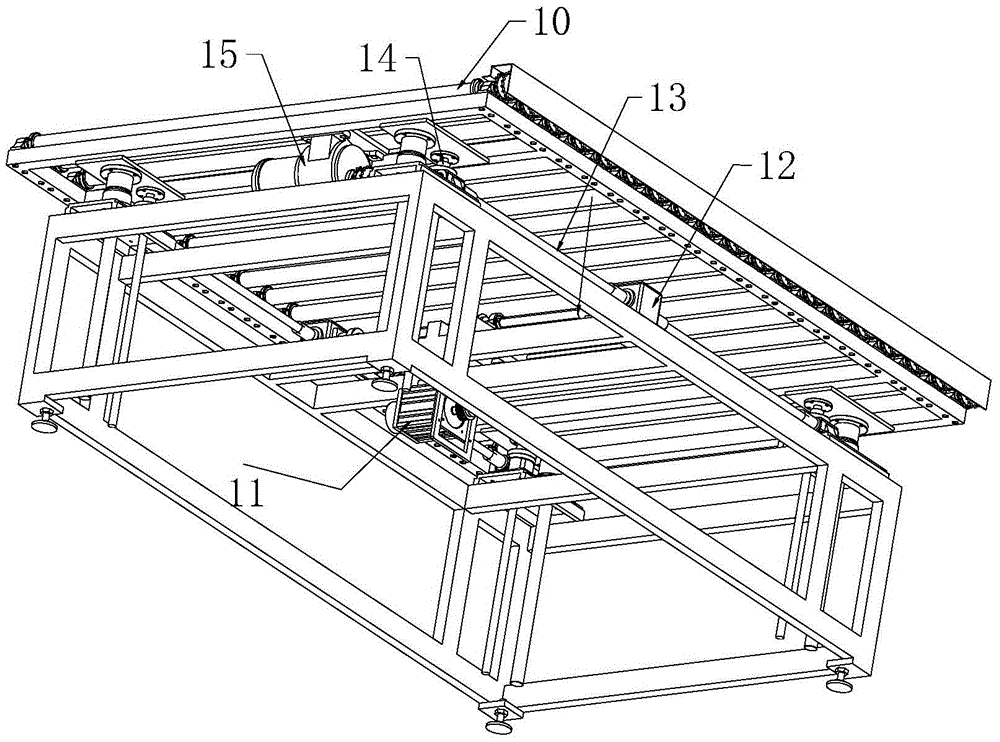

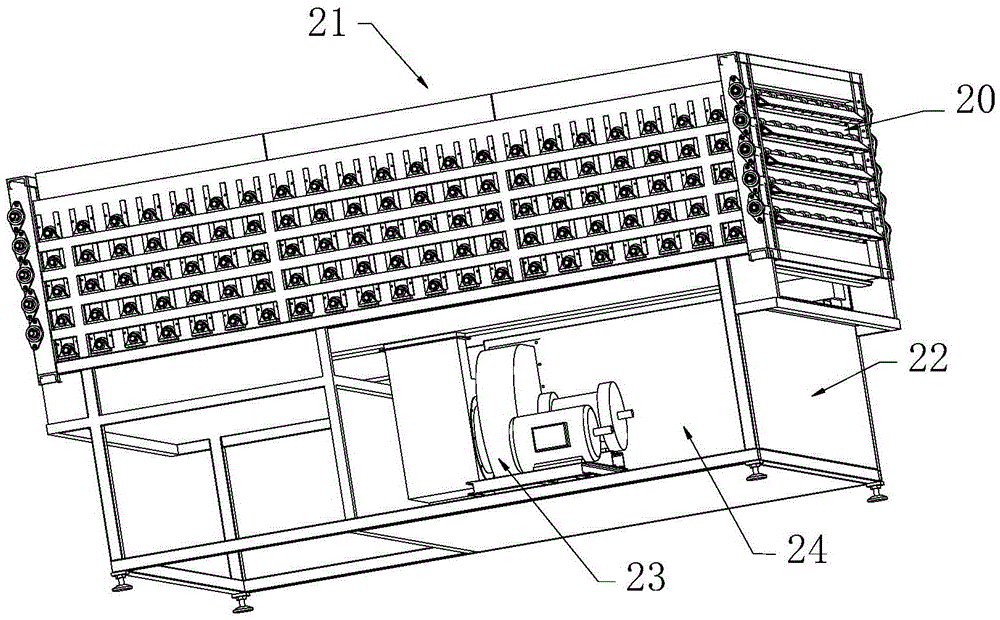

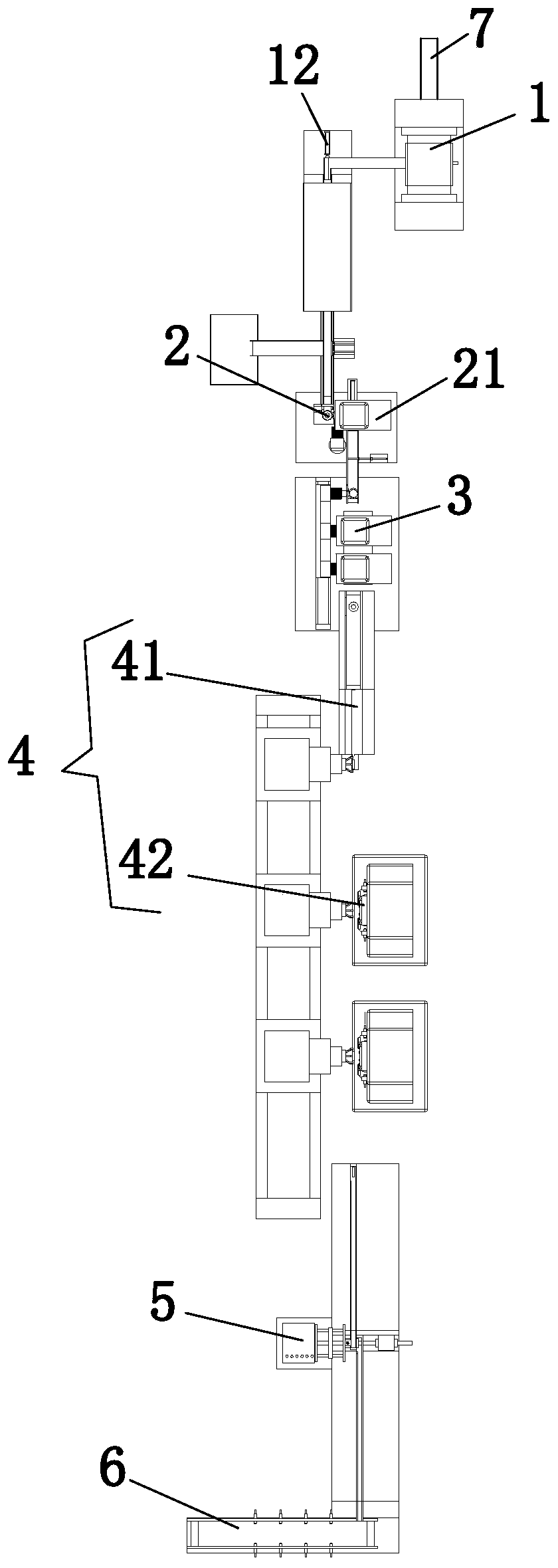

Multilayer clean tunnel furnace

The invention discloses a multilayer clean tunnel furnace. The multilayer clean tunnel furnace comprises the following parts arranged in a material conveying direction in sequence: a loading lifting platform for lifting and conveying materials within a preset height, a multilayer preheating section including multiple first conveying layers and used for preheating the materials on each of the first conveying layers, a multilayer heating section including multiple second conveying layers and used for heating materials on each of the second conveying layers, a multilayer precooling section including multiple third conveying layers and used for precooling materials on each of the third conveying layers, an unloading lifting platform for lifting and conveying materials within a preset height, a wind leaching cooling section for cooling the materials, and a discharge platform for sending out the materials. The multilayer clean tunnel furnace has such multiple beneficial effects as uniform material heating, good cleanness, high production efficiency, short production line and energy and space saving.

Owner:SHENZHEN SANXIN JMT GLASS

Bearing intelligent precision forging automatic production line

InactiveCN111069517AThere is no poor quality inside and outsideLittle difference in internal and external qualityShaping toolsPerforating toolsProduction linePunching

The invention relates to the technical field of bearing production equipment, in particular to a bearing intelligent precision forging automatic production line which comprises a feeding mechanism, anupsetting mechanism, a punching flattening mechanism, a continuous reaming mechanism, a finishing diameter mechanism and a discharging mechanism, wherein the feeding mechanism comprises a feeding component and a pushing component; the upsetting mechanism comprises an overturning component and an upsetting component; the overturning component is arranged at the tail end of the pushing component; the punching flattening mechanism is arranged by the side of the upsetting component; the continuous reaming mechanism comprises a conveying component and a continuous reaming component; the conveyingcomponent is arranged by the side of the punching flattening mechanism; the continuous reaming component is arranged at the tail end of the conveying component; the finishing diameter mechanism is arranged at the tail end of the continuous reaming component; and the discharging mechanism is arranged at the tail end of the finishing diameter mechanism. The bearing intelligent precision forging automatic production line can realize automatic processing of bearing precision forging, lowers the labor intensity, shortens the blank transferring distance, reduces the temperature differences of different processing parts of the blank, and improves the production efficiency and the bearing precision.

