Patents

Literature

40results about How to "Increase the solidification rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sulphuric acid dew point corrosion resisting steel and method for producing same

InactiveCN101736202AShort Cooling IntensityStable temperatureProcess efficiency improvementElectric furnaceChemical compositionMolten steel

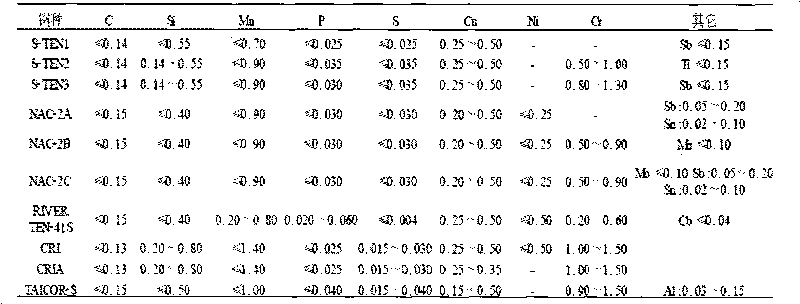

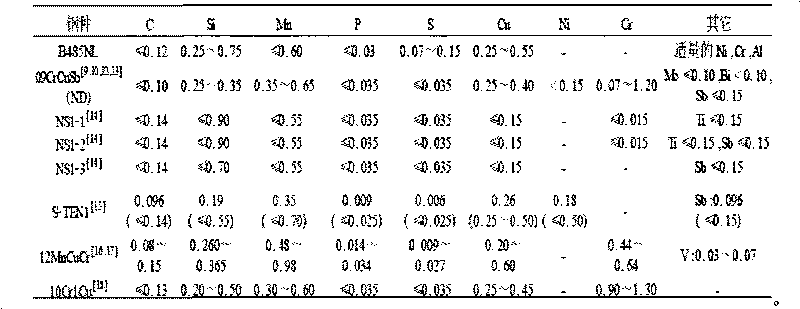

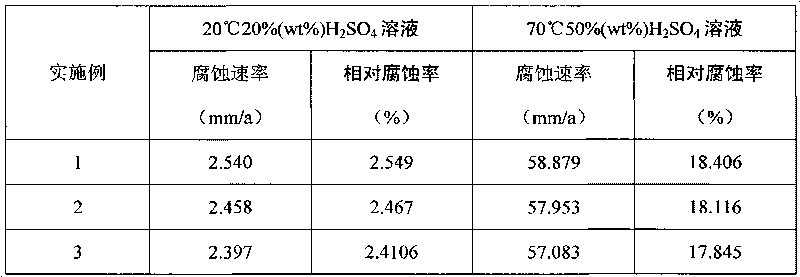

The invention discloses sulphuric acid dew point corrosion resisting steel and a method for producing the same by continuously casting and rolling a thin steel billet with an electric furnace. The molten steel comprises the following chemical components by weight percent: 0.03-0.08 percent of C, 0.10-0.45 percent of Si, 0.40-1.0 percent of Mn, 0.025 percent of P or less, 0.035 percent of S or less, 0.15-0.50 percent of Cu, 0.40-1.0 percent of Cr, 0.02-0.15 percent of Sb, 0.04-0.30 percent of Ni and 0.01-0.05 percent of Ti and also comprises 100ppm of N or less. The thin steel billet is continuously cast at the speed of 3.5-5.5m / min, and the cast thin steel billet is placed in the electric furnace of 900-1050 DEG C, soaked at 1100-1200 DEG C, rolled at 1040-1120 DEG C, finally rolled at 850-920 DEG C and winded at 550-650 DEG C. The Cu-Cr-Sb composite micro-alloyed sulphuric acid dew point corrosion resisting steel having good mechanical performance, welding performance and corrosion resisting performance can be produced by continuously casting and rolling the thin steel billet with the electric furnace.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

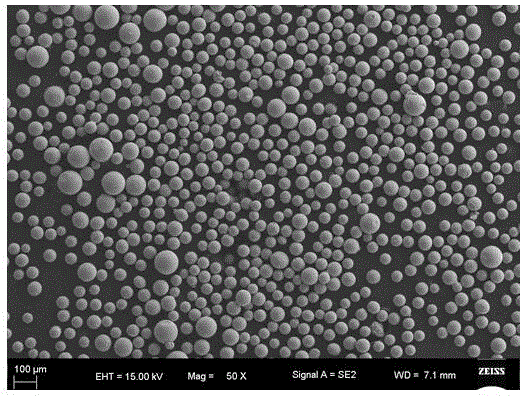

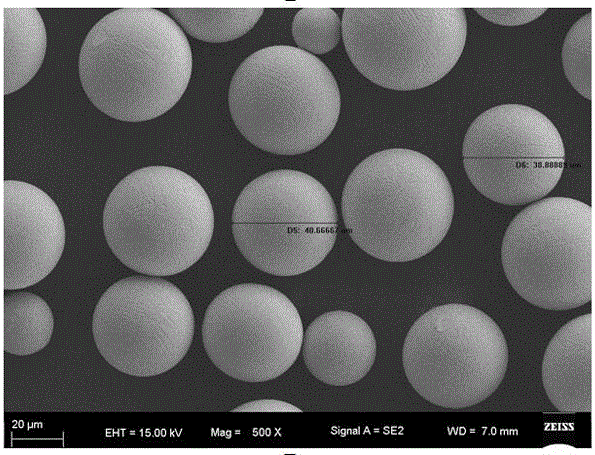

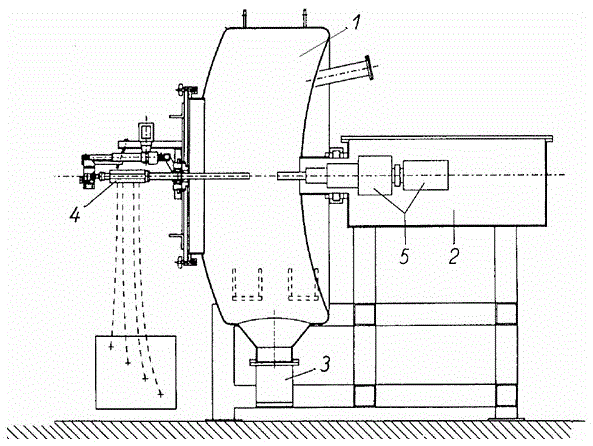

Preparation method of Waspalloy spherical powder for additive manufacturing

InactiveCN106623959AFast pure meltingReduce the introductionAdditive manufacturing apparatusTransportation and packagingVacuum pumpingElectrostatic separation

A preparation method of Waspalloy spherical powder for additive manufacturing includes the steps of conducting alloy component compounding according to AMS 5706 standards and subjecting master ingots to vacuum melting twice; producing the master ingots into alloy electrode bars by means of forging and machining; subjecting an atomizing unit to pre-vacuum-pumping treatment, and feeding the atomizing unit with mixed inert protective gas; feeding the electrode bars into an atomizing chamber by a feeding system, heating electrode bar end faces by a plasma torch, preparing metal liquid droplets under the centrifugal action of a rotating electrode, and making the metal liquid droplets form spherical metal powder by flash setting; using a powder collecting device comprising an electrostatic separation component for removing inclusions of the spherical metal powder and collecting purified powder. The preparation method has the advantages of high production efficiency, high batch stability and high -270-mesh powder yield and can be used for easily preparing the Waspalloy spherical powder high in purity, sphericity and fluidity.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

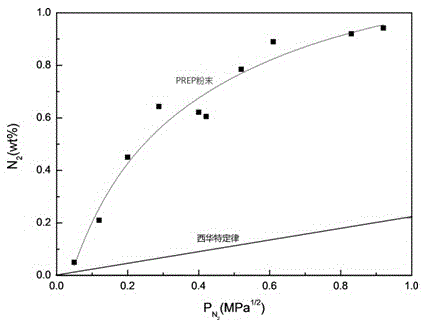

Preparation method of high-nitrogen stainless steel spherical powder

InactiveCN105618776AEnhance nitrogen increase rateIncrease powder nitrogen contentStainless steel electrodeMetal impurities

The invention provides a preparation method of high-nitrogen stainless steel spherical powder. The preparation method comprises the following steps: preparing materials according to stainless steel components and carrying out a melting process of a mother alloy ingot; preparing the mother alloy ingot into a common stainless steel electrode bar through forging and machining; carrying out pre-vacuumizing treatment on atomization equipment and introducing high-purity nitrogen gas; conveying the electrode bar into an atomization chamber through a feeding system and heating the end face of the electrode bar by using a plasma torch; ionizing the nitrogen gas in an electric arc region into nitrogen ions, high-energy nitrogen molecules and un-ionized nitrogen neutral atoms so as to improve the nitrogen content of stainless steel; preparing metal liquid drops by using a centrifugal effect of a rotary electrode and instantly condensing the metal liquid drops into spherical metal powder; after cooling the high-nitrogen stainless steel spherical powder, removing non-metal impurities through an electrostatic impurity removing device; and finally, carrying out powder package by adopting multilayered vacuum heat sealing. The preparation method of the high-nitrogen stainless steel spherical powder has the characteristics of high production efficiency, strong batch stability, high fine powder yield and the like; and the stainless steel spherical powder with high nitrogen content, good purity, strong mobility and smooth and clean surface can be easily prepared.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

Solidification method for preparing para-aramid by adopting dry jet-wet spinning

InactiveCN104451935AIncrease productivityIncrease production speedArtificial filament washing/dryingWet spinning methodsUltimate tensile strengthAramid

The invention provides a solidification method for preparing para-aramid by adopting dry jet-wet spinning. The method is characterized by comprising the following specific steps: extruding a PPTA-H2SO4 spinning solution from a spinneret plate; enabling liquid flow extruded from the spinneret plate to vertically pass through an air layer and feeding to a solidification bath; leading out through a godet wheel, so as to obtain a nascent fiber; and washing, winding and drying, so as to obtain a para-aramid fiber precursor, wherein the solidification bath is sulfuric acid solution and is formed by sulfuric acid and water; the mass fraction of the solidification bath is 2.0%-15.0%; and the temperature of the solidification bath is 1-12 DEG C. The fineness of the fiber can be significantly reduced under the condition of the solidification bath; the strength of the para-aramid fiber is improved; the apparent defects of the fiber can be reduced; and the fiber quality is improved, thus the stability of a spinning process and the quality of a fiber product can be effectively improved.

Owner:DONGHUA UNIV

Method for refining laser additive manufacturing titanium alloy grain through ultrasonic impact and induction heating

InactiveCN107649682AGrain refinementImprove fatigue strengthAdditive manufacturing apparatusIncreasing energy efficiencyRoom temperatureCrystal structure

The invention provides a method or refining a laser additive manufacturing titanium alloy grain through ultrasonic impact and induction heating. On the basis of a laser additive manufacturing titaniumalloy technology, combination of ultrasonic impact and induction heating is adopted to refine the titanium alloy grain, after laser cladding is conducted to form a layer, an ultrasonic impact deviceis utilized to process the cladding layer, when a multi-layer sample part is formed, laser cladding and ultrasonic impact are conducted alternately so that the cladding layer can be subjected to medium temperature plastic deformation, thus a plastic deformation layer with the certain thickness can be formed, coarse columnar crystal structures in the deformation layer form deformation subgrain or textured microstructures along with increasing of the dislocation density, and accordingly the cladding layer structure is refined. The problems that the deformation resistance is large, the plasticityat the normal temperature is poor, the deformation resilience is large, and deformation is prone to generating defects such as cracks in the plastic processing process of the titanium alloy in a coldstate are solved. Meanwhile, refining of the laser additive manufacturing titanium alloy grain is achieved by utilizing ultrasonic impact, the prominent problems that the laser additive manufacturingtitanium alloy columnar crystal is coarse, and the anisotropy is obvious are solved, and the comprehensive mechanical properties of the titanium alloy are improved.

Owner:XI AN JIAOTONG UNIV

Preparation process for quasi-crystal particles reinforced aluminum base composite material

A process for preparing pseudo crystal granule reinforced magnesium group composite material, wherein the process for preparing AlCuFe pseudo crystal particles comprises the steps of, preparing powder, obtaining 20-100 um pseudo crystal particles after screening, with its composition being Al, Cu, Fe, after base stock melting, charging reinforced particles into alloy fondant for full mixing, depositing on the base stock along with the atomization alloy solid-liquid mixing at the atomizing action, finally the granule reinforced magnesium group composite material with even reinforced particle size distribution and fine base metal crystal grains can be prepared.

Owner:SHANGHAI JIAO TONG UNIV

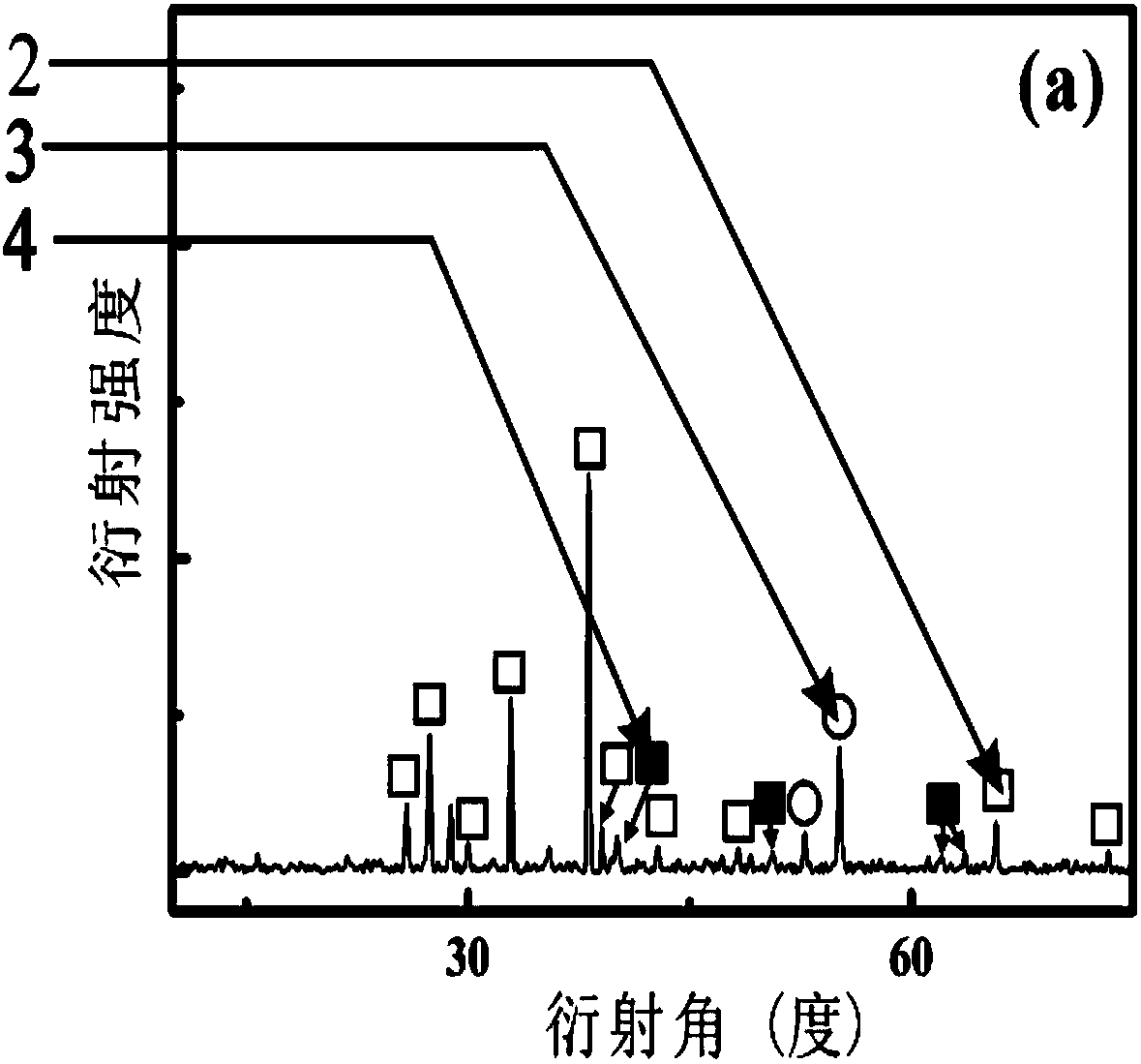

Solidification preparation method for aluminum oxide-based ternary nanometer eutectic/amorphous ceramic

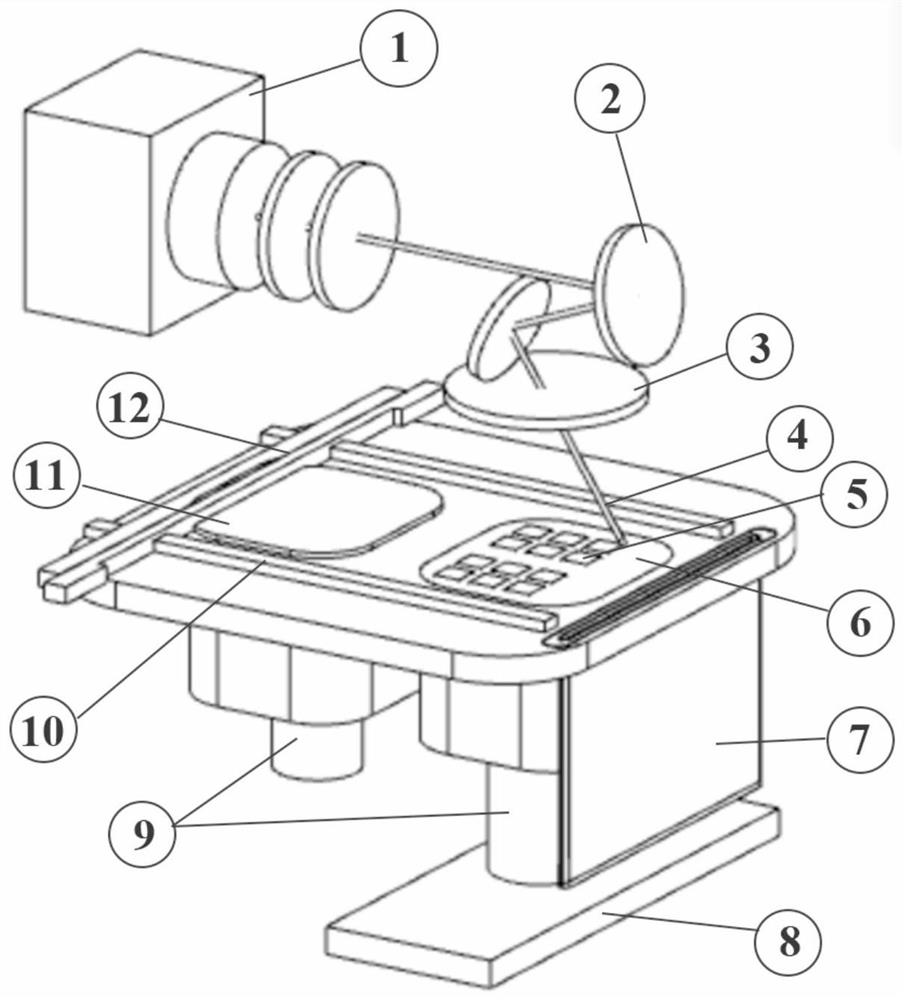

ActiveCN107663081AIncrease the solidification rateWide range of solidification ratesDirectional solidificationOxide

