Special polyurethane resin for soft basketball leather and preparation method of special polyurethane resin

A technology of polyurethane resin and basketball leather, which is applied in the direction of textiles and papermaking, etc. It can solve the problems of poor washing effect of resin, poor softness and comfort, dry surface feel, etc., and achieve soft and full hand feeling, soft hand feeling, excellent hydrolysis resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

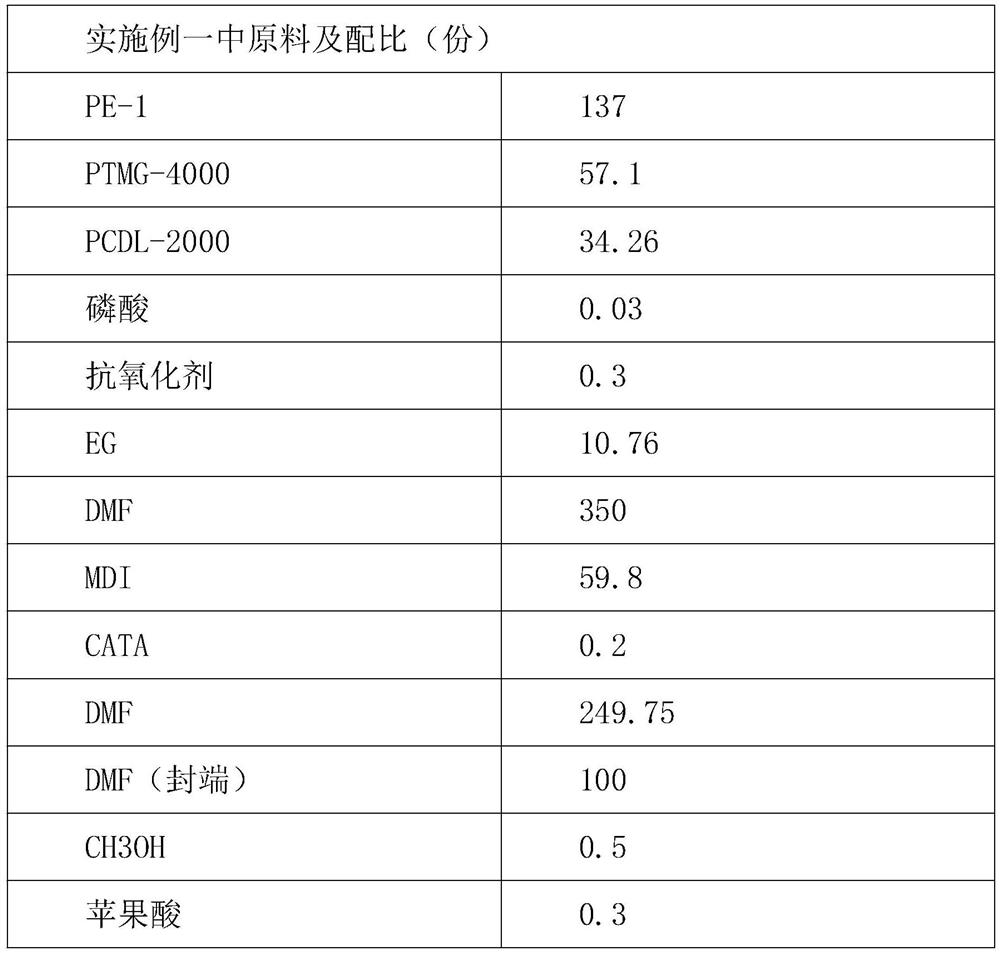

[0026] Embodiment 1: According to Table 1, the present invention discloses a special polyurethane resin for soft basketball leather, which comprises the following components in parts by weight: 137 parts of PE-1, 57.1 parts of PTMG-4000, 34.26 parts of PCDL-2000, and 0.03 parts of phosphoric acid , 0.3 parts of antioxidant, 10.76 parts of EG, 350 parts of DMF, 59.8 parts of MDI, 0.2 parts of CATA, 249.75 parts of DMF, 100 parts of DMF (capped), 0.5 parts of CH3OH and 0.3 parts of malic acid.

[0027] A preparation method of special polyurethane resin for soft basketball leather, comprising the following steps:

[0028] S1. Put PE-1, PTMG-4000, PCDL-2000, antioxidant, phosphoric acid, EG and appropriate amount of DMF into a three-necked flask, stir evenly with a mechanical stirrer at high speed, then add MDI in batches, and control the temperature at 70-80°C reaction viscosity;

[0029] S2. According to the reaction speed of step S1, add CATA (catalyst) as appropriate, moderat...

