Medium-speed coal mill primary air chamber guide device

A guide device and coal mill technology, applied in the field of medium-speed coal mills, can solve problems such as wear of the non-working surface of the coal mill barrel wall, increased maintenance workload, internal flow field disorder, etc., to reduce the maintenance workload, Improve work efficiency and avoid flow field disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

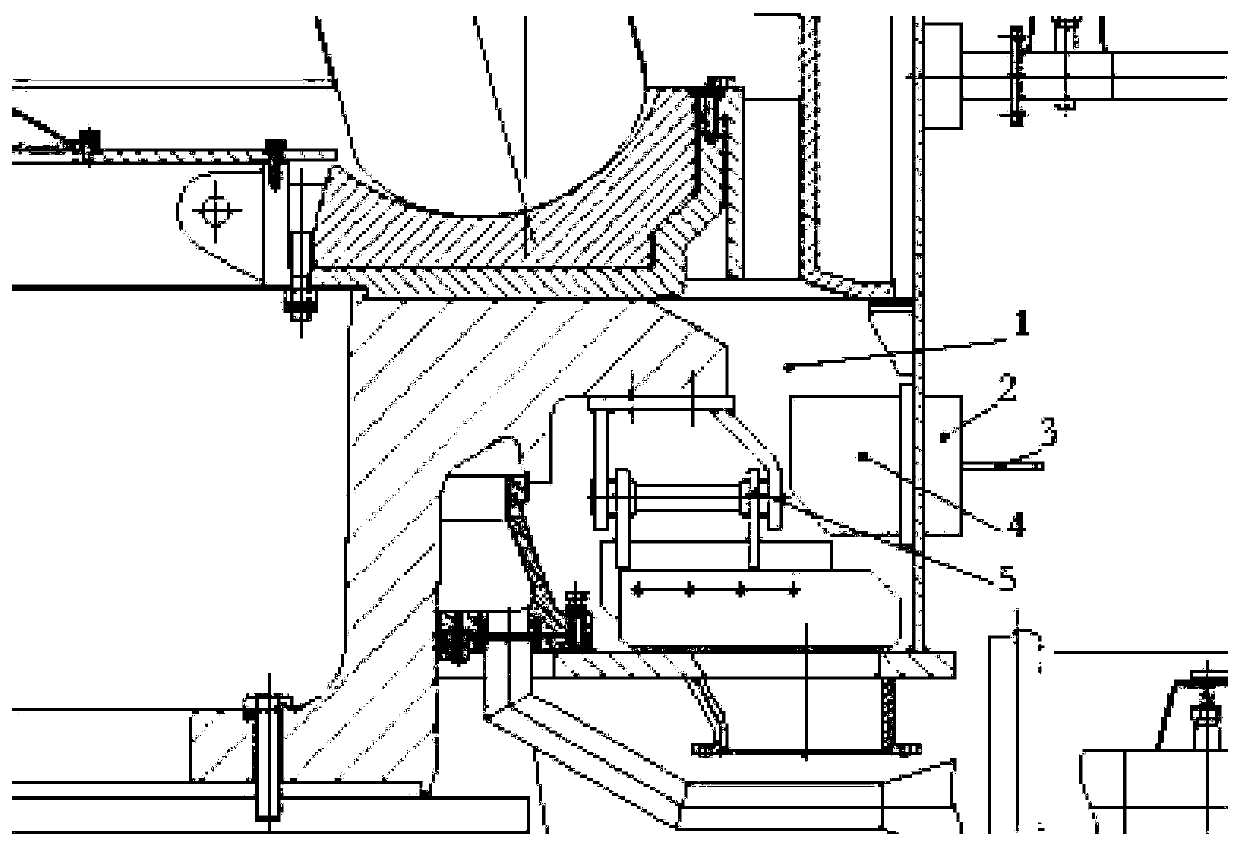

[0030] Specific implementation mode one: combine figure 1 To illustrate this embodiment, a medium-speed coal mill primary air chamber guide device described in this embodiment includes a sealing box 2, an adjustment handle 3 and a guide unit 4;