Owner:浙江赛赛轴承有限公司

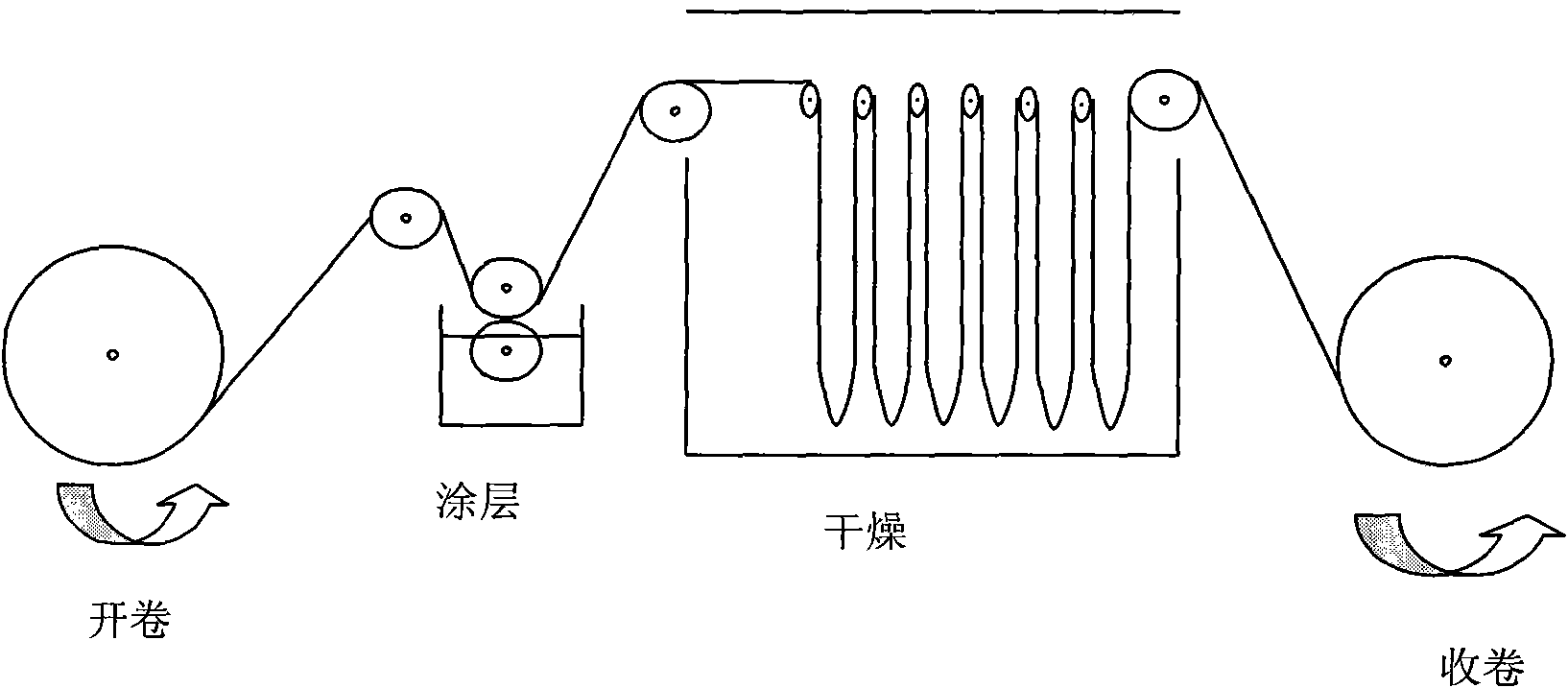

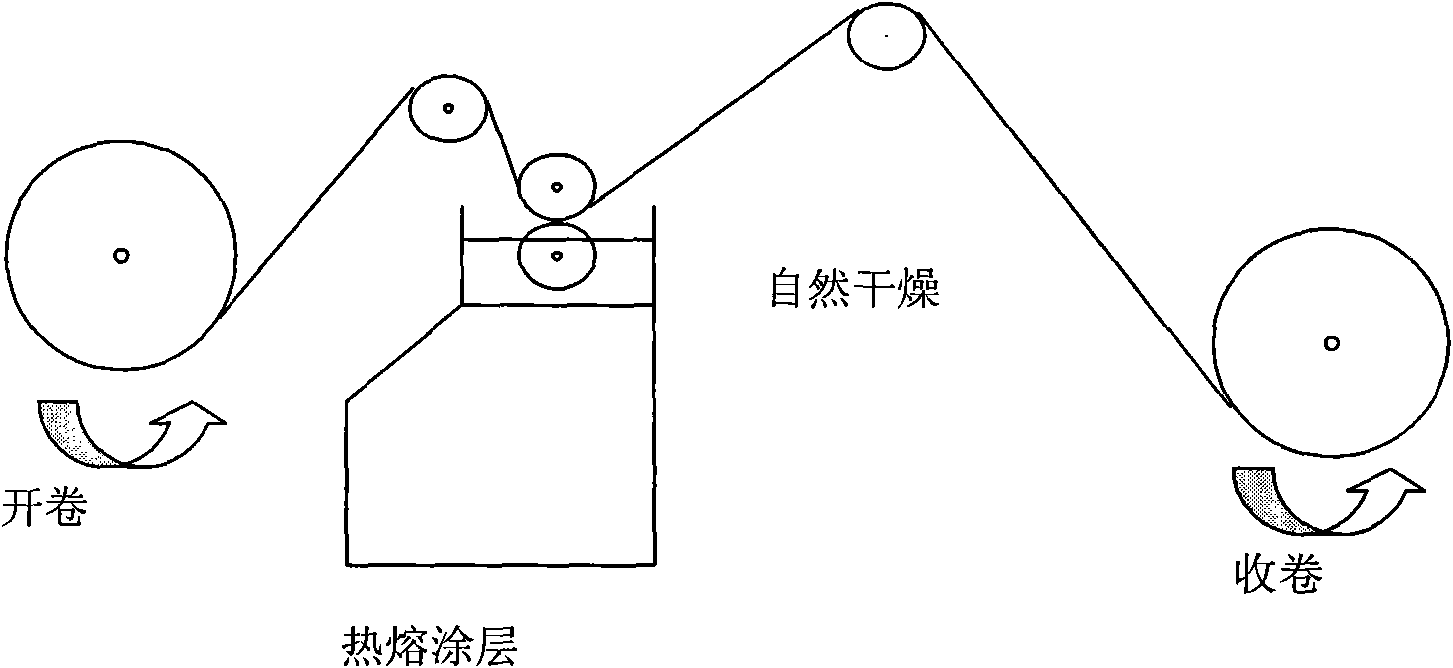

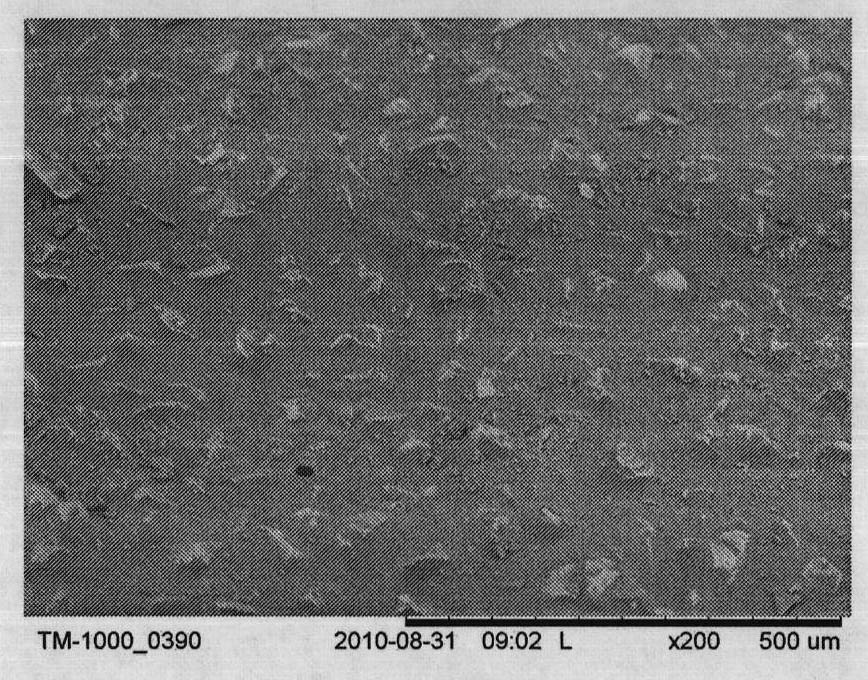

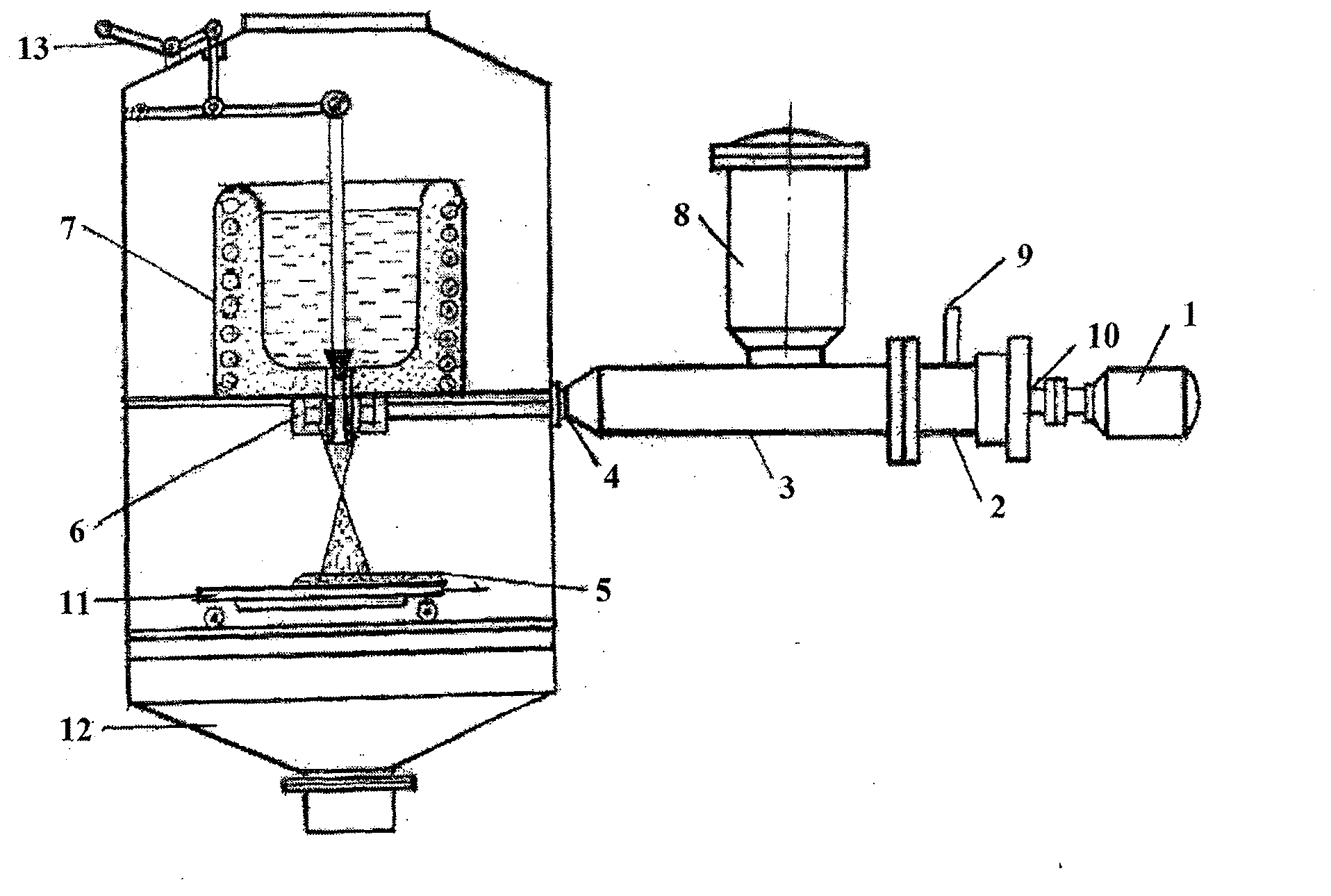

Method for forming hot melt super coating on coated abrasive tool

InactiveCN102009038ADense surface structureLow costLiquid surface applicatorsAbrasion apparatusHot melt coatingStearate

The invention discloses a method for forming a hot melt super coating on a coated abrasive tool, which is to heat and melt a material and coat the molten material by a roller coating equipment onto the surface of the coated abrasive tool, and is characterized in that: the material is stearate, or a mixture of stearate and paraffin wax or a mixture of stearate, paraffin wax and antioxidant or mixture of stearate, paraffin wax, antioxidant and EVA resin or PP resin and is heated and melted at the temperature of 110 to 160 DEG C; the molten stearate or mixtures of the stearate is coated on the surface of abrasive paper or abrasive cloth by hot melt coating equipment; and naturally cooling, drying and obtaining hot melt coating products. The hot melt coating has the advantages of no toxicity, no solvent, low cost, short production route and the like compared with water soluble or solvent coating, and the obtained abrasive tool has a more compact surface structure and has the advantages of blockage prevention, burn prevention and the like in use.

Owner:ZIBO RIKEN MT COATED ABRASIVES

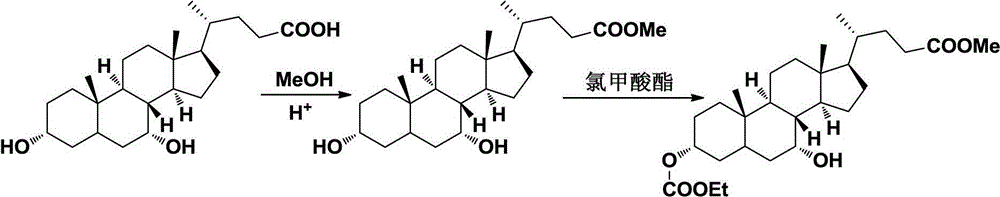

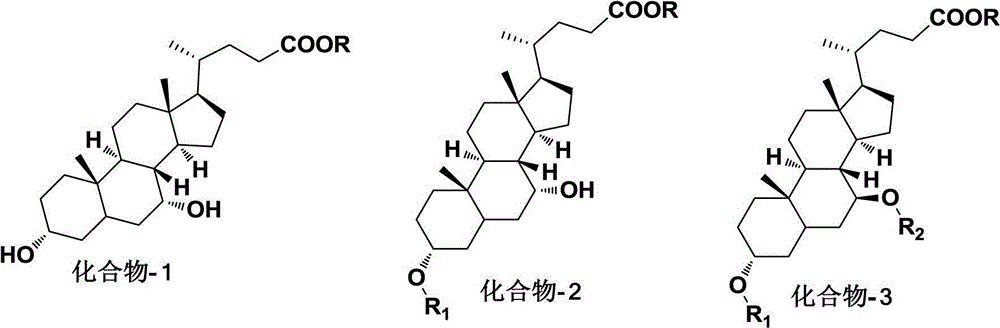

Novel synthesizing method for preparing ursodesoxycholic acid (UDCA) from chenodeoxycholic acid

ActiveCN102746359AShort production lineHigh yieldSteroidsBulk chemical productionChenodeoxycholic acidP-nitrobenzenesulfonyl chloride

The invention relates to a novel method for preparing UDCA from chenodeoxycholic acid. The method includes taking the chenodeoxycholic acid as a raw material, performing protection on carboxyl and selective protection on 3-carboxyl, then subjecting carboxyl at position 7 to a reaction through Mitsunobu or producing ester from paratoluensulfonyl chloride, methanesulfonyl chloride and paranitrobenzenesulfonyl chloride, and stripping off a protecting group to prepare the UDCA. Compared with other processes, the method has the advantages of being mild in reaction condition, simple in operation, high in efficiency, yield and optical purity and the like, and provided with a bright industrial production prospect.