The invention relates to a solidification preparation method for aluminum oxide-based ternary nanometer eutectic / amorphous ceramic. A laser floating zone-melting directional solidification device is adopted for preparing an oxide ceramic material, and the heating capacity, relative moving capacity and combination with liquid metallic quenching phase of the laser floating zone-melting directional solidification device are utilized to quickly cool the melt and acquire the nanometer eutectic / amorphous ceramic in a wide solidification rate range. According to a melt falling liquid metal quenchingmethod based on a laser floating zone-melting directional solidification method provided by the invention, the ultrahigh cooling speed can be achieved at the moment of leaving the laser irradiation, namely, falling into the liquid metal for quenching, the cooling rate distribution spans at least four orders of magnitudes (10-10<6> micron / s), the solidification structure is abundant and the preparation for oxide nanometer eutectic / amorphous ceramic is easily realized.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for preparing nickel-based abrasion resisting and corrosion resisting coating through ultrahigh-rate laser cladding

InactiveCN108165982AGuaranteed performanceIncrease the solidification rateMetallic material coating processesOptoelectronicsCorrosion resistant

The invention relates to a method for preparing a nickel-based abrasion resisting and corrosion resisting coating through ultrahigh-rate laser cladding, and belongs to the technical field of surface treatment. Through the methods that proper nickel-based powder is selected, the positions of powder gathering points and laser focus points are adjusted, and technology parameters are adjusted, the defect-free abrasion resisting and corrosion resisting coating with the good surface flatness and small thickness can be rapidly and accurately produced, ultrahigh-rate laser cladding is achieved, and the purposes of improving the production efficiency and saving the production cost are achieved.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

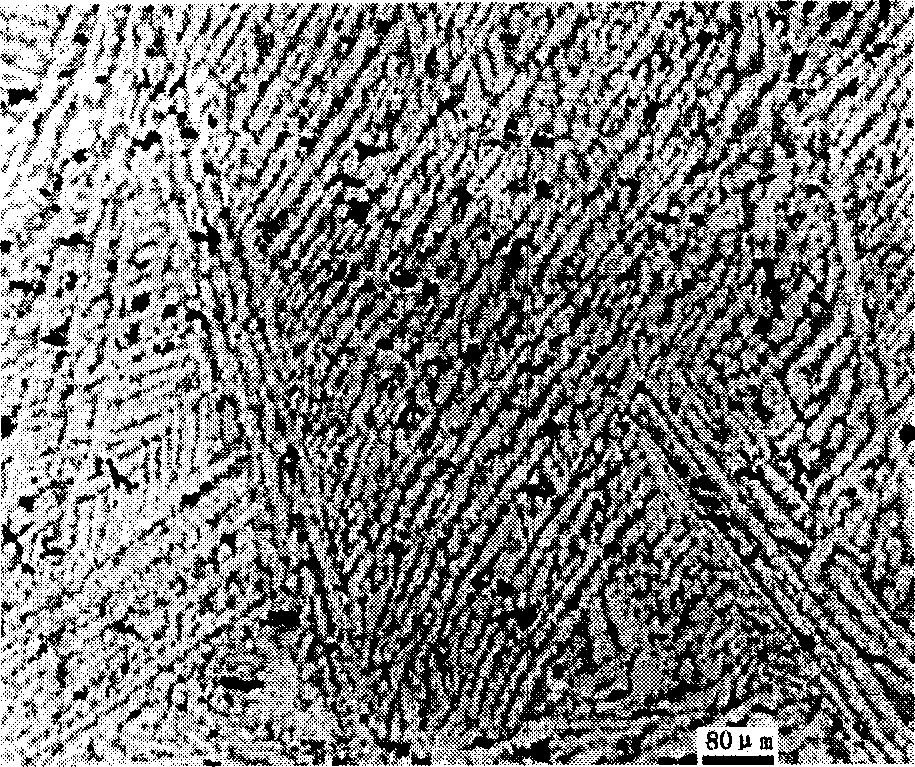

Assistant alloy for Nd-Fe-B permanent magnetic material and its preparation method

ActiveCN1805073AIncrease the solidification rateImprove efficiencyInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementHeat flow

The invention relates to an auxiliary alloy of neodymium iron boron permanent magnetic material and relative one-way control heat flow preparation method. The invention is characterized in that: said auxiliary alloy comprises one or several rare-earth elements, whose total amount is between 30-60wt%, and the other is transition group and one or several kinds of other metallic elements. The producing method comprises: melting raw material to cast the rotational water cooling disc; the rotational water cooling disc forces the water cooling to control the one-way hot flow direction to form the auxiliary alloy with fine cylinder crystal solidified organism. Compared to traditional neodymium iron boron auxiliary alloy producing method, the invention has high producing efficiency, non-component error analysis, uniform solidified organism, easy breakage and high magnetic property without uniform heating process.

Owner:LESHAN YOUYAN RARE EARTH NEW MATERIAL CO LTD

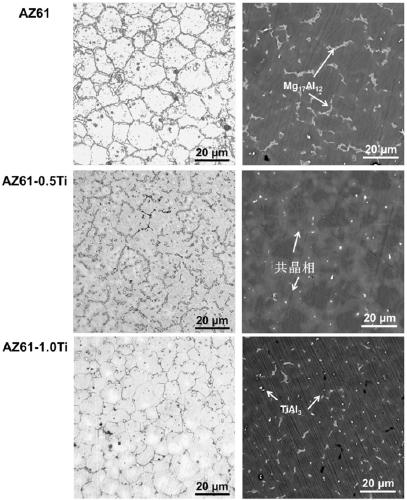

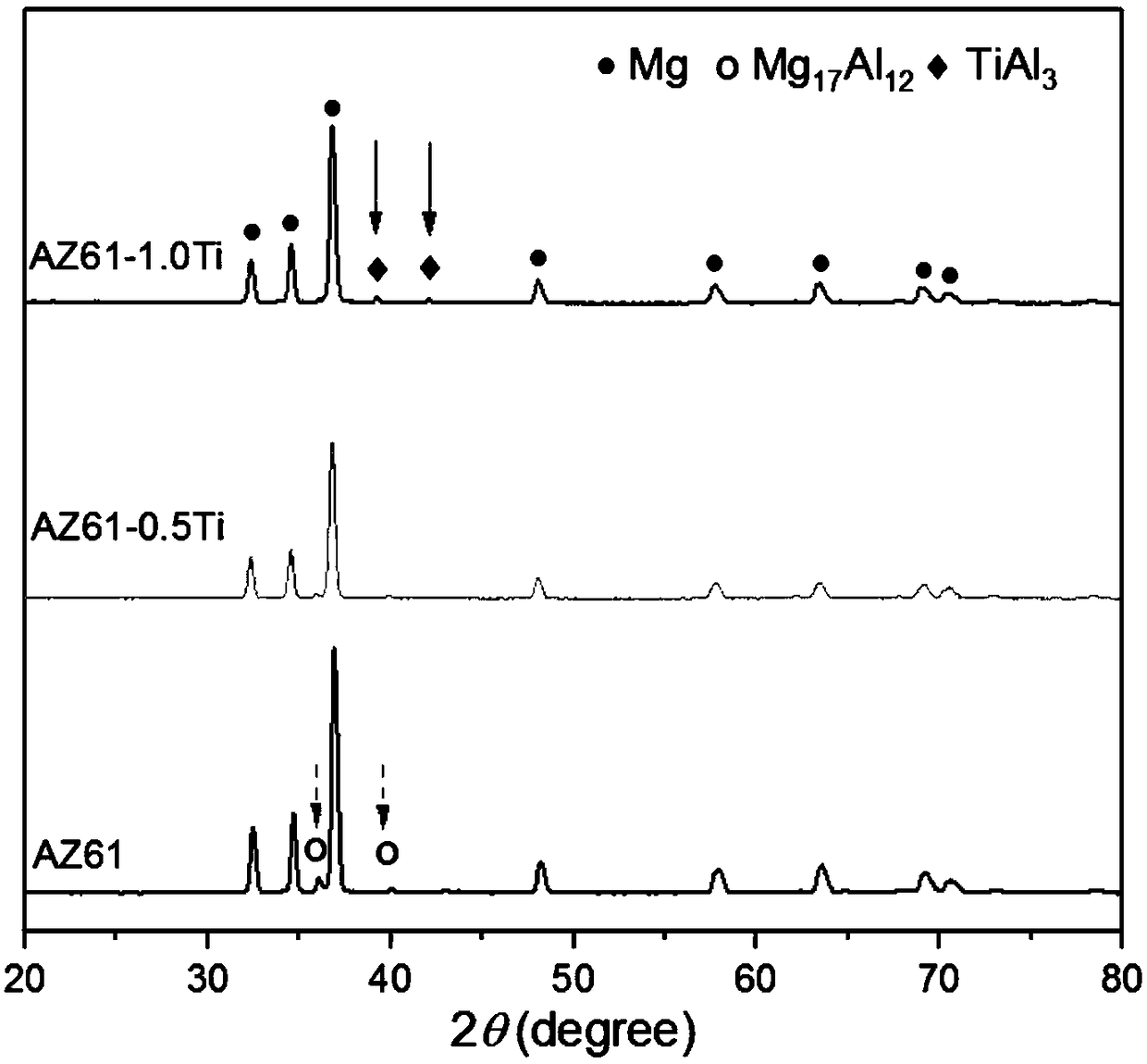

Magnesium-aluminum alloy with continuous eutectic structure and preparation method thereof

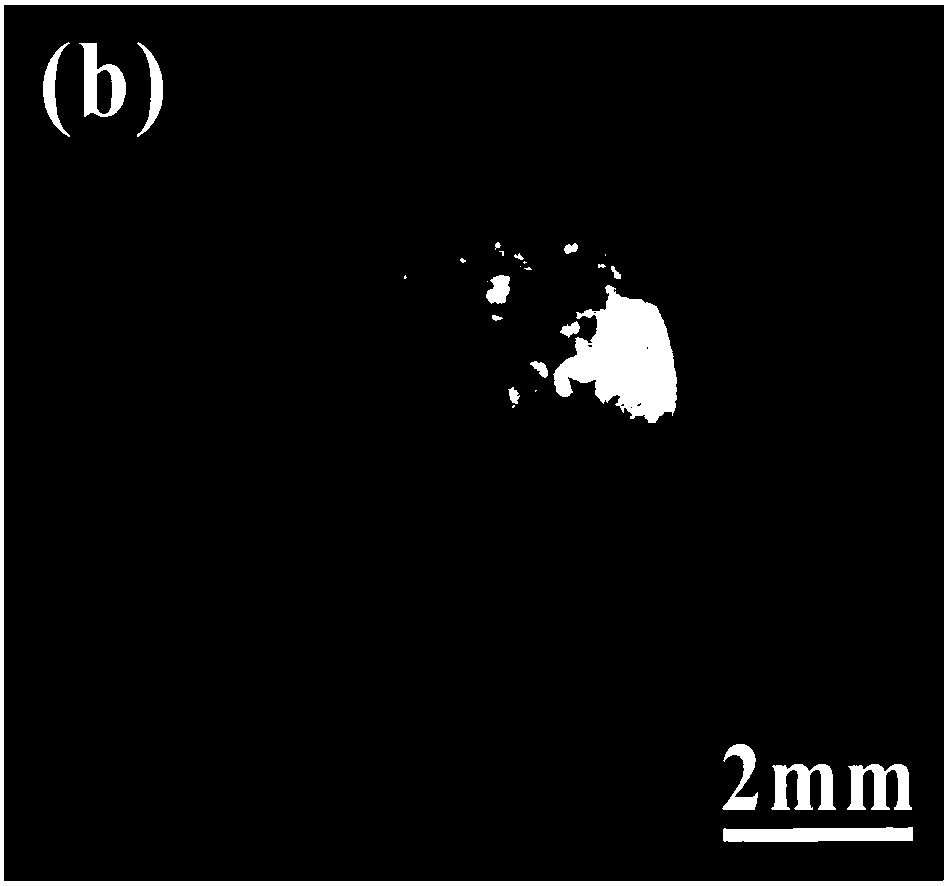

ActiveCN108950334AImprove corrosion resistanceIncrease the solidification rateSelective laser meltingMelting tank

The invention discloses a magnesium-aluminum alloy with continuous eutectic structure and a preparation method thereof, and the alloy is composed of a magnesium-aluminum alloy matrix and a continuouseutectic phase distributed at the grain edge of the matrix. The preparation method comprises the following steps that (1) nano-sized titanium powder and the magnesium-aluminum alloy powder are placedin a ball mill, and ball milling is conducted under protective atmosphere to obtain the mixed powder; and (2) the mixed powder is used as a raw material, and the magnesium-aluminum alloy with the continuous eutectic structure is prepared through selective laser melting under the protective atmosphere. According to the preparation method, the titanium is introduced in the magnesium-aluminum alloy preparation process, aluminum atoms in a molten pool are attracted to migrate, and eutectic reaction is generated on the edge of the crystal grain to generate the continuous eutectic phase; meanwhile,the characteristic that the selective laser melting solidification speed is high is utilized, the formation of the continuous eutectic phase is promoted while the content of a second phase Mg17Al12 isreduced, so that galvanic corrosion effect of the magnesium aluminum alloy is effectively weakened, and the corrosion resistance of the magnesium-aluminum alloy is improved; and meanwhile, better interface combination is achieved, so that the mechanical property of the magnesium-aluminum alloy is improved.

