Casting process and casting mould of large propeller hub body

A hub body and large-scale technology, which is applied in the direction of casting mold, mold composition, core, etc., can solve the problems that cannot meet the casting needs of large castings, the solidification time of large hub body castings is long, and the inhalation and oxidation of high-temperature melts are intensified. problems, to achieve the effect of reducing precipitation and reactive pore defects, reducing the phenomenon of suction slag entrainment, and improving the heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

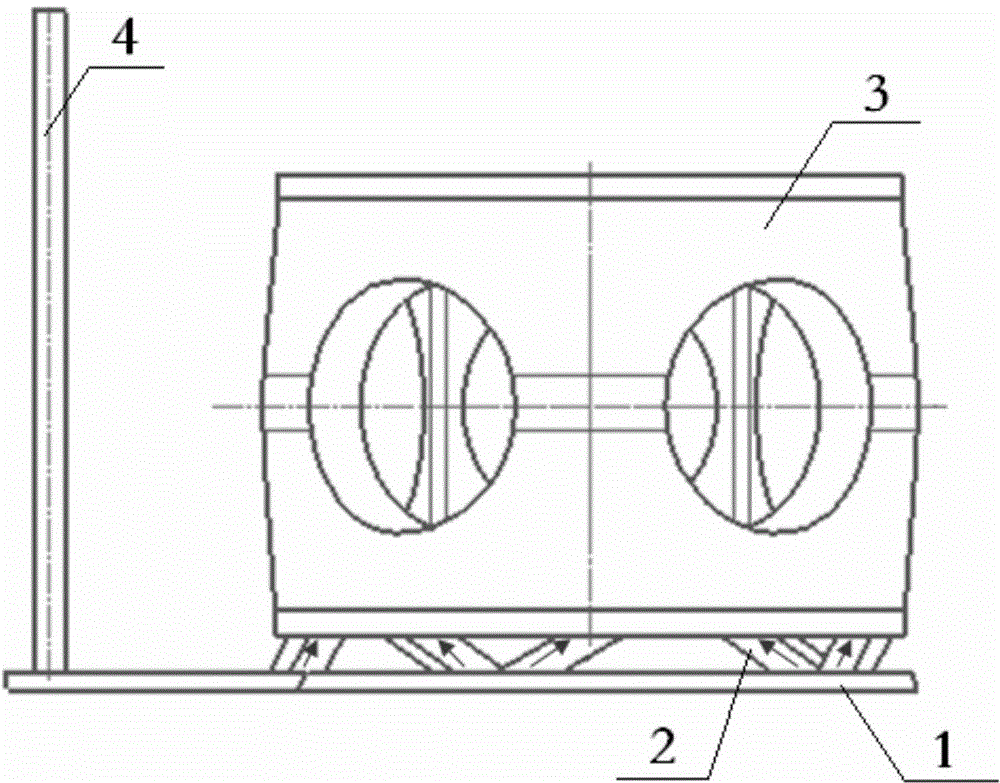

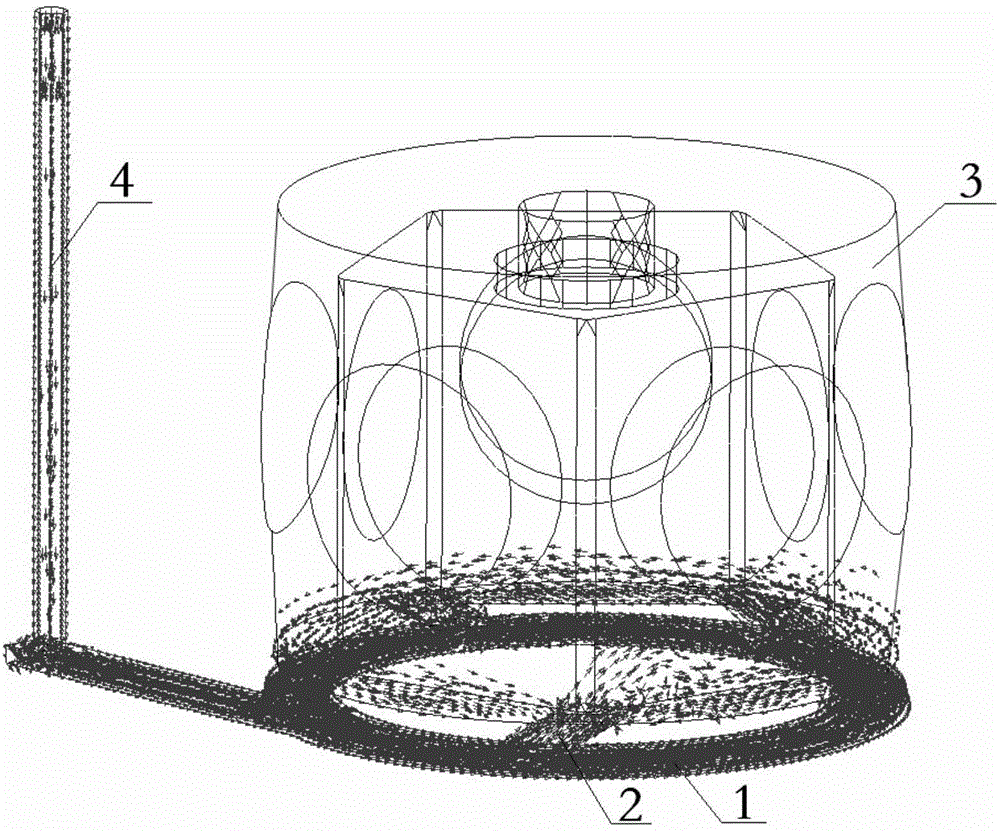

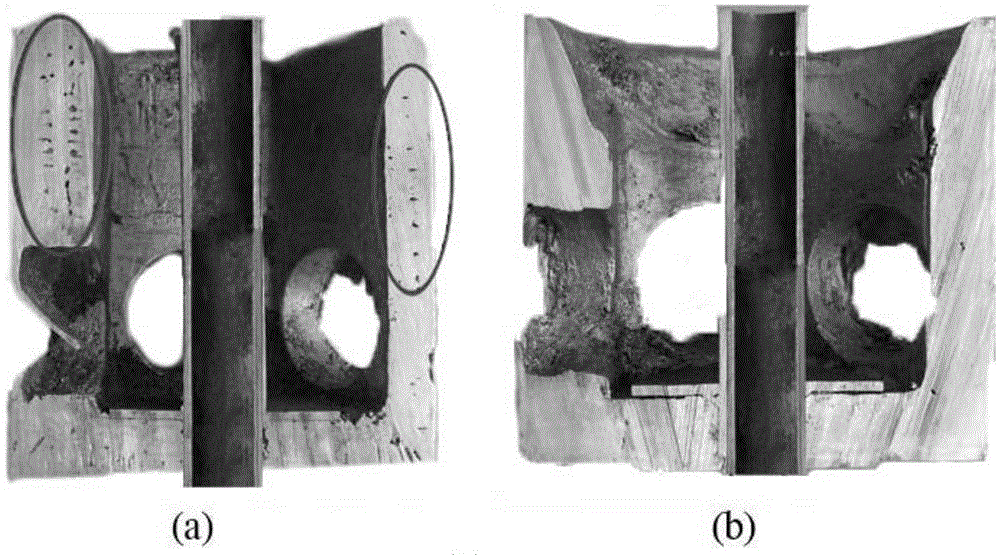

[0035] figure 1 It is a structural schematic diagram of the large-scale propeller hub body mold in embodiment 1; figure 2 It is a schematic diagram of the flow of the melt in the large propeller hub body casting mold of embodiment 1; image 3 It is the comparison between the hub body obtained in Example 1 and the hub body obtained by using the existing casting method, a is the hub body obtained by the existing casting method; b is the hub body obtained in Example 1;

[0036] This embodiment discloses a large propeller hub body casting mold, which is used for casting the propeller hub body of a large marine adjustable pitch propeller with a diameter of 1.7 meters and a weight of about 8 tons. The casting mold of the large propeller hub body adopts the side bottom casting pouring system as a whole, and the specific structure is as follows: figure 1As shown, it includes the cavity 3, the inner runner 2 and the runner 1, the runner 1 is an annular channel arranged under the cav...