Owner:HEFEI HUAFANG PHARMA SCI & TECH

Preparation method for (WC/high-speed steel) steel-bonded cemented carbide and lamination material

InactiveCN103882361ASpeed up coolingEasy to forgeMolten spray coatingEmbossing decorationsHigh energyWear resistant

The invention belongs to the technical field of injection deposition of(WC / high-speed steel) steel-bonded cemented carbide and preparation of lamination materials, and provides a new method for preparing (WC / high-speed steel) steel-bonded cemented carbide by employing high-speed solid-phase particles such as WC, TiC or VC to performing injection deposition on a high-speed molten steel flow, and a new steel type for superhard cutter steel and hot work die steel. The invention provides a new technology for preparing armoring and special composite wear-resistant parts formed by compounding two layers or multiple layers of WC superhard high-speed steel and plain carbon steel or stainless steel. The invention provides a technical means for performing high-energy rapid quenching on molten steel, and under all kinds of technological states, the prepared (WC / high-speed steel) steel-bonded cemented carbide possesses the mechanical properties comprehensively better than those of conventional high-speed steel. A new special research means is provided for researching and developing new materials and revealing new phenomenon in material science. The technical scheme enables our country injection deposition technology to be improved to a world leading level, and have wide popularization meaning and application value.

Owner:吴庆华 +2

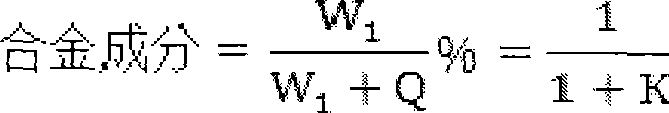

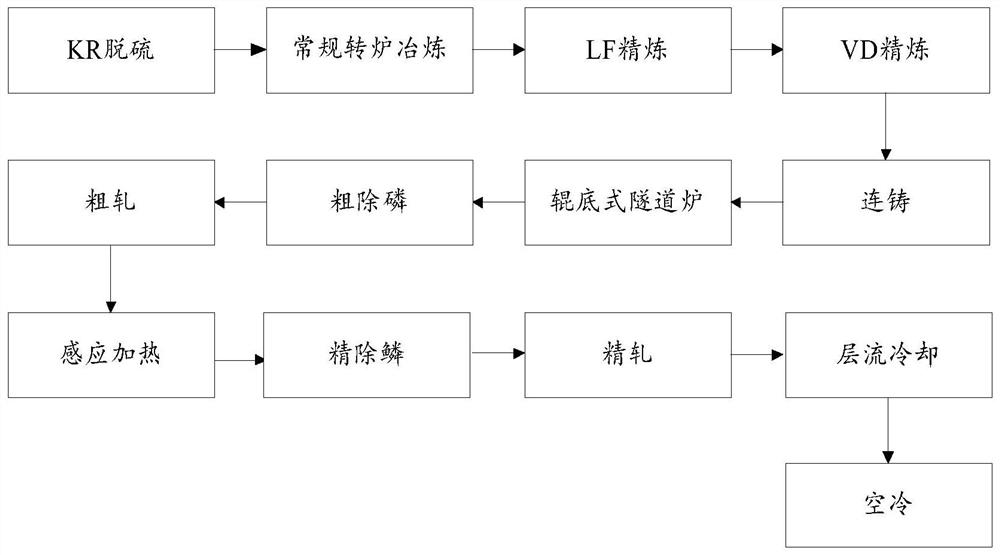

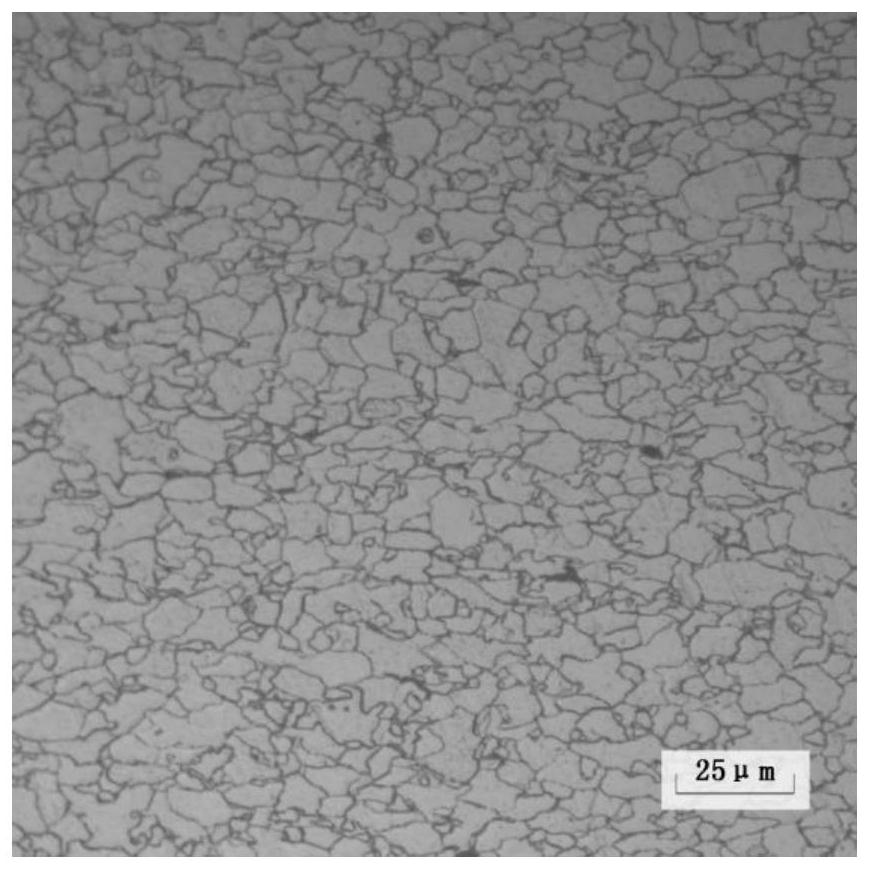

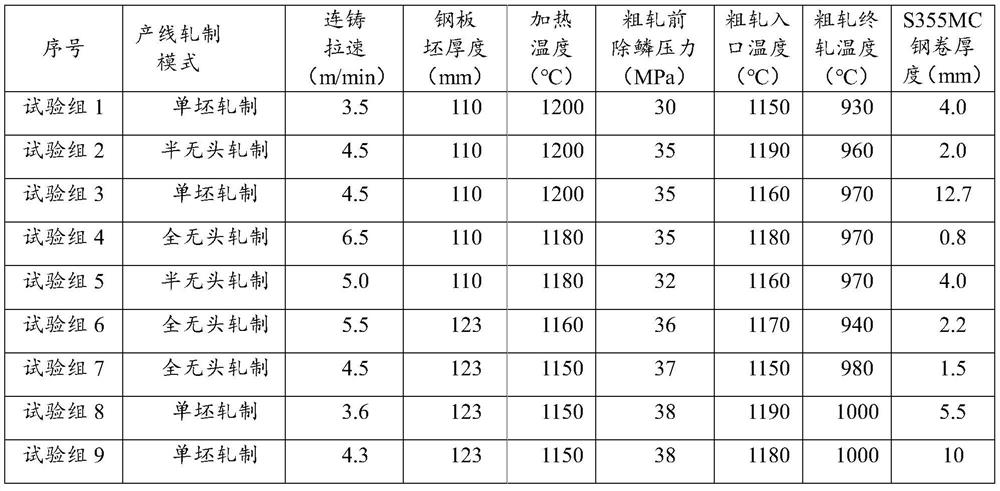

Method for preparing S355MC steel coil based on multi-mode sheet billet continuous casting and rolling production line and product obtained from method for preparing S355MC steel coil based on multi-mode sheet billet continuous casting and rolling production line

InactiveCN111676419AImprove corner temperatureEliminate edge defectsWork cooling devicesMetal rolling arrangementsProduction lineLaminar cooling

The invention belongs to the technical field of metal material machining and steel, and particularly relates to a method for preparing an S355MC steel coil based on a multi-mode sheet billet continuous casting and rolling production line and a product obtained from the method for preparing an S355MC steel coil based on a multi-mode sheet billet continuous casting and rolling production line. The method for preparing the S355MC steel coil based on the multi-mode sheet billet continuous casting and rolling production line comprises the following steps that smelting and continuous casting are carried out to obtain a sheet billet, the sheet billet is sequentially subjected to heating treatment, descaling before rough rolling, rough rolling, electromagnetic induction heating, descaling before finish rolling, finish rolling, laminar cooling, coiling and cooling, and an S355MC steel coil is obtained; and the sheet billet comprises the following components of, in percentage by mass, 0.03%-0.15% of C, smaller than or equal to 0.05% of Si, 0.6%-1.5% of Mn, 0.02%-0.35% of Al, smaller than or equal to 0.010% of P, smaller than or equal to 0.005% of S, 0.01%-0.10% of Nb, smaller than or equal to 0.005% of N, and the balance iron and inevitable impurities. The method for preparing the S355MC steel coil expands the thickness range of the final product S355MC steel coil, and has the advantagesof short production line, short process, energy conservation, emission reduction and cost reduction.

Owner:SHOUGANG CORPORATION

Preparation method for making glass wine divider through two-step method

ActiveCN105152522AStress reliefReduce the number of workersGlass blowing apparatusGlass productionElectric heatingWork in process

The invention relates to a preparation method for making a glass wine divider through a two-step method. The first step is to make a cup body, and comprises the preparation processes as follows: preparing glass raw material, melting the raw material by a furnace, feeding by a feeder, making a cup body preform through blowing of a bulb-blowing machine, taking out the cup body preform manually, manually feeding the cup body preform to a fire incision machine for incision, manually making a wine pouring opening, manually feeding the cup body to an electrical heating furnace for annealing, discharging out of the furnace and inspecting so as to obtain a semi-finished product; the second step is to make a cup handle on the cup body, and comprises the preparation processes as follows: taking the semi-finished product, feeding the semi-finished product into the electric heating furnace for heating, mounting the cup body on a tool clamp manually, connecting the cup handle manually, correcting the cup handle manually to prepare into the wine divider, manually conveying the wine divider to the annealing furnace for annealing, discharging the wine divider out of the furnace and inspecting, and packaging. By adopting the preparation method provided by the invention, half of workers are reduced, the production is carried out by two steps, the production line is shorter, and the defective cup body obtained through the first step is not used in the second step of connecting the cup handle on the cup body, so that the production cost is reduced, the product quality is improved and a high promotion value is realized.

