Tool cathode and clamping method for electrolytic machining of special-shaped cavity

A tool cathode and special-shaped technology, which is applied in the direction of electrochemical processing equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of inability to adapt to small batches or single-trial electrolytic processing of workpieces, and low efficiency, so as to facilitate observation of the processing process, The effect of improving work efficiency and uniform flow field diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

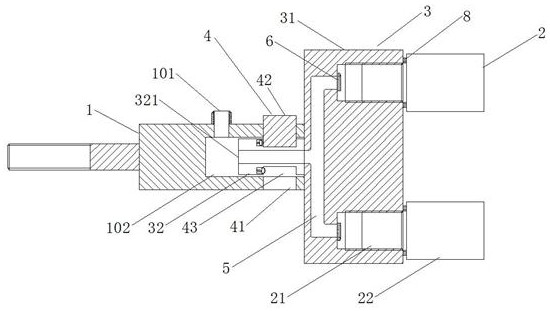

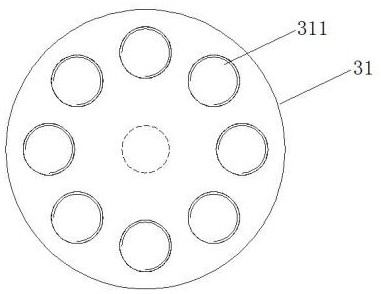

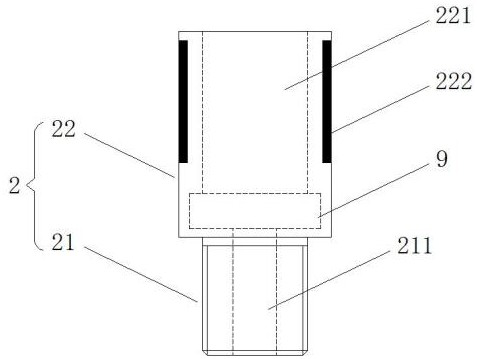

[0035] This embodiment discloses a tool cathode for electrolytic machining of a special-shaped cavity, including a cathode rod 1 and a cathode 2, a first liquid inlet 101 is provided on the cathode rod 1, a blind hole 102 is provided in the center of the cathode rod 1, and a combined cathode Disk 3, the combined cathode disk 3 includes a disk 31 and a cylindrical rod 32, the cylindrical rod 32 extends into the blind hole 102 and can rotate in the blind hole 102, the cylindrical rod 32 is connected to the cathode rod 1 through the key connection mechanism 4, The interior of the disc 31 and the cylindrical rod 32 are connected in hollow to form an electrolyte channel 5, and one end of the cylindrical rod 32 extending into the blind hole 102 is provided with a second liquid inlet 321, and the surface of the disc 31 is provided with several threaded holes 311 connected with the cathode 2 , The threaded hole 311 communicates with the electrolyte channel 5, and the threaded hole 311 ...

Embodiment 2

[0038]This embodiment discloses a tool cathode for electrolytic machining of a special-shaped cavity, including a cathode rod 1 and a cathode 2, a first liquid inlet 101 is provided on the cathode rod 1, a blind hole 102 is provided in the center of the cathode rod 1, and a combined cathode Disk 3, the combined cathode disk 3 includes a disk 31 and a cylindrical rod 32, the cylindrical rod 32 extends into the blind hole 102 and can rotate in the blind hole 102, the cylindrical rod 32 is connected to the cathode rod 1 through the key connection mechanism 4, The interior of the disc 31 and the cylindrical rod 32 are connected in hollow to form an electrolyte channel 5, and one end of the cylindrical rod 32 extending into the blind hole 102 is provided with a second liquid inlet 321, and the surface of the disc 31 is provided with several threaded holes 311 connected with the cathode 2 , The threaded hole 311 communicates with the electrolyte channel 5, and the threaded hole 311 i...

Embodiment 3

[0049] This embodiment discloses a method for clamping the cathode of a tool for electrolytic machining of a special-shaped cavity. The cathode rod 1 is connected to the spindle 10 of the machine tool through the cathode rod thread, and the cylindrical rod 32 of the combined cathode disc 3 extends into the blind hole 102 of the cathode rod 1. In this process, the key connection mechanism 4 is connected to the cathode rod 1, and the threaded part 21 of the cathode 2 is installed in the threaded hole 311 of the disc 31, and the cathode part 22 enters the transparent acrylic reaction back pressure cavity 11, and the transparent acrylic reaction back pressure Both the cavity 11 and the workpiece 12 to be processed are installed on the workpiece holder 13, and are positioned and clamped by threads.

[0050] The cathode is placed in a transparent reaction back pressure chamber for electrolytic processing, which is convenient for observing the processing process. At the same time, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com