Method for refining laser additive manufacturing titanium alloy grain through ultrasonic impact and induction heating

A technology of induction heating and ultrasonic impact, which is applied in the field of preparation of titanium alloy grains, can solve the problems of inconspicuous grain refinement effect and prominent anisotropy of titanium alloy components, and achieve the improvement of comprehensive mechanical properties and grain refinement Uniform, full effect effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

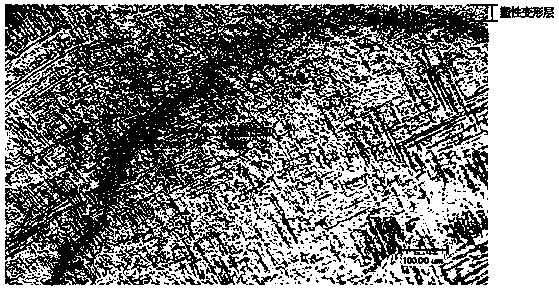

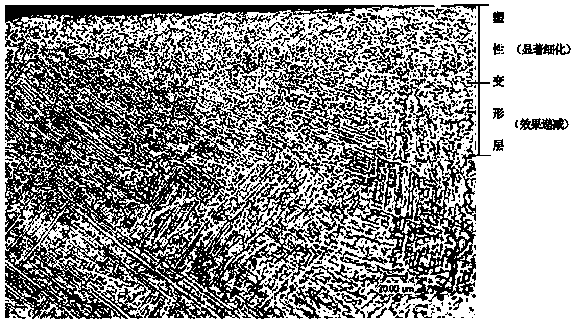

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0024] see figure 1 , the preparation process of the present invention is as follows:

[0025] 1. Basic process parameters of laser additive manufacturing titanium alloy: TC4 titanium alloy powder particle size 50-150μm, laser power 210W, scanning speed 10mm / s, powder feeding amount 2.5g / min, Z-axis lifting amount 0.10mm, scanning distance 0.3mm ;

[0026] Induction heating auxiliary setting basic parameters: the induction coil is a rectangle of 50×150mm, the induction heating set temperature is 600°C, the design fixture is installed at the end of the stepper motor slide rail, and the cladding layer is lifted synchronously during the forming process to ensure the temperature of the sample basically stable.

[0027] The parameters of the ultrasonic impact process are the impact power of 1000W and the impact frequency of 40kHz. The ultrasonic impact gun uses...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com