Owner:CHONGQING JIANLI GLASS PROD CO LTD

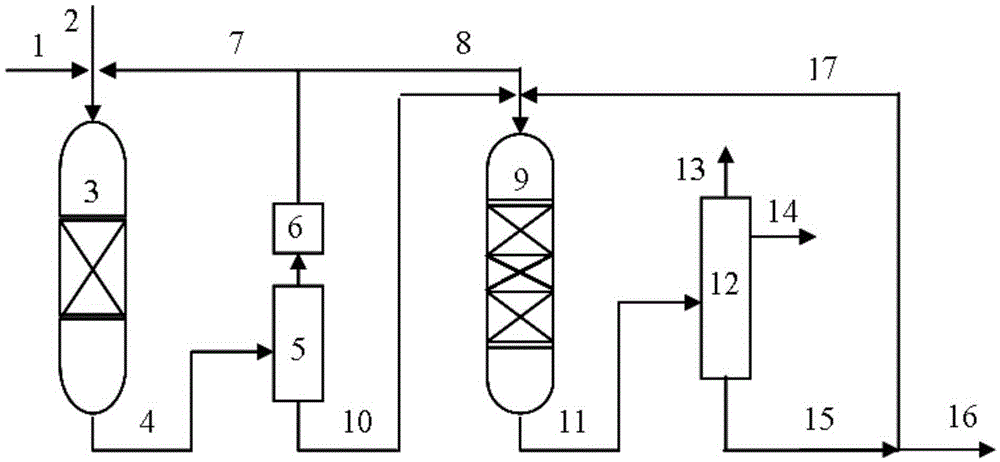

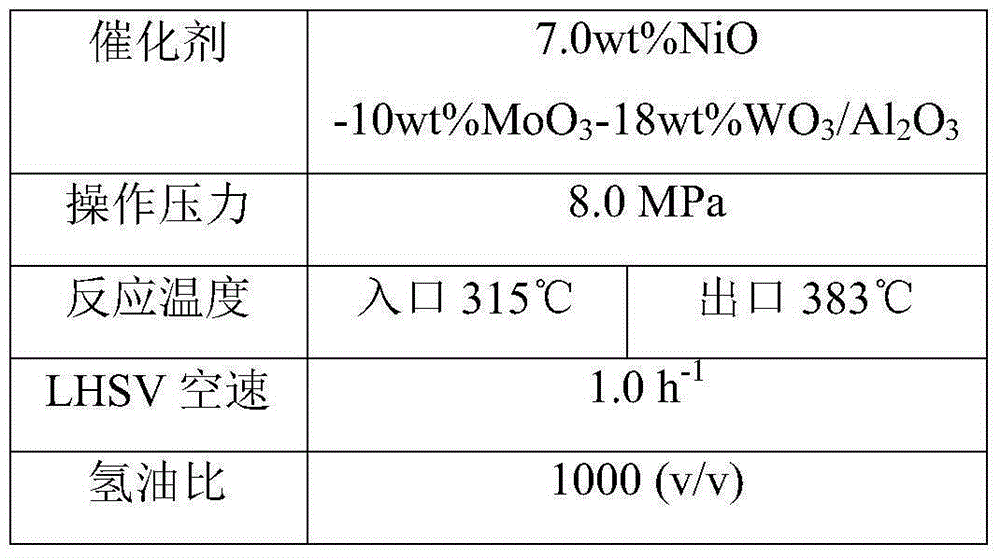

Method for production of C6-C8 arene from light cycle oil

InactiveCN106588537AHigh activity and selectivityShort production lineHydrocarbon by isomerisationHydrocarbon by hydrogenationCycle oilTransalkylation

The invention relates to a method for production of C6-C8 arene from light cycle oil, and mainly solves the problems of long route, low C6-C8 arene yield and low purity in previous technologies. According to the invention, by means of hydrotreatment, and hydrogenation ring opening and transalkylation two-step reaction, light cycle oil can be converted to C6-C8 arene. The technical scheme well solves the problems, and can be used for the field of production of monocyclic light aromatic hydrocarbons from distillate oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

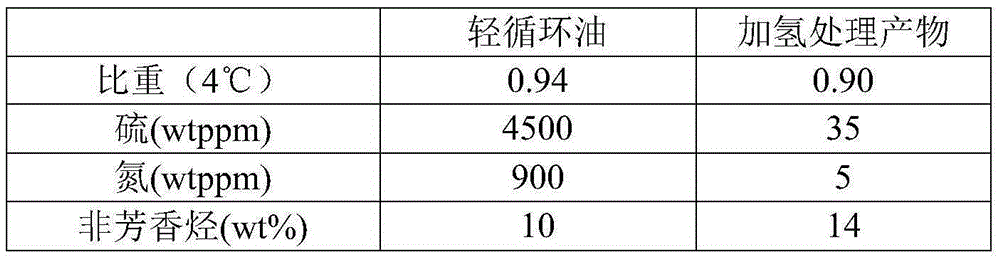

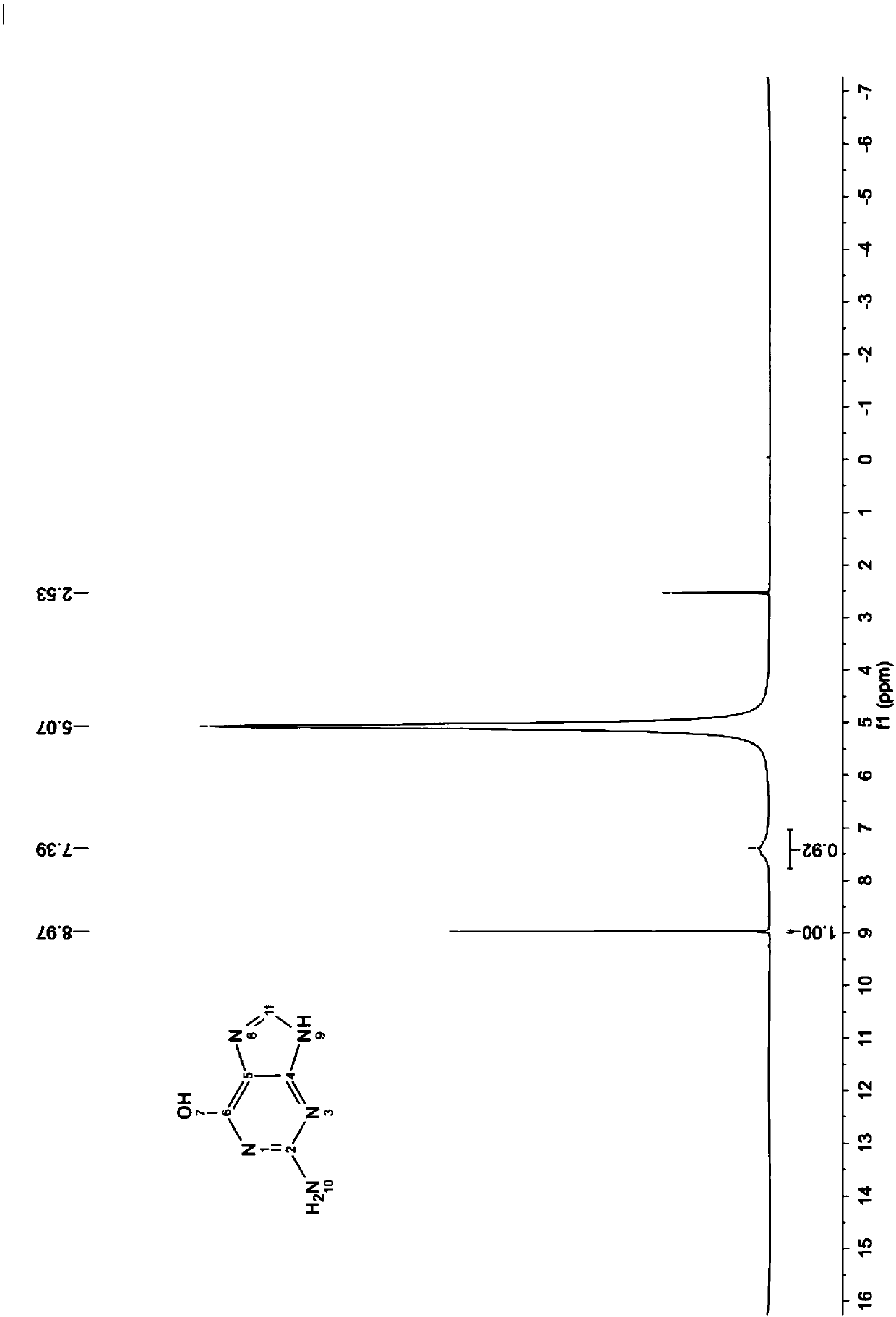

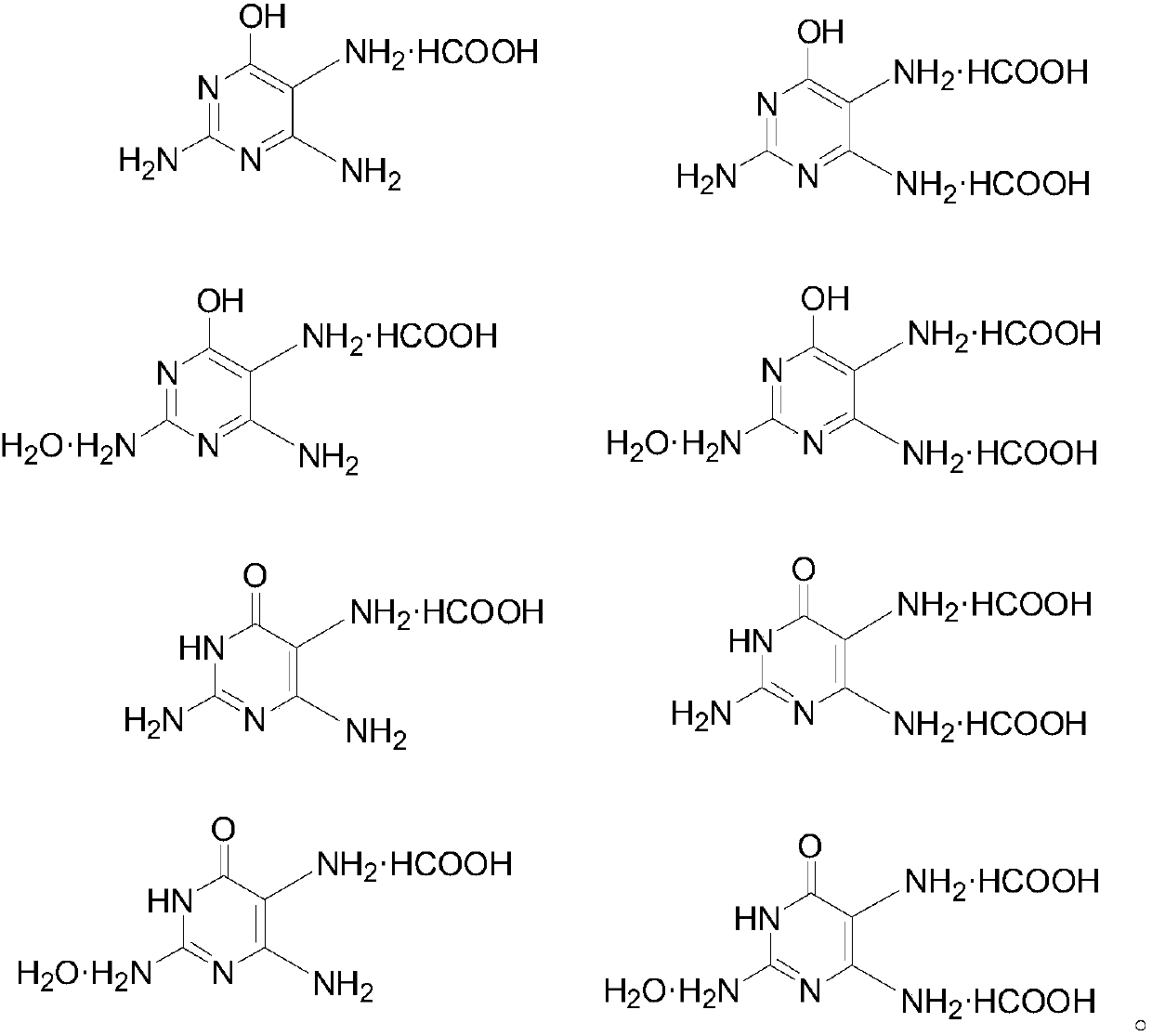

2,4,5-triamido-6-hydroxy pyrimidine formate, preparation method and application

The invention discloses 2,4,5-triamido-6-hydroxy pyrimidine formate and a preparation method. The preparation method comprises the following steps: enabling 2,4-diamido-5-nitro-6-hydroxy pyrimidine toreact with hydrogen in catalyst A and alkaline solution B, and obtaining 2,4,5-triamido-6-hydroxyl pyrimidine; and enabling a hydrogenation product to perform the salt forming reaction with formic acid to obtain 2,4,5-triamido-6-hydroxy pyrimidine formate. The invention discloses a method for preparing guanine by utilizing the 2,4,5-triamido-6-hydroxy pyrimidine formate. The preparation method isshort in production route, and high in molar yield, wherein the total molar yield is 90 percent or higher. The solvent can be recycled and generally used, the content of the salt and strong acid in the production wastewater can be greatly reduced, and the emission amount is little. The pyrimidine formate is a brand new compound. The pyrimidine formate is used for substituting the pyrimidine sulfate to prepare the guanine, so that a great amount of sulfate can be prevented from flowing into the production wastewater.

Owner:潍坊奥通药业有限公司

Breakfast grain food with spiced salt flavour

InactiveCN1457680ASimple production processShort production lineFood preparationVegetable oilCorn flour

The breakfast grain food in spiced salt flavor is produced with corn flour, rice powder, buckwheat powder, oat powder, separated soybean protein, soybean phosphatide, oat fiber, whole milk powder, sugar, vegetable oil and spiced salt seasoning. The breakfast grain food in spiced salt flavor has specially designed formula and is produced through extrusion in double-screw extruder and other apparatus. It is crisp, fragrant, spicy and rich in nutrients, and may be preserved for long time.