[0031] The primary air chamber 1 of the medium-speed coal mill is provided with a guide unit 4, one end of the adjustment handle 3 is connected to the guide unit 4, the sealing box 2 is a cuboid with one end open, and the side of the sealing box 2 is provided with a long through hole. The casing of the medium-speed coal mill is provided with a sealing box 2, and the sealing box 2 extends through the casing of the medium-speed coal mill into the primary air chamber 1, and the other end of the adjustment handle 3 passes through the medium-speed coal pulverizer once. The strip through hole on the shell and the sealing box 2;

[0032] In this specific embodiment, the medium-speed coal mill is one of the important equipment of the thermal...

specific Embodiment approach 2

[0035] Specific implementation mode two: combination figure 1 Describe this embodiment. This embodiment is a further limitation of the guide device for the primary air chamber described in the first specific embodiment. The guide device for the primary air chamber of a medium-speed coal mill described in this embodiment, the guide The unit 4 is set between the primary air chamber 1 of the medium-speed coal mill and the scraper device 5 of the medium-speed coal mill;

[0036] In this specific embodiment, the guide unit 4 is arranged between the primary air chamber 1 of the medium-speed coal mill and the scraper device 5 of the medium-speed coal mill. The internal air volume, wind direction and wind speed of the medium-speed coal mill primary air chamber are uniform, It can ensure the efficient operation of the air ring of the coal mill, reduce the unit consumption of the coal mill, and improve the working efficiency of the coal mill.

specific Embodiment approach 3

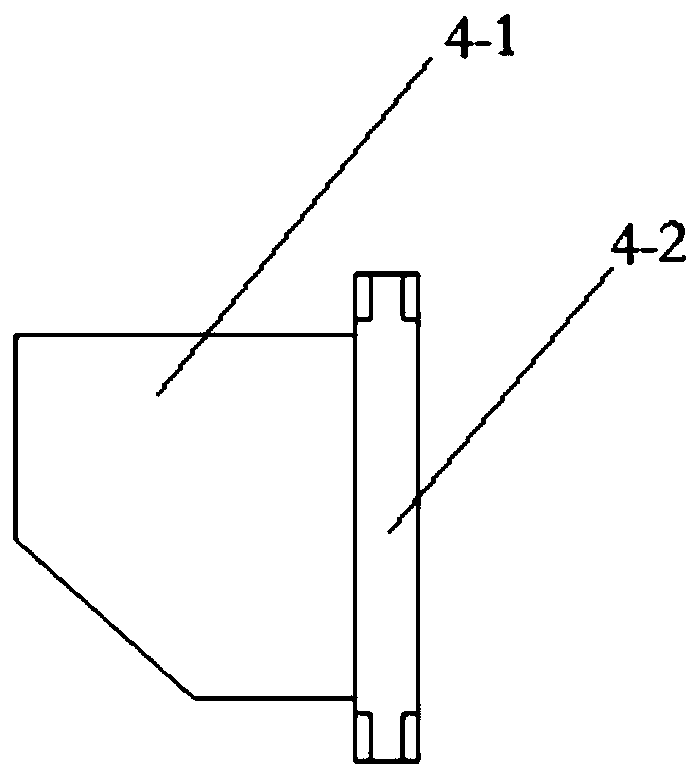

[0037] Specific implementation mode three: combination figure 2 Describe this embodiment. This embodiment is a further limitation of the guide device for the primary air chamber described in the second specific embodiment. In the guide device for the primary air chamber of a medium-speed coal mill described in this embodiment, the guide The unit 4 includes a baffle 4-1 and a rotating shaft 4-2, and the rotating shaft 4-2 is provided with a baffle 4-1 along the direction of the outer circumferential wall;

[0038] In this specific embodiment, the primary air chamber of the medium-speed coal mill is provided with a guide unit, one end of the adjustment handle is connected to the guide unit, and the other end of the adjustment handle passes through the shell of the medium-speed coal mill and the seal on the sealing box at one time. Long through holes, the staff can adjust the wind speed and wind direction in the primary air chamber by adjusting the handle, avoid the internal flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com