Owner:CENT SOUTH UNIV

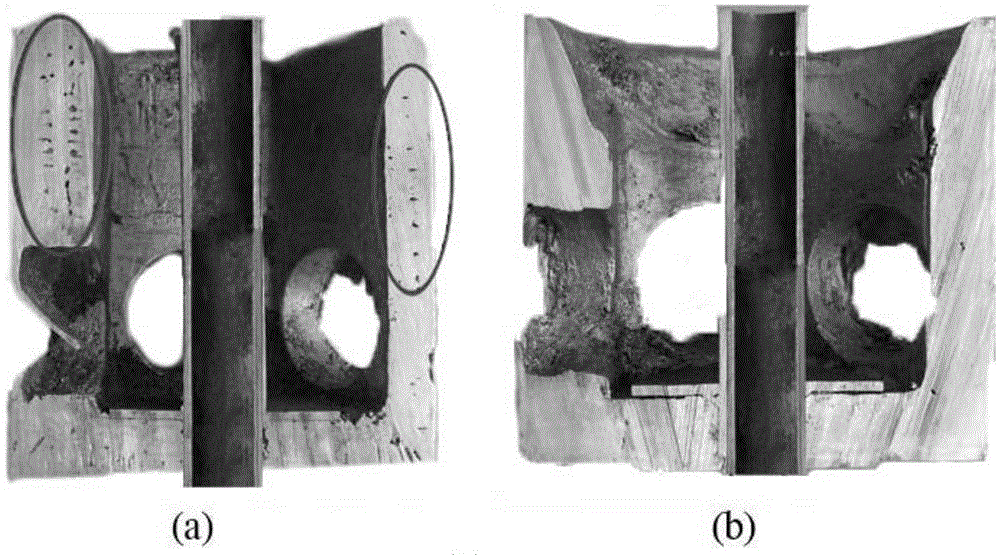

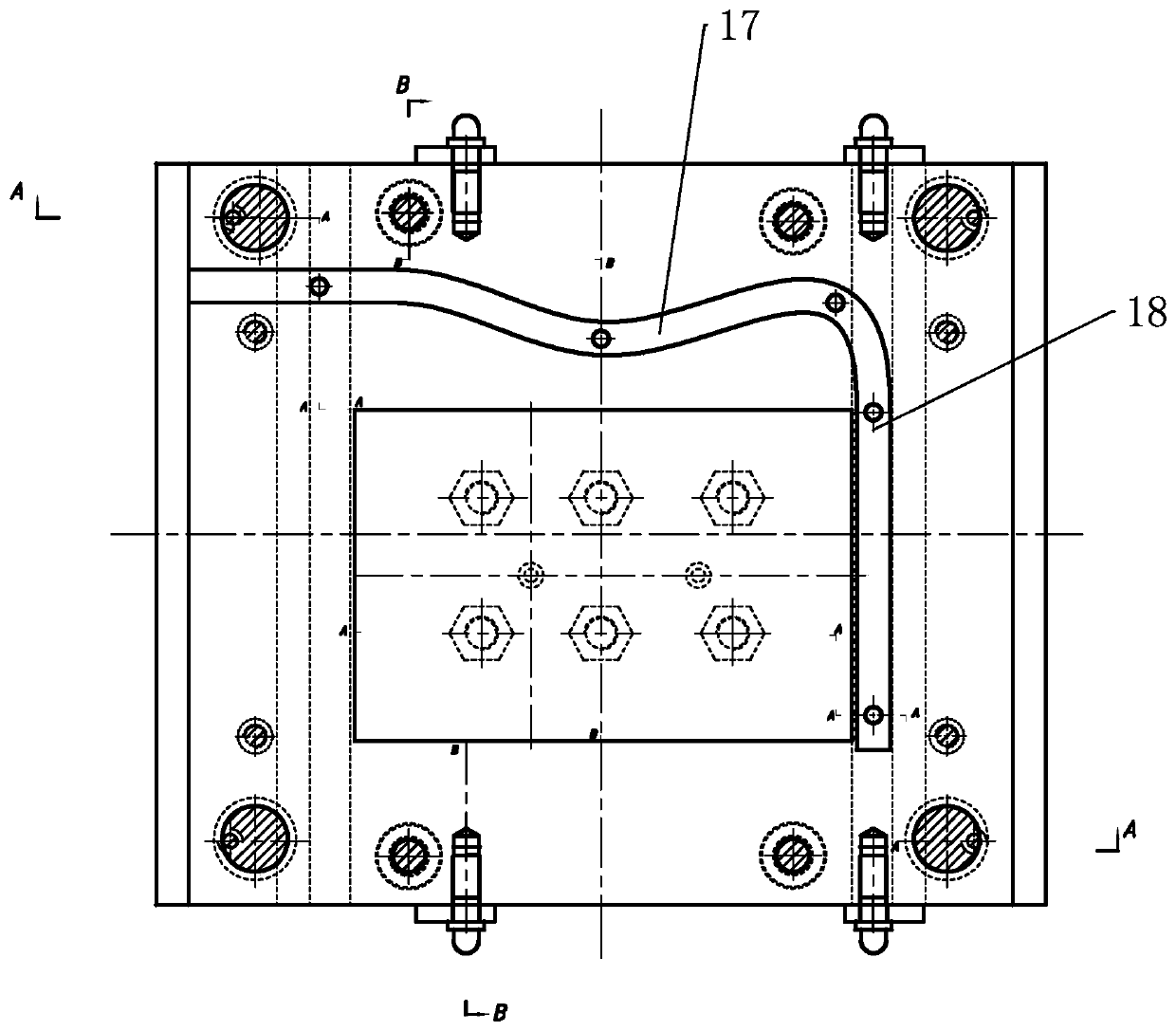

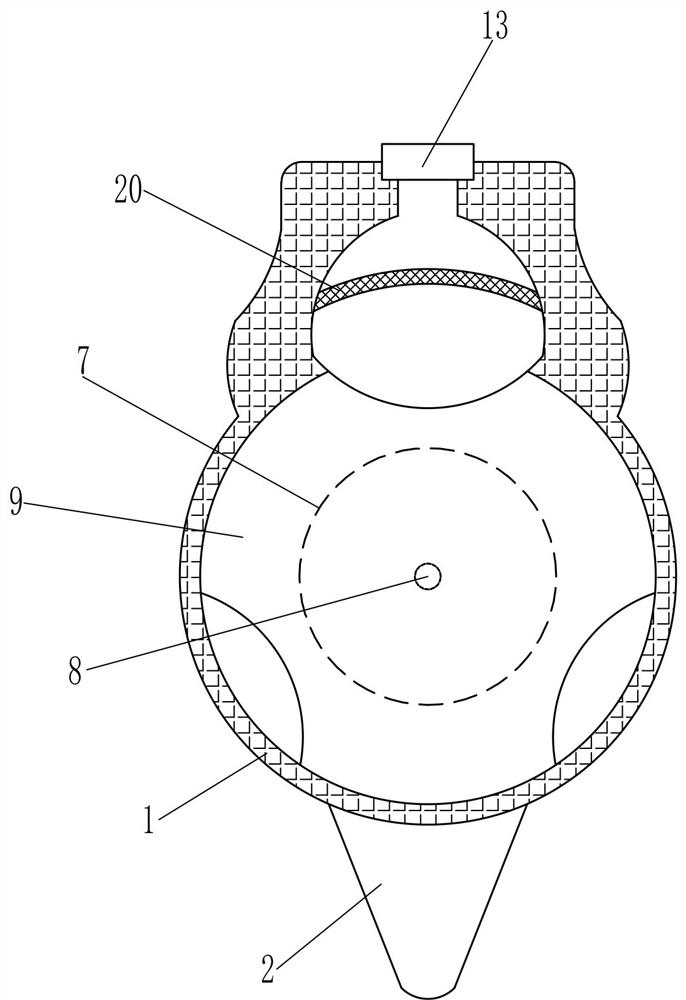

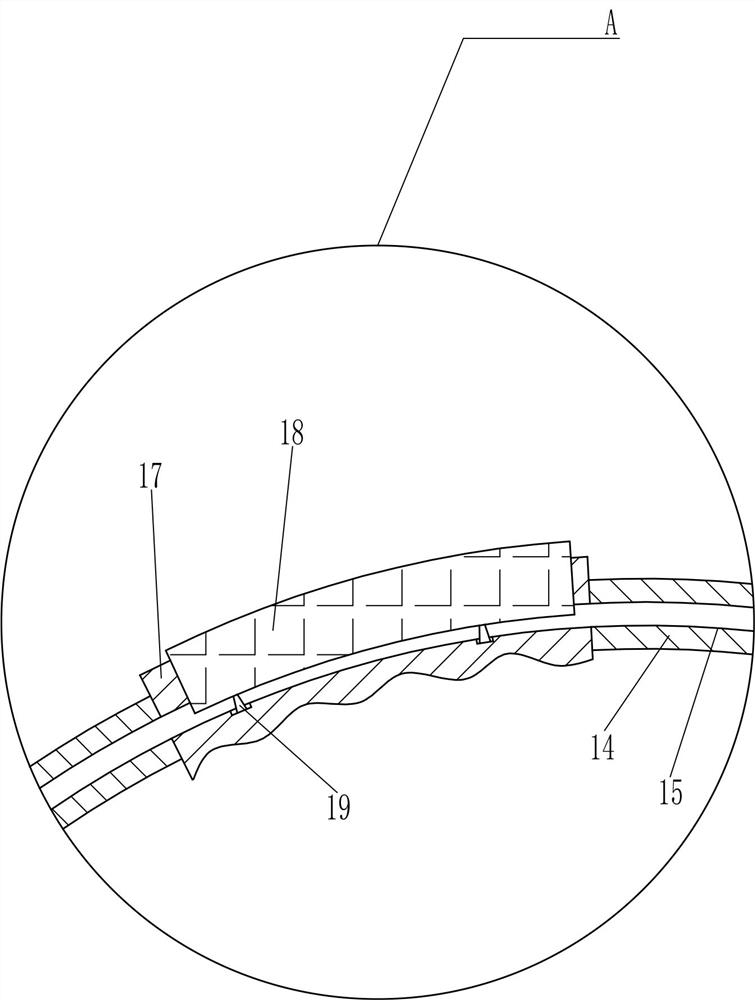

Casting process and casting mould of large propeller hub body

InactiveCN104014742AAvoid flow disturbanceImprove qualityFoundry mouldsFoundry coresPropellerCasting

The invention provides a casting process and a casting mould of a large propeller hub body. The casting process comprises the following steps: a melt enters a cavity from the bottom of the casting mould, and an included angle between the flow direction of the melt entering the cavity and the bottom surface of the cavity is 20-80 degrees; the whole cavity is filled with the melt, cooling is performed, and then the casting mould is dismantled to obtain the propeller hub body. The casting process is simple and feasible, the turbulent flow degree of castings during filling can be effectively reduced, the solidification rate of large castings is increased, and the large propeller hub body cast by adopting the process has few precipitating and reacting pore defects. The casting mould is scientific and reasonable in structure and can be used for casting the large propeller hub body with few precipitating and reacting pore defects.

Owner:DALIAN UNIV OF TECH

Stainless steel welding rod improving vertical welding process performance

ActiveCN112975199ARaise the melting point of the coatingLower melting rateWelding/cutting media/materialsSoldering mediaSlag (welding)Microcrystalline cellulose

The invention provides a stainless steel welding rod improving vertical welding process performance. The stainless steel welding rod comprises a stainless steel core wire and a coating wrapping the surface of the stainless steel core wire, the coating is prepared from the following raw materials, in parts by weight, 30-40 parts of rutile, 3-8 parts of zircon quartz, 5-10 parts of feldspar, 10-18 parts of marble, 2-6 parts of fluorite, 2-8 parts of dolomite, 1-5 parts of magnesia, 1-5 parts of aluminum oxide, 5-10 parts of electrolytic manganese metal, 5-10 parts of chromium metal, 3-6 parts of ferrotitanium, 2-7 parts of iron powder, 1-2 parts of sodium alginate and 1-2 parts of microcrystalline cellulose. According to the stainless steel welding rod improving the vertical welding process performance, the excellent flat welding process performance of an acid coating stainless steel welding rod is reserved, meanwhile, by designing the coating of the welding rod, the welding rod melting rate is reduced, the slag forming number in unit time is reduced, the slag solidification rate is improved, vertical welding slag is stably solidified and does not flow downwards, and the vertical welding operability of the stainless steel welding rod is improved.

Owner:TIANJIN GOLDEN BRIDGE WELDING MATERIALS GRP

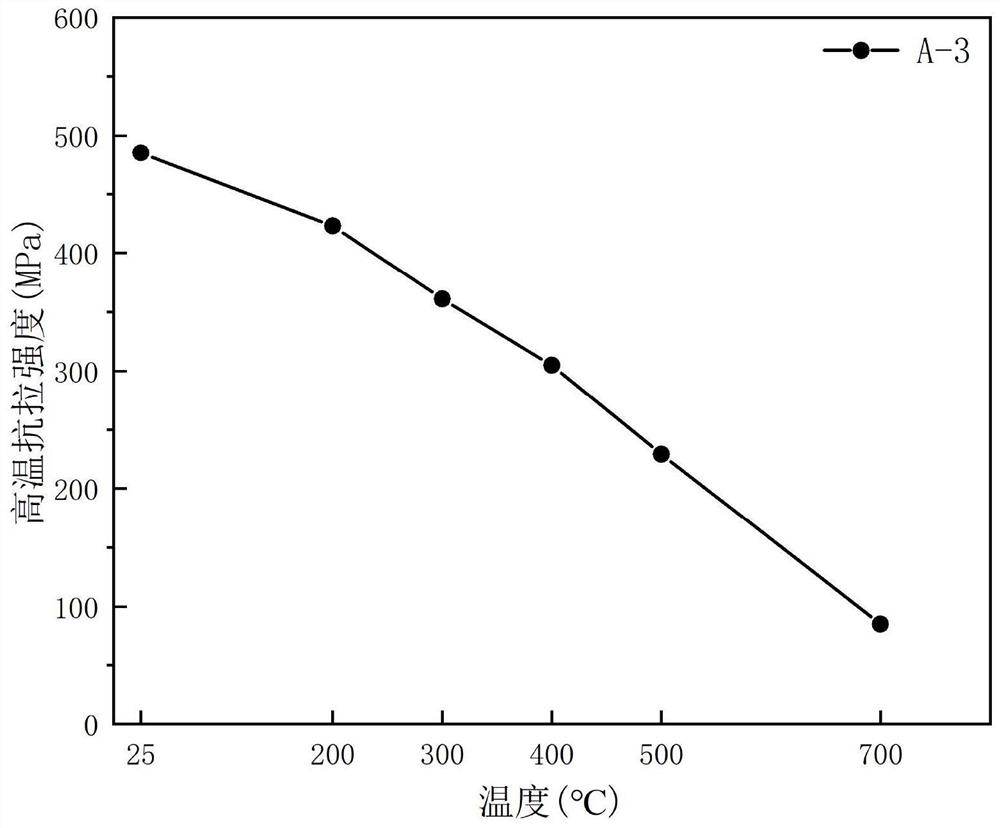

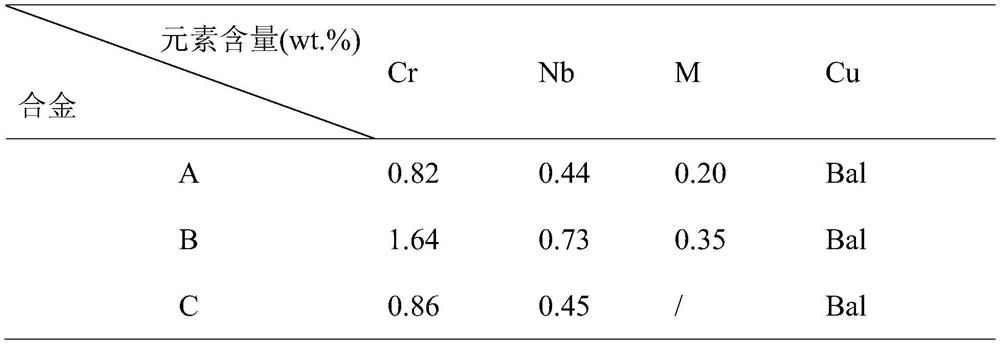

Method for improving strength and conductivity of smelted and cast Cu-Cr-Nb alloy

InactiveCN112695219ARealize direct castingHigh strengthTemperature control deviceFoundry mouldsMetal moldUltimate tensile strength

The invention relates to a method for improving strength and conductivity of a smelted and cast Cu-Cr-Nb alloy, and belongs to the field of copper alloy materials. The alloy is mainly prepared from Cu, Cr, Nb and M, the proportion of Cr is 0.5-2.5 wt.%, the proportion of Nb is 0.1-1.0 wt.%, the proportion of M is 0.1-0.50 wt.%, and the balance is copper. The M is composed of at least four elements of RE, Ag, B, P, Si, Ca, Li, Mg, Ti, Fe, Zr and Mn, and the RE is selected from at least one of Ce, La, Y, Pr, Nd, Sm, Sc, Gd and Dy. According to the method, the microalloying element M is added into the alloy, and the large-size high-strength high-conductivity Cu-Cr-Nb-M alloy which is fine in structure and uniform in component is prepared through smelting, casting and thermomechanical treatment. A metal mold is used as an inner mold and surrounds a cooling pipe, a sand mold is used as a special combined mold of an outer mold, and the melt solidification rate is increased through cooling water. By means of the combined action of M microalloying, rapid solidification and thermomechanical treatment, the structure of the alloy is regulated and controlled, the performance of the alloy is improved, a multi-scale multi-phase, fine-grain, sub-grain and dislocation entangled microstructure is obtained, direct casting forming of the large-size Cu-Cr-Nb alloy is achieved, and synchronous improvement and good matching of the strength and the electric conductivity are achieved. The process is simple, the production cost is low and the application prospect is good.

Owner:CENT SOUTH UNIV

Reduced graphene oxide reinforced zinc-based medical material and preparation method thereof

ActiveCN110157950AImprove mechanical propertiesIncrease the solidification rateAdditive manufacturingIncreasing energy efficiencyGraphite oxideZinc

The invention discloses a reduced graphene oxide reinforced zinc-based medical material. The reduced graphene oxide reinforced zinc-based medical material is composed of a zinc base body and reduced graphene oxide, wherein the mass percentage of the reduced graphene oxide accounts for 0.05-0.2% by weight. On one hand, the reduced graphene oxide excellent in mechanical performance is adopted as a second phase reinforced zinc base body; and on the other hand, the characteristics that selective laser melting can achieve fast solidification and the reduced graphene oxide is excellent in heat-conducting property are utilized, and a tiny molten pool can be cooled rapidly, so that a fine and uniform structure is obtained; and the mechanical performance of the zinc base body is further enhanced through refined crystalline strengthening.

