Magnesium-aluminum alloy with continuous eutectic structure and preparation method thereof

A magnesium-aluminum alloy and crystal structure technology, which is applied in the field of alloy preparation, can solve the problems of not considering the potential difference between titanium and magnesium, deterioration of magnesium-aluminum alloy corrosion resistance, galvanic corrosion, etc., to achieve coarse grain size, improve corrosion resistance, The effect of increasing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Using titanium powder and AZ61 powder as raw materials, weigh 0.05g titanium metal powder (purity>99%, particle size 20-60nm) and 9.95g AZ61 powder (purity>99.9%, particle size 40- 80 μm), placed in a ball mill, and fed with high-purity argon, set the rotation speed at 300rad / min, and the ball milling time was 6h, to obtain uniformly dispersed titanium / AZ61 mixed powder. Under the protection of high-purity argon with a purity of 99.999%, under the parameters of laser power 90W, scanning speed 250mm / min, and spot diameter 90μm, the corrosion-resistant magnesium-aluminum alloy was prepared by SLM process.

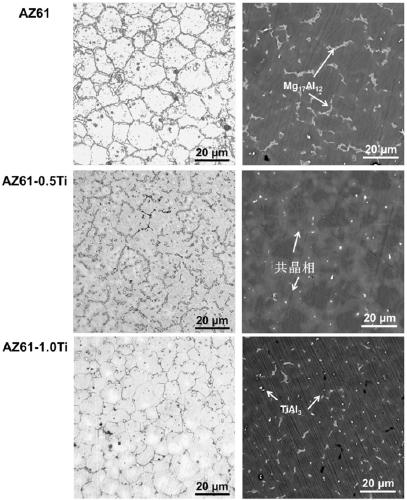

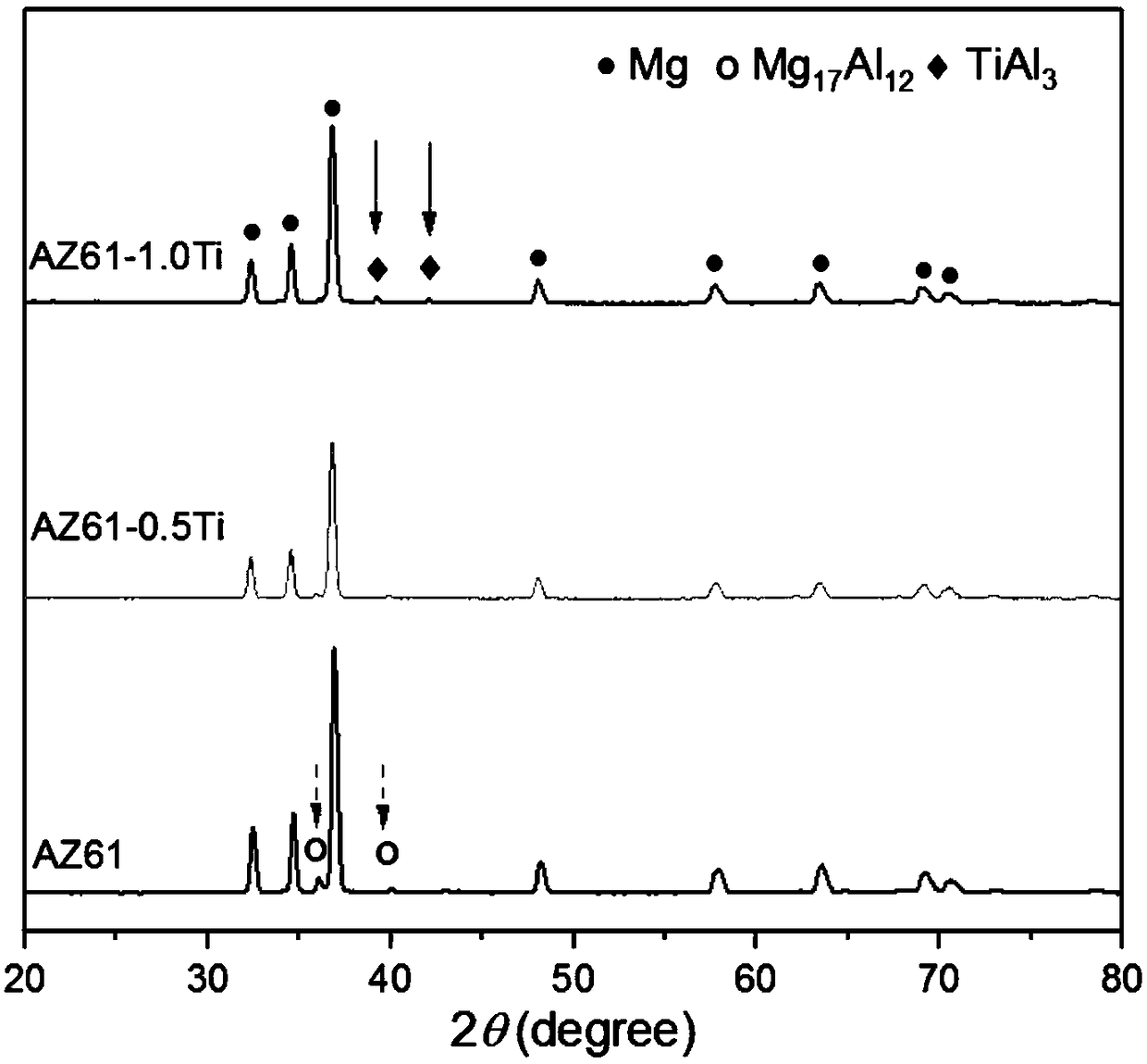

[0027] Microstructure tests found that 0.5wt.% titanium refined the grain size of AZ61-Ti, and the Mg in the alloy 17 Al 12 phase was greatly reduced, a continuous eutectic phase was formed, and no aggregation of titanium was detected ( figure 1 ); XRD test found ( figure 2 ), Mg 17 Al 12 The corresponding characteristic peaks become weaker, indicating that Mg 1...

Embodiment 2