Owner:沐林营养科技(长沙)有限公司

Food sorting device

PendingCN107838043AStable sortingAccurate sortingPackaging automatic controlSortingStructural engineeringProcess engineering

The invention belongs to the field of food processing, and specifically relates to a food sorting device including a metal detection device, a weighing device and a check-out device; the check-out device is used for collecting results detected by the metal detection device and the weighing device according to specifications; the metal detection device includes a conveying frame provided with a first conveying belt, a metal detecting frame erected on a first conveying frame through bridge frame rods arranged at two sides of the first conveying frame, and a metal detector arranged on the metal detecting frame and located right above a middle section of the first conveying belt; the weighing device includes a weighing station provided with a second conveying belt and a weighing controller arranged at one side of the weighing station; the check-out device includes a conveying frame, a conveying belt, a protective edge and a sorting plate. The sorting device is simple, stable and accurate in sorting, high in sorting efficiency and low in false detection probability.

Owner:福清福荣食品有限公司

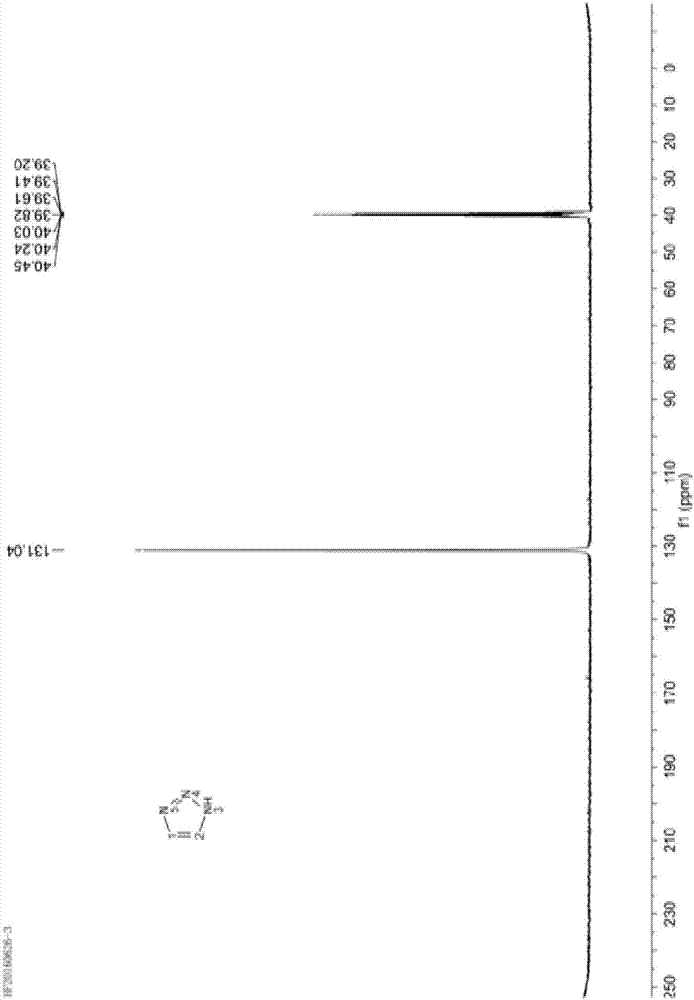

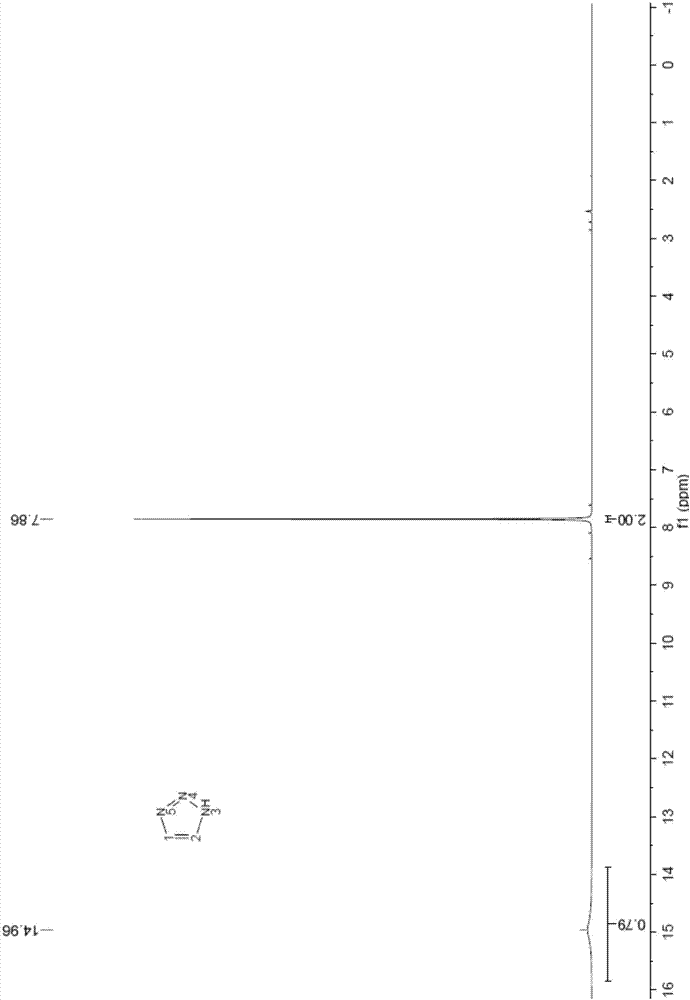

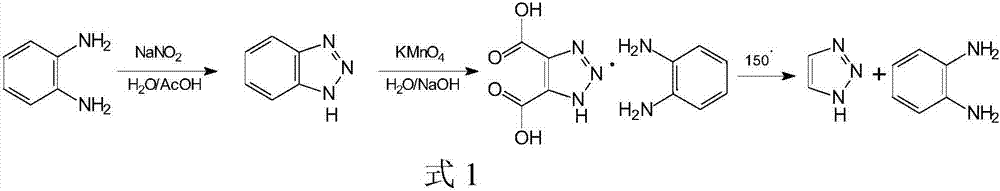

Preparation method of 1H-1, 2, 3-triazole

ActiveCN107382885AAchieve recyclingSuitable for industrialized mass productionOrganic chemistryCompound aProduction line

The invention discloses a preparation method of 1H-1, 2, 3-triazole. The preparation method comprises the following step: performing a reaction on a compound A and sodium nitrite in a solvent I, wherein the compound A is 1,2-diamido-ethylene, 1,2-diamido-ethylene salt or a mixture of 1,2-diamido-ethylene and 1,2-diamido-ethylene salt. Compared with the prior art, the preparation method has the beneficial effects that (1) a production line is short, the conversion rate of a target product is high, the utilization ratio of atoms is high, and the atom economy is high; (2) the molar yield is high, and the total molar yield is above 90%; (3) the solvent can be recycled and reused, and the discharge amount of waste water is very small; and (4) a production process is safe and controllable.

Owner:潍坊奥通药业有限公司

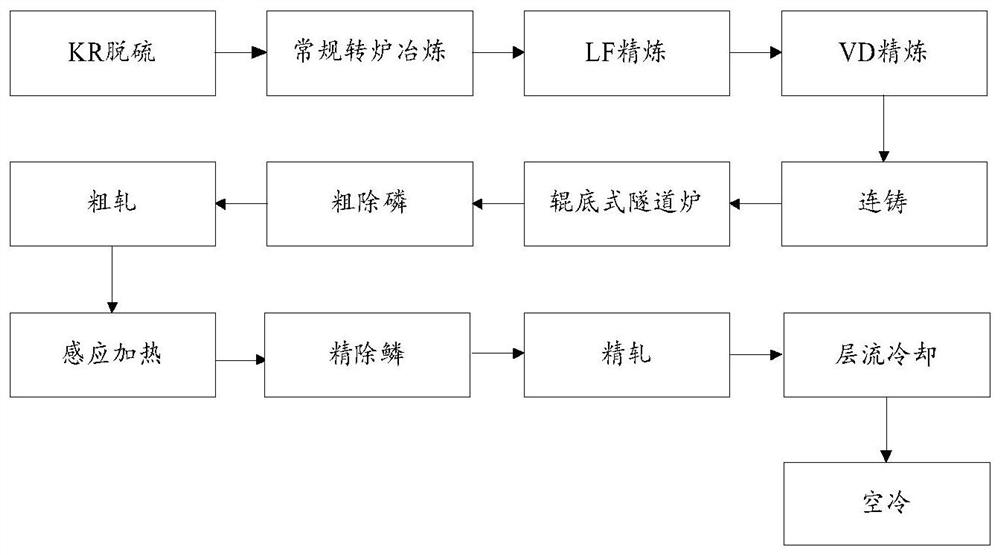

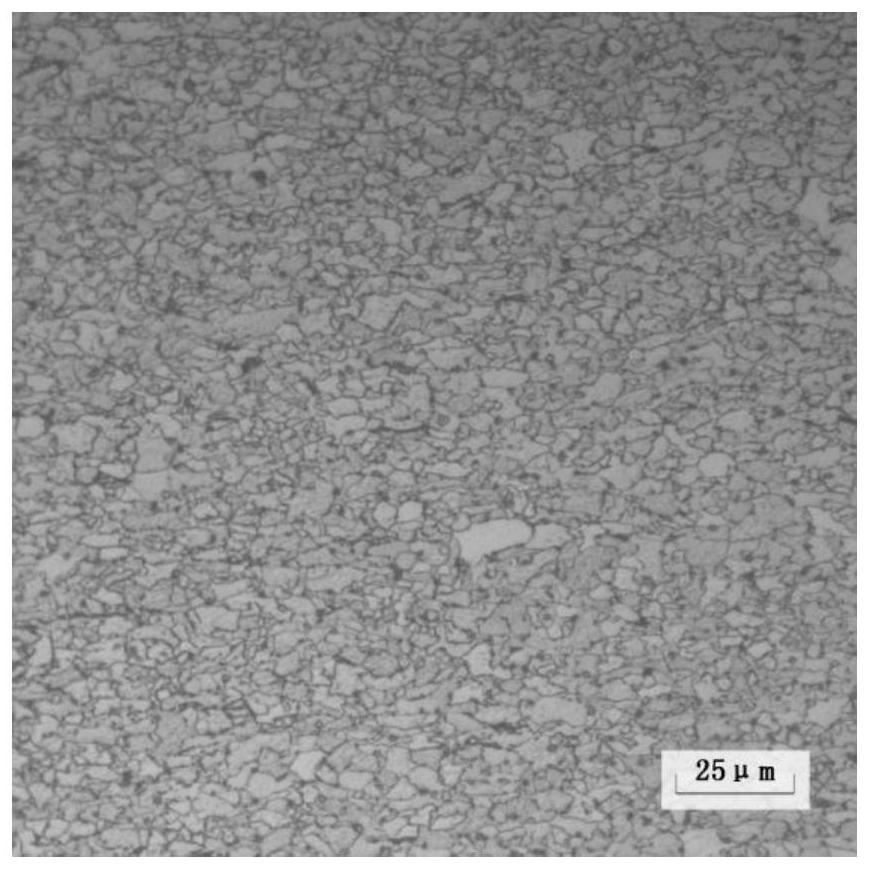

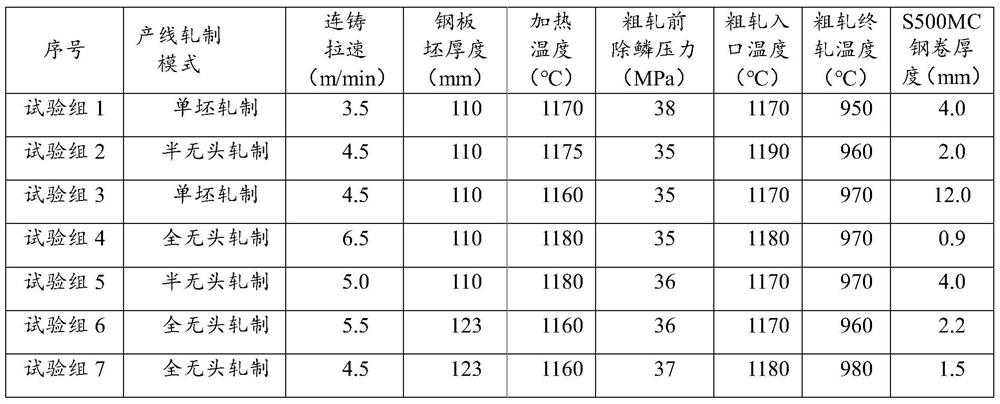

Method for preparing S500MC steel coil based on multi-mode sheet billet continuous casting and rolling production line, and product

InactiveCN111672907AImprove corner temperatureEliminate edge defectsTemperature control deviceWork treatment devicesProduction lineLaminar cooling

The invention belongs to the technical field of metal material processing, and particularly relates to a method for preparing an S500MC steel coil based on a multi-mode sheet billet continuous castingand rolling production line, and a product. The method for preparing the S500MC steel coil based on the multi-mode sheet billet continuous casting and rolling production line comprises the steps: smelting and continuous casting are conducted to obtain a sheet billet, the sheet billet is sequentially heated, subjected to scale removal before rough rolling, rough rolling, electromagnetic inductionheating, scale removal before finish rolling, finish rolling and laminar cooling, coiled and cooled, and the S500MC steel coil is obtained, wherein the sheet billet is prepared from the components inpercentage by mass: 0.03-0.15% of C, less than or equal to 0.05% of Si, 0.6-1.5% of Mn, 0.02-0.35% of Al, less than or equal to 0.010% of P, less than or equal to 0.005% of S, 0.01-0.10% of Nb, 0.015-0.15% of Ti, less than or equal to 0.005% of N, and the balance of iron and inevitable impurities. The method expands the thickness range of a final product of the S500MC steel coil and has the advantages of short production line, short process, energy conservation, emission reduction and cost lowering.