Owner:JIANGXI UNIV OF SCI & TECH +1

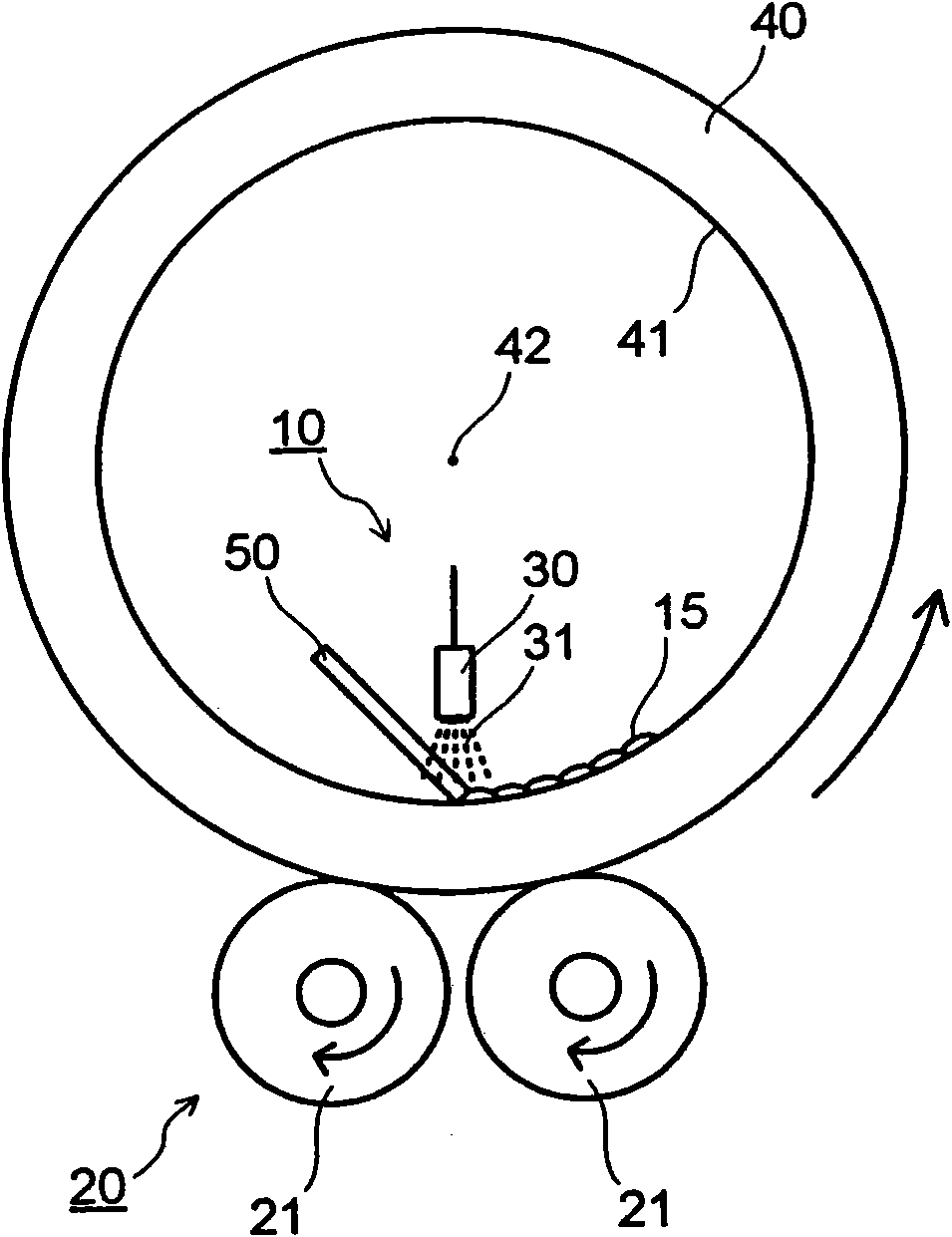

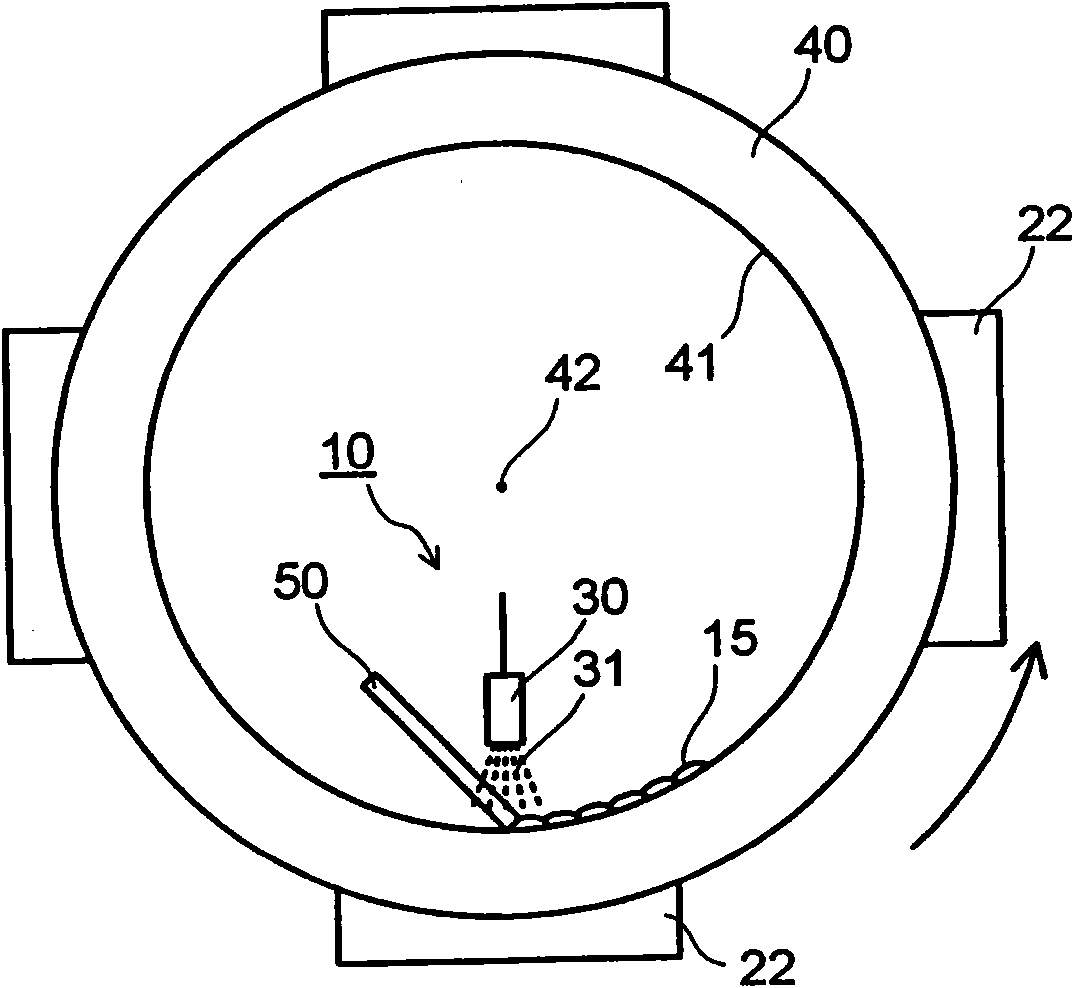

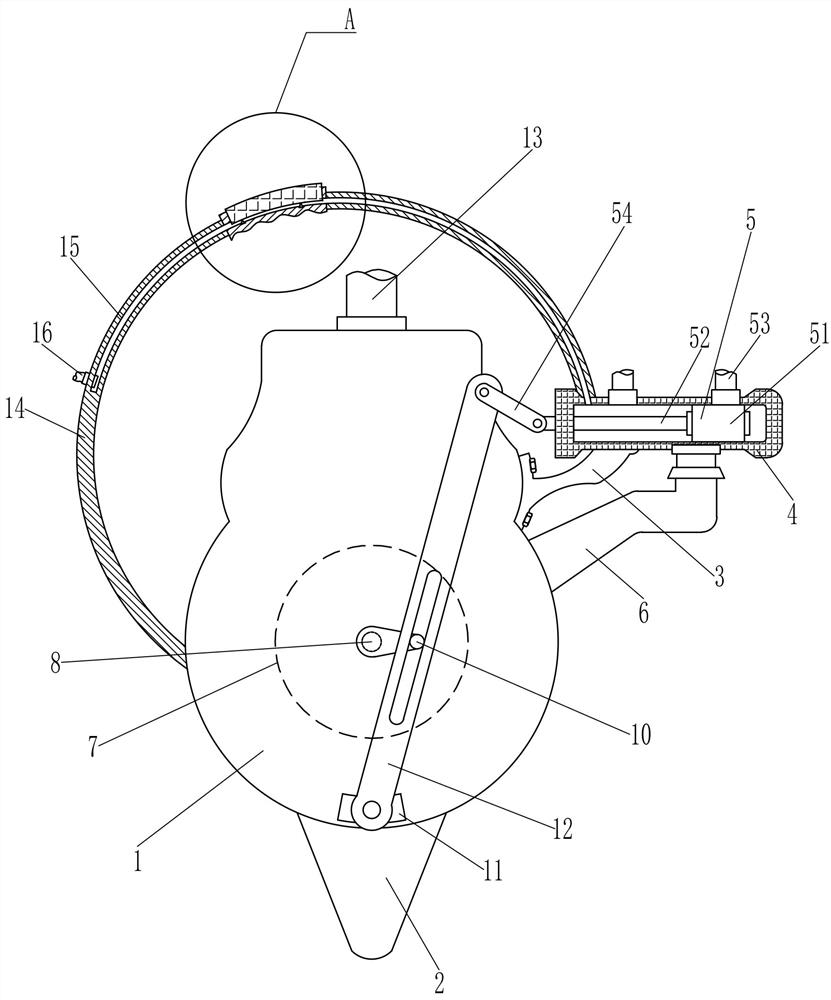

Soft alloy layer forming apparatus and soft alloy layer forming method

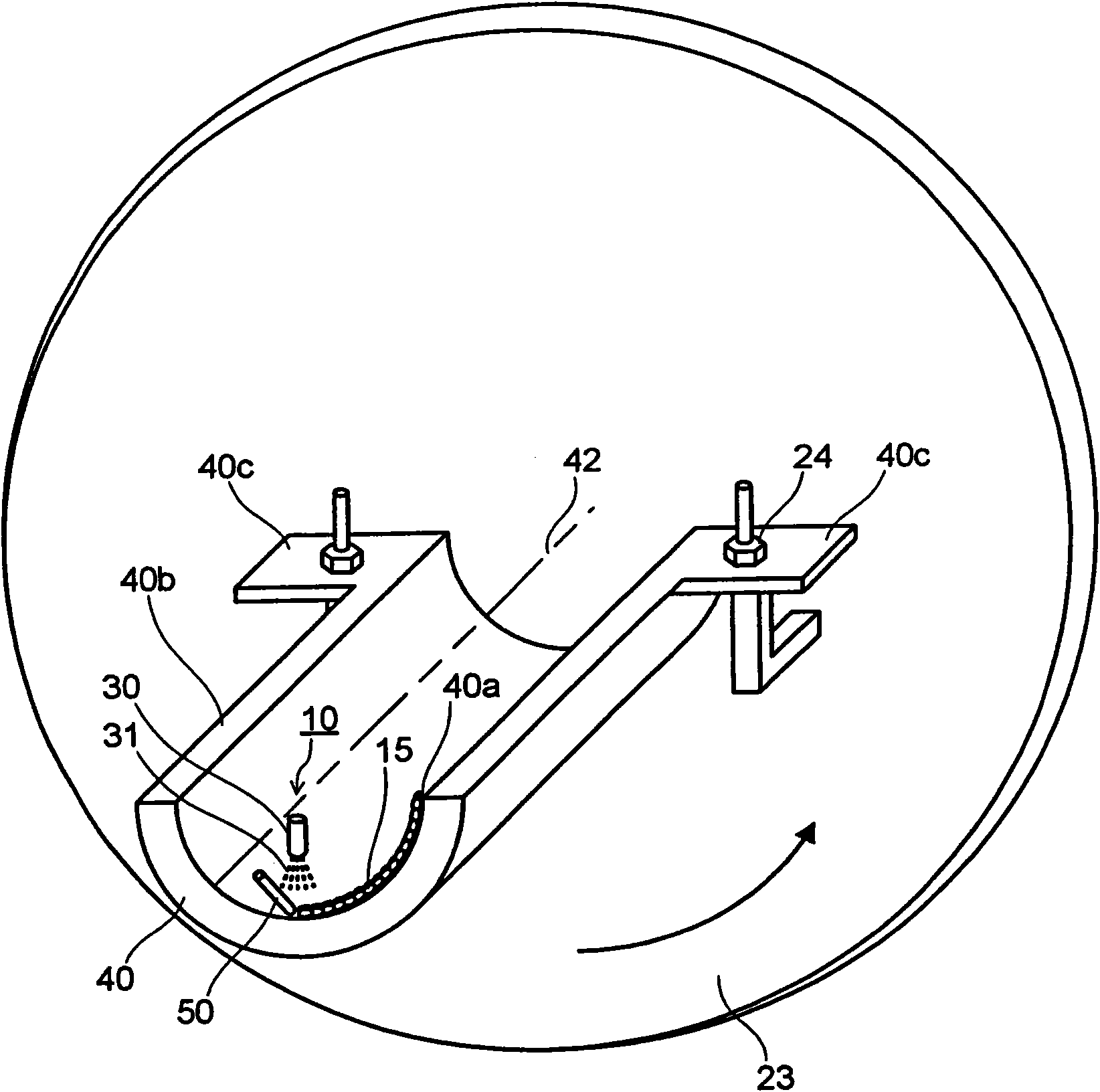

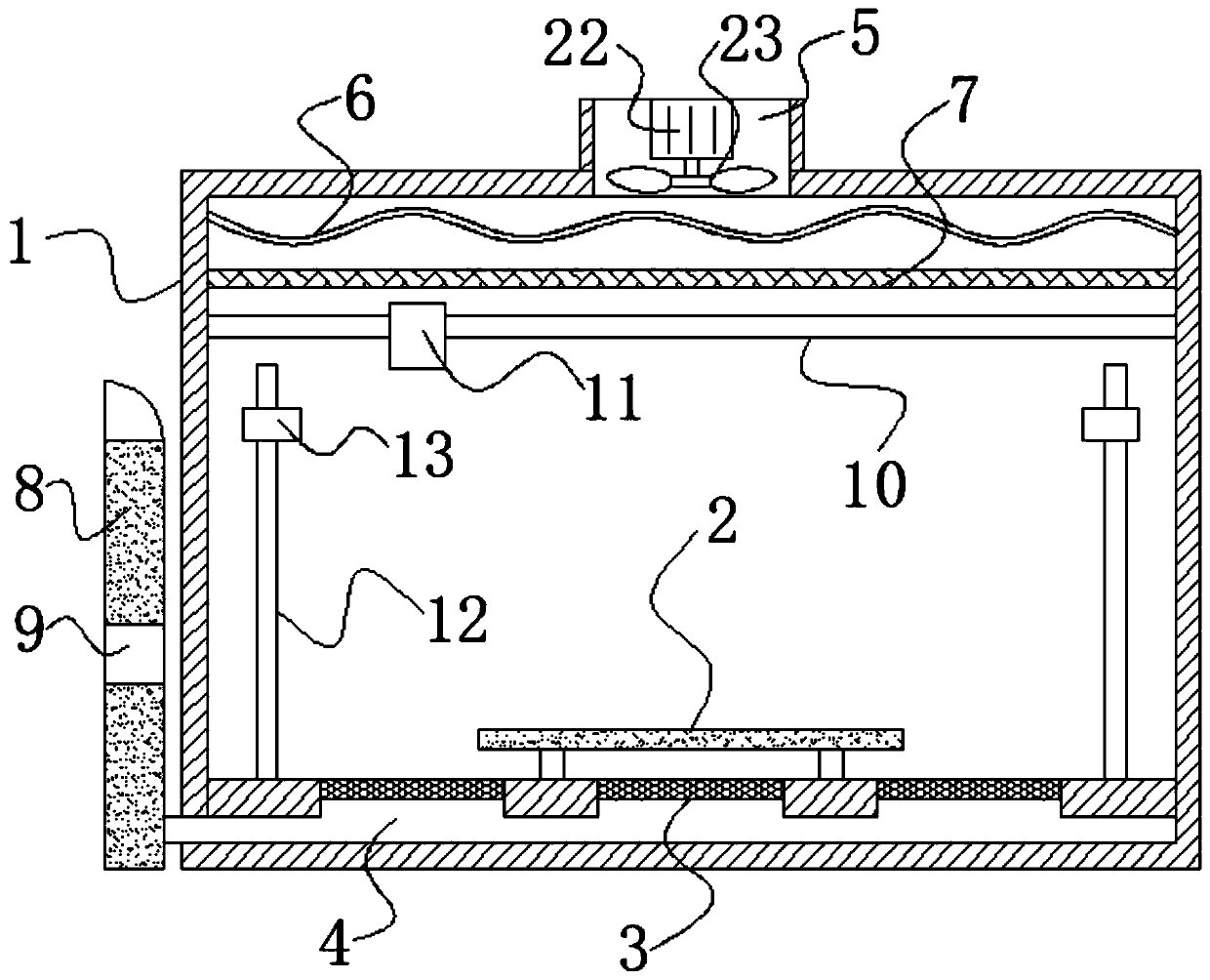

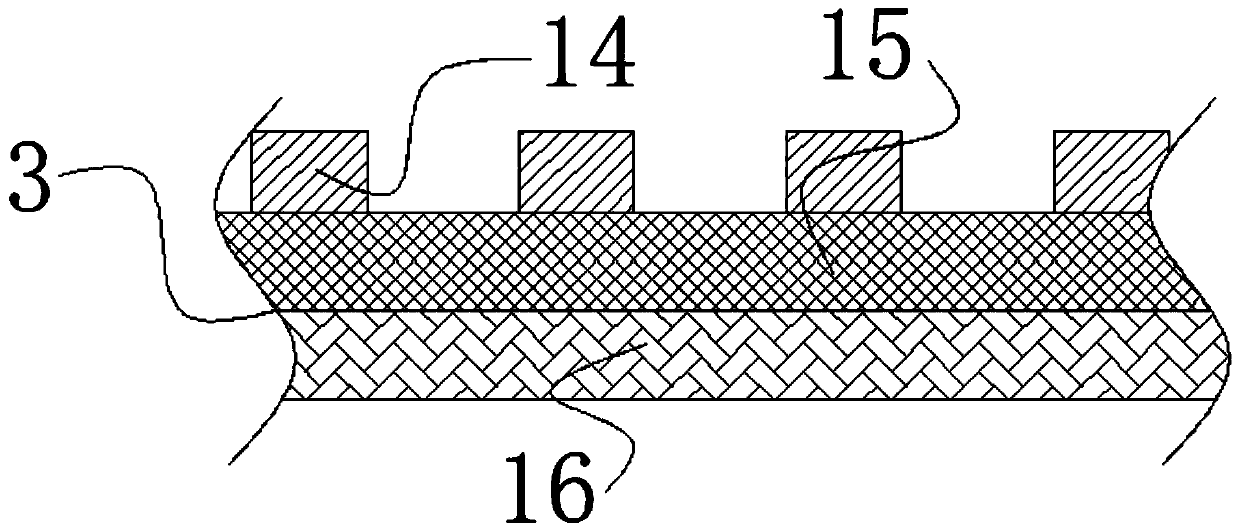

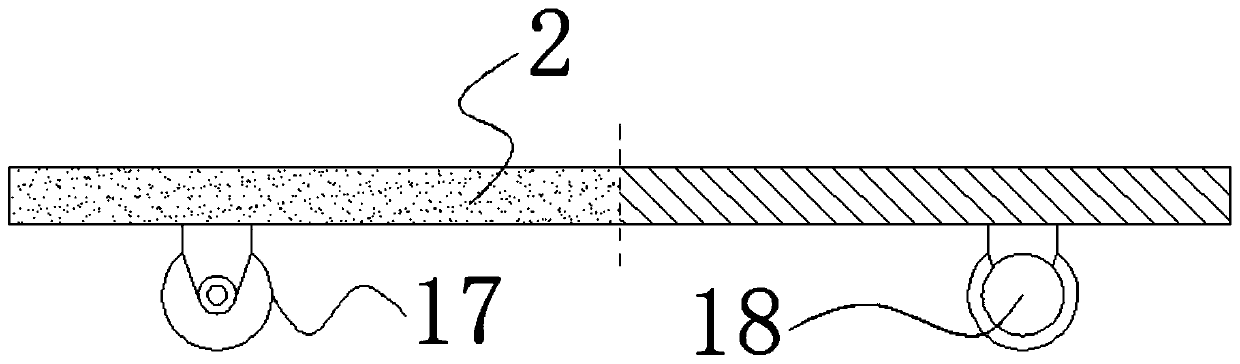

InactiveCN101614241AIncrease the solidification rateHigh tensile strengthBearing componentsAlloyMetal

A soft alloy layer forming apparatus (10) includes a base metal support part (20) rotationally supporting a base metal (40) with a center axis (42) of an inner periphery of the base metal (40) being a rotation axis, and an arc generating unit (30) movable in a direction of the rotation axis of the inner periphery of the base metal (40), fixed at a predetermined distance from the inner peripheral face (41) of the base metal (40), and generating an arc (31) between itself and the base metal (40). While rotating the base metal (40) and maintaining the distance constant between the arc generating unit (30) and the inner peripheral face (41) of the base metal (40), a soft alloy member (50) is melted by the arc generating unit (30) to form a soft alloy layer (15) on the inner peripheral face (41) of the base metal (40). The invention also relates to a soft alloy layer forming method.

