Method for improving strength and conductivity of smelted and cast Cu-Cr-Nb alloy

A cu-cr-nb, alloy strength technology, applied in casting molding equipment, metal extrusion control equipment, casting molds, etc., can solve the problem of no reported strength data, achieve simultaneous improvement and good matching, and improve alloys performance, the effect of increasing the cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

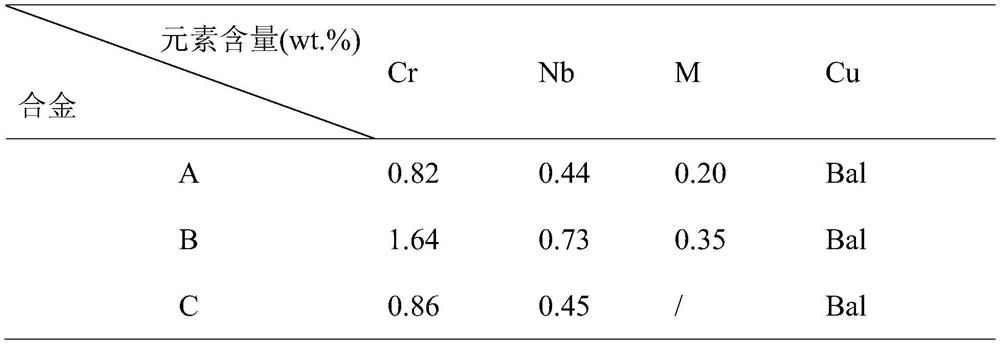

[0038] Embodiment 1: Alloy A-1 is prepared by smelting and casting (the composition is shown in A in Table 1)

[0039] Step 1: Configure pure metal raw materials according to the composition requirements of alloy A in Table 1, and prepare Cr-Nb and Cu-M master alloys by arc melting (wherein M is a mixture of RE, Ti, Zr, according to the mass ratio of 4:3:3 Composition, wherein RE is a mixture of Sc, Y, Pr, Nd, composed according to the mass ratio of 5:3:1:1);

[0040] Step 2: Melt the intermediate alloy and copper in a vacuum induction furnace. After all the alloy elements are melted and alloyed, inject the alloy melt into the casting mold. The casting mold is composed of a metal inner mold and a sand mold; The material is copper, and the cooling pipe is surrounded upwards from the bottom of the outer wall of the copper mold. Cooling water is passed into the pipe, and the temperature of the cooling water is lower than 10°C. The thickness ratio to the sand mold is 2:1.

[004...

Embodiment 2

[0044] Embodiment 2: Alloy A-2 is prepared by smelting and casting (the composition is shown in A in Table 1)

[0045] The first step: prepare master alloy, same as embodiment 1;

[0046] Second step: alloy smelting and casting, same as embodiment 1;

[0047] The third step: alloy homogenization heat treatment, same as embodiment 1;

[0048] Step 4: Process the alloy ingot into a cube of 50mm×50mm×50mm, carry out 6 passes of multi-directional forging, the forging temperature is 550°C, the forging deformation of each pass is 5%, and then adjust the forging direction by 90°, high temperature The aging temperature is 475°C, the time is 120min, the secondary deformation is 5% for each pass of forging, the temperature is 350°C, and the time is 60min for low-temperature aging after 6 passes of multi-directional forging.

[0049] After testing, the conductivity of the alloy at room temperature is 91% IACS, the tensile strength at room temperature is 469Mpa, and the tensile strength...

Embodiment 3

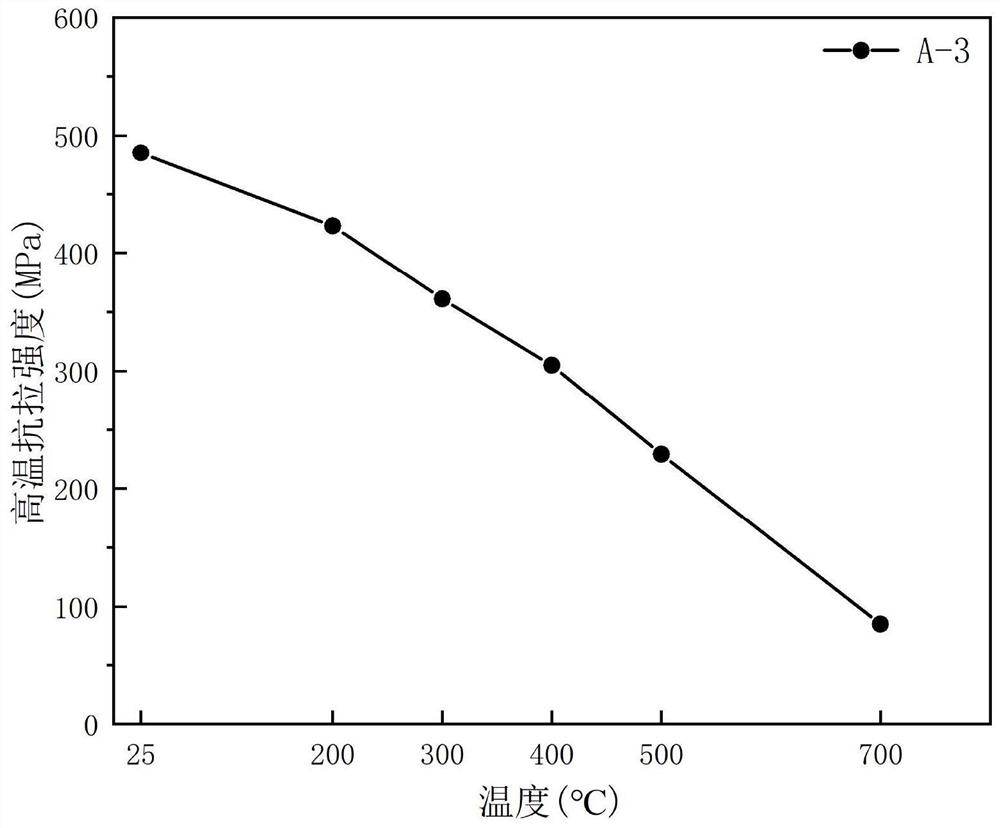

[0050] Embodiment 3: Alloy A-3 is prepared by smelting and casting (the composition is as shown in A in Table 1)

[0051] The first step: prepare master alloy, same as embodiment 1;

[0052] Second step: alloy smelting and casting, same as embodiment 1;

[0053] The third step: alloy homogenization heat treatment, same as embodiment 1;

[0054] Step 4: Process the alloy ingot into a cube of 50mm×50mm×50mm, carry out 9 passes of multi-directional forging, the forging temperature is 550°C, the forging deformation of each pass is 5%, and then adjust the forging direction by 90°, high temperature The aging temperature is 475°C, the time is 120min, the secondary deformation is 5% for each pass of forging, the temperature is 350°C, and the time is 60min for low-temperature aging after 9 passes of multi-directional forging.

[0055] After testing, the conductivity of the alloy at room temperature is 93%IACS, the tensile strength at room temperature is 485Mpa, and the tensile streng...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com