Owner:SHOUGANG CORPORATION

Preparation method for synthesizing anidulafungin intermittent ([1,1':4',1''-Terphenyl]-4-carboxylic acid, 4''-(pentyloxy)-) through one-step method

ActiveCN107759461AServing market needsHigh yieldOrganic compound preparationCarboxylic compound preparationBromobenzoic AcidsPalladium catalyst

The invention belongs to the field of compound preparation and discloses a preparation method for synthesizing an anidulafungin intermittent ([1,1':4',1''-Terphenyl]-4-carboxylic acid, 4''-(pentyloxy)-) through a one-step method. The method comprises the following steps: under a condition of an alkali solution, by taking N,N-dimethyl formamide as a solvent, catalyzing with a palladium catalyst, adding 4-bromobenzoic acid, 1,4-phenylenediboronic acid pinacol ester and 4-(n-pentyloxy) bromobenzene as raw materials, and performing an SUZUKI coupling reaction, thereby obtaining a target product, namely the anidulafungin intermittent ([1,1':4',1''-Terphenyl]-4-carboxylic acid, 4''-(pentyloxy)-). The raw materials used in the method are all industrial products available in the market, the raw materials are easily available, in addition, the steps are simple, the reaction conditions can be controlled, wastes are greatly reduced in the production process of the product, and chemical environmental-friendly requirements of the current society are met.