Owner:KK TOSHIBA

Efficient paint spraying chamber

The invention discloses an efficient paint spraying chamber, which comprises a paint spraying room. A hollow space is fixedly arranged in the paint spraying room, an air inlet is fixedly formed in themiddle of the upper surface of the paint spraying room, an air exhaust pipe is fixedly arranged on the lower part of the surface of one side of the paint spraying room, an air exhaust space is fixedly arranged on the lower side in the paint spraying room and communicates with the air exhaust pipe, a placement plate is arranged in the middle of the bottom surface in the paint spraying room, vertical sliding rods are fixedly arranged on the two sides of the bottom surface of the paint spraying room correspondingly, the upper parts of rod bodies of the vertical sliding rods are slidably connected with vertical sliding blocks, and filter cotton is fixedly arranged on the upper part of the paint spraying room. In the efficient paint spraying chamber, automatic paint spraying is adopted, thus the operation efficiency is improved, meanwhile, spraying operation is conducted without labor, thus health damage to personnel is reduced, the air inlet is formed in the upper part, heating is conducted through an electric heating pipe, then filtering is conducted, thus the situation that air impurities fall on an object, and consequently smooth paint spraying is affected is reduced, and the solidification rate of a paint body is increased.

Owner:盐城韩丰汽车零部件有限公司

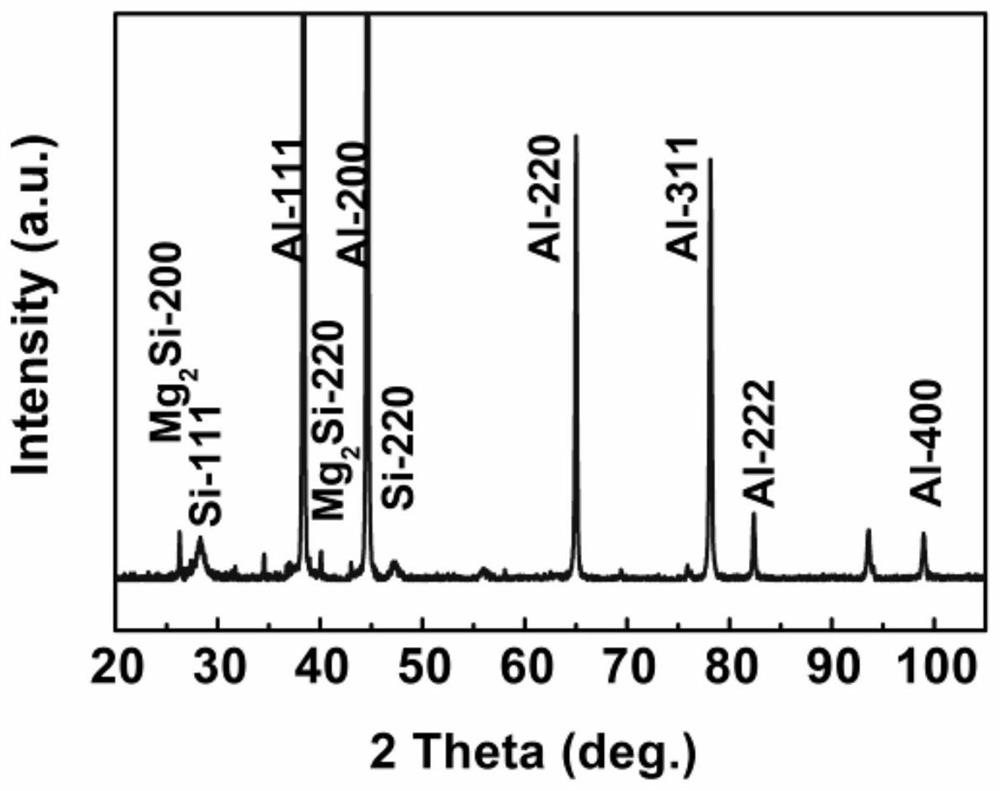

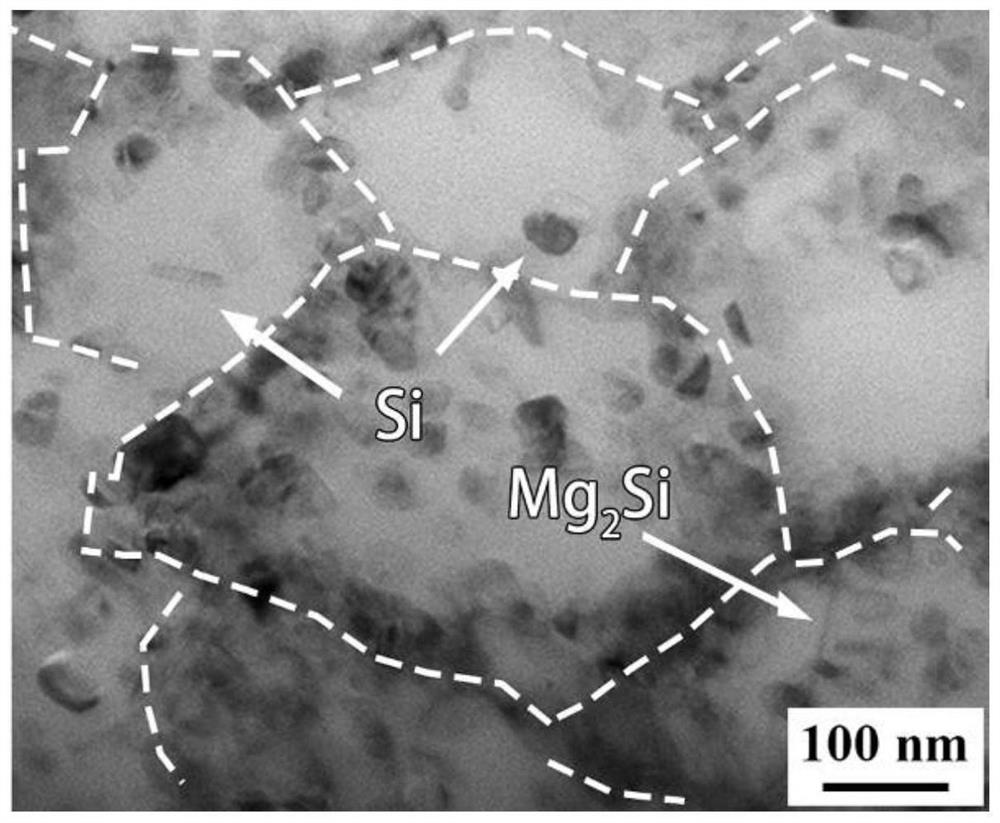

Laser additive and heat treatment composite process for high-strength and high-toughness aluminum-silicon alloy or composite material thereof

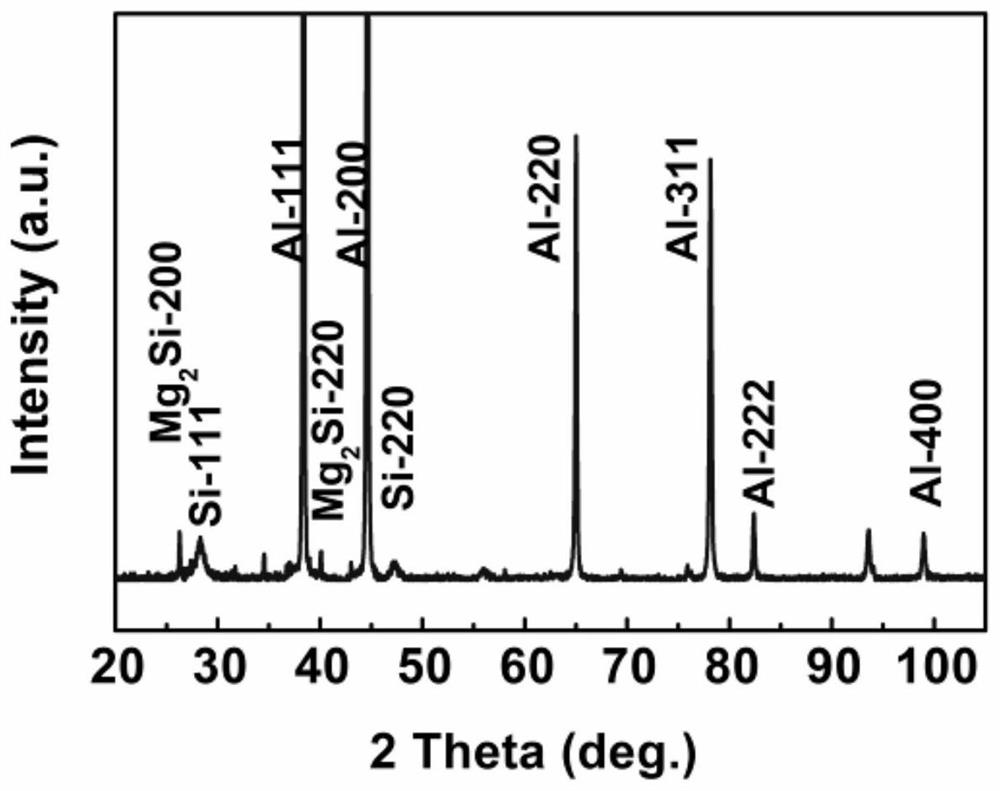

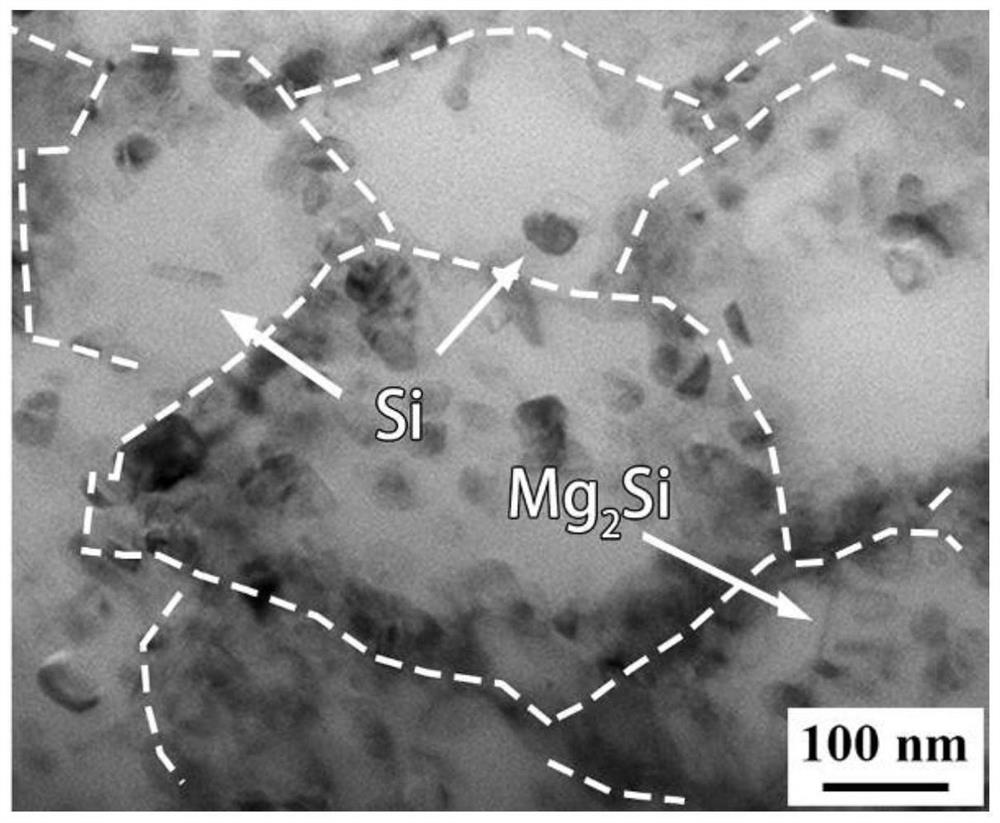

ActiveCN112536446AIncrease the solidification rateImproves strength and hardnessAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingSilicon alloy

The invention discloses a laser additive and heat treatment composite process for a high-strength and high-toughness aluminum-silicon alloy or a composite material thereof, and belongs to the technical field of metal materials. The process comprises the following steps of: firstly, carrying out selective laser melting printing on an aluminum-silicon alloy and a composite material thereof under thematching of parameters of thin powder laying, low power, high speed and air cooling to obtain a supersaturated solid solution structure; and then carrying out low-temperature aging heat treatment onthe supersaturated solid solution to finally obtain a high-performance sample which retains a printing-state fine structure and contains a fine reinforced phase. The strength and plasticity of the aluminum-silicon alloy and the composite material thereof can be remarkably improved, AlSi10Mg is taken as an example, and the strength and plasticity after treatment by the preparation process are superior to those of a same-system printed piece which is industrially applied at present. The process has the advantages of capability of preparing complex porous structural parts, high material utilization rate, high production efficiency, short production process, simplicity, safety, no pollution and economy.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Casting device for aluminum alloy thin-walled piece water-cooled metal shell mould

PendingCN110918891AReduce cooling rateImprove filling abilityFoundry mouldsFoundry coresManufacturing cost reductionThin walled

The invention relates to the technical field of metal casting, in particular to a casting device for an aluminum alloy thin-walled piece water-cooled metal shell mould. The casting device for the aluminum alloy thin-walled piece water-cooled metal shell mould comprises a metal shell mould, and is characterized in that the thermal capacity of the metal shell mould is reduced, the cooling speed of an aluminum alloy thin-walled piece in a mould filling process is reduced, and the mould filling capacity of a molten liquid in the device is improved by reducing the wall thickness of a casting mould;after the mould filling of the aluminum alloy thin-walled piece is completed, the metal shell mould is subjected to quick water cooling so as to improve the cooling speed of the molten liquid in a solidifying process, accelerate the solidifying rate of a casting, refine the structure of the aluminum alloy thin-walled piece and improve the mechanical properties; the casting device for the aluminumalloy thin-walled piece water-cooled metal shell mould solves the difficult problems that the mould filling of the aluminum alloy thin-walled piece is difficult to perform and the mechanical properties are poor; moreover, the metal shell mould can also be reused; the production efficiency is improved; and the manufacturing cost and the environmental pollution are reduced.

Owner:HUNAN UNIV OF SCI & TECH

Assistant alloy for Nd-Fe-B permanent magnetic material and its preparation method

ActiveCN100372031CIncrease the solidification rateImprove efficiencyInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementHeat flow