Embodiment 2

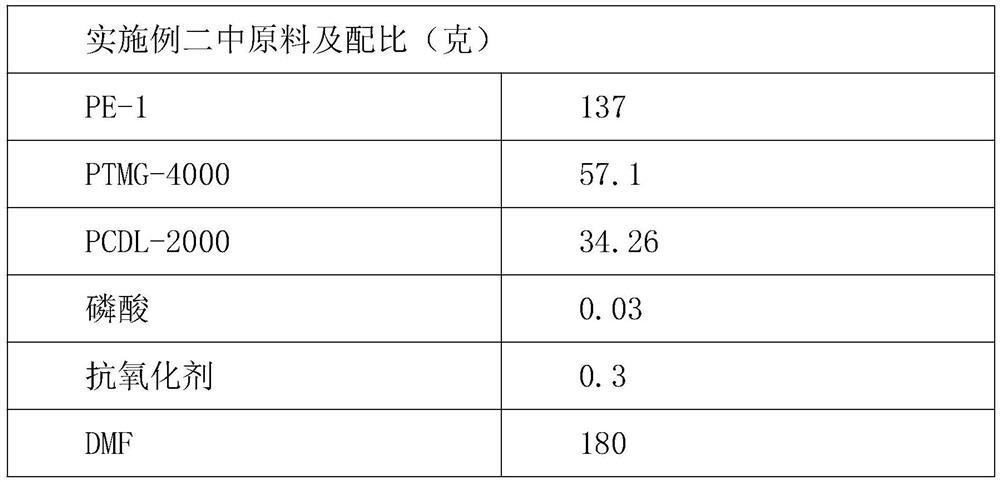

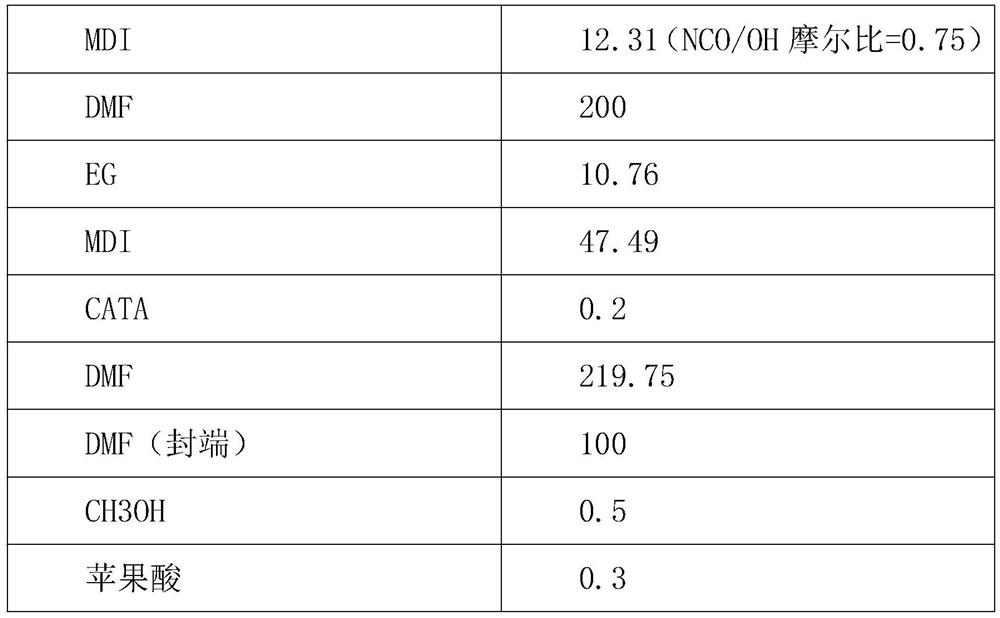

[0033] Embodiment 2: According to Table 2, the present invention discloses a special polyurethane resin for soft basketball leather, which comprises the following components by weight: 137 parts of PE-1, 7.1 parts of PTMG-40005, 34.26 parts of PCDL-2000, and 0.03 parts of phosphoric acid , 0.3 parts of antioxidant, 180 parts of DMF, 12.31 parts of MDI, 200 parts of DMF, 10.76 parts of EG, 47.49 parts of MDI, 0.2 parts of CATA, 19.75 parts of DMF, 100 parts of DMF (capped), 0.5 parts of CH3OH and malic acid 0.3 parts.

[0034] A preparation method of special polyurethane resin for soft basketball leather, comprising the following steps:

[0035] S1. Put PE-1, PTMG-4000, PCDL-2000, antioxidant, phosphoric acid, and an appropriate amount of DMF into a three-necked flask, stir evenly with a mechanical stirrer at high speed, add prepolymerized MDI, and control the temperature at 70-75℃ for prepolymerization 2H;

[0036] S2. After the prepolymerization of the raw materials in step S...

Embodiment 3

[0042] Embodiment 3: According to Table 3, the present invention discloses a special polyurethane resin for soft basketball leather, which comprises the following components by weight: 123.25 parts of PE-1, 51.37 parts of PTMG-4000, 30.82 parts of PCDL-2000, and 0.03 parts of phosphoric acid , Antioxidant 0.3 parts, DMF180 parts, MDI 11.08 parts, DMF 200 parts, EG 9.68 parts, MDI 42.72 parts, CATA 0.2 parts, DMF219.75, DMF (capped) 100 parts, CH3OH 0.5 parts, malic acid 0.3 parts, HD-1 5 copies, HD-2 5 copies and HD-3 20 copies.

[0043] A preparation method of special polyurethane resin for soft basketball leather, comprising the following steps:

[0044] S1. Put PE-1, PTMG-4000, PCDL-2000, antioxidant, phosphoric acid, and an appropriate amount of DMF into a three-necked flask, stir evenly with a mechanical stirrer at high speed, then add prepolymerized MDI, and control the temperature at 70-75℃ for prepolymerization 2H;

[0045] S2. After the prepolymerization of step S1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com