[0029] Using titanium metal powder and AZ61 powder as raw materials, weigh 0.1g titanium powder (purity>99%, particle size 20-60nm) and 9.9g AZ61 powder (purity>99.9%, particle size 40-60nm) according to the mass ratio of 0.01:0.99 80 μm), placed in a ball mill, and fed with high-purity argon, set the rotation speed at 300rad / min, and the ball milling time was 6h, to obtain uniformly dispersed titanium / AZ61 mixed powder. Under the protection of high-purity argon with a purity of 99.999%, under the parameters of laser power 90W, scanning speed 250mm / min, and spot diameter 90μm, the corrosion-resistant magnesium-aluminum alloy was prepared by SLM process.

[0030] Microstructural tests found that ( figure 1 ), 1.0wt.% titanium completely consumed the coarse Mg in AZ61 17 Al 12 Phase, a large number of eutectic phases were generated, and it was found that a new second phase containing titanium was generated at the grain boundary; XRD test found that ( figure 2 ), the titanium-c...

Embodiment 3

[0032] Using titanium powder and AZ61 powder as raw materials, weigh 0.05g titanium metal powder (purity>99%, particle size 20-60nm) and 9.95g AZ61 powder (purity>99.9%, particle size 40- 80 μm), placed in a ball mill, and fed with high-purity argon, set the rotation speed at 300rad / min, and the ball milling time was 6h, to obtain uniformly dispersed titanium / AZ61 mixed powder. Under the protection of high-purity argon with a purity of 99.999%, under the parameters of laser power 75W, scanning speed 250mm / min, and spot diameter 90μm, the corrosion-resistant magnesium-aluminum alloy was prepared by SLM process.

[0033] The microstructure test found that the corrosion-resistant magnesium-aluminum alloy prepared under 75W power had a small amount of pores, and a small amount of magnesium-aluminum alloy powder was not completely melted. Electrochemical tests found that the corrosion potential from -1.44mV SCE down to -1.24mV SCE , reduces its corrosion current, increases impeda...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com