Owner:LESHAN YOUYAN RARE EARTH NEW MATERIAL CO LTD

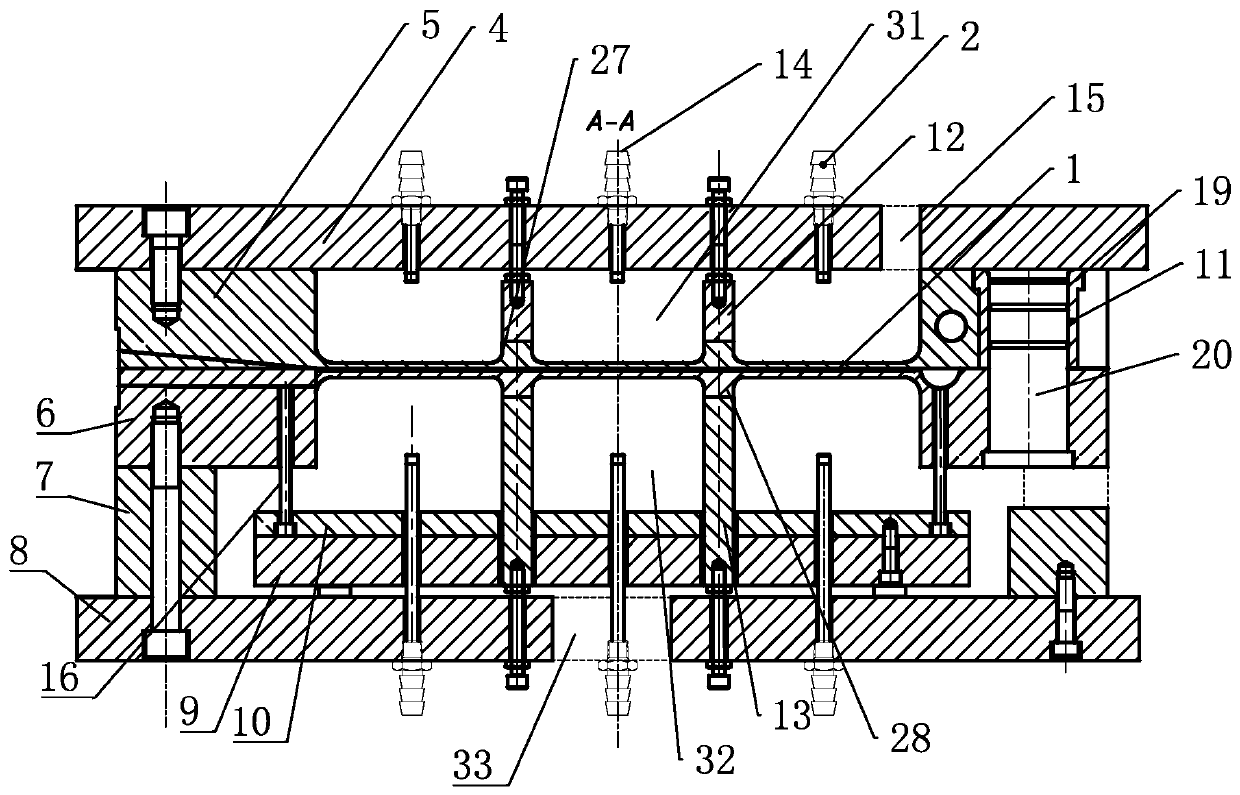

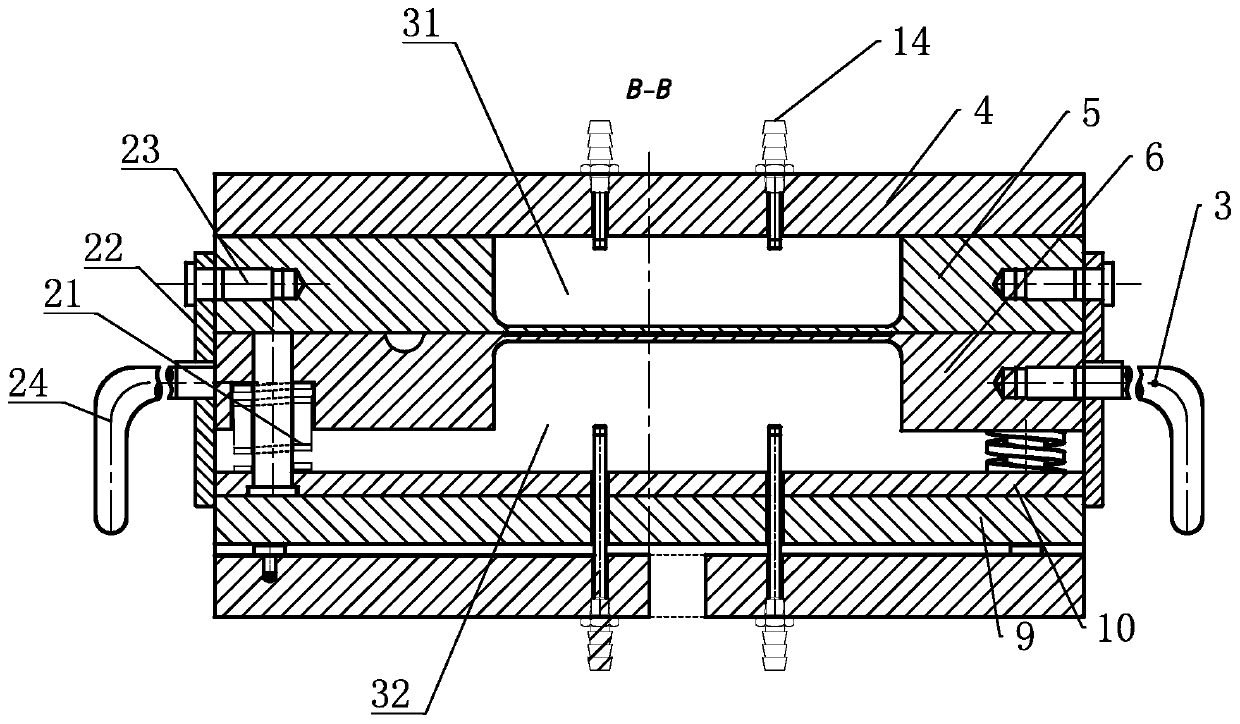

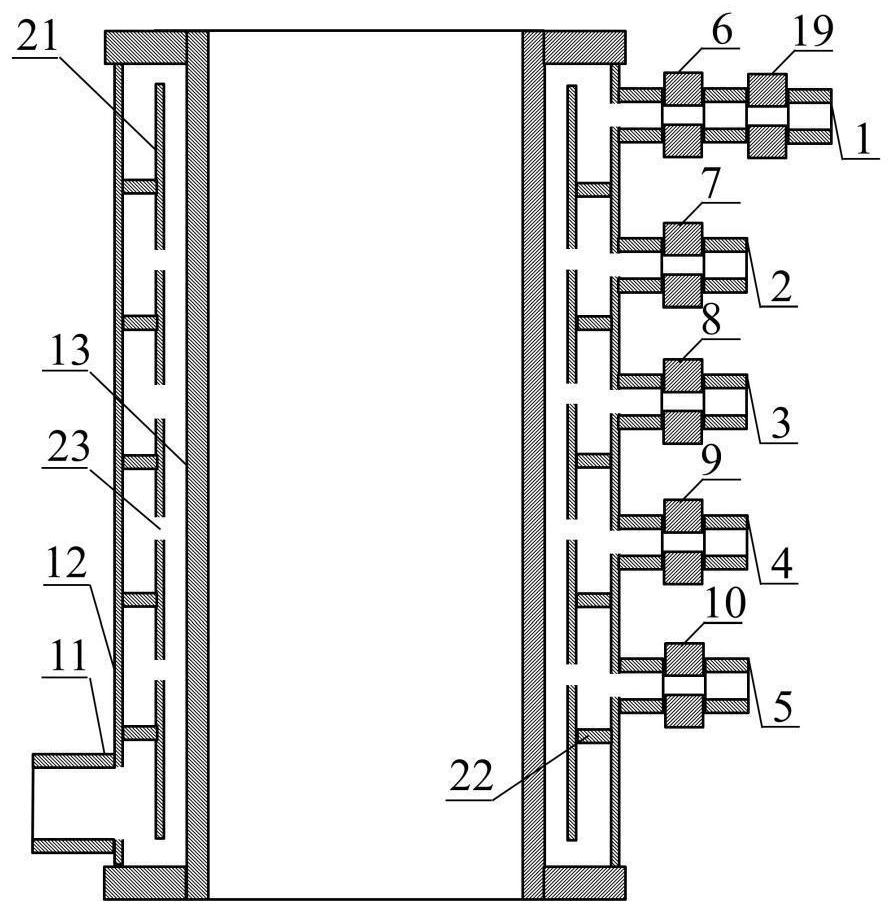

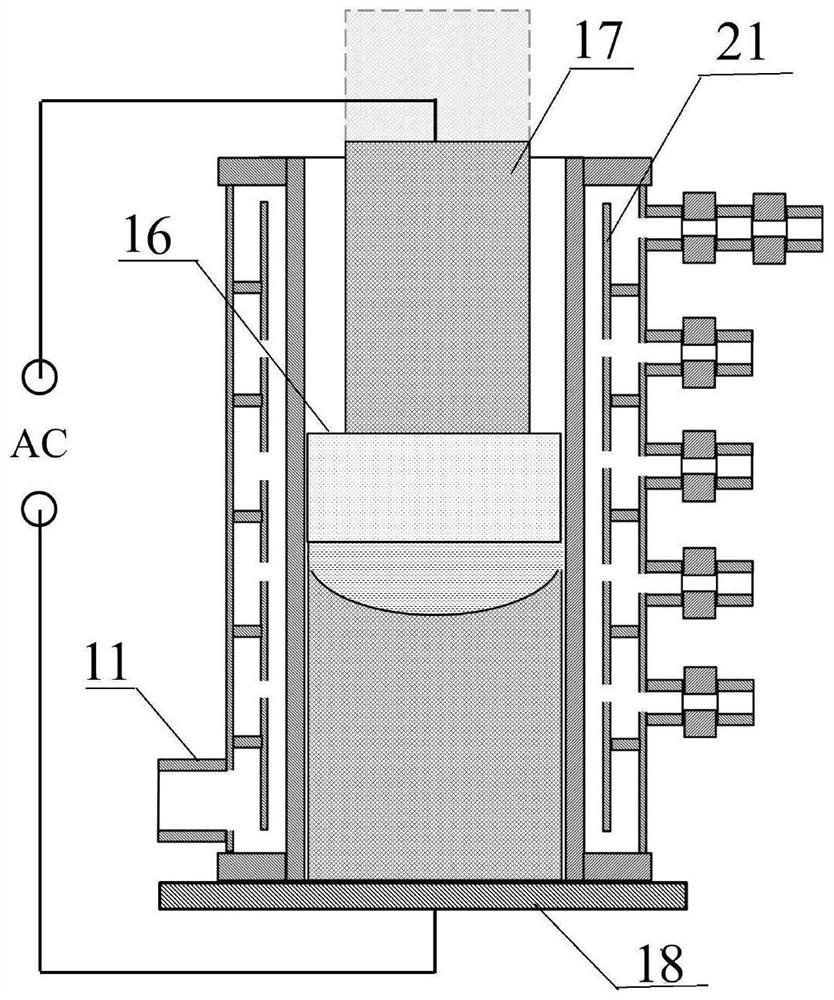

Method for carrying out electroslag remelting by using single-inlet multi-outlet type water-cooling crystallizer electroslag remelting device

ActiveCN114438337AShallow depthIncrease the solidification rateIncreasing energy efficiencyMetallurgyOutfall

The invention discloses an electroslag remelting device of a single-inlet and multi-outlet type water-cooled crystallizer and a use method, which can achieve the purposes of simultaneously refining internal structure grains of an electroslag ingot and improving the surface quality of the electroslag ingot. Therefore, the invention develops a single-inlet multi-outlet type water-cooling crystallizer which consists of a lower water inlet, a water outlet at the topmost part of the crystallizer and a plurality of water outlets vertically arranged along the height direction of the crystallizer. During electroslag remelting, opening and closing of each water outlet are dynamically adjusted according to the height of an electroslag ingot in the crystallizer; and in the electroslag remelting process, the water outlet in the topmost part of the water-cooling crystallizer is always in an open mode, and the other water outlets are sequentially opened and closed according to the height of an electroslag ingot. No matter how the water cooling system of an existing single-inlet single-outlet water cooling crystallizer is changed, the problem that the internal quality or the surface quality of an electroslag ingot is poor and cannot be improved at the same time always exists. According to the single-inlet multi-outlet type water cooling crystallizer developed by the invention, the optimal electroslag ingot surface quality and the optimal electroslag ingot internal quality are obtained at the same time.

Owner:SUZHOU UNIV

Micro-segregation controlling method of bloom heavy rail steel

The invention discloses a micro-segregation controlling method of bloom heavy rail steel, and belongs to the field of iron steel metallurgy. The controlling method is carried out at a continuous casting stage according to the following steps: 1, performing continuous casting electromagnetic stirring under a condition that the stirring magnetic field strength for electromagnetic stirring is 40x10<-4> to 50x10<-4>T in a combined way of electromagnetic stirring and secondary cooling electromagnetic stirring, and ensuring that a concrete mounting position for the secondary cooling electromagneticstirring has a distance of being 5.0 m to 6.0 m away from molten steel surface of a crystallizer, the stirring current frequency is 6.0 Hz to 8.0 Hz, and the magnetic field strength is 180x10<-4> to 200x10<-4>T; casting the molten steel by using a medium ladle at an overheating degree being 35 DEG C to 45 DEG C; and requiring a secondary cooling area to be in the coverage of 15.0 m away from the molten steel surface of the crystallizer at a continuous casting secondary cooling stage. The controlling method is carried out based on the parameters, so that the local condensation velocity of the bloom heavy rail steel is improved, and composition of condensation tissues of casting blanks are improved and controlled; columnar crystals are relatively developed, crystal bars are thin and compact,a crystal grain form of an equiax crystal is changed, and the crystal bars are thin, compact and clear; and a space of a secondary dendrite arm is reduced, and the micro-segregation extent is controlled preferably.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

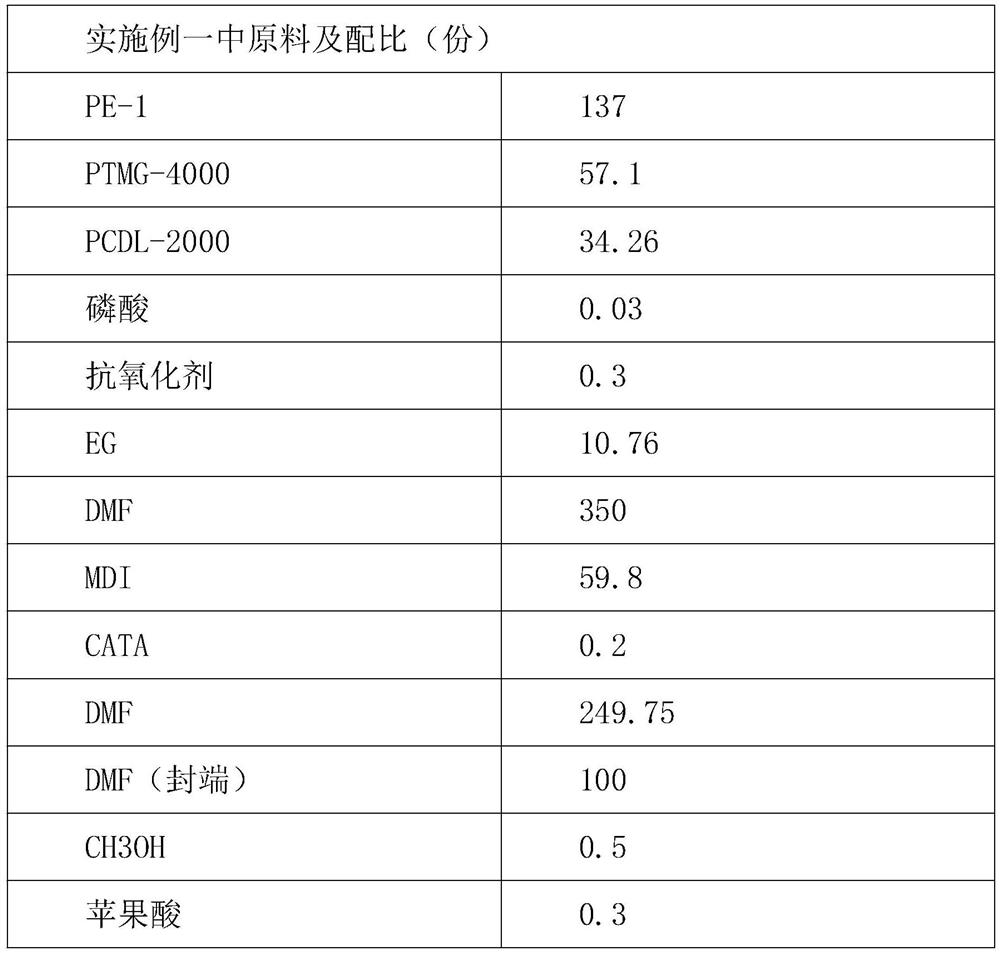

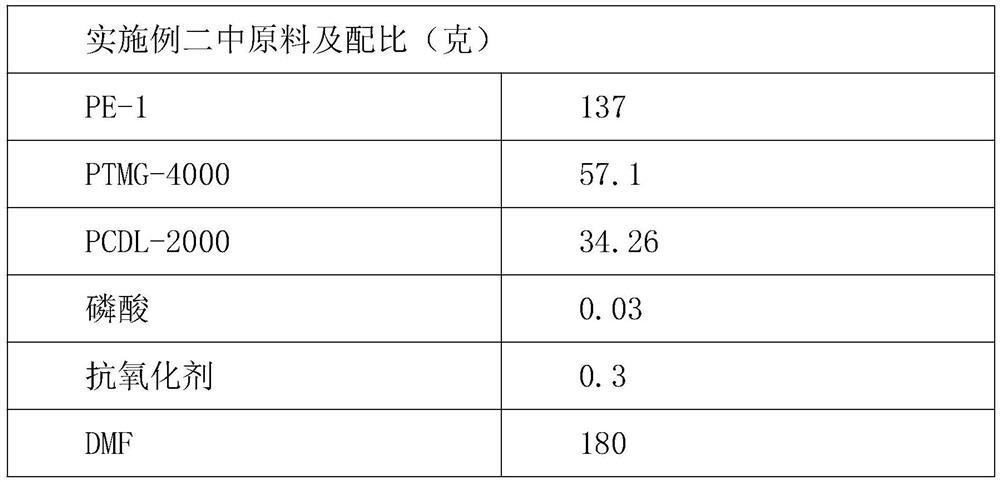

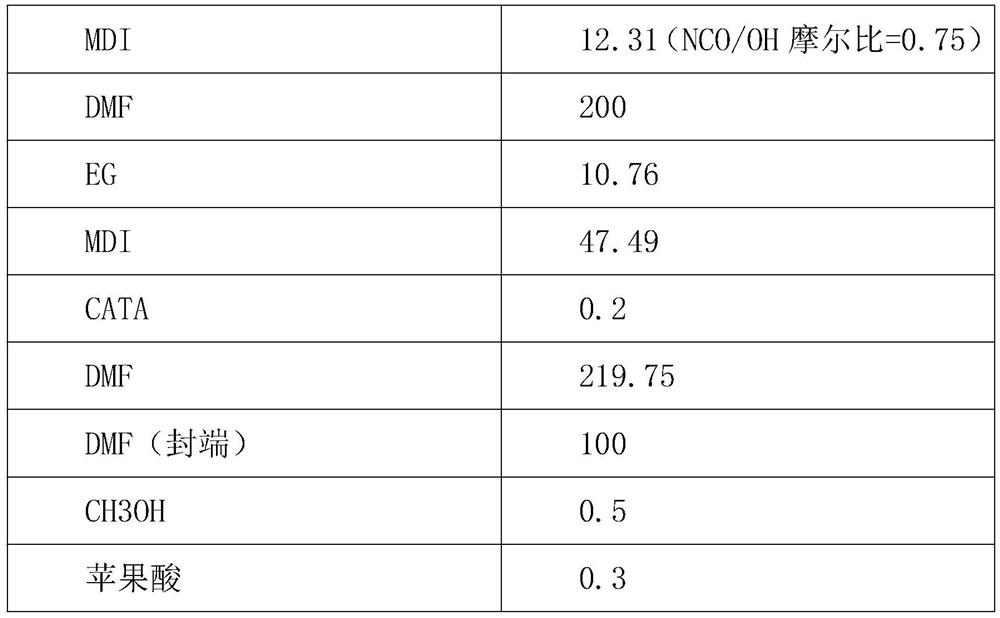

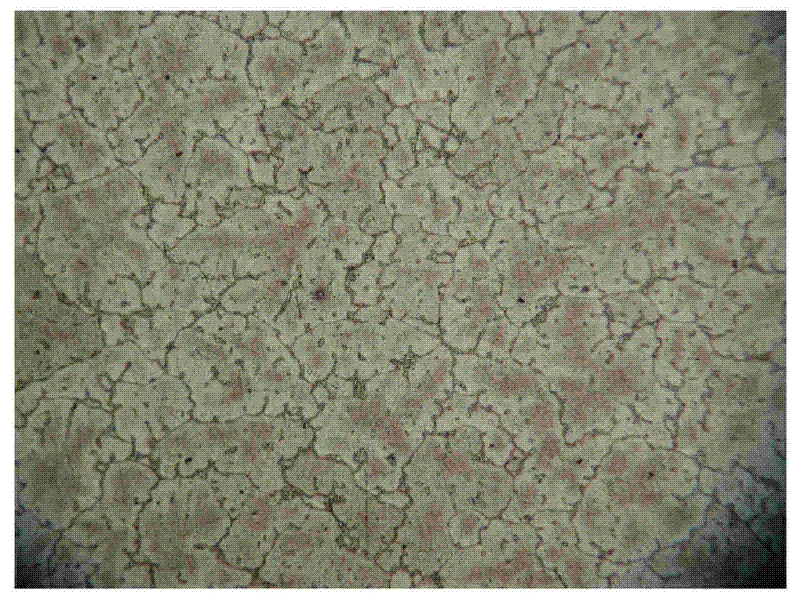

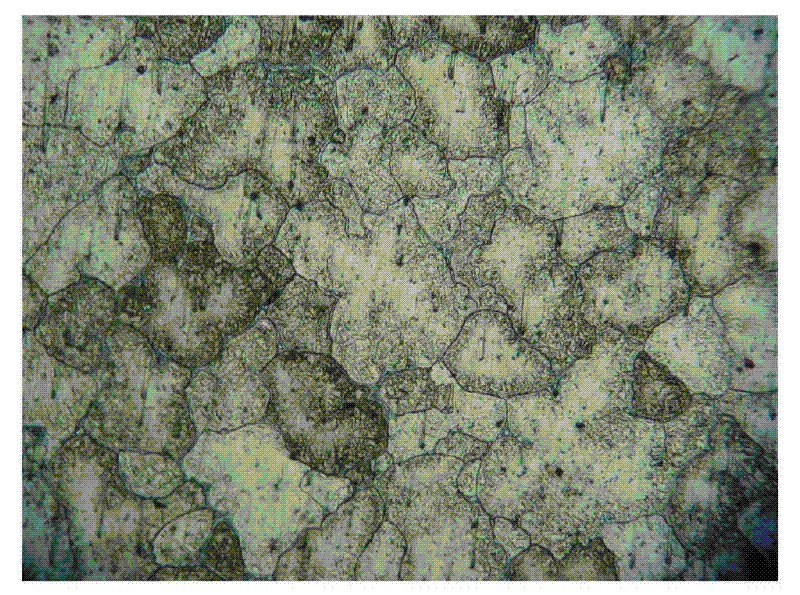

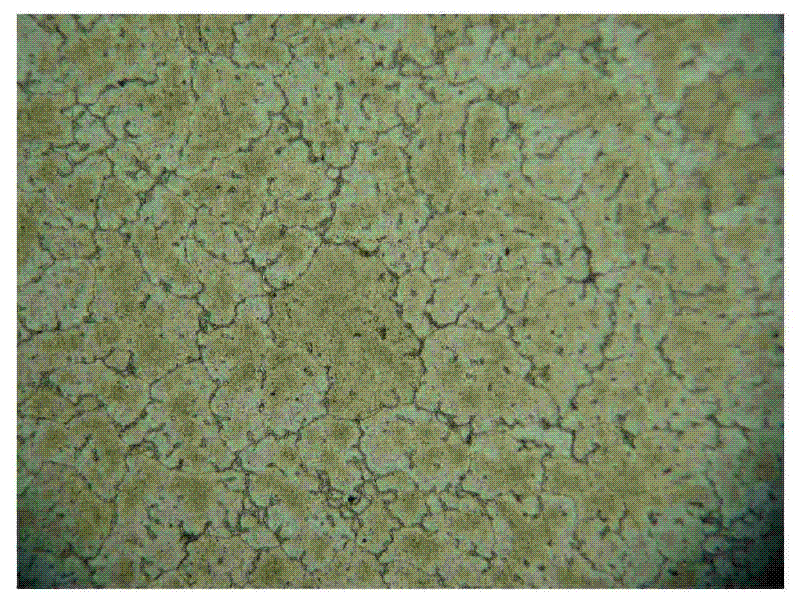

Special polyurethane resin for soft basketball leather and preparation method of special polyurethane resin

