Environment-friendly high-gram-weight paper towel production system

A production system and environment-friendly technology, applied in the direction of physical treatment of paper, mixer, coating, etc., can solve the problems of low production efficiency of paper towels, slow glue solidification, etc., to avoid clogging, accelerate the rate of solidification, and facilitate scraping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

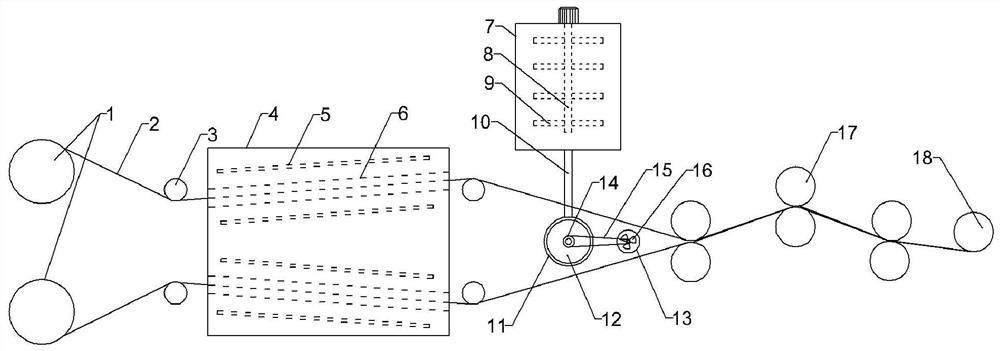

[0024] Such as figure 1 As shown, an environment-friendly high-gram-weight toilet paper production system includes a base paper unwinding mechanism, a base paper preheating mechanism, a glue spraying mechanism, a heat press mechanism, and a base paper rewinding mechanism. The raw paper unwinding mechanism includes two rotating raw paper rolls 1 and two groups of guide rollers 3, each group of guide rollers 3 is two, and the two groups of guide rollers 3 are respectively rotated and arranged on both sides of the preheating mechanism. The raw paper winding mechanism includes a rotating winding roller 18, and the raw paper 2 is wound on the winding roller 18 after preheating, glue spraying and hot pressing. The preheating mechanism includes a preheating sleeve 4, and two channels 6 for the raw paper 2 to pass through are horizontally opened in the preheating sleeve 4, and heating elements 5 are installed on both sides of the two channels 6. The heat-press mechanism includes thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com