Owner:TIANJIN DERCHEMIST SCI TECH

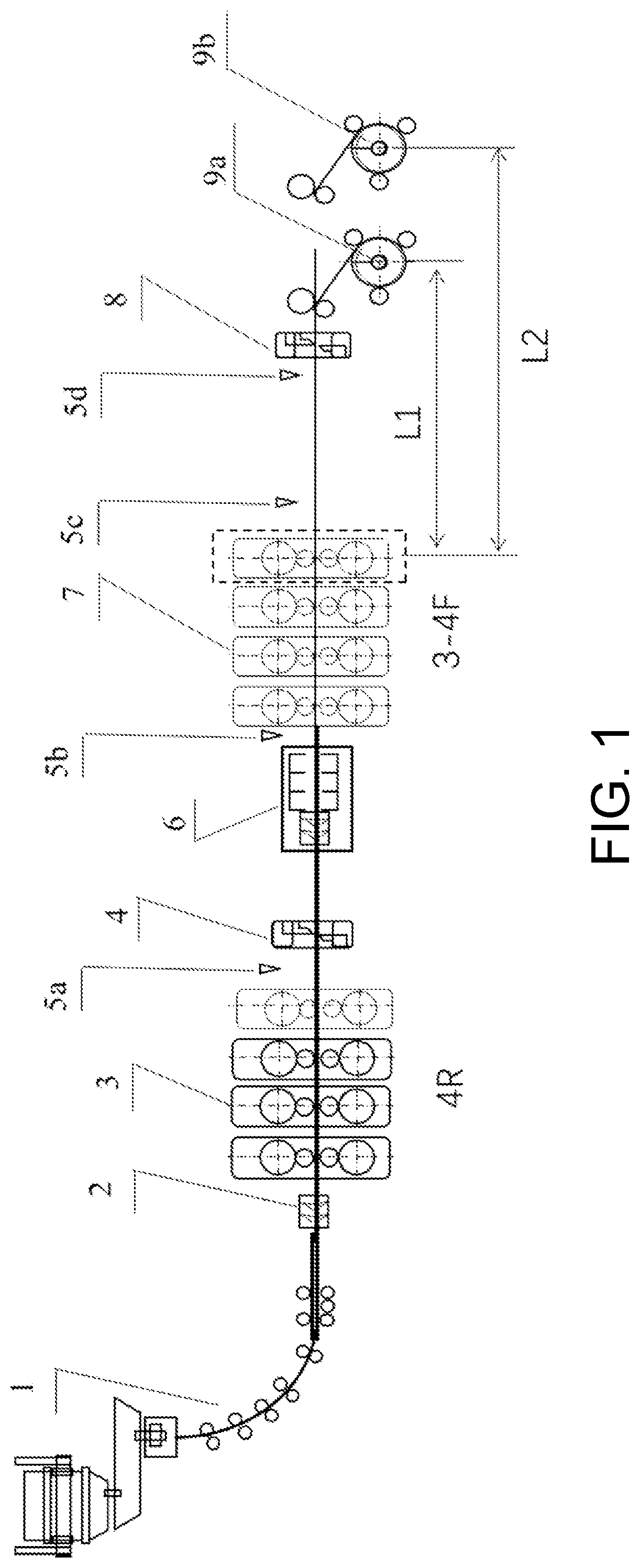

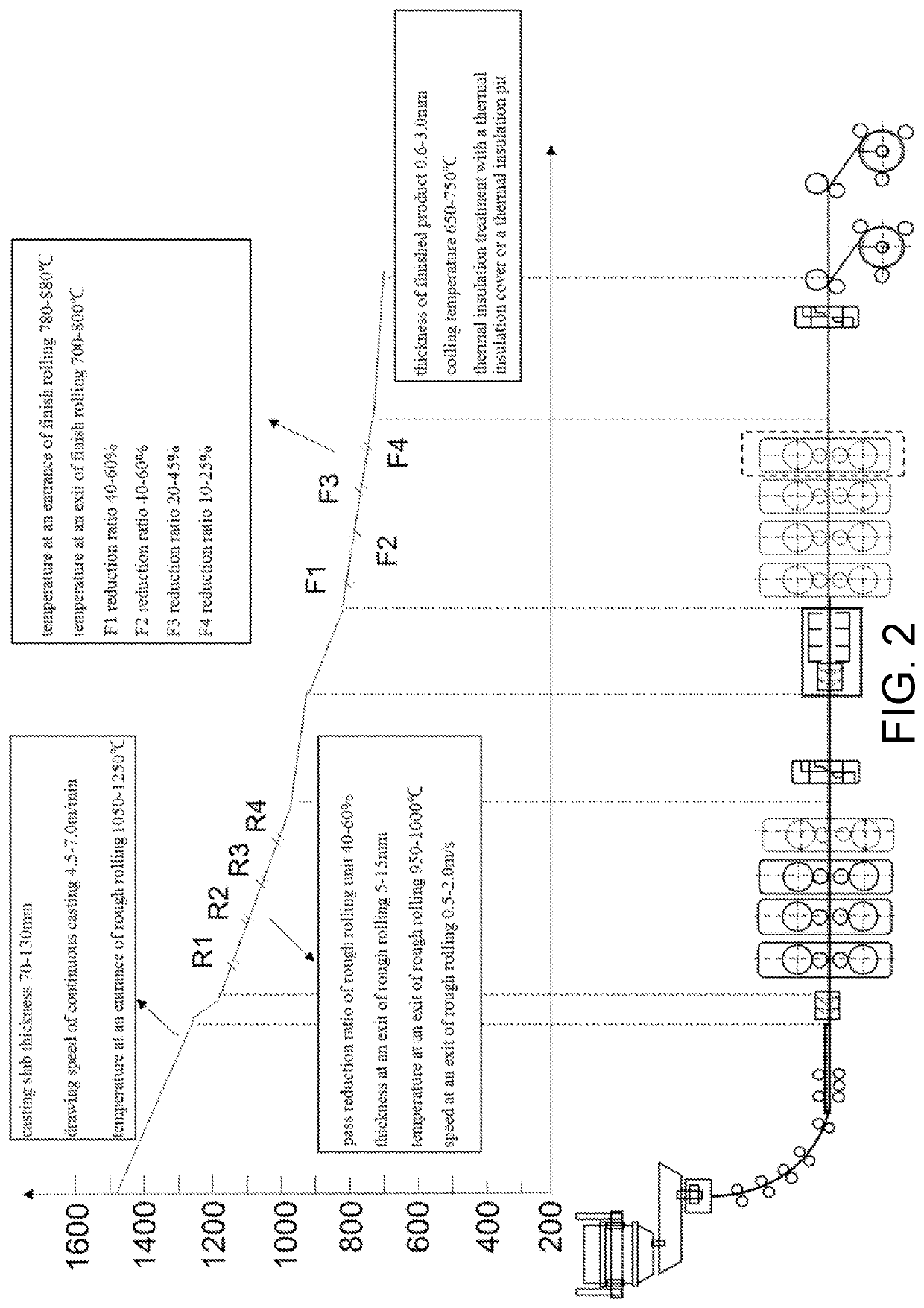

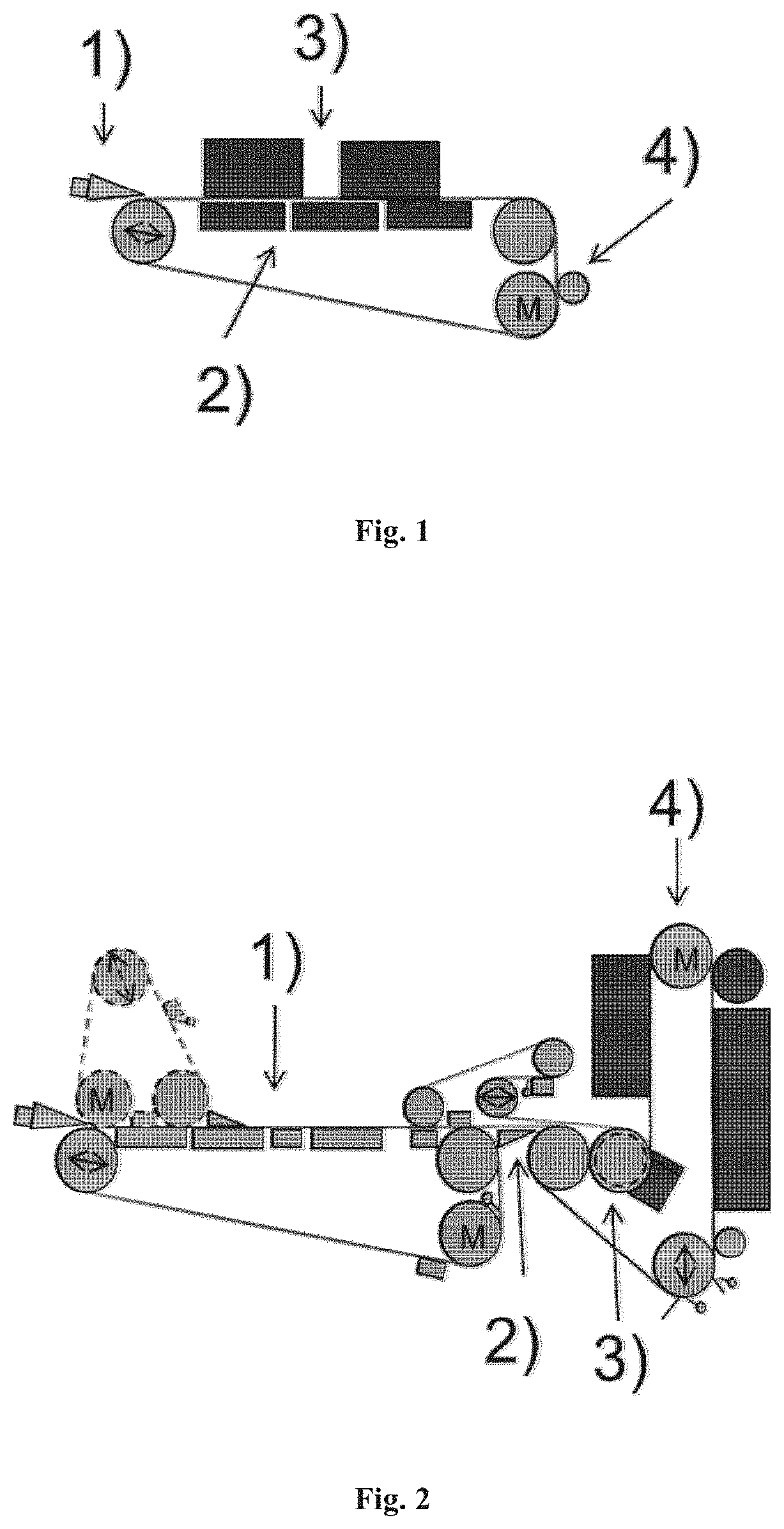

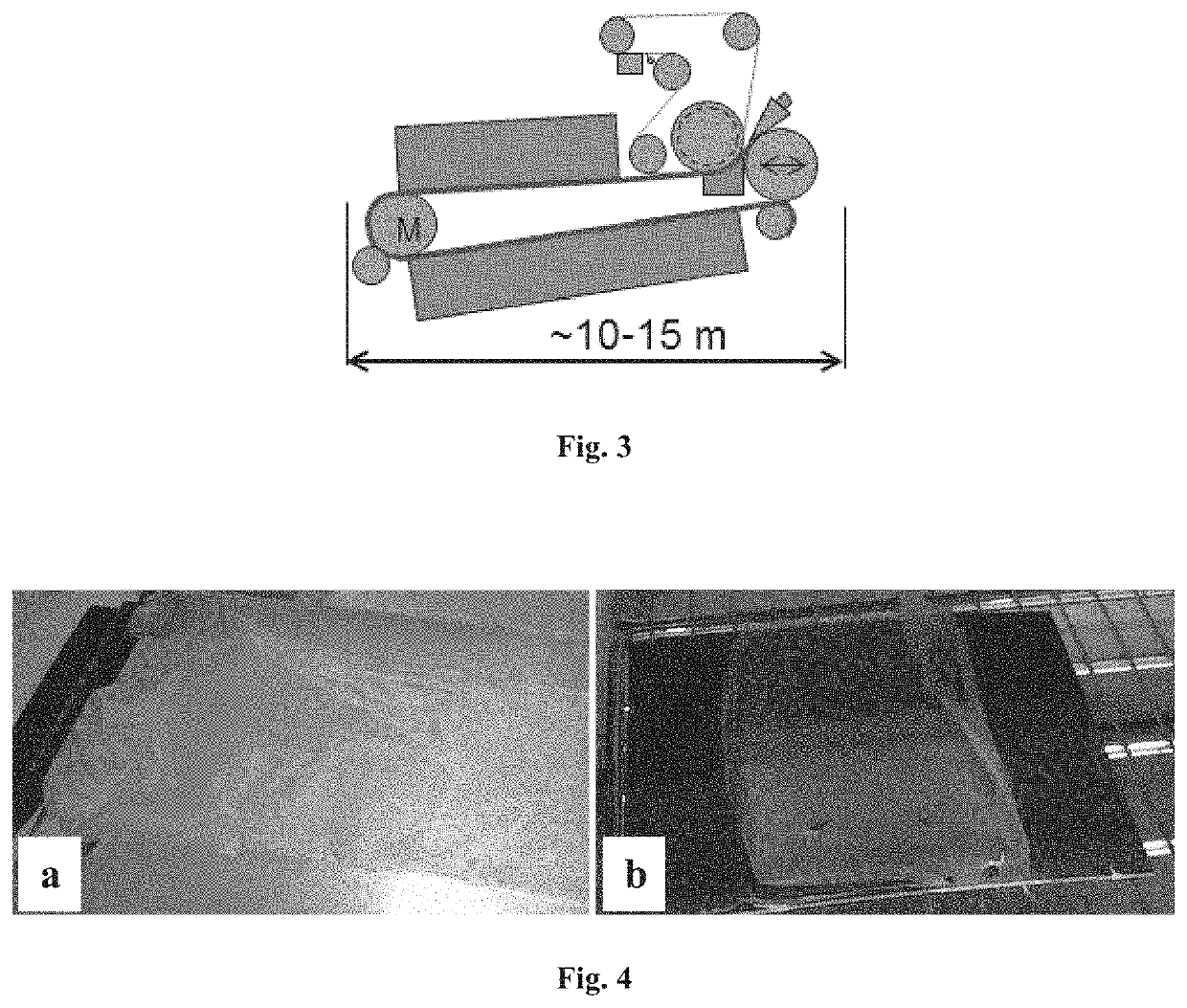

Endless hot-rolled strip production device and method for ferrite rolling

PendingUS20220152674A1Reasonable configurationPrecise temperature controlTemperature control deviceMeasuring devicesEngineeringHigh pressure water

The device has a short production line, and all components are reasonably configured. A multifunctional cooling control device is adopted to integrate high-pressure water descaling and intermediate billet cooling functions, which is simpler and more efficient. Layout of a 4R+(3−4)F rolling mill, four thermos-detectors and short-distance underground coilers are use. The method includes the steps: carrying out continuous casting to manufacture a slab, high-pressure water rotating descaling, rough rolling by a four-stand high reduction rough rolling unit, machining by a drum shear, cooling after high-pressure water descaling in the multifunctional cooling control device, finish rolling by a three-stand or four-stand finish rolling unit, air cooling, dividing coils by a high-speed flying shear, and coiling by underground coilers, wherein temperature monitoring is respectively carried out after rough rolling, before finish rolling, after finish rolling, and before coiling by the underground coiler.

Owner:WUHAN IRON AND STEEL CO LTD

Method for manufacturing high quality recombinant bamboo

InactiveCN104875249AHeating evenlyHigh speedLaminationLamination apparatusEngineeringEnergy consumption

The invention belongs to the field of fire doors, and particularly relates to a method for manufacturing high quality recombinant bamboo. The method comprises steps of firstly, selecting bamboo wood, secondly, uniformly paving the bamboo wood and applying glue on the bamboo wood to form a bamboo plate to be pre-pressed, thirdly, pushing the pre-pressed bamboo plate into a high frequency hot press, fourthly, pre-pressing the bamboo plate to be pre-pressed, fifthly, starting the high frequency hot press to manufacture a bamboo plate through high frequency hot pressing for 6 to 45 minutes, and sixthly, unloading pressure which is applied on the bamboo plate by an upper pressing plate and a side pressing plate after high frequency hot pressing, and sending the bamboo plate from the high frequency hot press. The high frequency hot press comprises a lower support board used for supporting a bamboo plate to be pre-pressed, an upper pressing plate used for pressing on the bamboo plate to be pre-pressed and a side pressing plate applying pressure on a side of the bamboo plate to be pre-pressed. The high frequency voltage is characterized in that a high frequency electric field can penetrate a base plate, so that the inner and the outer of the base plate can be synchronously and uniformly heated, the method is quick in speed and low in energy consumption, so the method is particularly suitable for hot-press gluing a bamboo plate with a large section.

Owner:ZHEJIANG YONGYU FURNITURE CO LTD

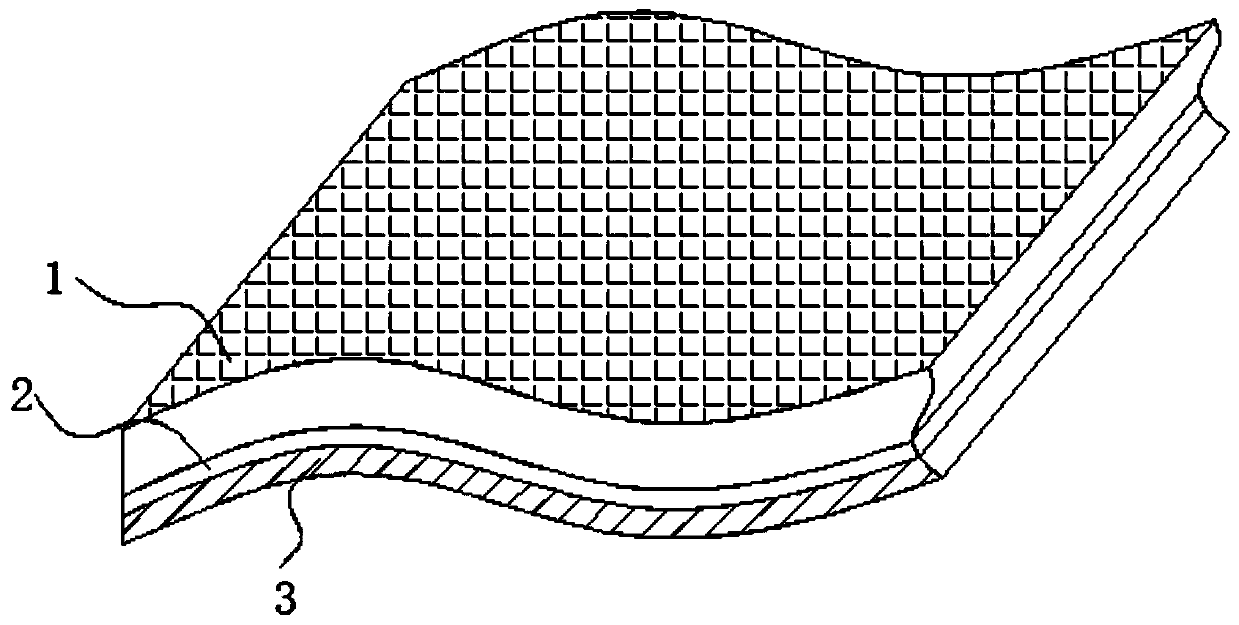

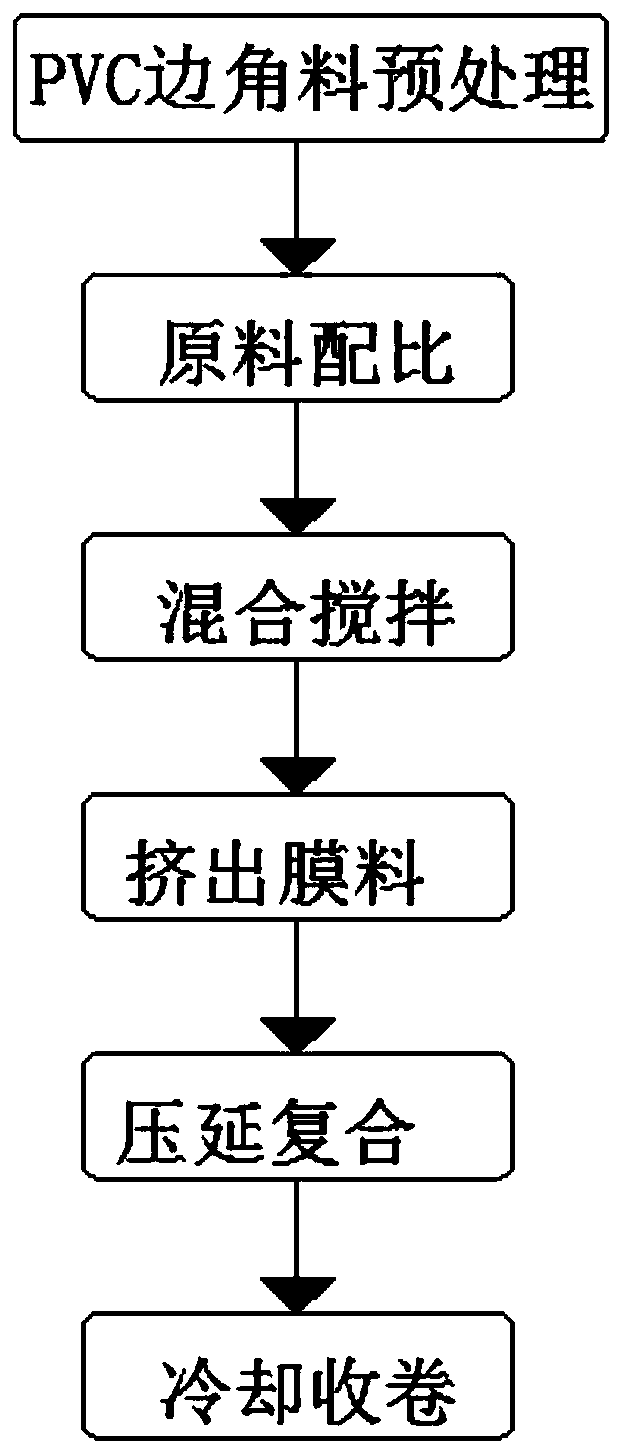

Novel environmental-protection calendered antiskid ground mat

InactiveCN109774201ASolve UtilizationModerate weightSynthetic resin layered productsFlat articlesProduction lineHigh energy

The invention discloses a novel environmental-protection calendered antiskid ground mat. The novel environmental-protection calendered antiskid ground mat comprises a non-woven carpet and a calenderedfilm; the calendered film is compounded at the bottom of the non-woven carpet through rotary calendering of a cold roller and a pressure roller; and a combination layer is formed in the compound position of the non-woven carpet and the calendered film. The novel environmental-protection calendered antiskid ground mat solves the utilization rate of PVC wastes, and enables waste leftovers to changevaluable things; meanwhile, through proper weight and good antiskid effect of the antiskid ground mat produced by the PVC wastes, persons are convenient to go indoors and outdoors, the carrying is easy, the manpower is saved, and the transportation cost is reduced; secondly, such high-energy-consumption equipment as a large boiler is not used in an antiskid ground mat machining process; and compared with gluing compound or scraping compound production processes for most existing ground mats, the antiskid ground mat is prepared through crushing and mixing of films and extrusion compounding, sothat the production line is short, labors are few, the production period is fast, and the environmental pollution is reduced.