InactiveCN112409562AImprove wear resistanceImprove scratch resistanceTextiles and paperPolyesterPolymer science

The invention discloses special polyurethane resin for soft basketball leather and a preparation method thereof, and relates to the technical field of chemical products and preparation methods thereof. The material is prepared from the following components in parts by weight: 5.37-5.98 parts of MDI, 70-100 parts of DMF, 12.33-13.70 parts of polyester polyol, 5.14-5.71 parts of polyether polyol, 3.01-3.42 parts of polycarbonate polyol, 0.77-1.08 parts of EG, 0.03-5 part of antioxidant, 0.003-3 part of phosphoric acid, 0.02-3 part of CATA, 0.03-5 part of malic acid, 0.05-7 part of CH3OH, 0.5-3 parts of HD-1, 0.5-5 parts of HD-2, and 2-4 parts of HD-3. According to the special polyurethane resin for the soft basketball leather and the preparation method of the special polyurethane resin, in the aspect of formula design, polyhydric alcohols are selected from high-molecular-weight polyester polyhydric alcohols and high-molecular-weight polyether polyhydric alcohols in a mixed mode, and dueto selection of the high-molecular-weight polyester polyhydric alcohols, a polyurethane soft segment is softer and softer and fuller in hand feeling; due to the introduction of the polyether polyol with large molecular weight, the hand feeling of the basketball leather is softer, and the leather is endowed with excellent surface wet and astringent touch feeling and better resilience.

Owner:华大化学(安徽)有限公司

High-pressure counter-pressure casting method of Al-5 percent Cu base alloy

The invention relates to a high-pressure counter-pressure casting method of an Al-5 percent Cu base alloy, solving the problems of little tensile strength, low extensibility and low density of an Al-5 percent Cu base alloy obtained by the prior counter-pressure casting method. The casting method comprises the following steps: (1) adjusting a counter-pressure casting machine to form a high-pressure counter-pressure casting machine; (2) weighting and welding raw materials to obtain a melt; and (3) carrying out the high-pressure counter-pressure casting on the melt to obtain Al-5 percent Cu basealloy. The casting method combines a high-pressure solidification technology and a counter-pressure casting technology, and the obtained Al-5 percent Cu base alloy achieves the tensile strength of 519.5 MPa, the extensibility of 16.97 percent and high density. The invention can be favorably applied to the aerospace industry, the nuclear industry and the weapon industry.