Embodiment 2

[0041] Figure 4 It is an axial sectional view of the casting core of Example 2.

[0042] This embodiment is basically the same as Embodiment 1, the difference is that the casting core 5 of the large propeller hub body mold in this embodiment is provided with a cooling water channel 6, such as Figure 4 As shown, the cooling channel 6 is fixed on the bottom of the sand box through a rigid base. In order to enhance the cooling water 7 effect, the water inlet 8 of the cooling channel 6 is arranged at the bottom of the mold, and the water outlet 9 is arranged at the top of the mold. The cooling channel 6 is made of red copper. When the casting mold is used to cast a large propeller hub body casting, the heat of the sand core can be taken away in time by the cooling water 7 in the cooling water channel 6 to realize the effect of cooling from the inside. The mutual cooperation of internal and external heat exchange accelerates the solidification rate of large hub body castings a...

Embodiment 3

[0045] This embodiment is basically the same as Embodiment 1, except that the included angle between the axis of the sprue of the large hub body casting mold and the tangent line of the runner in this embodiment is 30°.

[0046] In this embodiment, the angle between the axis of the inner runner and the tangent of the runner is 30°, which can effectively reduce the degree of turbulence during filling of the casting and accelerate the solidification rate of the large casting. There are few precipitated and reactive porosity defects.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com