Owner:山东新宜佳地毯有限公司

Toughened glass cutting and polishing integrated equipment

InactiveCN114671602AShort production lineIncrease productivityPolishing machinesGrinding feedersPolishingElectric machinery

The invention discloses the technical field of tempered glass processing, and relates to tempered glass cutting and polishing integrated equipment which comprises a U-shaped mounting base, a conveying mechanism, a first positioning mechanism, a pressing mechanism and a second positioning mechanism are arranged in the U-shaped mounting base, and a transverse cutting knife is rotationally connected to the inner side wall of the right end of the U-shaped mounting base. A first motor is fixedly connected to the position, on the right side of the transverse cutting knife, of the top end of the U-shaped mounting base, a first rotating rod is fixedly connected to the output end of the first motor, a rotating frame is slidably connected to the surface of the first rotating rod, and a longitudinal cutting knife is rotatably connected to the end of the rotating frame. According to the tempered glass cutting device, the transverse cutting knife and the longitudinal cutting knife are arranged, under the cutting action of two different directions, the joint cutting position of tempered glass is separated from the surface of the tempered glass, the cutting position is exposed, the tempered glass is immediately polished by the polishing roller, and therefore the production route is shortened, the cutting device can continuously work, and the production efficiency is improved.

Owner:天长市中凯玻璃实业有限公司

Method for rapidly manufacturing recombinant bamboo

InactiveCN104875269ACool evenlyUniform and further rapid coolingWood working apparatusFlat articlesEngineeringEnergy consumption

The invention belongs to the field of fire doors, and particularly relates to a method for rapidly manufacturing recombinant bamboo, wherein the method is uniform in heating process, quick in speed and low in energy consumption. The method comprises steps of firstly, selecting bamboo wood, secondly, uniformly paving the bamboo wood and applying glue on the bamboo wood to form a bamboo plate to be pre-pressed, thirdly, pushing the pre-pressed bamboo plate into a high frequency hot press, fourthly, pre-pressing the bamboo plate to be pre-pressed, and fifthly, starting the high frequency hot press to manufacture a bamboo plate through high frequency hot pressing for 6 to 45 minutes. The high frequency hot press comprises a lower support board used for supporting a bamboo plate to be pre-pressed, an upper pressing plate used for pressing on the bamboo plate to be pre-pressed and a side pressing plate applying pressure on a side of the bamboo plate to be pre-pressed. The high frequency voltage is characterized in that the high frequency electric field can penetrate a base plate, so that the inner and the outer of the base plate can be synchronously and uniformly heated, the method is quick in speed and low in energy consumption, so the method is particularly suitable for hot-press gluing a bamboo plate with a large section.

Owner:ZHEJIANG YONGYU FURNITURE CO LTD

Cellulose based film structure and method for producing the same

ActiveUS20200325626A1Quality improvementEasy to disassembleFlexible coversWrappersCellulosePolymer science

According to an example aspect of the present invention, there is provided a cost-effective method of producing cellulose based films by introducing an intense water removal system to the process, and cellulose based films thereof having improved properties.

Owner:TEKNOLOGIAN TUTKIMUSKESKUS VTT

Micro-filling film sealing machine provided with hydrophobic groove

InactiveCN103130164ASimple structureLow costLiquid fillingBottle-handling machinesProduction lineSmall footprint

The invention discloses a micro-filling film sealing machine provided with a hydrophobic groove. The micro-filling film sealing machine provided with the hydrophobic groove is mainly composed of an operating platform, a transmission system and a drive filling system, and the transmission system and the drive filling system are arranged on the operation platform. The micro-filling film sealing machine provided with the hydrophobic groove has the advantages of being simple in structure, low in cost, small in occupied area, and short in production line.

Owner:SICHUAN PHARMA

A preparation method of two-component modal polyester functional fabric

ActiveCN104480692BAvoid lostImproves crust effectSingeingBleaching apparatusPolyesterProduction line

The invention discloses a method for preparing a two-component modal polyester functional fabric. The invention uses an alkali-free treatment liquid in the cold pile treatment, which is not easy to produce wrinkles and indentations, does not need stacking and steaming, has a short production line, and uses amino The mixed system of trimethylene phosphonic acid, tin oxide, and water-soluble lanolin as a hydrogen peroxide stabilizer not only has a good bleaching effect, but also avoids fiber loss, and then effectively improves the hardness of modal fibers through fumigation and synergistic treatment. The skin effect can not only allow the reactive dyes to fully penetrate during dyeing or printing, ensure uneven coloring, but also have a good antibacterial effect. The fabric of the invention has a smooth and skin-friendly feel, and the preparation process is simple.

Owner:安徽中天新材料科技股份有限公司

Production method of glass wine distributor with handle based on cold cutting process

PendingCN112624596AStress reliefOptimize layoutGlass reforming apparatusDomestic vesselsProcess engineeringIndustrial engineering

The invention discloses a production method of a glass wine distributor with a handle based on a cold cutting process. The production method comprises the following steps: blowing and forming a wine distributor blank; carrying out cold cutting processing on the wine distributor blank to obtain a wine distributor primary finished product: carrying out cold and heat shock cutting on the wine distributor blank according to the size required by the process; cutting and grinding the primary finished product of the wine distributor to obtain a wine distributor semi-finished product; sealing the wine distributor semi-finished product and forming a wine pouring opening; arranging the handle on the wine distributor semi-finished product; and annealing, inspecting and packaging the wine distributor finished product. Compared with the prior art, the production process is more flexible, the production line is shorter and is more beneficial to factory arrangement, the labor can be effectively reduced, and the production quality can be improved by adopting a multi-step method to produce the wine distributor; and the cold cutting process is adopted, the cup opening of the manufactured wine distributor product is thinner, the attractiveness is better, and the problems that a bloated flanging line is formed at the cup opening in the hot cutting process and residues are left due to the flanging line are solved.

Owner:CHONGQING HECHUAN JINXING GLASS PROD CO LTD

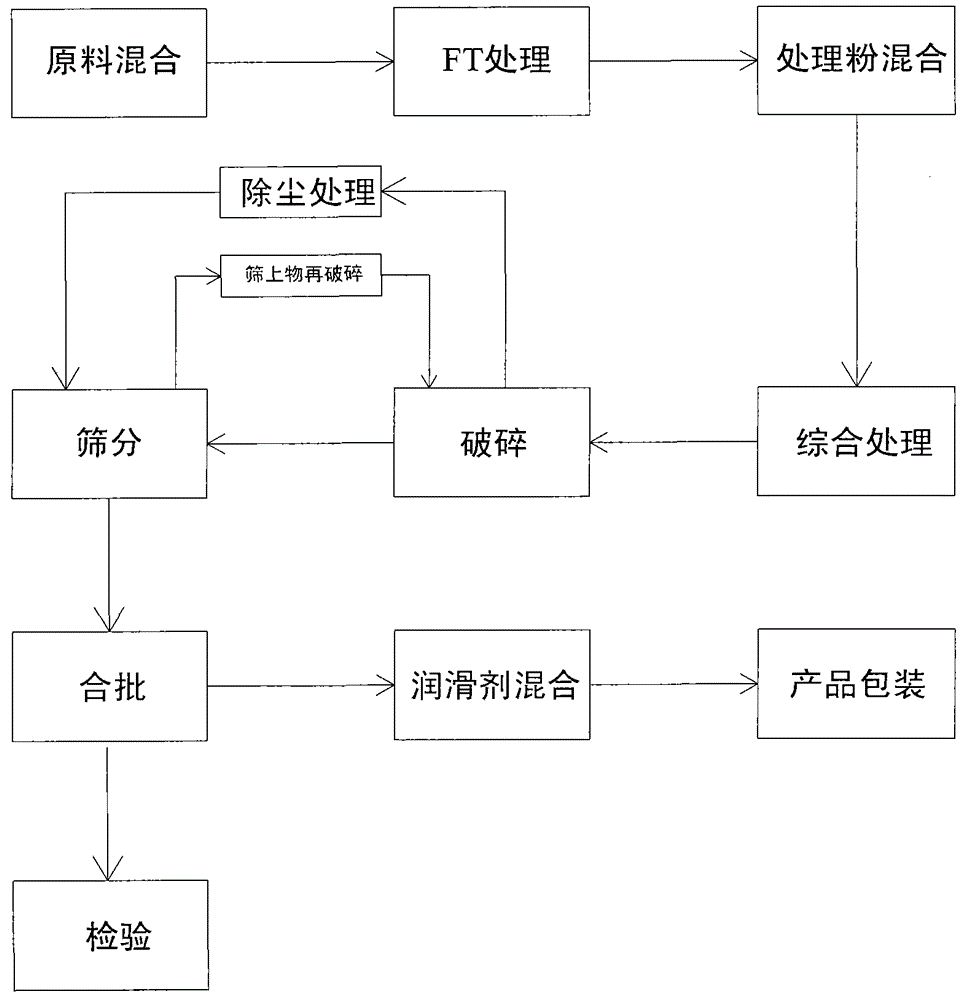

Production process of hak-2 diffusion pre-alloyed fe-mo-cu-ni powder

The invention discloses an iron-based powder production process and particularly relates to an HAK-2 diffusion prealloying Fe-Mo-Cu-Ni powder production process. According to the HAK-2 diffusion prealloying Fe-Mo-Cu-Ni powder production process, the hardness of power after sintering is 3 RB more than that of DB46, the compressibility is higher by 0.05g / cm3, a production route is short, and ingredients, process parameters and product quality are easy to control. The HAK-2 diffusion prealloying Fe-Mo-Cu-Ni powder production process sequentially comprises the steps of raw material mixing, FT treatment, treated powder mixing, comprehensive treatment, breaking, screening, blending, lubricant mixing and product packaging from left to right.

Owner:吉凯恩(霸州)金属粉末有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Preparation method for synthesizing anidulafungin intermittent ([1,1':4',1''-Terphenyl]-4-carboxylic acid, 4''-(pentyloxy)-) through one-step method Preparation method for synthesizing anidulafungin intermittent ([1,1':4',1''-Terphenyl]-4-carboxylic acid, 4''-(pentyloxy)-) through one-step method](https://images-eureka.patsnap.com/patent_img/31ac0688-2a46-4734-a53b-736fdbd65695/FDA0001461731410000011.png)

![Preparation method for synthesizing anidulafungin intermittent ([1,1':4',1''-Terphenyl]-4-carboxylic acid, 4''-(pentyloxy)-) through one-step method Preparation method for synthesizing anidulafungin intermittent ([1,1':4',1''-Terphenyl]-4-carboxylic acid, 4''-(pentyloxy)-) through one-step method](https://images-eureka.patsnap.com/patent_img/31ac0688-2a46-4734-a53b-736fdbd65695/BDA0001461731420000011.png)

![Preparation method for synthesizing anidulafungin intermittent ([1,1':4',1''-Terphenyl]-4-carboxylic acid, 4''-(pentyloxy)-) through one-step method Preparation method for synthesizing anidulafungin intermittent ([1,1':4',1''-Terphenyl]-4-carboxylic acid, 4''-(pentyloxy)-) through one-step method](https://images-eureka.patsnap.com/patent_img/31ac0688-2a46-4734-a53b-736fdbd65695/BDA0001461731420000031.png)