Owner:HARBIN INST OF TECH

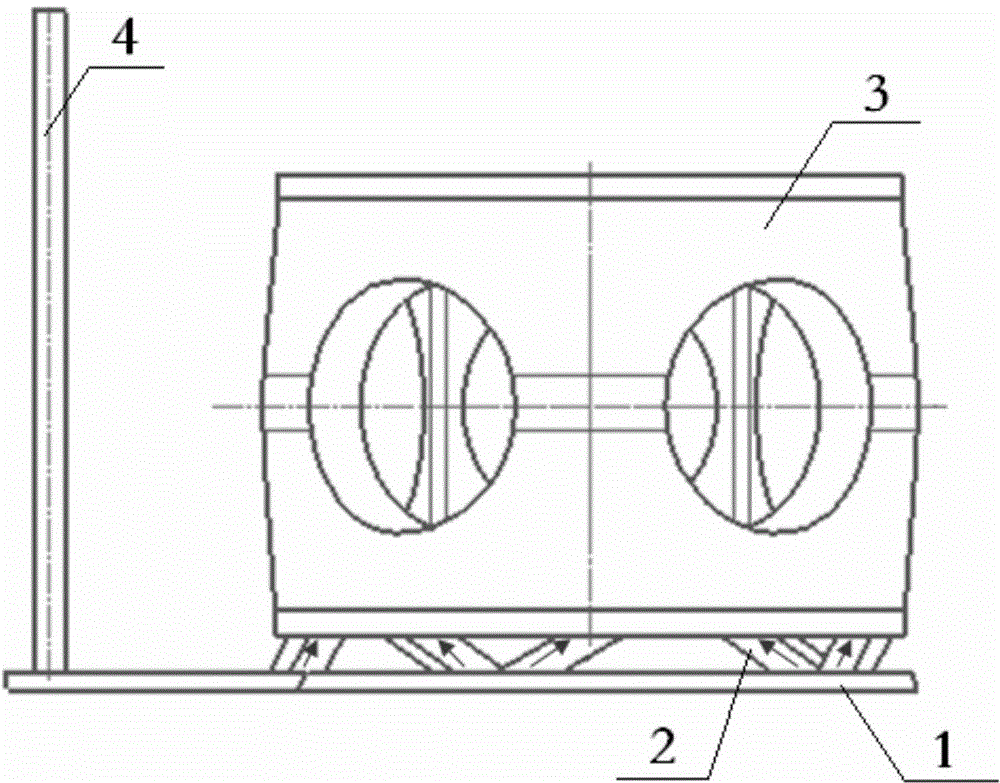

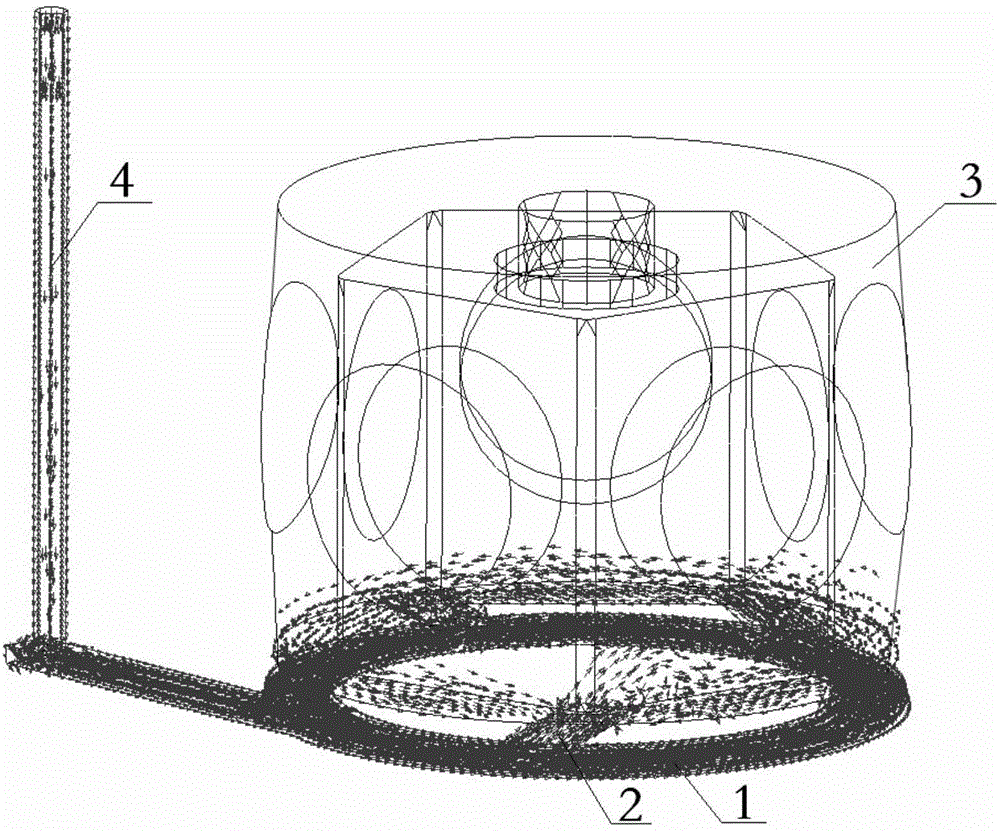

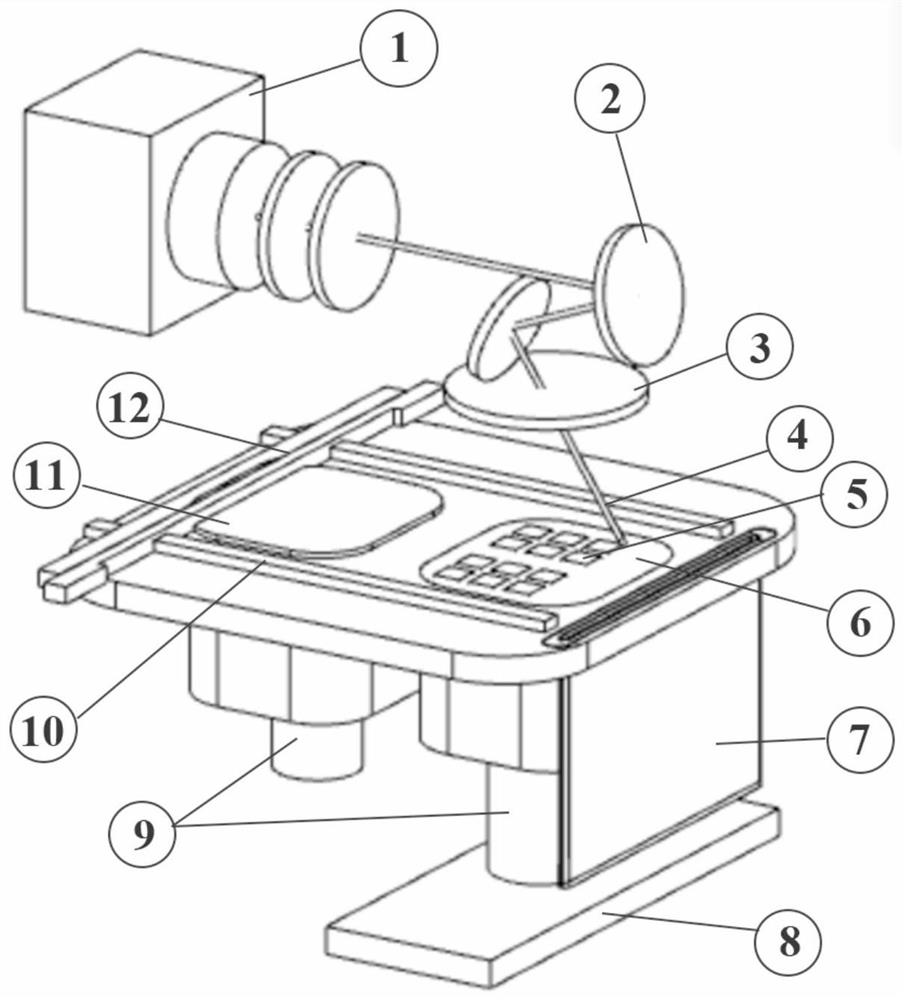

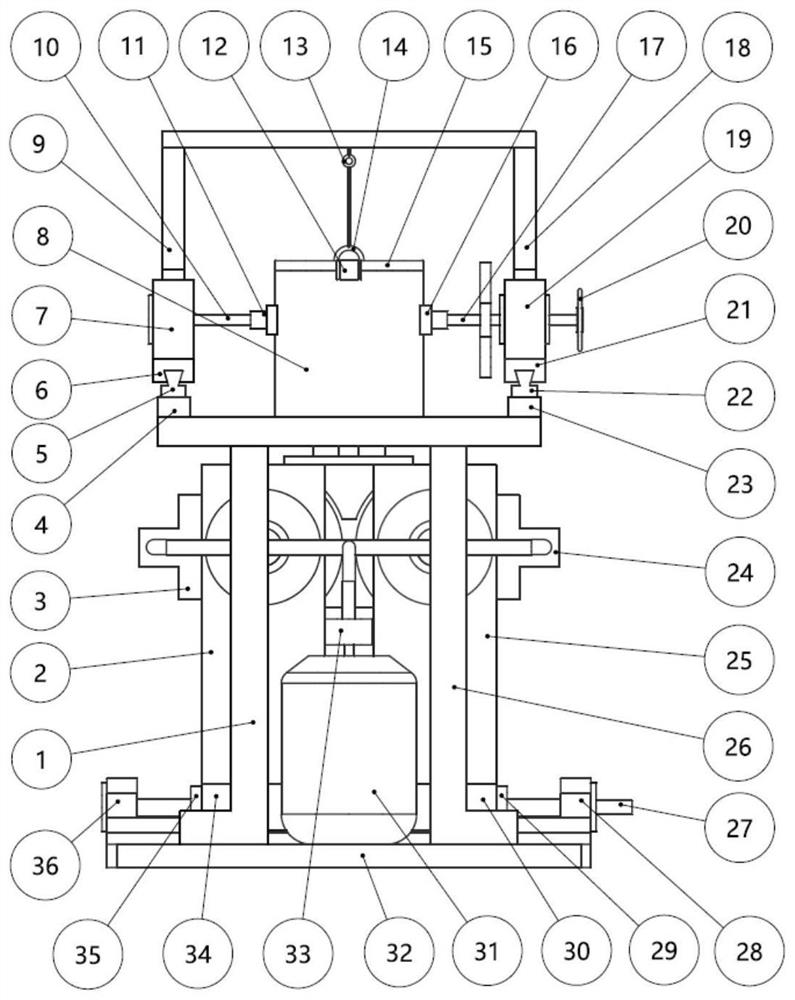

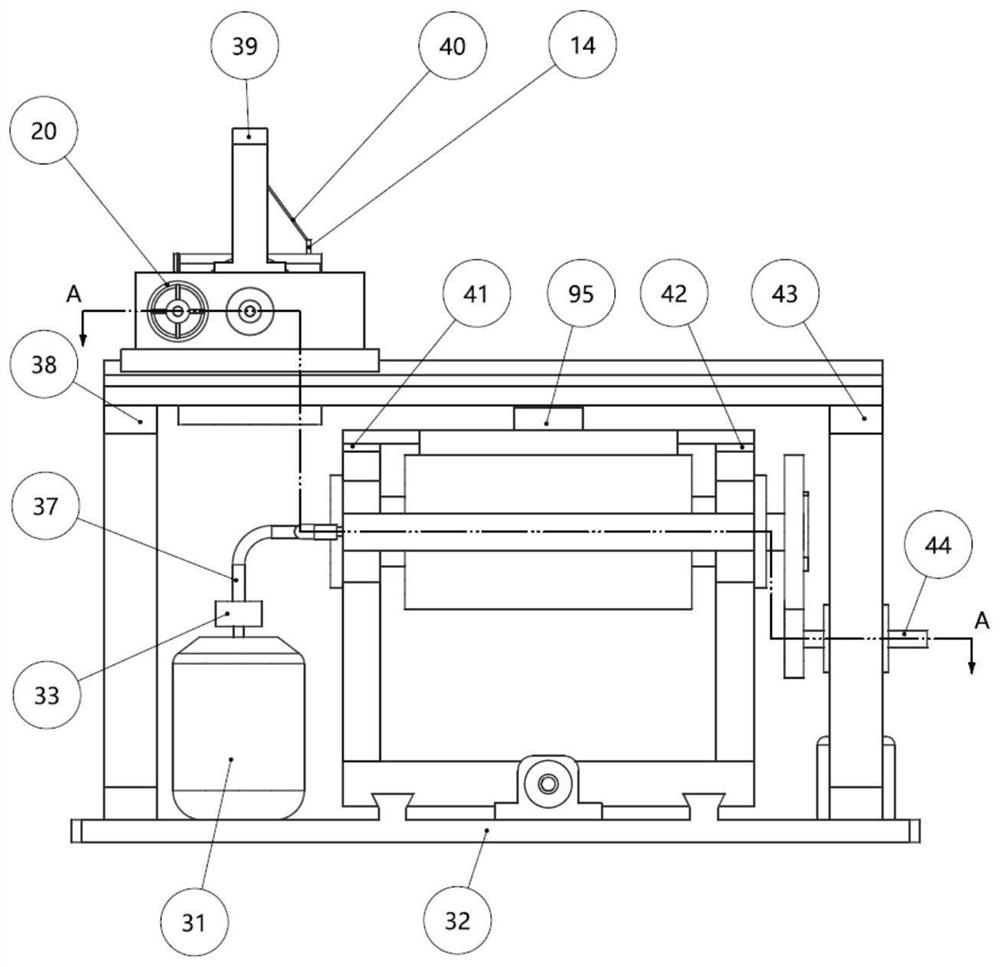

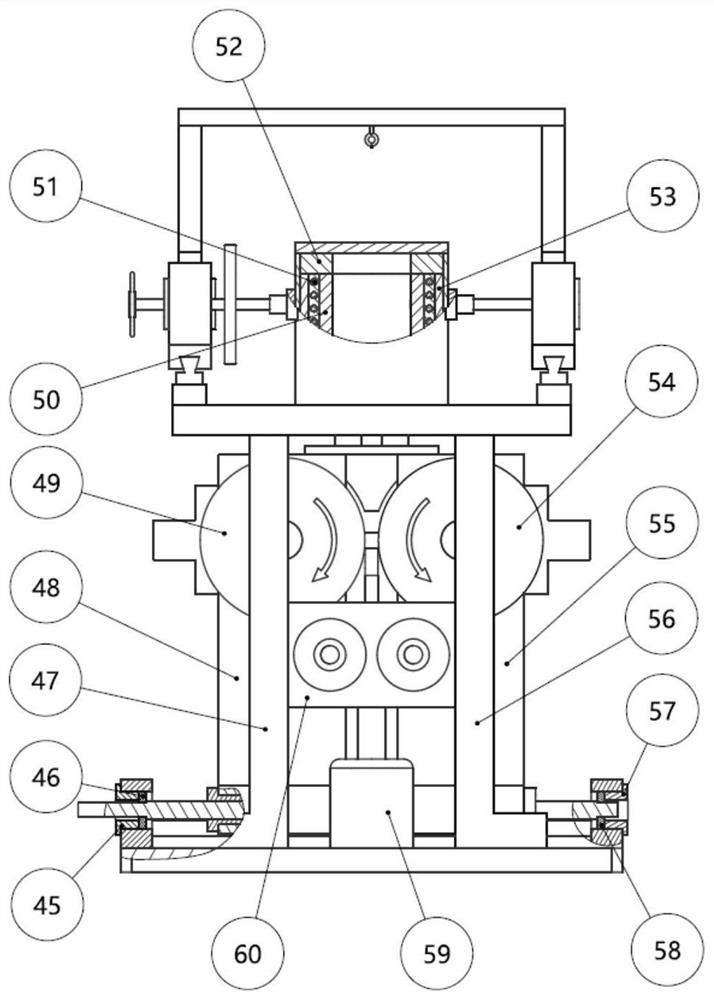

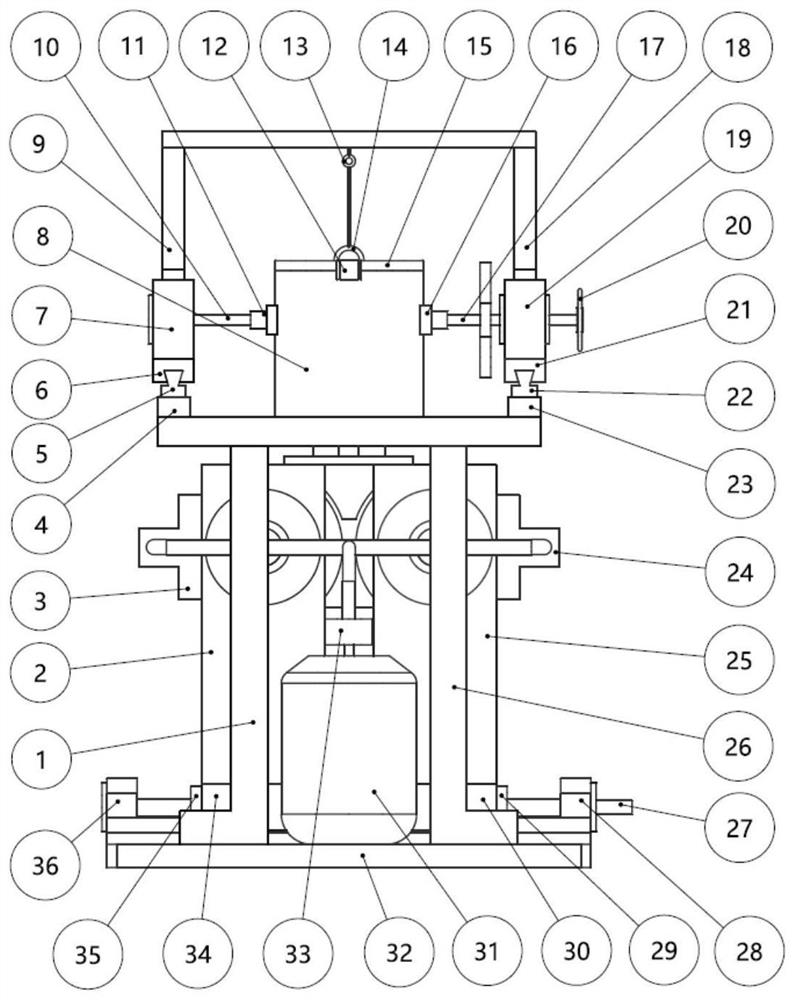

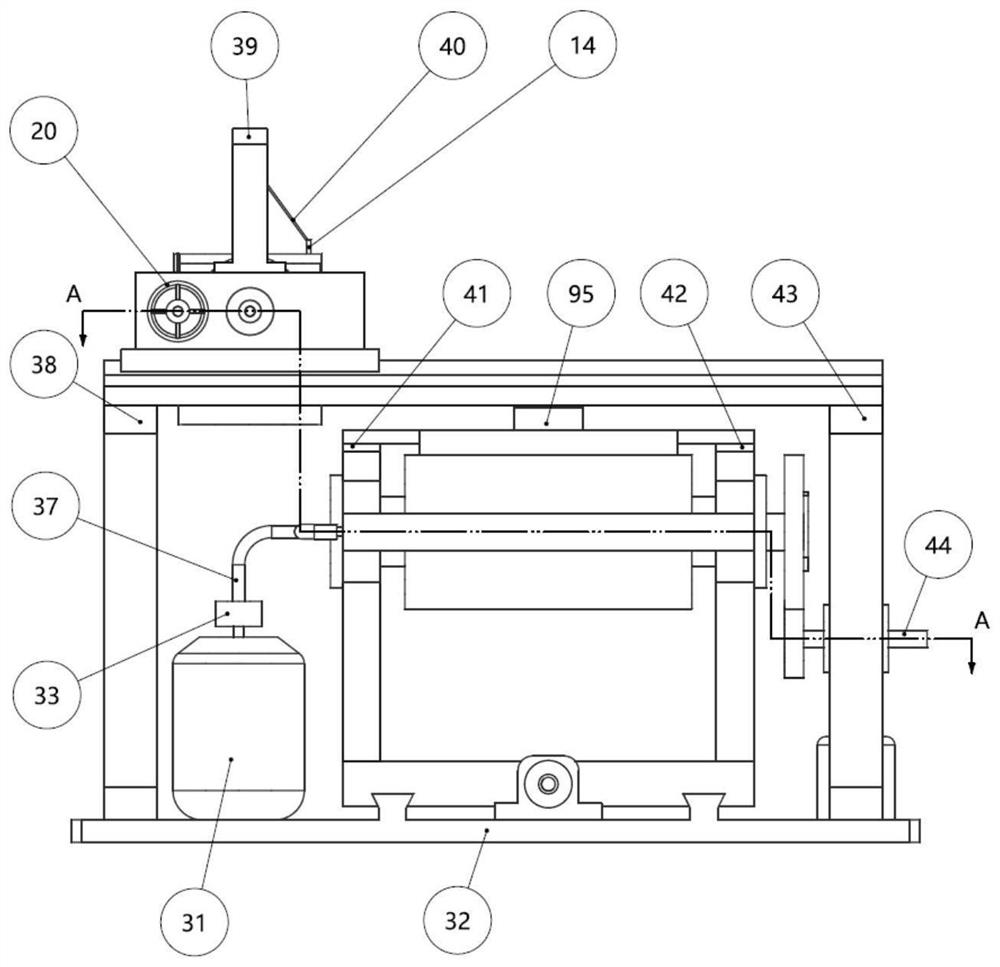

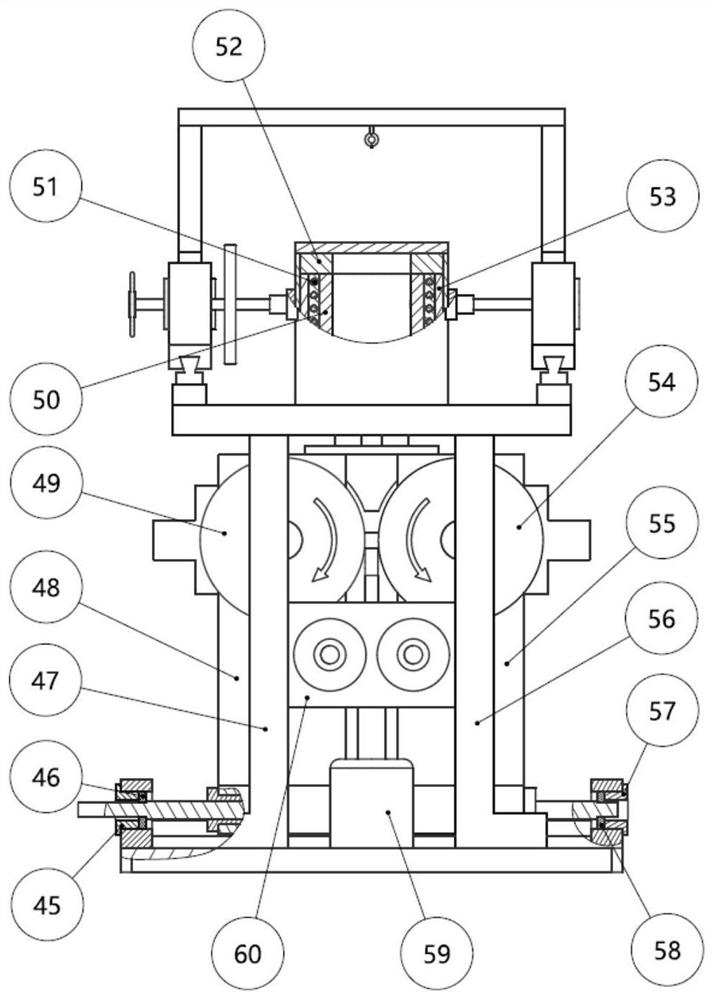

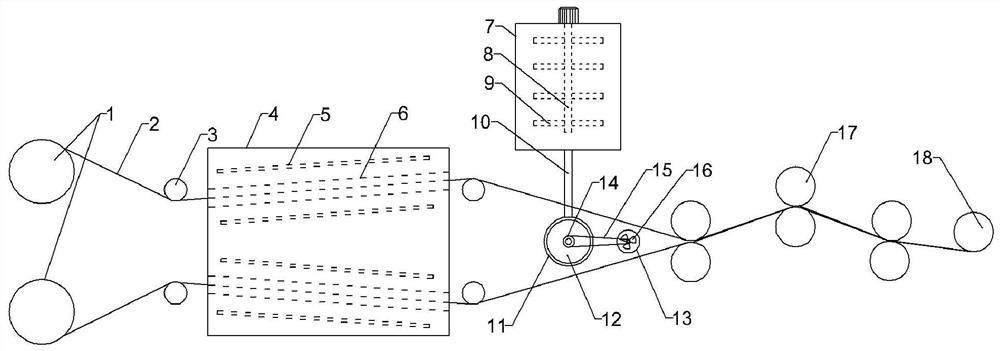

A light alloy casting and rolling experimental device

The invention discloses a light alloy casting and rolling experimental device, which belongs to the field of light alloy casting. Aiming at the problem of the lack of an existing twin-roll casting and rolling integrated forming device, the invention combines alloy heating and casting into a Integral, the alloy is heated and kept warm, the melting furnace is directly pushed above the rolls, the rotary dial of the melting furnace is turned, the melting furnace cover is automatically opened, and the alloy melt is directly poured into the gap between the two rolls. The alloy melt is kept in a heat preservation state before pouring, thereby reducing the heat loss of the alloy melt, and also reducing the degree of alloy oxidation, and at the same time, the safety of the entire operation process is high. Setting the cooling channel on the outer side of the roll coordinates the difficulty of roll adjustment and reduces the processing difficulty of the roll. The invention can always keep the axes of the two rolls parallel and synchronously adjusted. Through the improvement of the transmission route, the synchronous alignment of the two rolls is realized. To rotate to ensure the effect of processing.

Owner:JILIN UNIV

A laser additive and heat treatment composite process for preparing high-strength and tough aluminum-silicon alloys or their composite materials

ActiveCN112536446BIncrease the solidification rateImproves strength and hardnessAdditive manufacturing apparatusIncreasing energy efficiencySilicon alloyMetallic materials

The invention discloses a high-strength and tough aluminum-silicon alloy or its composite material laser additive and heat treatment composite process, which belongs to the technical field of metal materials. In this process, the aluminum-silicon alloy and its composite materials are selected by laser melting and printing under the parameters of thin powder spreading, low power, high speed, and external air cooling to obtain the supersaturated solid solution structure; then the supersaturated solid solution is processed. The low-temperature aging heat treatment finally obtains a high-performance sample that retains the fine structure of the printed state and contains a fine reinforcing phase. The present invention can significantly improve the strength and plasticity of aluminum-silicon alloys and their composite materials. Taking AlSi10Mg as an example, the strength and plasticity of this preparation process are better than those of the same system printing parts currently used in industry. The methods involved The invention has the advantages of being able to prepare structural parts with complex porous shapes, high material utilization rate, high production efficiency, short production process, simple, safe, pollution-free and economical.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Raw material proportioning equipment for jade imitation

The invention relates to a raw material proportioning device, in particular to a raw material proportioning device for jade imitation. The technical problem of the present invention is how to provide a raw material ratio equipment for jade imitation that can quickly produce jade imitation products and can flexibly adjust the color depth of dyeing agent. A raw material proportioning device for jade imitation, comprising a casing, a discharge pipe, etc.; the bottom of the casing is provided with a discharge pipe. In the present invention, through the cooperation of the mounting body and its upper device, two dyes of different colors are blended to produce the dyes required for production, which avoids the simple color pattern of imitation jade caused by the direct use of dyes of a single color. The curing agent is convenient to speed up the solidification rate of the resin mixture. It is used to filter the resin through the curved screen to prevent the large particles mixed in the resin from flowing into the equipment, so as to ensure the stable operation of the equipment.

Owner:朱观香

Light alloy casting and rolling experimental device

The invention discloses a light alloy casting and rolling experimental device, belongs to the field of light alloy casting, and aims to solve the problem that an integrated forming device capable of realizing double-roller casting and rolling is lacked at present. According to the device, alloy heating and casting are combined into a whole, an alloy is subjected to heat preservation after being heated, a smelting furnace is directly pushed to the position above rollers, a rotating poking wheel of the smelting furnace is rotated, a smelting furnace cover is automatically opened, and the alloy melt is directly poured into a roller gap between the two rollers. The alloy melt is always in a heat preservation state before pouring, so that the heat loss of the alloy melt is reduced, the oxidation degree of the alloy is also reduced, and meanwhile, the safety of the whole operation process is relatively high. Cooling channels are arranged on the outer sides of the rollers, so that the roller adjusting difficulty is matched, and the roller machining difficulty is reduced; according to the device, the axes of the two rollers can be kept parallel and synchronously adjusted all the time, synchronous and opposite rotation of the two rollers is achieved through improvement of a transmission route, and the machining effect is guaranteed.

Owner:JILIN UNIV

Preparation process for quasi-crystal particles reinforced aluminum base composite material

A process for preparing pseudo crystal granule reinforced magnesium group composite material, wherein the process for preparing AlCuFe pseudo crystal particles comprises the steps of, preparing powder, obtaining 20-100 um pseudo crystal particles after screening, with its composition being Al, Cu, Fe, after base stock melting, charging reinforced particles into alloy fondant for full mixing, depositing on the base stock along with the atomization alloy solid-liquid mixing at the atomizing action, finally the granule reinforced magnesium group composite material with even reinforced particle size distribution and fine base metal crystal grains can be prepared.

Owner:SHANGHAI JIAOTONG UNIV

A kind of reduced graphene oxide reinforced zinc-based medical material and preparation method thereof

ActiveCN110157950BImprove mechanical propertiesIncrease the solidification rateAdditive manufacturingIncreasing energy efficiencyPhysical chemistryZinc

The invention discloses a zinc-based medical material reinforced by reduced graphene oxide, which is composed of a zinc matrix and reduced graphene oxide, wherein the mass percentage of the reduced graphene oxide is 0.05-0.2 wt%. On the one hand, reduced graphene oxide with excellent mechanical properties is used as the second phase to strengthen the zinc matrix; on the other hand, the characteristics of rapid solidification of laser selective melting and the excellent thermal conductivity of reduced graphene oxide are used to achieve rapid cooling of tiny molten pools , so as to obtain a fine and uniform structure, and further enhance the mechanical properties of the zinc matrix through fine-grain strengthening.

Owner:JIANGXI UNIV OF SCI & TECH +1

Environment-friendly high-gram-weight paper towel production system

InactiveCN113500828AResidue reductionReduce retentionLiquid surface applicatorsMechanical working/deformationPaper towelAdhesive glue

The invention relates to the technical field of paper towel production, in particular to an environment-friendly high-gram-weight paper towel production system which comprises a body paper unwinding mechanism, a body paper preheating mechanism, a glue spraying mechanism, a hot-pressing mechanism and a winding roller. The glue spraying mechanism comprises a glue spraying pipe and a glue stirring box, the glue spraying pipe is rotationally arranged between body paper and connected with a power piece, a plurality of glue spraying holes are evenly formed in the glue spraying pipe, the glue spraying pipe communicates with the glue stirring box, a stirring shaft is rotationally arranged in the glue stirring box, a plurality of stirring blades are fixed to the stirring shaft, and heating pieces are arranged in the stirring blades. According to the environment-friendly high-gram-weight paper towel production system, the body paper is preheated before glue spraying, glue is heated through the stirring blades, the glue with heat is sprayed to the preheated body paper, then hot pressing is conducted, the evaporation speed of water in the glue can be effectively increased, and therefore the glue solidification speed is increased, the body paper pressing efficiency is improved, and the body paper production efficiency is improved.

Owner:CHONGQING LIWEN SANITARY PAPER MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com